Measuring system for electric wire structure

A wire and cable and measurement system technology, applied in the field of measurement systems, can solve the problems of complex operation, small measurement range, low measurement accuracy, etc., and achieve the effects of extending service life, large use value, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

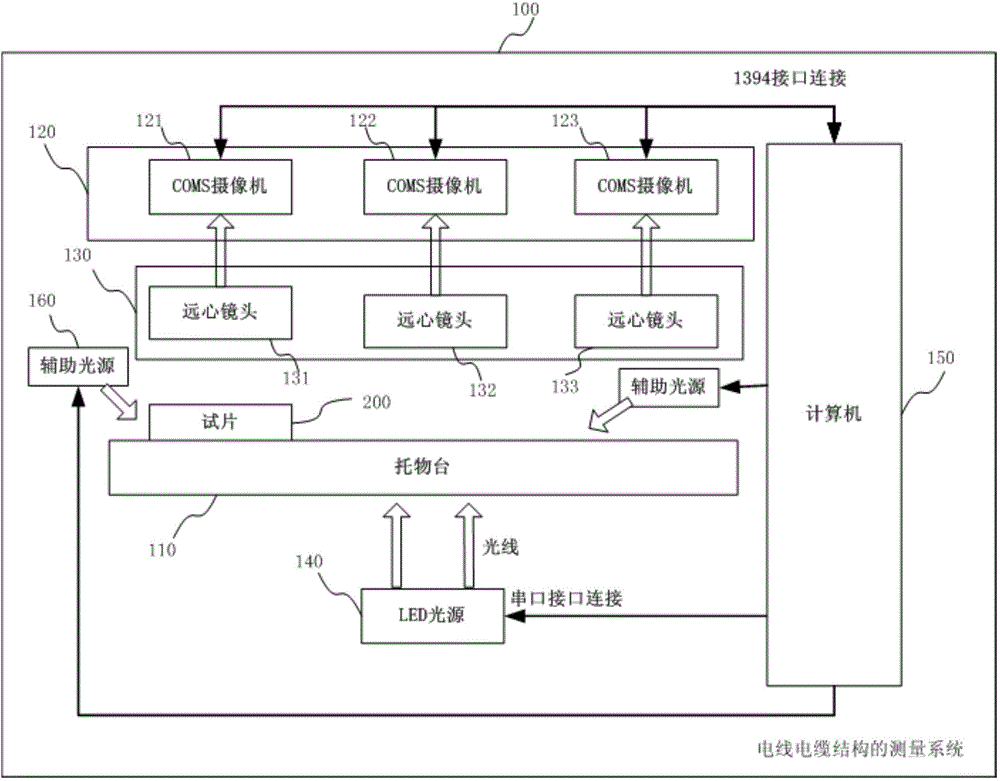

[0050] Such as figure 1 As shown, this embodiment discloses a wire and cable structure measurement system 100, which combines computer technology and image measurement technology, uses image measurement knowledge and algorithms, and combines computer data processing capabilities to complete the measurement of wire and cable structures.

[0051] Based on the factors of measurement accuracy, operating efficiency and equipment interface, the measurement system 100 of the wire and cable structure of the present embodiment includes a holding table 110, a plurality of image acquisition units, an LED light source 140, a computer 150 and a plurality of auxiliary light sources 160; image acquisition The unit includes a CCD (Charge-coupled Device, charge-coupled device) camera 120 and a telecentric lens 130 . Wherein, the holding table 110 is used to fix the test piece 200 for placing wires and cables; the LED light source 140 is located on the lower side of the holding table 110 ; Whe...

Embodiment 2

[0062] Such as Figure 4 As shown, the measuring system of the wire and cable structure of the present embodiment is the same as that of Embodiment 1, including a holding platform 110, a first image acquisition unit comprising a first CCD camera 120 and a first telecentric lens 131, comprising a second CCD camera 122 and the second image acquisition unit of the second telecentric lens 132, the third image acquisition unit comprising the third CCD camera 123 and the third telecentric lens 133, the LED light source 140 and the computer 15 (in Figure 4 , not marked); the supporting table 110 Shanghai is provided with three test piece placement positions, which are respectively: the first test piece placement position, the second test piece placement position and the third test piece placement position ( Figure 4, not marked), the placement position of the first test piece corresponds to the first image acquisition unit, the placement position of the second test strip correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com