Automatic correction device and correction method for moving arm

A boom and automatic technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of difficult to guarantee accuracy, high labor cost, and low correction accuracy, so as to achieve good accuracy, reduce labor cost, and improve correction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

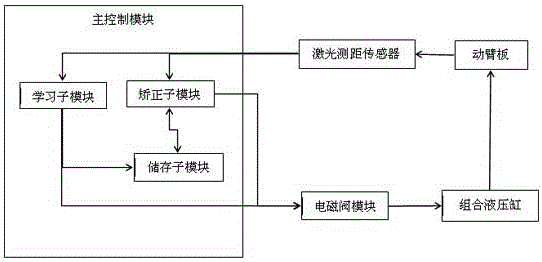

[0031] Such as figure 1 As shown, the automatic boom correction device provided by the present invention includes a main control module, a laser ranging sensor, a battery valve module, and a hydraulic cylinder combination;

[0032] The main control module is electrically connected to the laser ranging sensor and the battery valve module; the laser ranging transmitter is aligned with each boom plate of the boom to obtain the position of each boom plate; the hydraulic cylinder group is based on There are multiple groups of boom plate correction directions, each group of hydraulic cylinders corresponds to one boom plate correction; the battery valve module is combined with the hydraulic cylinder, and each group of hydraulic cylinders has a corresponding battery valve installed on the oil circuit;

[0033] The laser distance measuring sensor transmits the detected position information of each boom plate to the main control module;

[0034] The main control module compares the position in...

Embodiment 2

[0041] The automatic boom correction device provided by the present invention includes a main control module, a laser ranging sensor, a battery valve module, and a hydraulic cylinder combination;

[0042] The main control module includes a learning sub-module and a correction sub-module. The learning sub-module is electrically connected to a laser ranging sensor, a battery valve module, and a storage sub-module; the correction sub-module is connected to the laser ranging sensor and a battery Electrical connection of valve module and storage sub-module;

[0043] When the correction is performed for the first time or the correction parameters are revised again, the learning sub-module is first started; the laser ranging sensor transmits the detected position information of each boom plate to the learning sub-module; the learning sub-module performs position information and prediction The set standard position range value is compared. If it exceeds the standard position range value, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com