Method for preparing lithium chloride concentrate by using eluent of adsorptive lithium extraction as raw material

A technology of eluent and concentrate, applied in chemical instruments and methods, lithium halide, lithium carbonate;/acid carbonate, etc., can solve the problem of reducing the impurity content of the eluent for adsorption and extraction of lithium and affecting the adsorption method Problems such as the promotion and application of lithium extraction and low production efficiency can achieve the effects of reducing production costs, avoiding high acid-base and water consumption, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

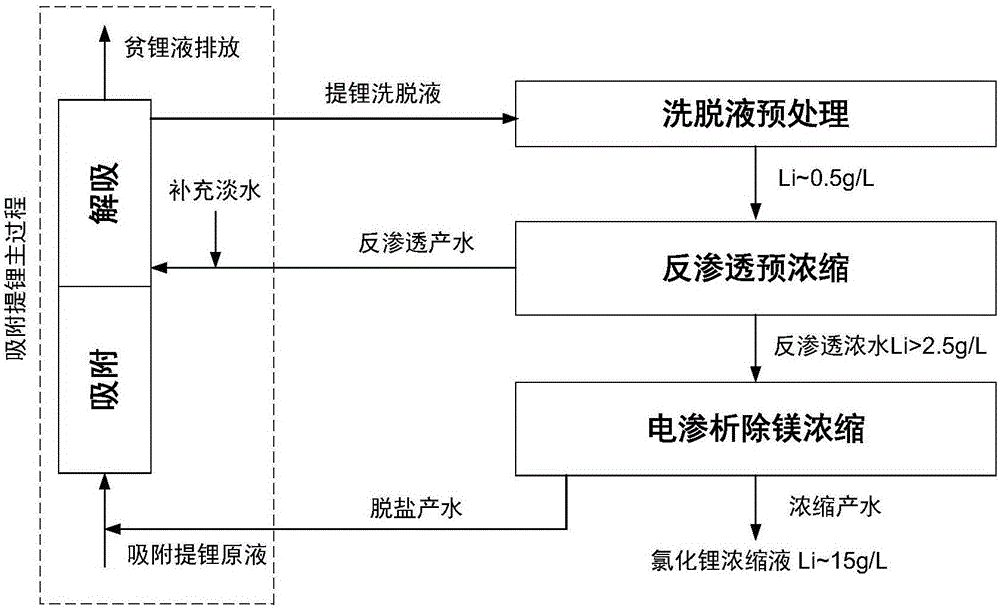

Method used

Image

Examples

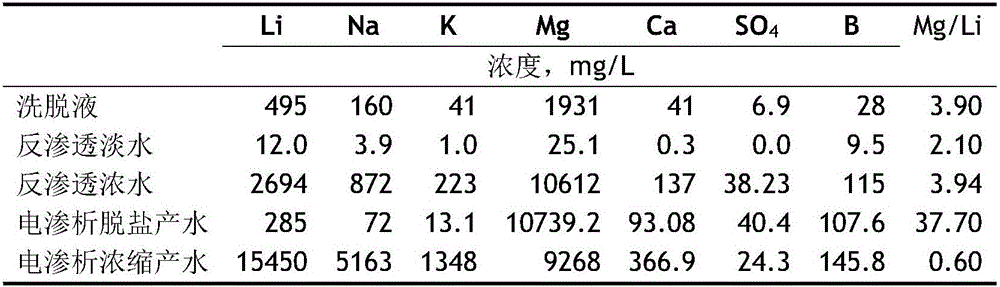

Embodiment 1

[0037] Pretreatment eluent:

[0038] An eluent for adsorption and extraction of lithium contains 495 mg / L lithium and 1931 mg / L magnesium, which are used as raw materials for treatment. After the raw material is vacuum filtered, its solid suspended matter content is less than 5 mg / L, and its pH value is adjusted to 6.0 to become the eluent after pretreatment.

[0039] Reverse osmosis pre-concentration:

[0040] Take 1000L of pretreated eluate and treat it with a reverse osmosis device equipped with Dow Chemical FILMTEC SW30-2540 membrane elements to obtain 820L of reverse osmosis fresh water and 180L of lithium containing 1700-7000mg / L reverse osmosis concentrated water.

[0041] Magnesium removal and concentration by electrodialysis:

[0042] Use an electrodialyzer consisting of 9 pairs of CIMS positive membranes and ACS negative membranes alternately arranged for treatment, with a total effective membrane area of 0.16m 2 . Concentrated reverse osmosis water is used as de...

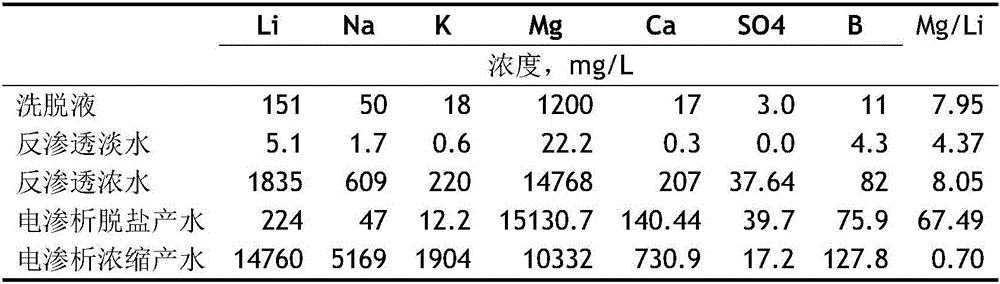

Embodiment 2

[0047] An eluent for adsorption and extraction of lithium, containing 151mg / L lithium and 1200mg / L magnesium, after vacuum filtration, its solid suspended matter content is less than 5mg / L, and its pH value is adjusted to 4.0 to form a pretreated eluent .

[0048] Take 1000L of the eluate after the pretreatment, and use a reverse osmosis device equipped with Dow Chemical FILMTEC SW30-2540 membrane elements to obtain 920L of reverse osmosis fresh water and 80L of reverse osmosis concentrated water.

[0049] Using the same electrodialyzer as in Example 1, only the membranes therein were replaced with K192 positive membrane and ASV negative membrane. Concentrated reverse osmosis water is used as desalination stock solution, 0.8L deionized water is used as concentrated solution feed water, the volume ratio of the two is 100, and 0.5mol / L NaNO is used as electrode circulating fluid 3 solution, at 160A / m 2 The constant current operation was carried out with the electric current, t...

Embodiment 3

[0054] An eluent for adsorption and extraction of lithium, containing 2490mg / L lithium and 1370mg / L magnesium, after vacuum filtration, its solid suspended matter content is less than 5mg / L, and its pH value is adjusted to 6.0 to become the eluent after pretreatment .

[0055] Take 1000L of pretreated eluate and treat it with a reverse osmosis device equipped with Dow Chemical FILMTEC SW30-2540 membrane elements to obtain 615L of reverse osmosis fresh water and 385L of reverse osmosis concentrated water.

[0056] Use an electrodialyzer consisting of 50 pairs of CSV positive membranes and A192 negative membranes alternately arranged, with a total effective membrane area of 5m 2 . Concentrated reverse osmosis water is used as desalination stock solution, 8L deionized water is used as concentrated solution feed water, the volume ratio of the two is 48, and 0.5mol / L NaNO is used as the electrode circulating fluid 3 solution, at 550A / m 2 The constant current operation was carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com