Device for continuously and efficiently forming yarn from reinforced nanofiber and spinning method

A nanofiber and yarn-forming technology, applied in the field of textile processing, can solve the problems of inability to control the fiber shape online and the poor stability of continuous production of nanofiber yarns, and achieve the effects of good continuous stability, good fiber orientation and high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

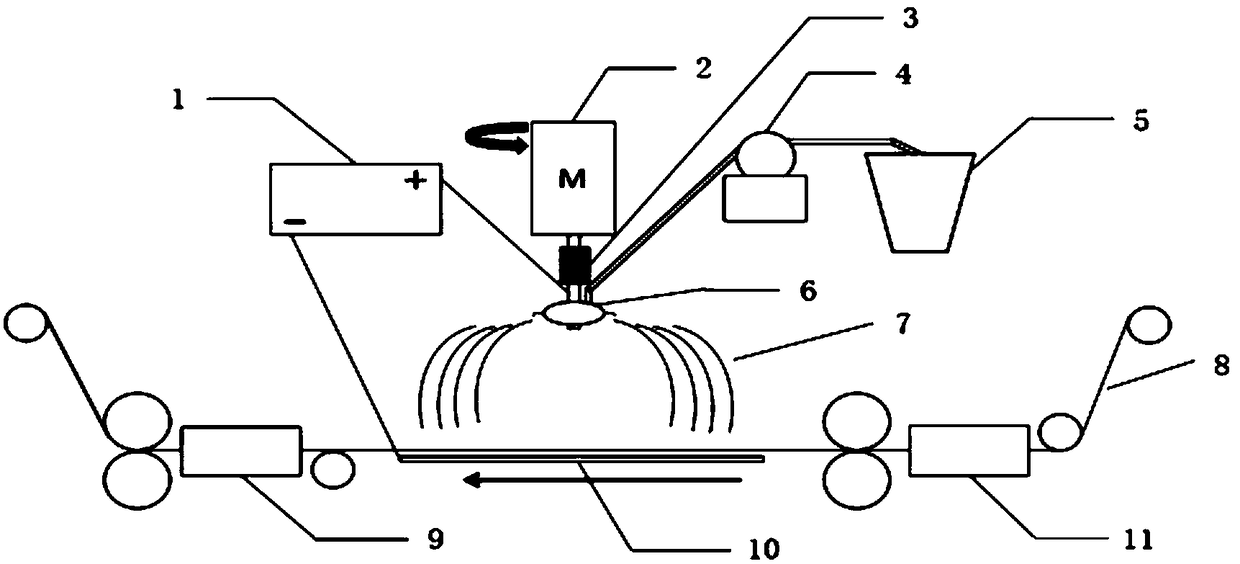

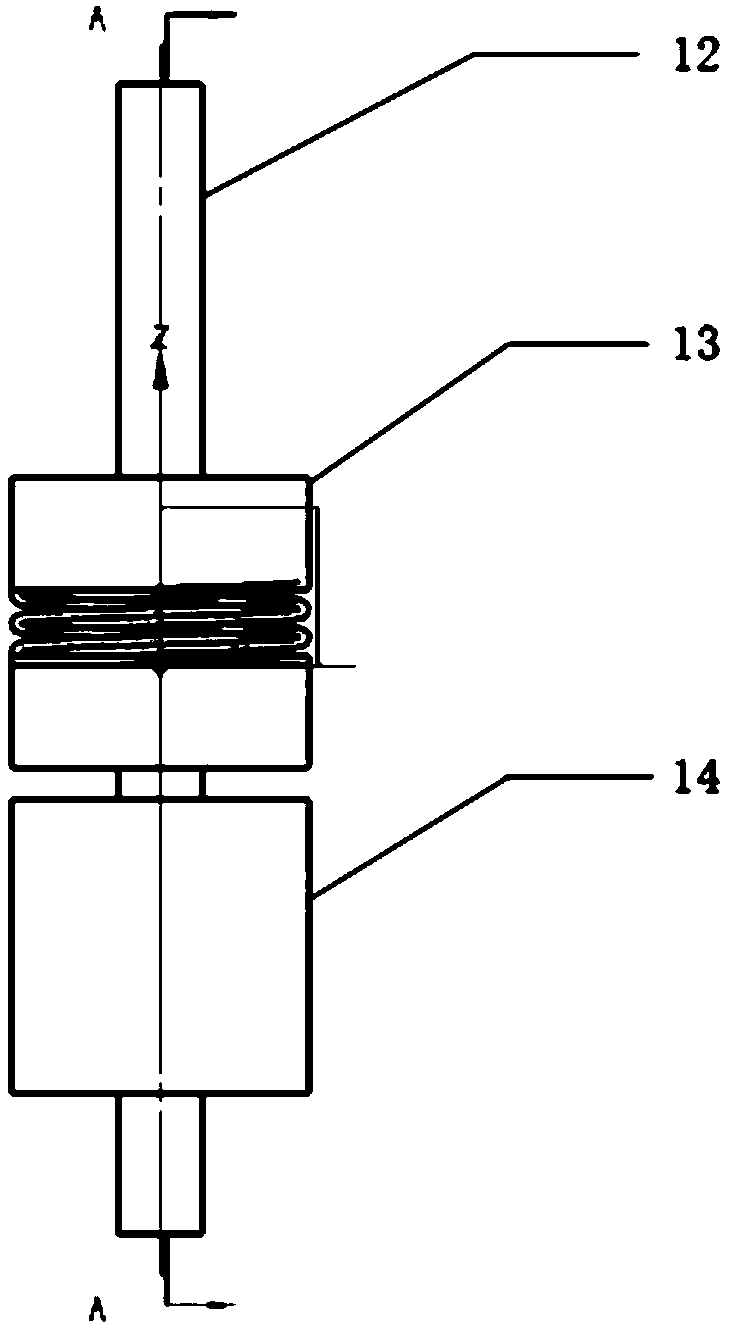

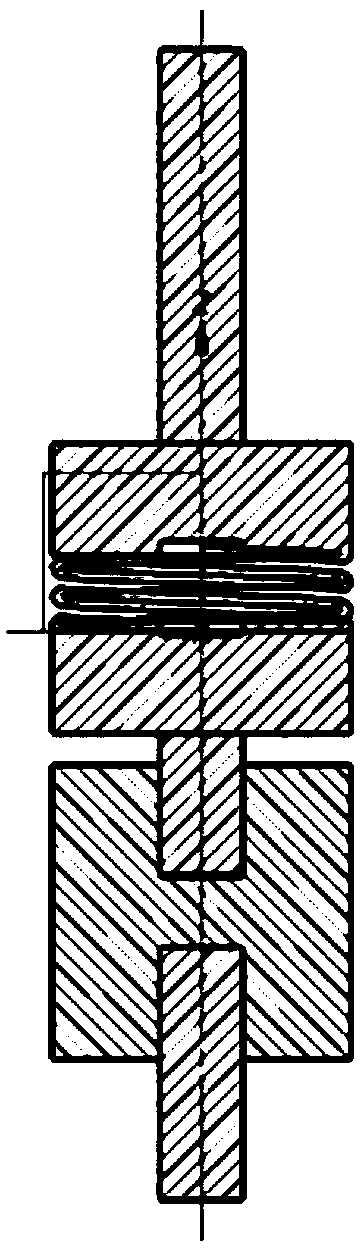

[0040] The spinning solution prepared by ethyl cellulose and ethanol / water solution was used for spinning. The spinning solution that concentration is 20% is injected in the spinneret 6 by peristaltic pump 3, and spinneret 6 is connected with electrostatic generator 1 anode, is set between the spinneret hole of spinneret 6 and the conductive rectangular plate 10 The distance is 8cm, turn on the electrostatic generator, set the voltage to 6kV, start the motor 2, set the rotating speed to 2500rpm, when the nanofiber 7 appears on the conductive plate 10, start the yarn forming device, and the collected yarn 8 passes through the twister 11 with After a certain twist, contact with the nanofiber 7 above the conductive plate 10, the collection yarn 8 begins to untwist under the action of the untwisting device 9, the untwisting process of the collection yarn 8 will make the nanofiber 7 in contact with it continue to twist, The collection yarn 8 has the opposite charge to increase the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com