Low-temperature denitration and desulfurization device for coking furnace flue gas and process

A technology for coke oven flue gas and low-temperature denitrification, which is applied to the treatment of nitrogen oxides and sulfur dioxide, and low-temperature denitration and desulfurization devices for coke oven flue gas, can solve problems such as substandard emission, and achieve low operating costs, high efficiency, and high efficiency. No secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

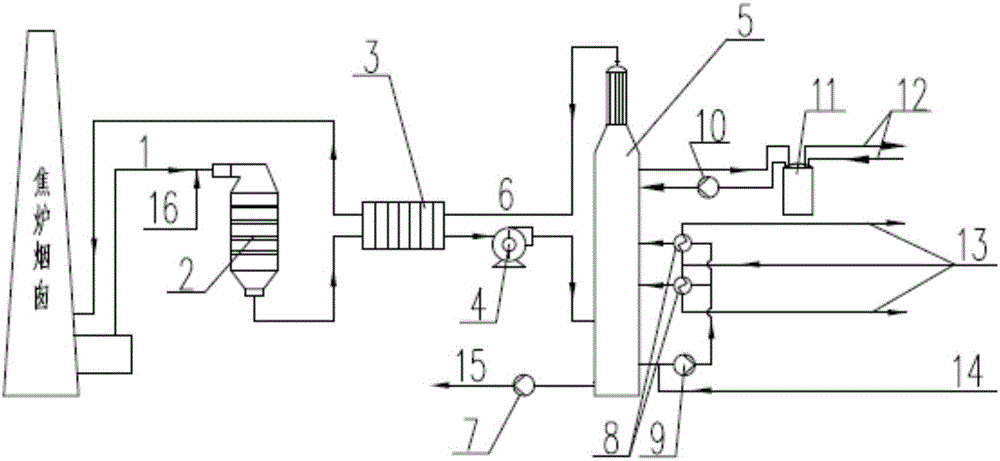

[0017] The denitrification catalyst adopts a low-temperature catalyst suitable for the low temperature of the coke oven flue gas. The optimal reaction temperature window of the catalyst is 190°C to 350°C; the reducing agent used in the denitrification is ammonia water. You can choose the denitrification reduction that suits you according to the actual situation of the coking plant. agent.

[0018] The desulfurization absorption liquid is a mixture of residual ammonia water 14 containing free ammonia and desulfurization liquid 15. The residual ammonia water 14 comes from the residual ammonia water tank of the coking plant, and the desulfurization liquid 14 comes from the desulfurization liquid buffer section at the lower part of the desulfurization tower 5.

[0019] The cooling of the desulfurization absorption liquid adopts the circulating cooling water 13 of the coking plant as a cold source to cool down the desulfurization absorption liquid to ensure the low temperature envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com