Scraping and wear-resistant impact-resistant polyvinyl chloride tube material and preparation method

A polyvinyl chloride, scratch-resistant technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of easy breaking and low scratch-resistant performance of polyvinyl chloride pipe materials, achieving low price and enhancing connection strength. and interfacial compatibility, the effect of good elongation at break

Active Publication Date: 2013-03-13

CHINA PETROLEUM & CHEM CORP

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, some units in China have been involved in the research of scratch-resistant PVC pipes. To improve the scratch-resistant PVC pipe materials, generally choose inorganic fillers with hard texture, unfavorable structure, and coupling treatment. In polyvinyl chloride, such as calcium carbonate and barium sulfate with a whisker structure can improve the scratch resistance of polyvinyl chloride materials, but the whisker material is relatively brittle, and it is easily affected by mechanical forces such as shearing during processing. Being broken, the scratch resistance of the PVC pipe material is still not high, which cannot meet the needs of the high-impact and high-wear pipe market.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

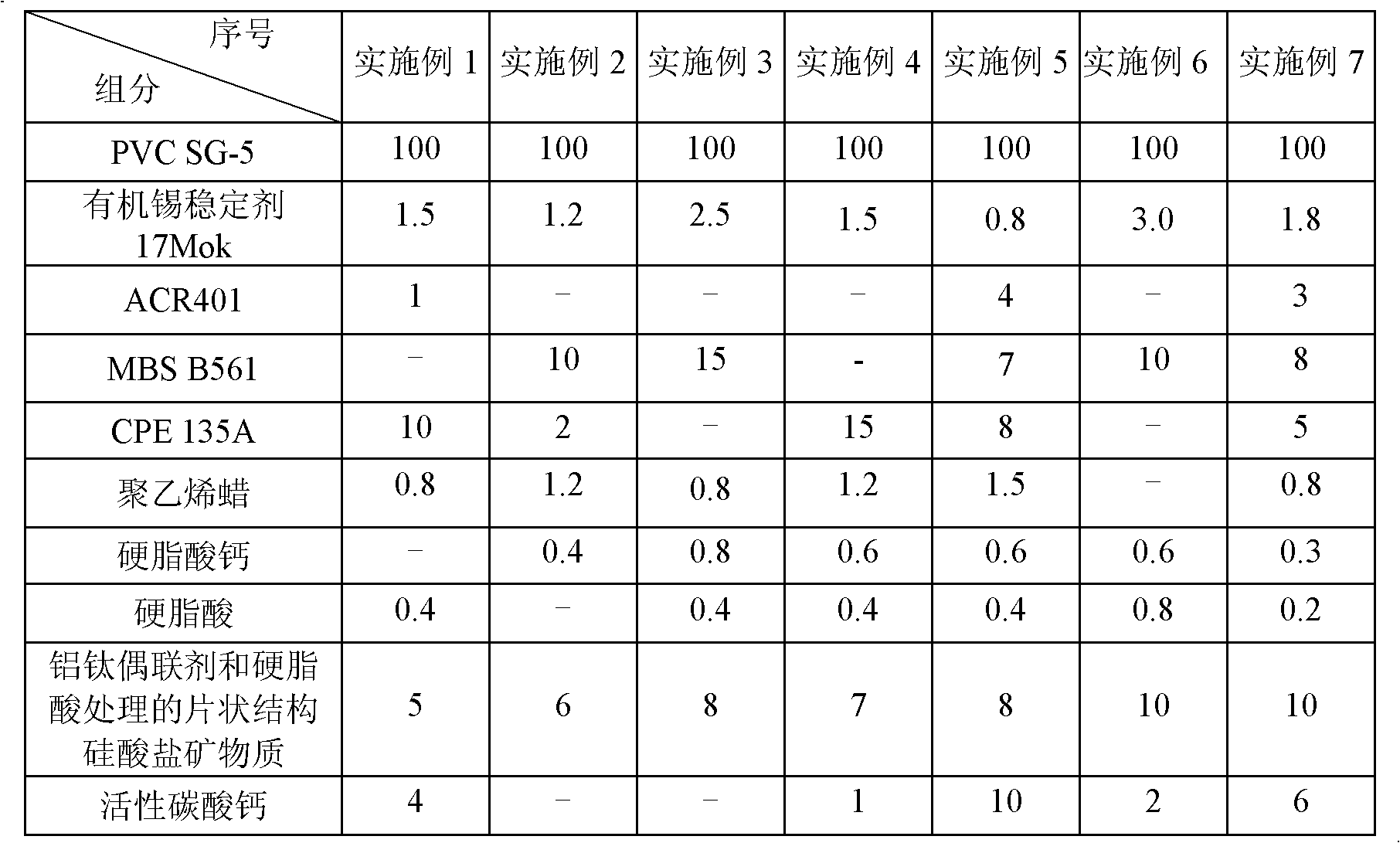

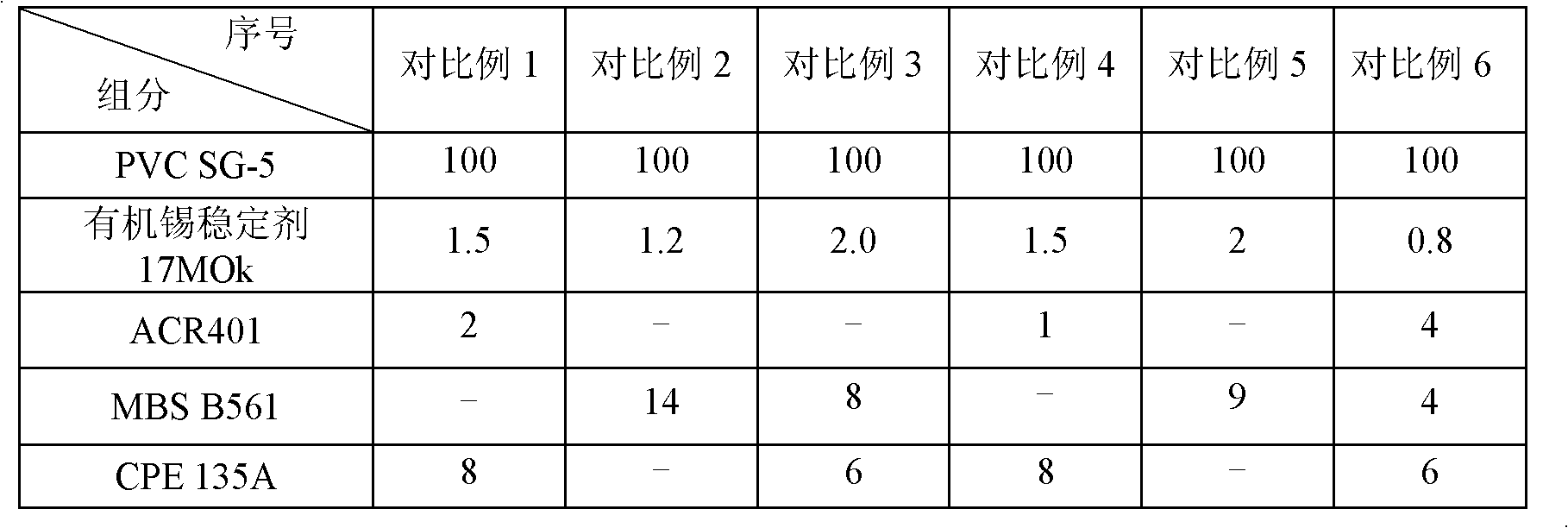

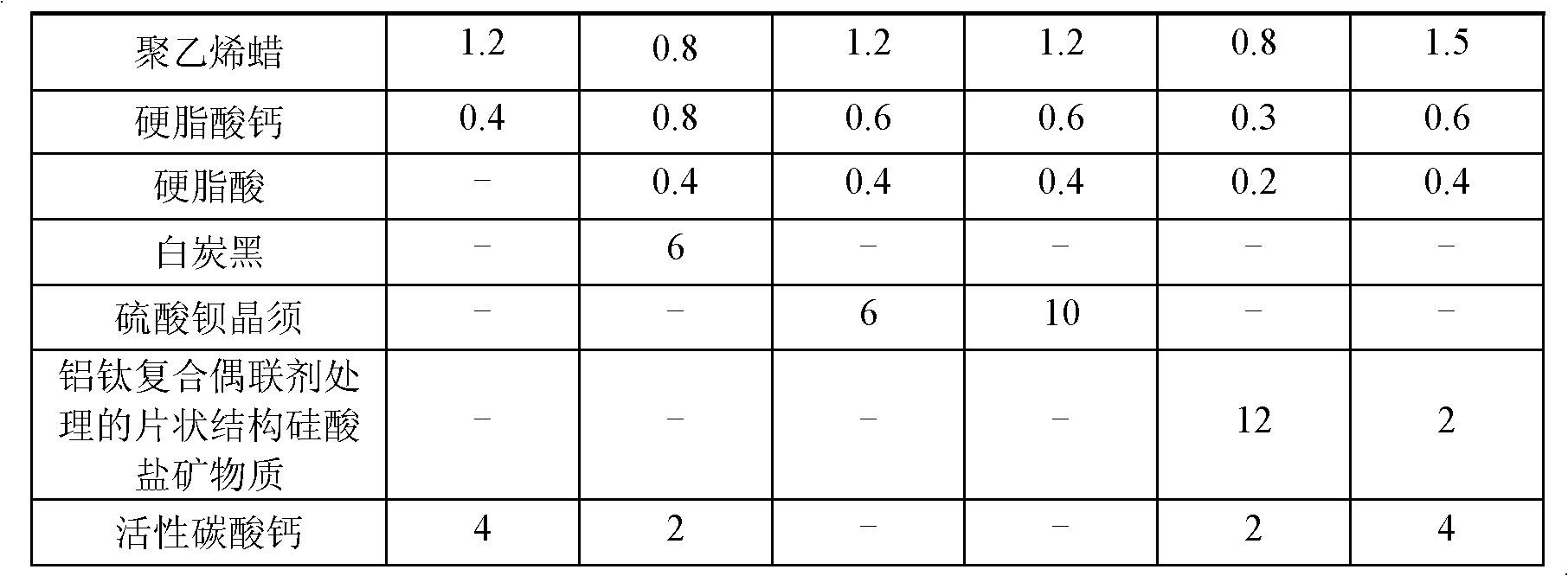

Embodiment 1~7

[0021] The proportioning components of the scratch-resistant and impact-resistant polyvinyl chloride pipe material composition are shown in Table 1, and Example 3 is the best implementation mode.

[0022] Table 1 Embodiment 1~7 high elongation rate PVC-M pipe material composition (by weight)

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

A scraping and wear-resistant impact-resistant polyvinyl chloride tube material belongs to the field of polymer materials. The tube material is prepared by the following components by weight: 100 parts of PVC resin, 0.8-3 parts of a stabilizing agent, 1-4 parts of a processing additive, 10-15 parts of a impact-resistant modifier, 1.2-2.5 parts of a lubricant, 0-10 parts of a filler, and 5-10 parts of a wear-resistant modifier. The wear-resistant modifier is a sheet-structure silicate mineral substance with a jade structure and treated by a coupling agent. The sheet-structure silicate mineral substance is from debris of jade processing, is grinded and screened, and is treated by the coupling agent, which enhances the connection strength and interface compatibility between the silicate mineral substance and polyvinyl chloride molecules. The appropriate adding amount of the wear-resistant modifier improves the scraping and wear resistance of the material of the invention, and also reduces the influence on other performance of the polyvinyl chloride tube material as much as possible. The polyvinyl chloride tube material of the invention is prepared by general processing technology, and has excellent scraping and wear resistance, good impact resistance and processing performance.

Description

technical field [0001] The invention belongs to the field of polymer materials, and in particular relates to a scratch-resistant and impact-resistant polyvinyl chloride pipe and a preparation method thereof. Background technique [0002] After research, it is found that the impact-modified PVC pipe with both strength and toughness can be produced through material modification on the basis of PVC formula and combined with advanced processing technology. Impact modified PVC pipe has the characteristics of light weight, small frictional resistance, high ring stiffness, good corrosion resistance, weather resistance, high cost performance, and does not require frequent replacement and maintenance, and is widely used in building drainage , sewage, and chemical engineering and other fields. Most of these pipes are mainly to improve their impact resistance. When transporting sewage from factories and mines containing waste residues, the waste residues in the liquid will contact and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08L23/28C08L51/00C08K13/06C08K9/04C08K3/34F16L9/12

Inventor 桂俊杰王晶张新华李静刘容德贾小波刘浩王秀丽孙丽朋

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com