Patents

Literature

70results about How to "Improve continuous stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grouper environmentally-friendly soft granulated feed and preparation method thereof

InactiveCN102178105ANutritional full priceBalanced nutritionFood processingClimate change adaptationEnvironmental resistanceEcological environment

The invention provides a grouper environmentally-friendly soft granulated feed and a preparation method thereof. The grouper environmentally-friendly soft granulated feed comprises the following nutritional components in percentage by weight: 40 to 50 percent of crude protein, 6 to 12 percent of crude fat, 8 to 15 percent of crude ash, 22 to 28 percent of carbohydrate, and 6 to 10 percent of moisture. According to the invention, the high-quality grouper environmentally-friendly soft granulated feed is studied, popularized and applied, so that the nutrition of the launched feed goes to be complete and balanced, and the palatability of the feed is good, not only can the feed digestive absorption rate of grouper be improved, but also the survival rate and growing speed of the grouper are improved, and the fish quality is improved. Therefore, non-polluted fish products are produced, and the cultivation economical benefit is improved; and the feed has active and profound significance in reducing the usage of small trash fish, lightening the sea area pollution, protecting the marine eco-environment, and promoting the sustained stable and health development of the marine fish culture industry.

Owner:福建省淡水水产研究所

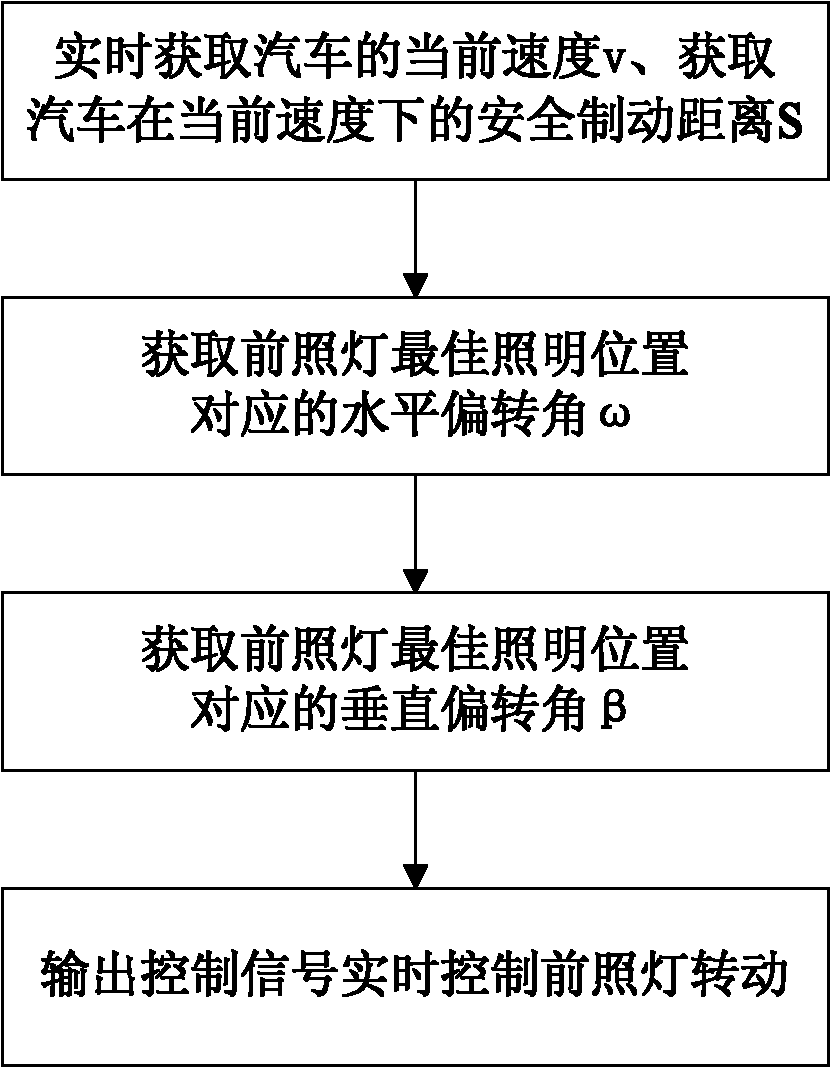

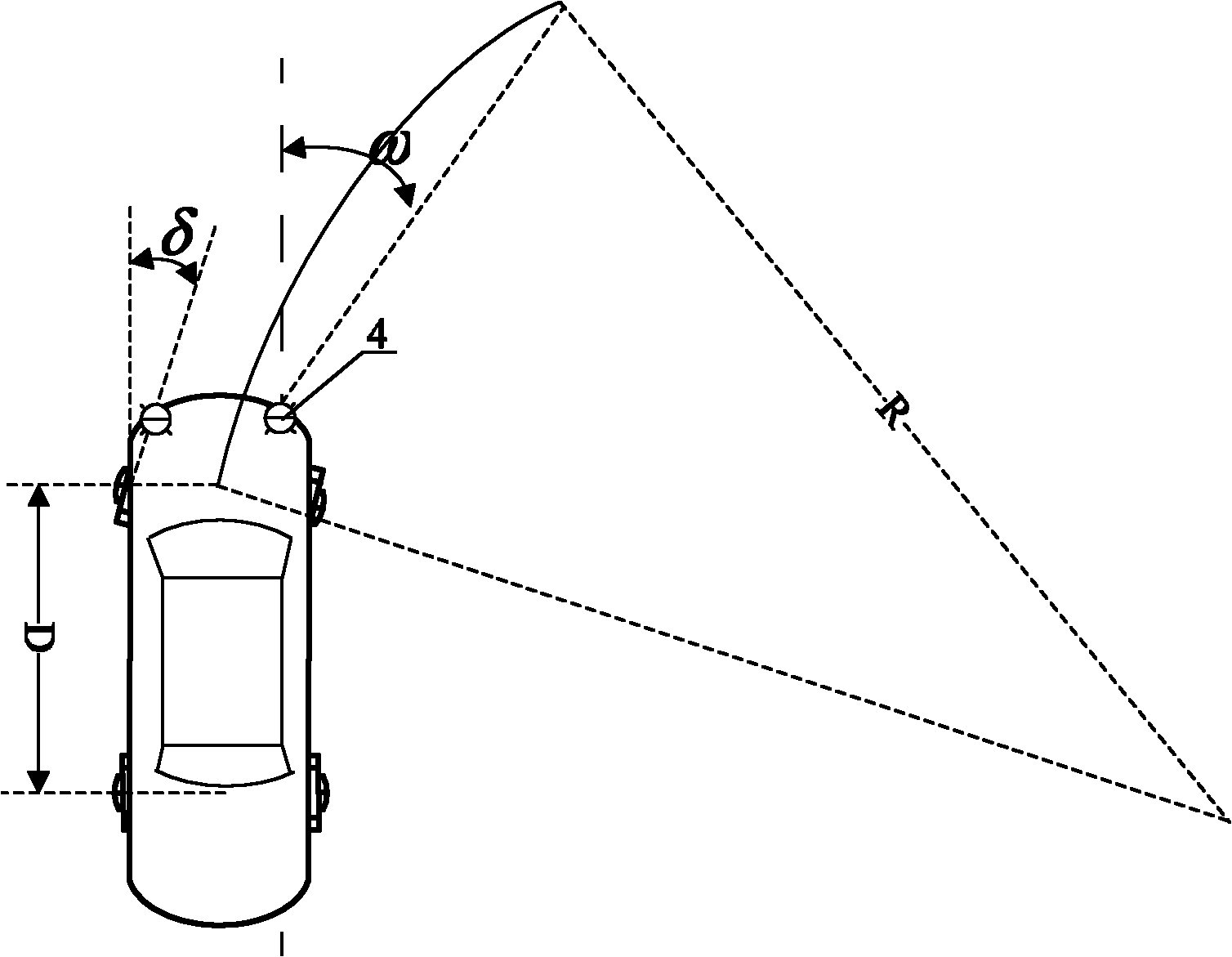

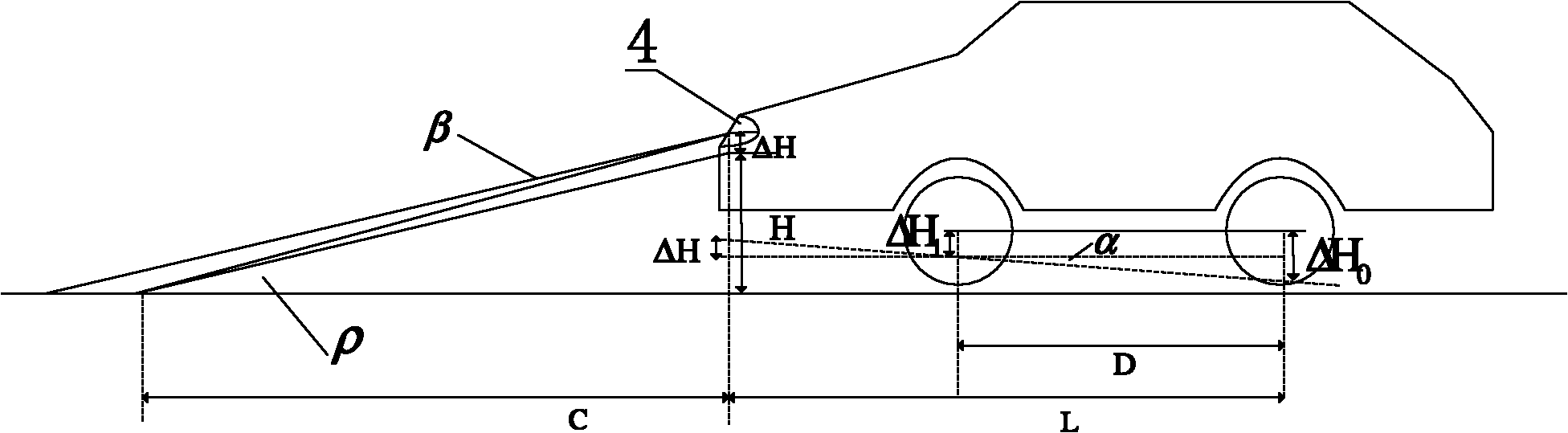

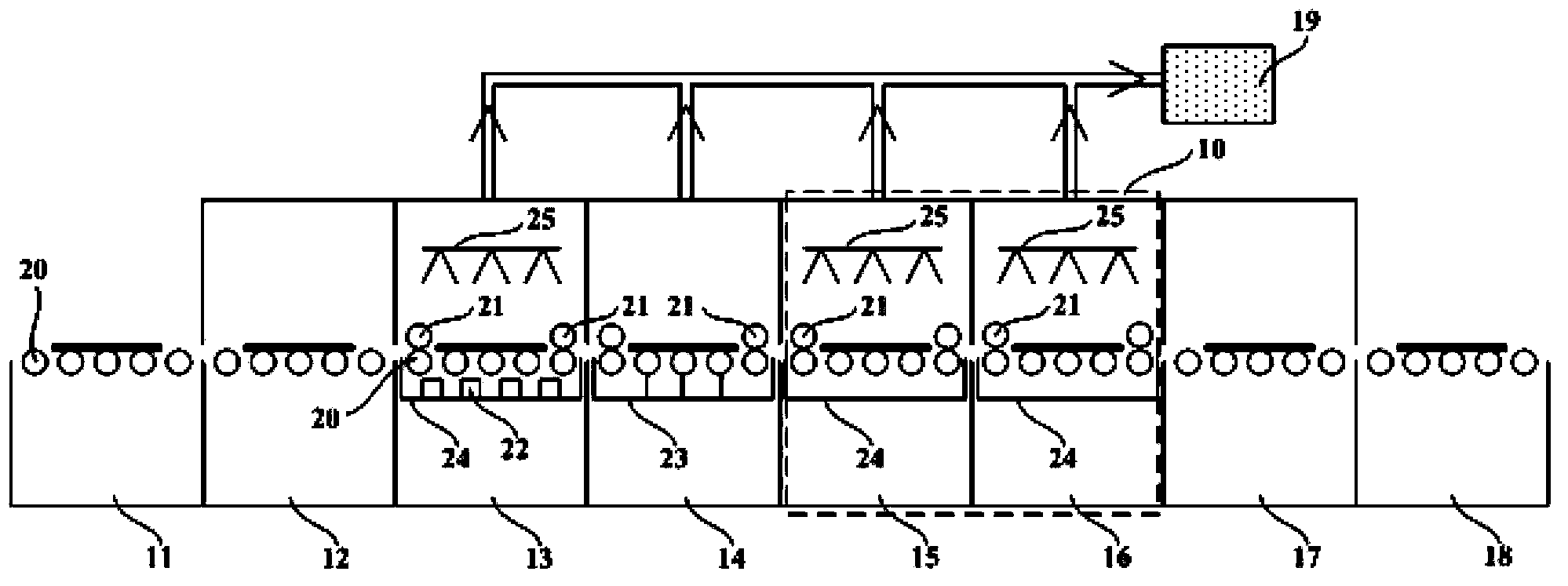

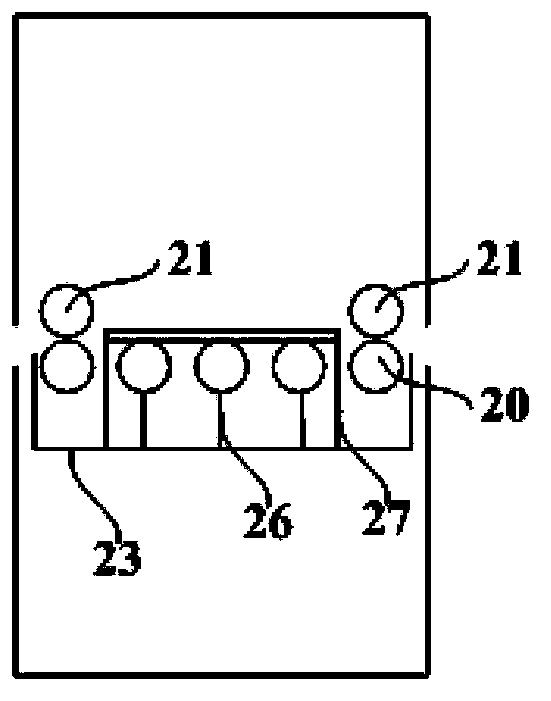

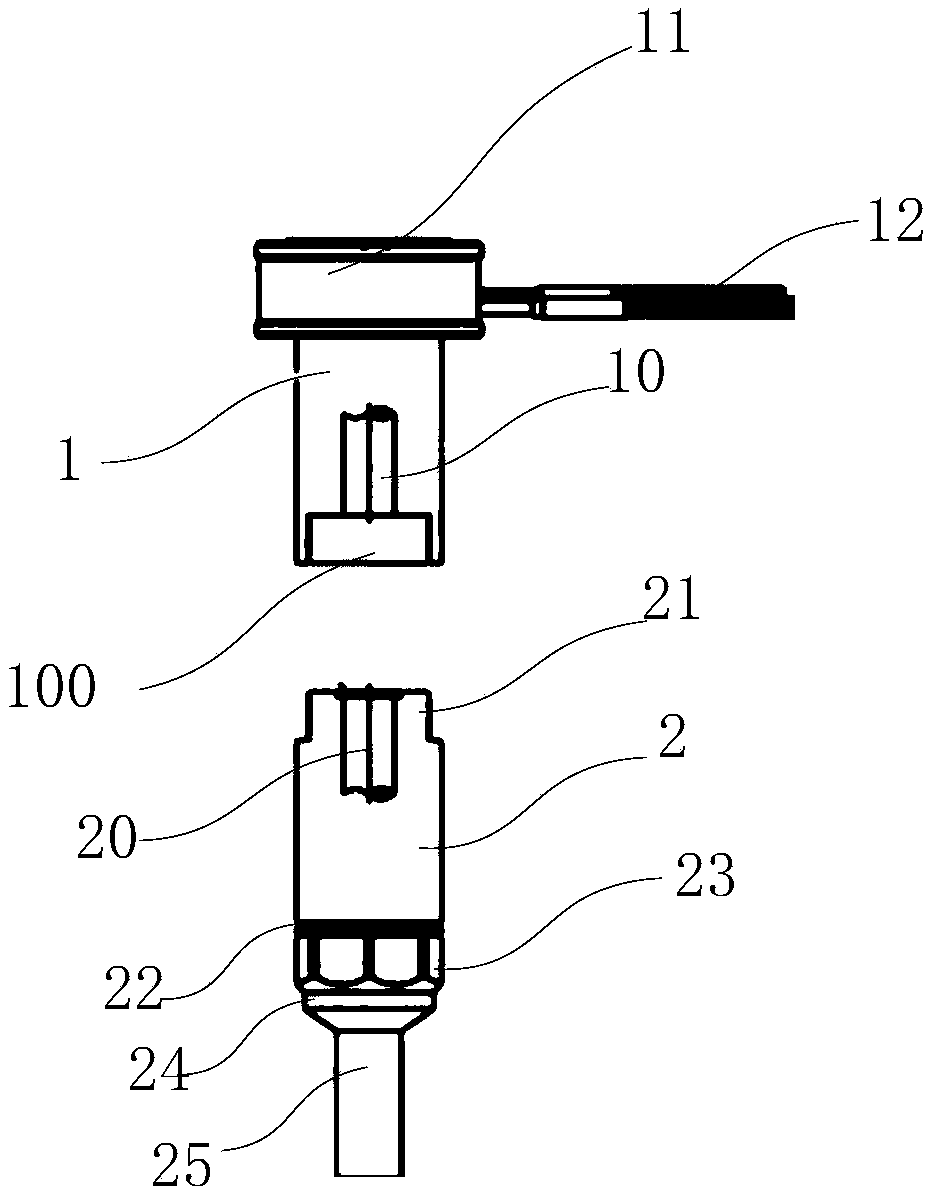

Headlamp adaptive control method and device

InactiveCN102029941AIncrease viewing distanceIncrease visual rangeOptical signallingRide heightControl signal

The invention discloses headlamp adaptive control method and device. The method comprises the steps of: (1) acquiring the current speed v of an automobile in real time, and acquiring the safe stopping distance S of the automobile at the current speed; (2) acquiring a horizontal deflection angle omega corresponding to the optimum lighting position of the headlamp; (3) acquiring a vertical deflection angle beta corresponding to the optimum lighting position of the headlamp; and (4) outputting control signals to control the turning of the headlamp in real time. The device comprises a control unit (1), and a detection unit (2) and a driving mechanism (3) which are respectively connected with the control unit (1), wherein the detection unit (2) comprises a speed sensor (21), a steering wheel angel sensor (22), a front ride height sensor (23), a rear ride height sensor (24), a sunshine and rain sensor (25) and an acceleration sensor (26). The invention has the advantages of large lighting range, good lighting effect, no reflected glare, simple structure, accurate control, good environmental suitability, safety, reliability and comfortable drive.

Owner:HUNAN UNIV

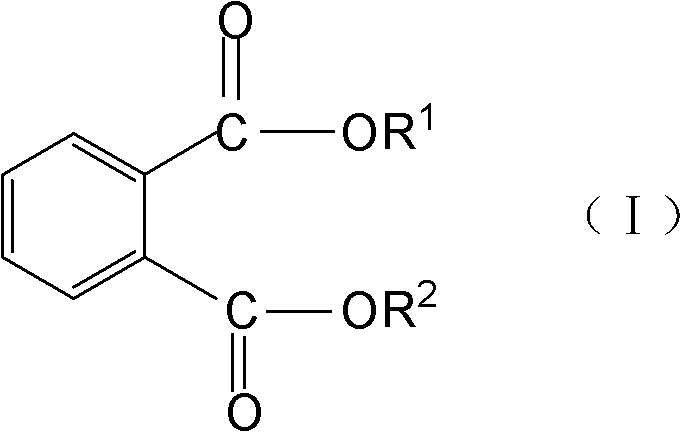

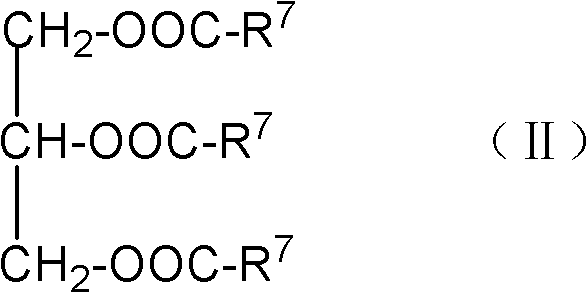

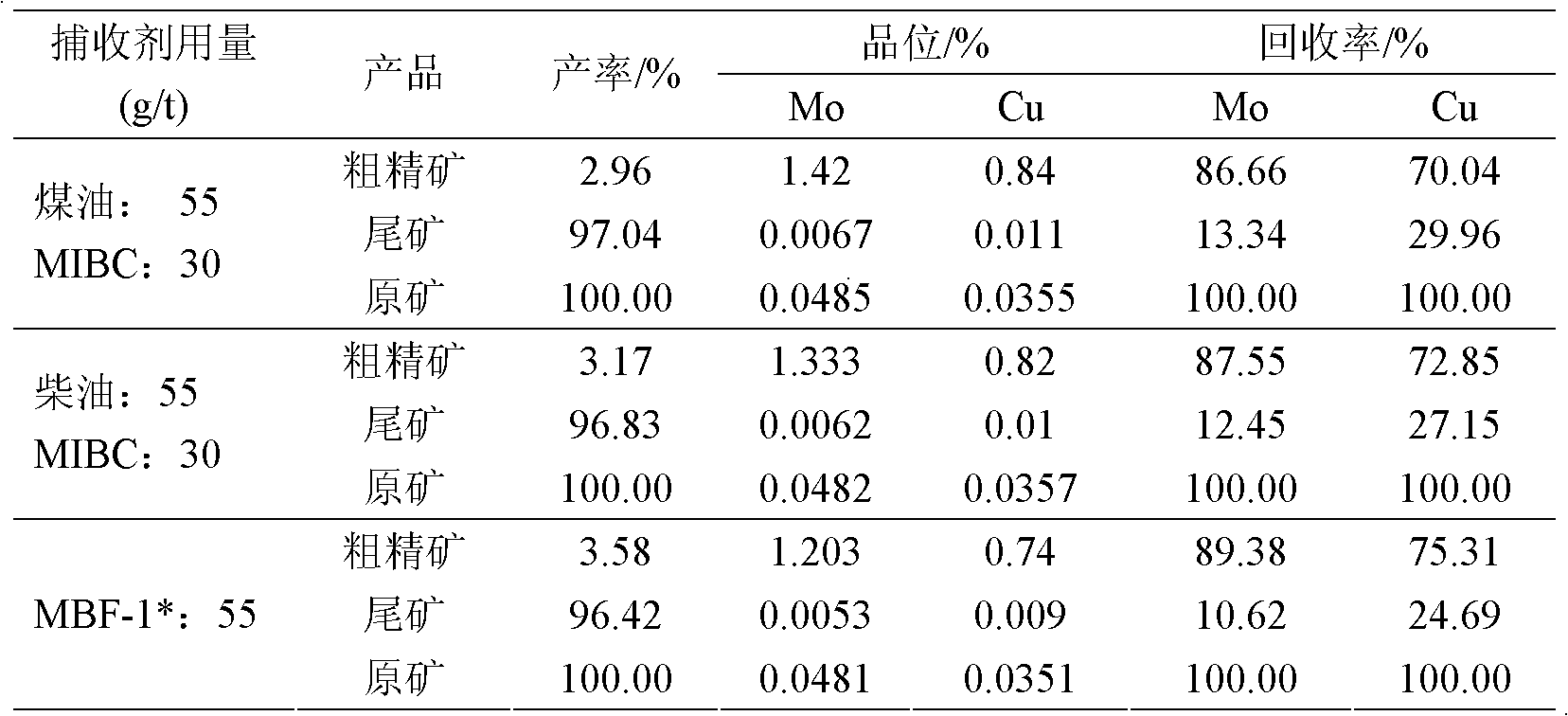

Composite floatation collector and preparation method thereof

Disclosed are a composite floatation collector and a preparation method thereof. The composite floatation collector is composed of phthalate, hydrocarbon type oil and high-carbon oxygen-containing organic compound according to the mass ratio of 2-10:10:2-10. The composite floatation collector has the advantages of fine low-temperature liquidity, fast bubbling, long duration of bubbling, fine dispersibility in pulp, high collecting capacity to coarse-grade mineral or ultrafine-grade mineral and the like, and is used for recovering molybdenum from molybdenum ore and copper-molybdenum ore and recovering coal from coal ore by means of floatation efficiently.

Owner:CENT SOUTH UNIV

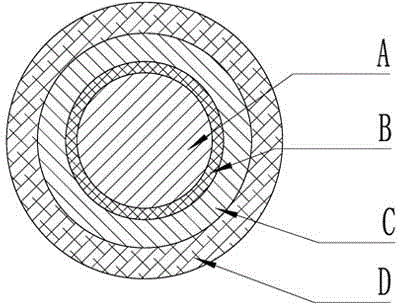

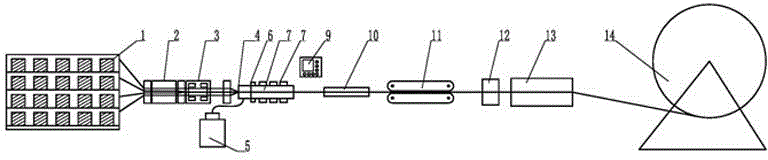

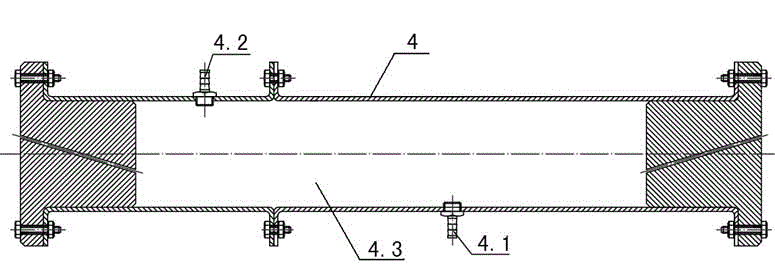

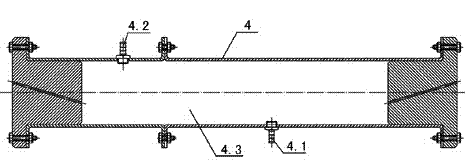

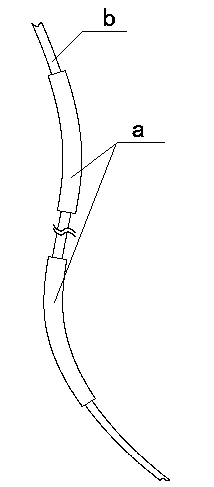

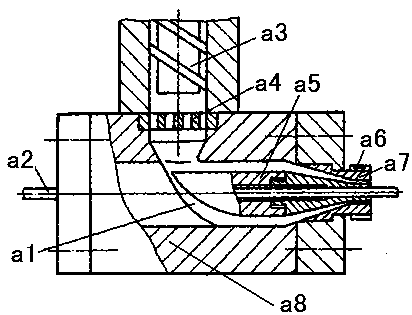

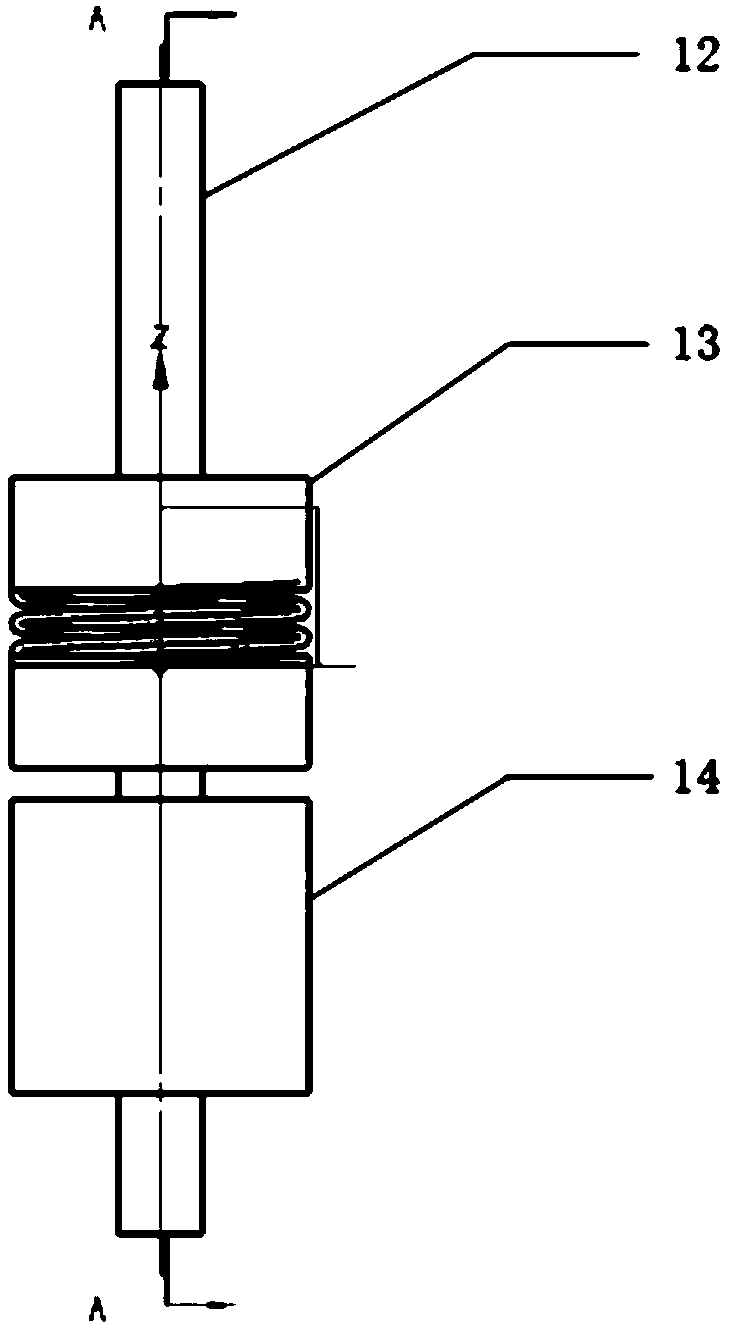

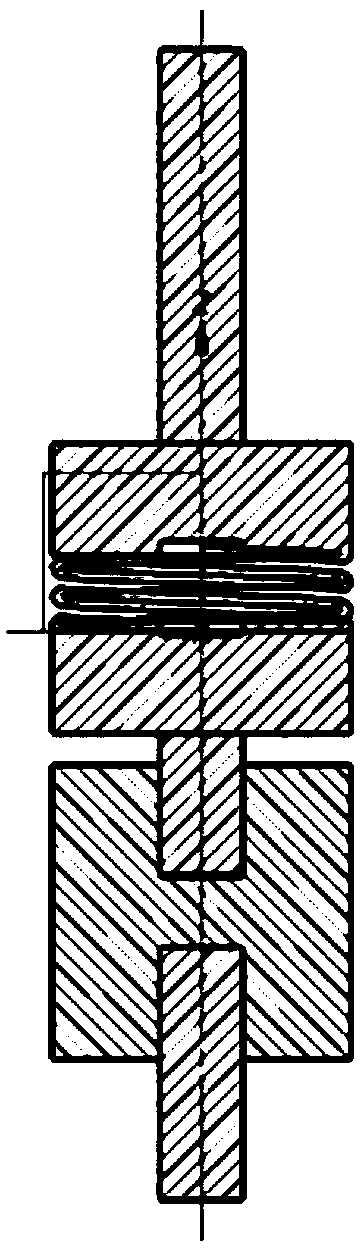

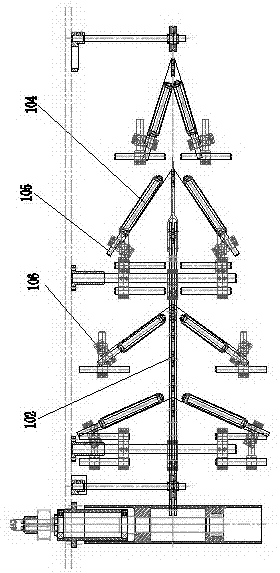

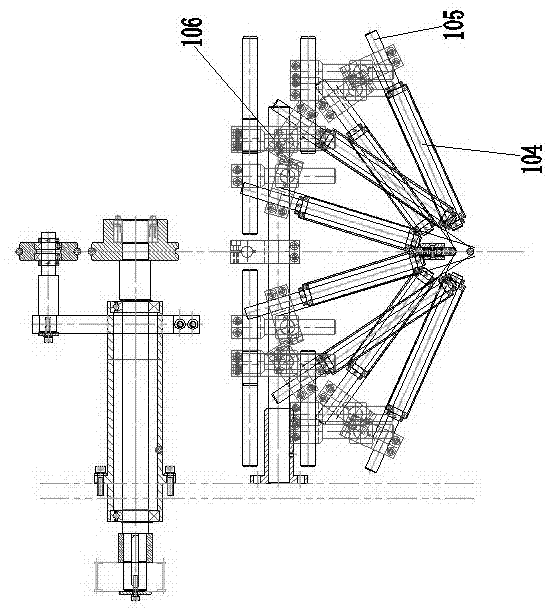

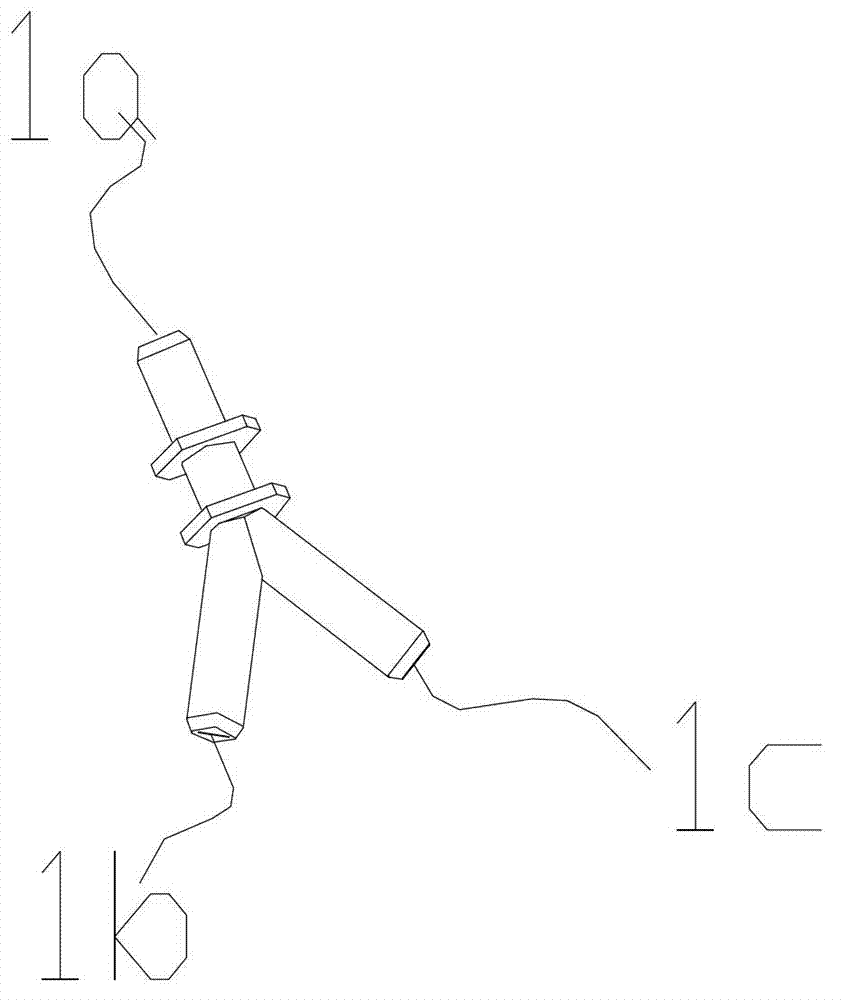

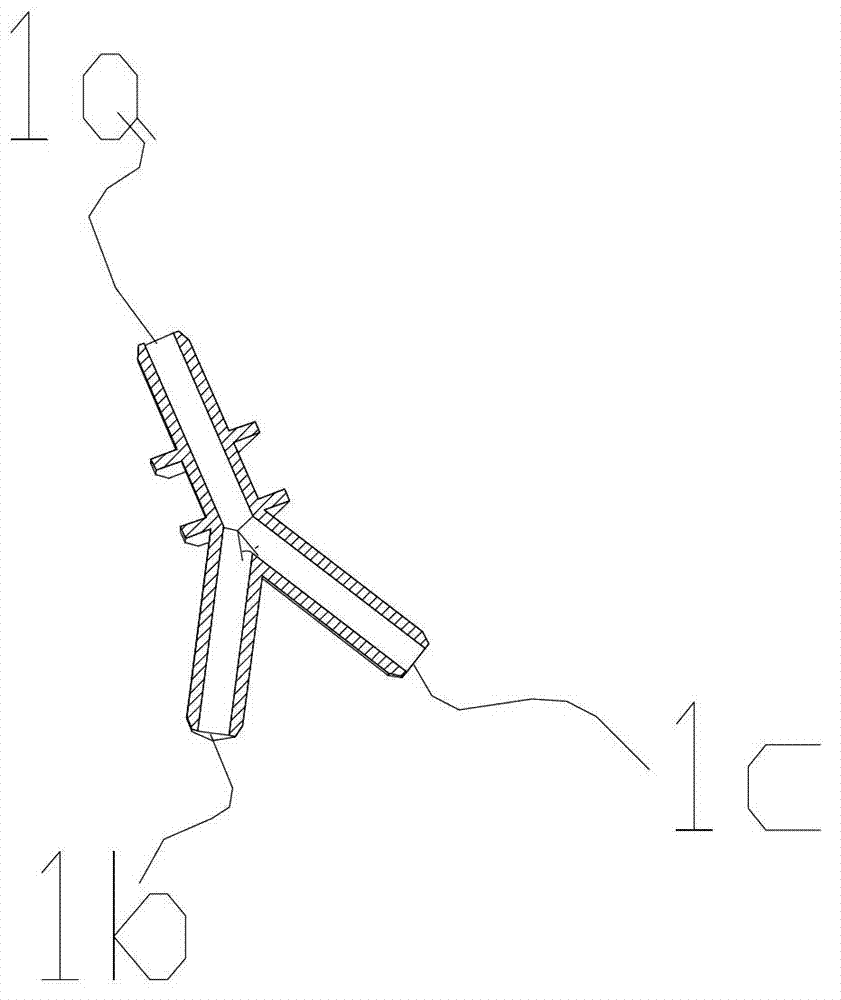

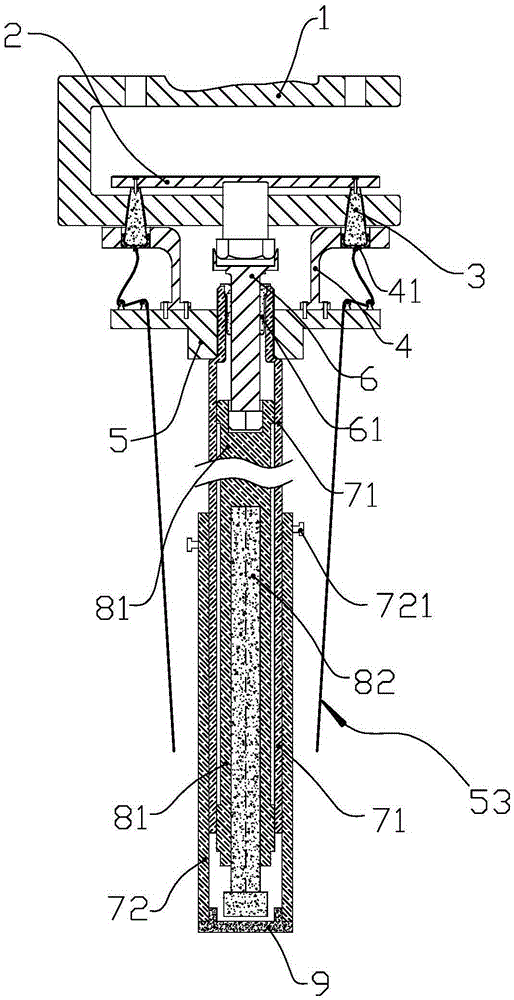

Multilayer compound eccentric-wear-preventing continuous sucker rod and manufacturing device and method thereof

ActiveCN104060944AAccelerated corrosionImprove partial wear resistanceDrilling rodsLayered productsEpoxyManufacturing technology

The invention relates to a multilayer compound eccentric-wear-preventing continuous sucker rod and a manufacturing device and a manufacturing method thereof. The sucker rod is characterized in that one section or several sections of the external surface of a fiber reinforced resin matrix composite rod body are respectively covered with a thermosetting wear layer; each thermosetting wear layer is made from one of polyurethane, a fluorocarbon coating, modified epoxide resin, vinylester resin, unsaturated polyester and phenolic resin; by adopting a manufacturing technology of multilayer composite winding and pultrusion or weaving and pultrusion, an internal layer of longitudinal fibers, an intertwining layer or a weaving layer and an external layer of longitudinal fibers are formed from interior to exterior in sequence; the manufactured rod body has a continuous length of 0-5000m. The sucker rod has the beneficial effects that the radial strength and the axial compressive strength are enhanced; the corrosion resistance and the eccentric wear resistance of the thermosetting wear layers are improved by 30%; the maximum temperature tolerance of the thermosetting wear layers is up to 190 DEG C; meanwhile, the bonding between an sucker rod body and each thermosetting wear layer is greater in length and quite high in strength, so that the slippage and the layering of an eccentric-wear-preventing layer from the surface of the sucker rod in the normal operation of an oil well are avoided.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

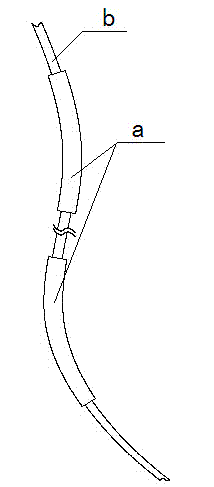

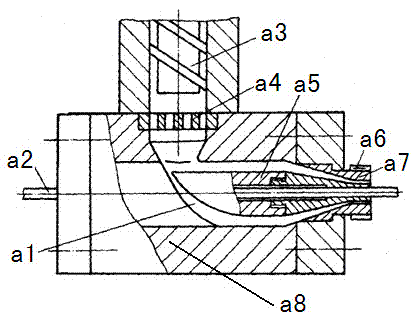

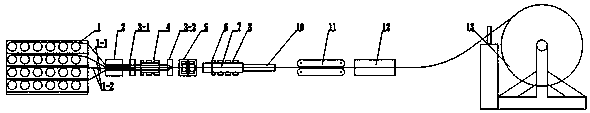

Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

ActiveCN103075112AAccelerated corrosionImprove partial wear resistanceDrilling rodsDrilling casingsEpoxyThermoplastic

The invention relates to a fibre reinforced composite anti-eccentric coiled rod and a preparation device thereof. The technical scheme adopted by the invention is as follows: one or more sections of the external surface of a fibre-reinforced resin matrix composite rod body is coated with a thermoplastic wear layer; the rod body is made of one of fibreglass, carbon fibre and basalt fibre; and a resin matrix is one of epoxy resin, urethane resin and vinyl ester resin. A plastic extruder and a cooling device are arranged between a draw gear and a winding device, the plastic extruder is used for coating one thermoplastic wear layer on one or more sections of the surface of a molded sucker rod, and then the cooling device is used for performing cooling treatment, so that the fibre reinforced composite anti-eccentric coiled rod is formed. The invention has the following beneficial effects: the coiled rod has excellent anticorrosion and anti-eccentric performances; the quantity of joints is greatly reduced; the breakage probability and the piston effect are reduced; and in addition, the production efficiency is high, and the operation is simple and convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

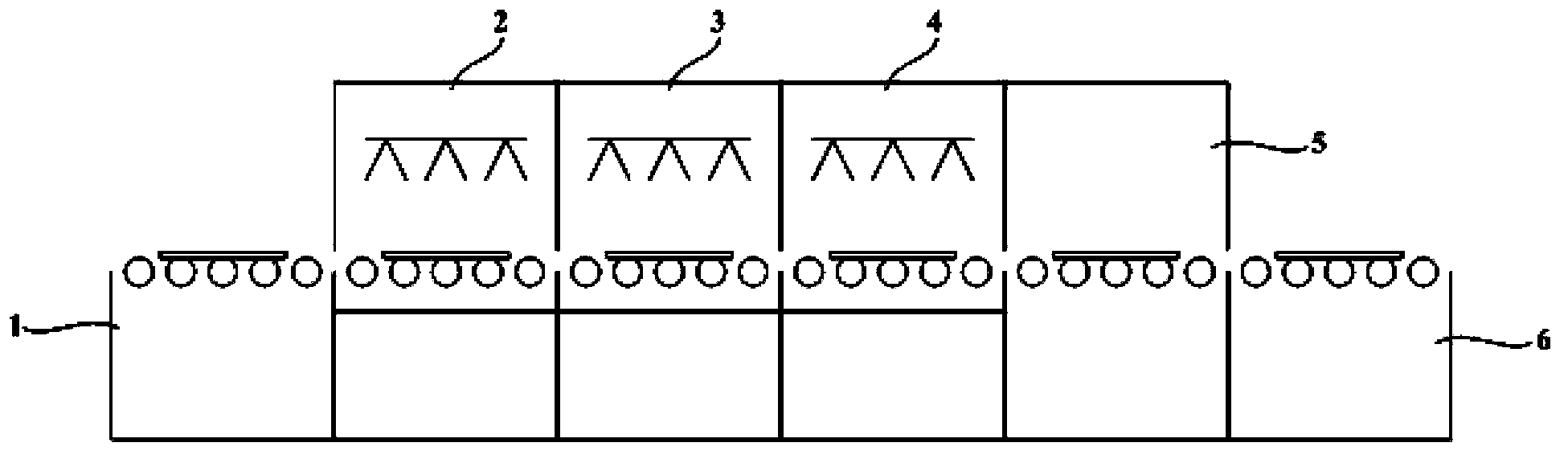

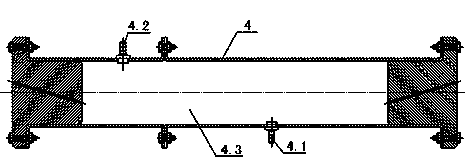

Wet etching apparatus and wet etching method

The invention relates to the technical field of etching, and discloses a wet etching apparatus and a wet etching method. The wet etching apparatus comprises a plate receiving chamber, a temperature control chamber, a wet etching chamber, a plate discharging chamber, a conveyer and a temperature control system positioned in the temperature control chamber, and an etching object is conveyed by the conveyer and sequentially goes through the plate receiving chamber, the temperature control chamber, the wet etching chamber and the plate discharging chamber; and the temperature control system is used for adjusting the temperature of the etching object to a preset temperature. The invention also provides the wet etching method. By adopting the above technical scheme in the invention, the temperature of the etching object is adjusted to the preset temperature, so when the etching object is etched by an etching solution, the etching rate consistency is guaranteed, the continuous stability of the etching production is improved, and the large-scale continuous online production requirement can be adapted.

Owner:ENN SOLAR ENERGY

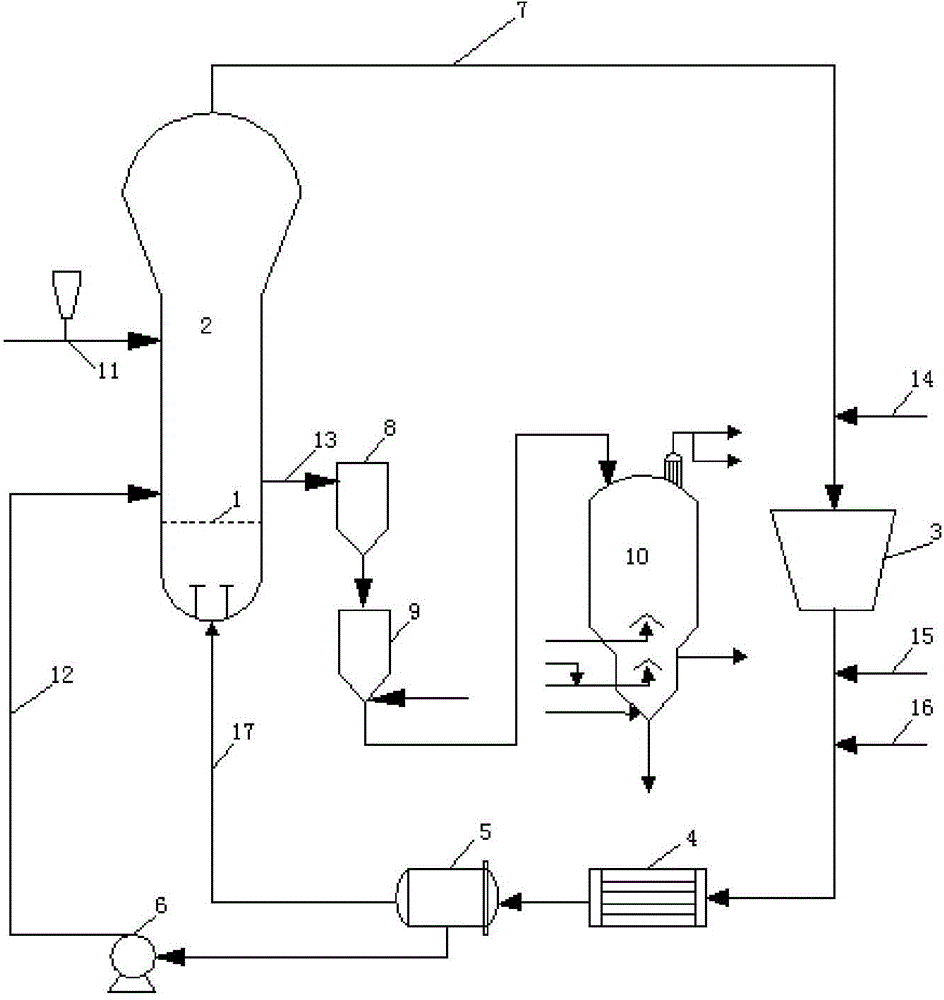

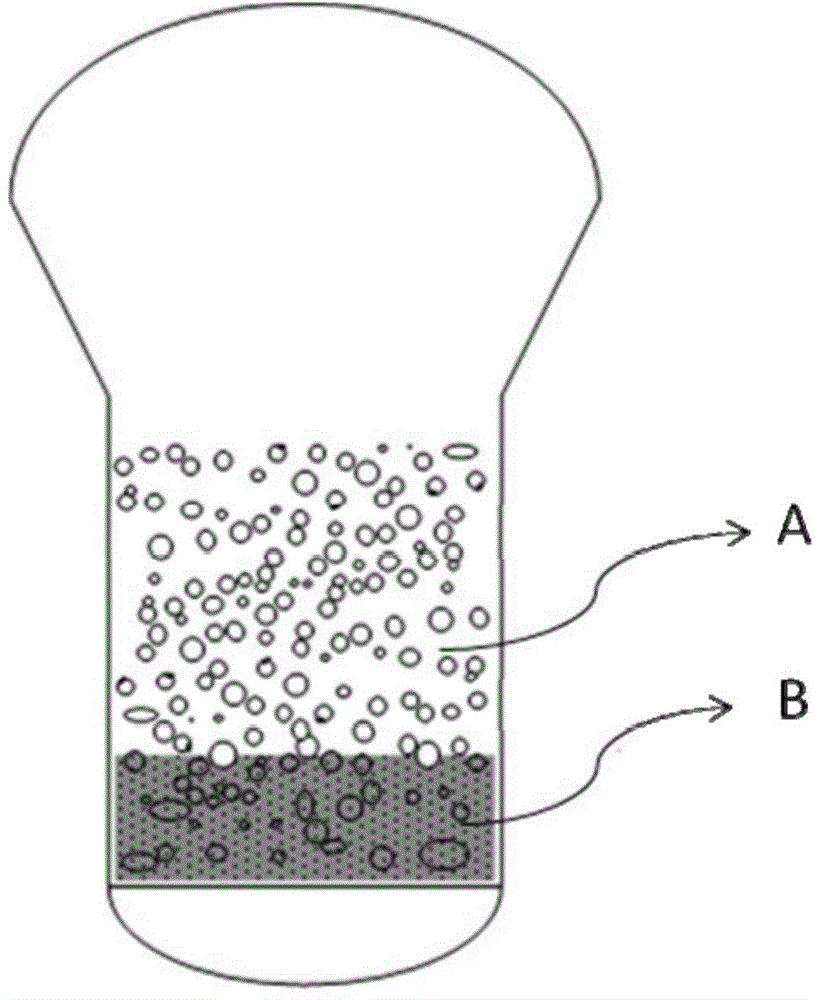

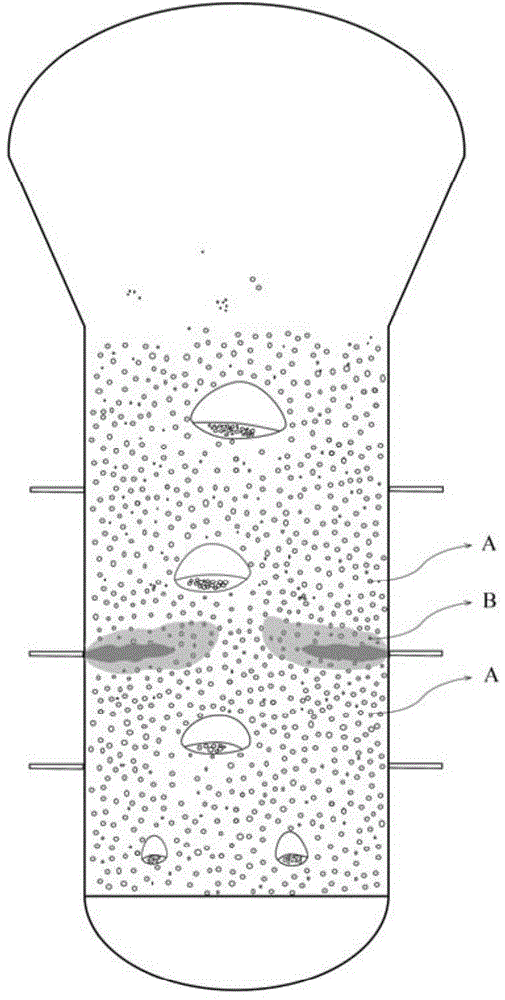

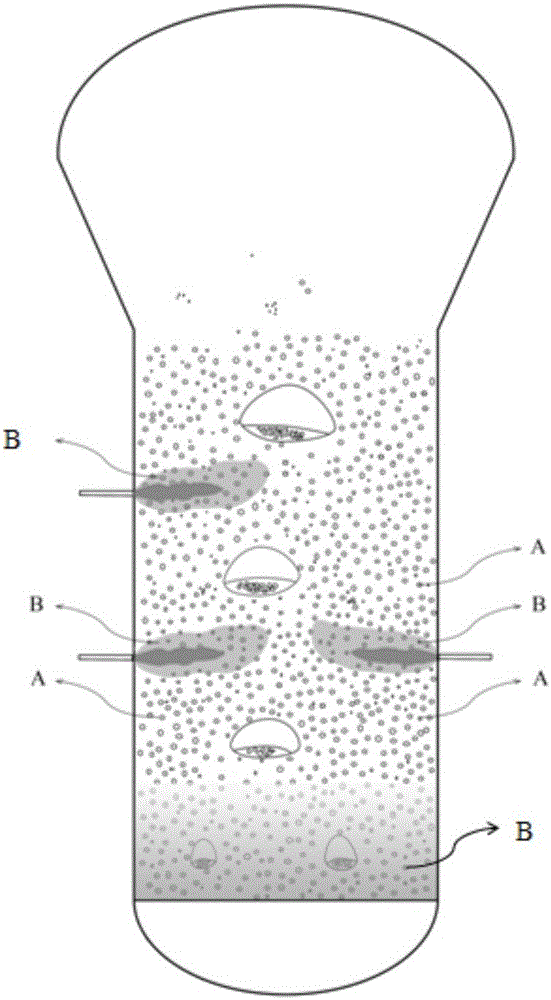

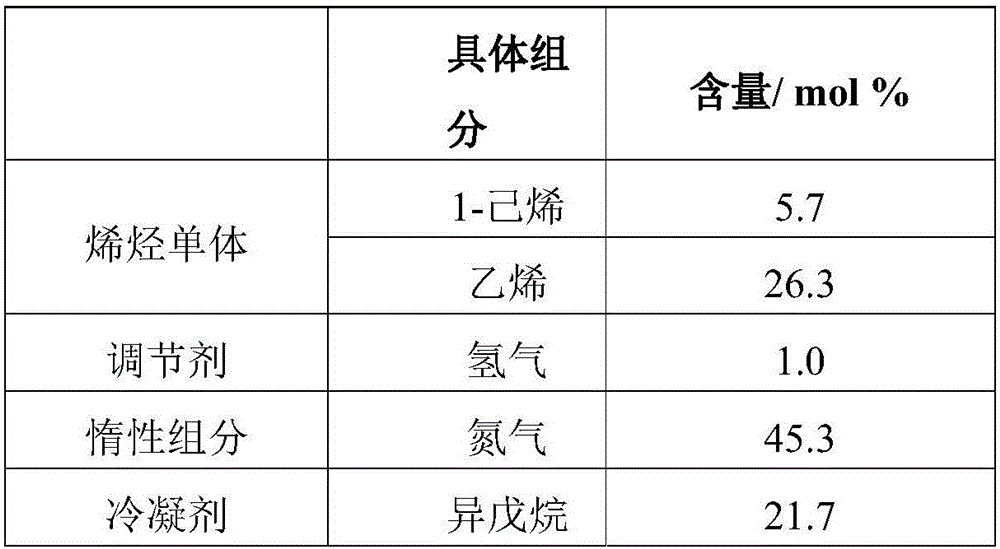

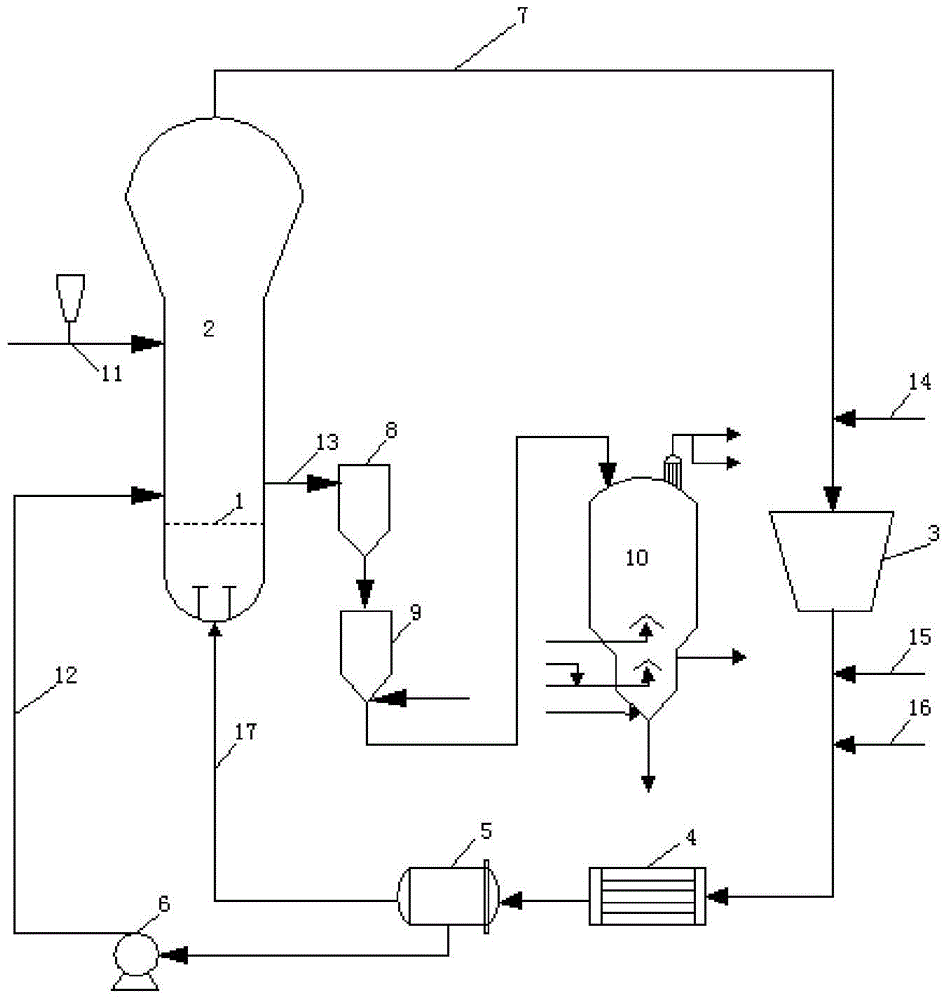

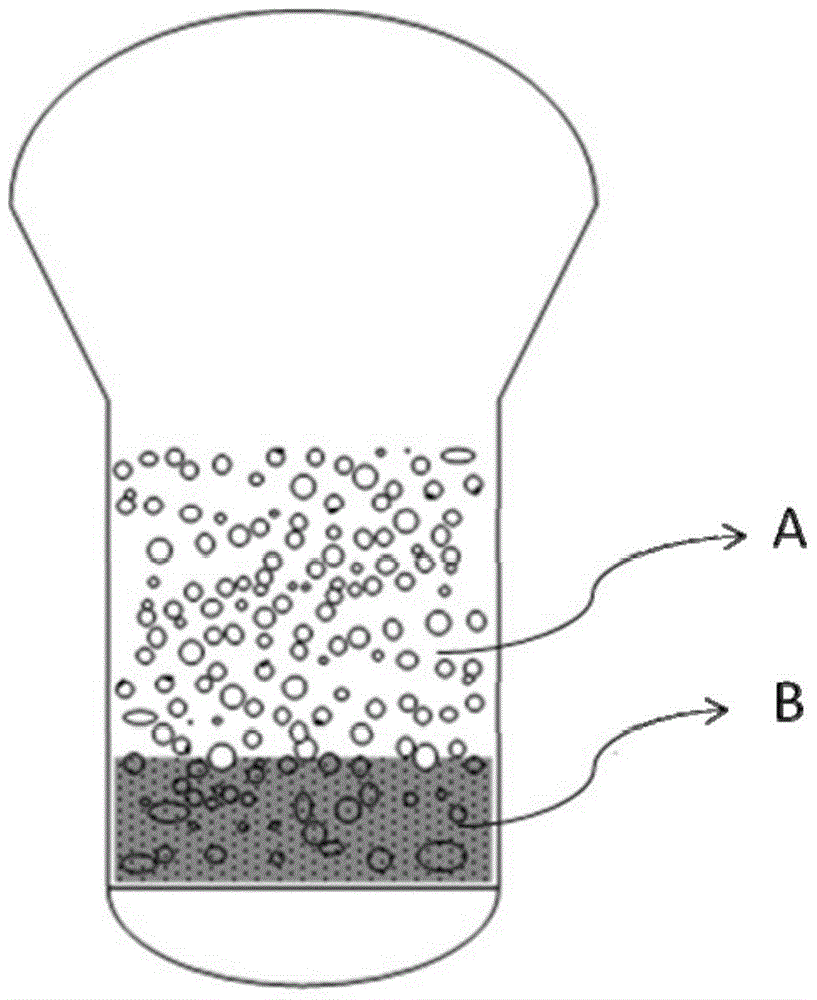

Method for preparing olefin polymer by utilizing multiple temperature reaction areas

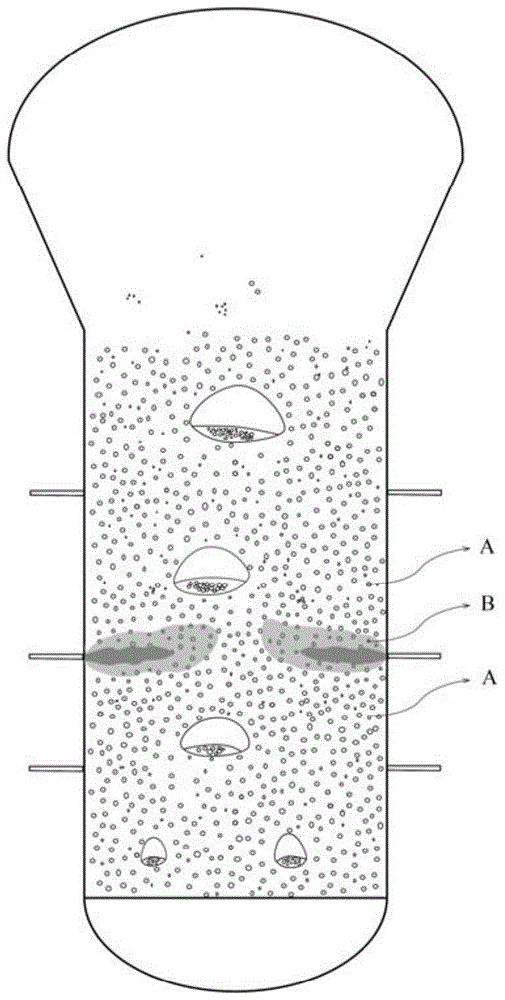

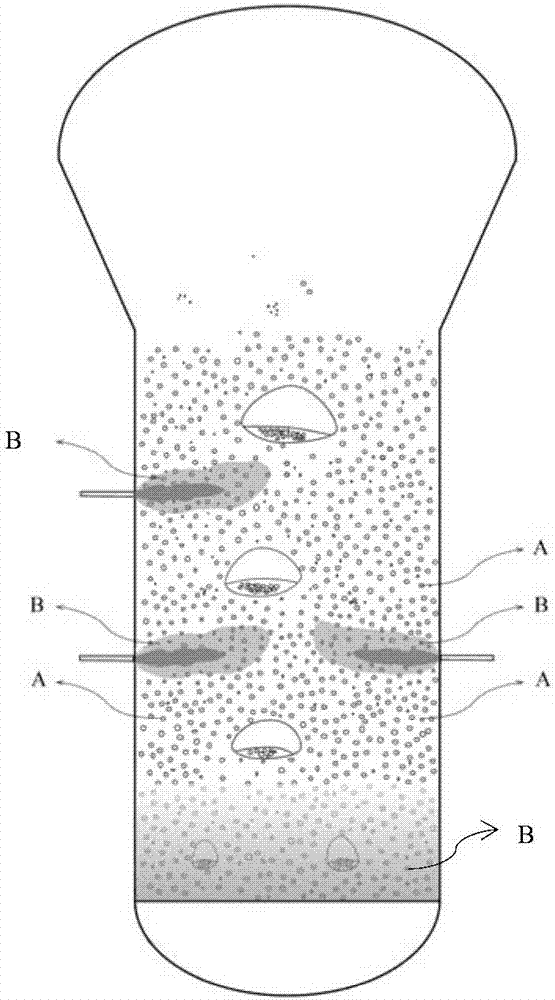

ActiveCN104628904AImprove cooling capacityHigh space-time yieldHeat transfer efficiencyFluidized bed

The invention discloses a method for preparing olefin polymer by utilizing multiple temperature reaction areas. The method provided by the invention comprises the following step of forming a plurality of olefin polymer reaction areas with different temperatures in a fluidized bed reactor by utilizing a circulating medium, wherein the circulating medium comprises an olefin monomer and a condensing agent. By utilizing the method, preparation of high-performance olefin polymer product by utilizing a single reactor is realized. The method is high in heat transfer efficiency. The olefin polymer prepared by utilizing the method is low in density, wide in distribution, uniform in degree of crystallinity and the like and can be widely applied to various fields of thin-film materials and the like.

Owner:ZHEJIANG UNIV

Method for preparing polyacrylonitrile bamboo charcoal composite fiber by in-situ polymerization

InactiveCN102002772AImprove continuous stabilityExcellent fiber processing performanceMonocomponent synthetic polymer artificial filamentSpinning solutions preparationSolventIn situ polymerization

The invention provides a method for preparing polyacrylonitrile bamboo charcoal composite fiber by in-situ polymerization, comprising the following steps of: (1) respectively adding polymeric monomer, initiator, solvent and bamboo charcoal modified nanometer micro powder in a polymerization kettle for continuous polymerization or batch polymerization so as to obtain polyacrylonitrile polymer and bamboo charcoal modified nanometer micro powder mixed spinning solution for spinning; (2) thermally insulating and filtering the spinning solution obtained in step (1), carrying out wet spinning or dry spinning to the solution by a spinneret assembly, and solidifying the solution coagulating bath formed by polymerizing solvent and water to obtain spun filament fiber; and (3) washing, drafting, drying, finishing, finalizing and winding the spun filament fiber obtained in step (2) to obtain bamboo charcoal polyacrylonitrile composite fiber filament which is cut according to requirement to obtain cotton-type or wool-type short fiber. The in-situ polymerization can ensure that the bamboo charcoal modified nanometer micro powder evenly disperses in a high polymer matrix, therefore, the continuous stability of the fiber preparation is improved; and the prepared novel bamboo charcoal polyacrylonitrile composite fiber has good bulkiness and daylight resistance, thus the application range of the bamboo charcoal fiber is enlarged.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

ActiveCN103075112BAccelerated corrosionImprove partial wear resistanceDrilling rodsDrilling casingsEpoxyThermoplastic

The invention relates to a fibre reinforced composite anti-eccentric coiled rod and a preparation device thereof. The technical scheme adopted by the invention is as follows: one or more sections of the external surface of a fibre-reinforced resin matrix composite rod body is coated with a thermoplastic wear layer; the rod body is made of one of fibreglass, carbon fibre and basalt fibre; and a resin matrix is one of epoxy resin, urethane resin and vinyl ester resin. A plastic extruder and a cooling device are arranged between a draw gear and a winding device, the plastic extruder is used for coating one thermoplastic wear layer on one or more sections of the surface of a molded sucker rod, and then the cooling device is used for performing cooling treatment, so that the fibre reinforced composite anti-eccentric coiled rod is formed. The invention has the following beneficial effects: the coiled rod has excellent anticorrosion and anti-eccentric performances; the quantity of joints is greatly reduced; the breakage probability and the piston effect are reduced; and in addition, the production efficiency is high, and the operation is simple and convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

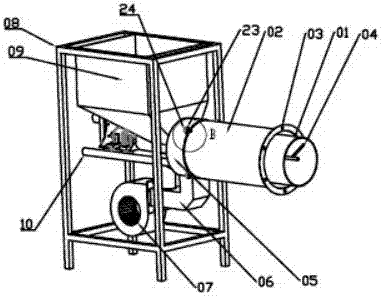

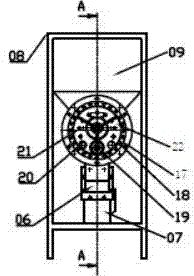

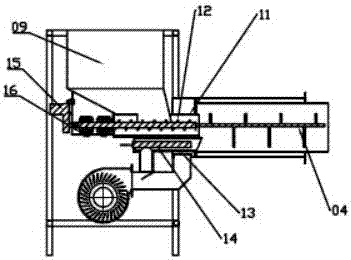

Compact anti-coking nozzle type biomass burner

InactiveCN107143870ACompact designOverall small sizeSolid fuel combustionLump/pulverulent fuel feeder/distributionThree levelSocial benefits

The invention discloses a compact anti-coking nozzle type biomass burner. The biomass burner mainly comprises a front replaceable sleeve nozzle, a rear feeding comprehensive device and a bottom air distribution auxiliary comprehensive device; and a main body adopts a double-layer sleeve structure, an inner sleeve is used for gasifying burning, and an outer sleeve is used for blast cooling protection. According to the burner, an economic and efficient rotary fire rabbling and ash removing device is adopted, in cooperation with a three-level multi-directional three-dimensional air distribution nozzle type structure design, the environment and working condition applicability is high, and the practicability is high; the biomass heat energy application technology is clean, efficient, energy-saving, environment-friendly, stable in operation, simple and convenient to operate, capable of preventing coking and wide in fuel applicability; and a feasible popularization scheme can be provided for new type urbanization, agricultural modernization and transformation of clean energy of various medium-and-small-sized coal-fired boilers in China, and remarkable economic and social benefits can be expected.

Owner:联合优发生物质能源徐州有限公司

Method for preparing bamboo charcoal and polyamide composite fibers by in situ polymerization

InactiveCN102409424AImprove continuous stabilityGood antibacterial and deodorant effectArtifical filament manufactureMonocomponent polyamides artificial filamentSolventChemistry

The invention relates to a method for preparing bamboo charcoal and polyamide composite fibers by in situ polymerization. The method comprises the following steps of: adding two polymerization monomers, a solvent, and bamboo charcoal modified nano micropowder to a stainless steel polymerization reaction kettle, carrying out an intermediate reaction, after the reaction is finished, cooling, crystallizing, centrifugally separating, washing and filtering to obtain a composite 66 salt for preparing a bamboo charcoal and polyamide composite melt; preparing the composite 66 salt into an aqueous solution, then adding to an autoclave, carrying out an intermittent or continuous melt polycondensation reaction to obtain the bamboo charcoal and polyamide composite melt, and carrying out melt spinningwith a melt spinning machine to obtain nascent filament fibers; and drying the nascent filament fibers, oiling, stretching, shaping, and winding to obtain bamboo charcoal and polyamide composite fiber filaments or cutting the fibers to obtain chopped fibers. By in situ polymerization, the bamboo charcoal nano modified micropowder is highly dispersed in a polymer matrix, thus the continuous stability of fiber preparation is improved, the fiber processing performance is excellent, and the physical and mechanical properties of the bamboo charcoal fibers are improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Nano TiO2/nano ZnO compounded lubricating oil additive and preparation method thereof

The invention discloses a nano TiO2 / nano ZnO compounded lubricating oil additive and a preparation method thereof. The addition amount of the nano TiO2 / nano ZnO is 0.02-1%, the particle size of the nano TiO2 is 10-20nm, the particle size of the nano ZnO is 20-40nm, and the weight ratio of the nano TiO2 to the nano ZnO is 1:1, 1:2 or 2:1. The nano TiO2 / nano ZnO compound is coated with oleic acid in the preparation process to enhance the stability and form a barrier between the surface and ambient medium, thereby lowering the chemical activity of the nano TiO2 / nano ZnO, being beneficial to enhancing the dispersity, weather resistance and chalking resistance and enhancing the continuous stability; and the prepared lubricating oil can not have the phenomenon of precipitation or separation, and can be firmly attached to the friction surface to protect the surface, thereby lowering and transferring the friction factor and prolonging the service life of the lubricating oil. The lubricating oil has the advantages of superhigh abrasion resistance, and greatly enhanced extreme pressure performance and long-time abradability.

Owner:南宁飞日润滑科技股份有限公司

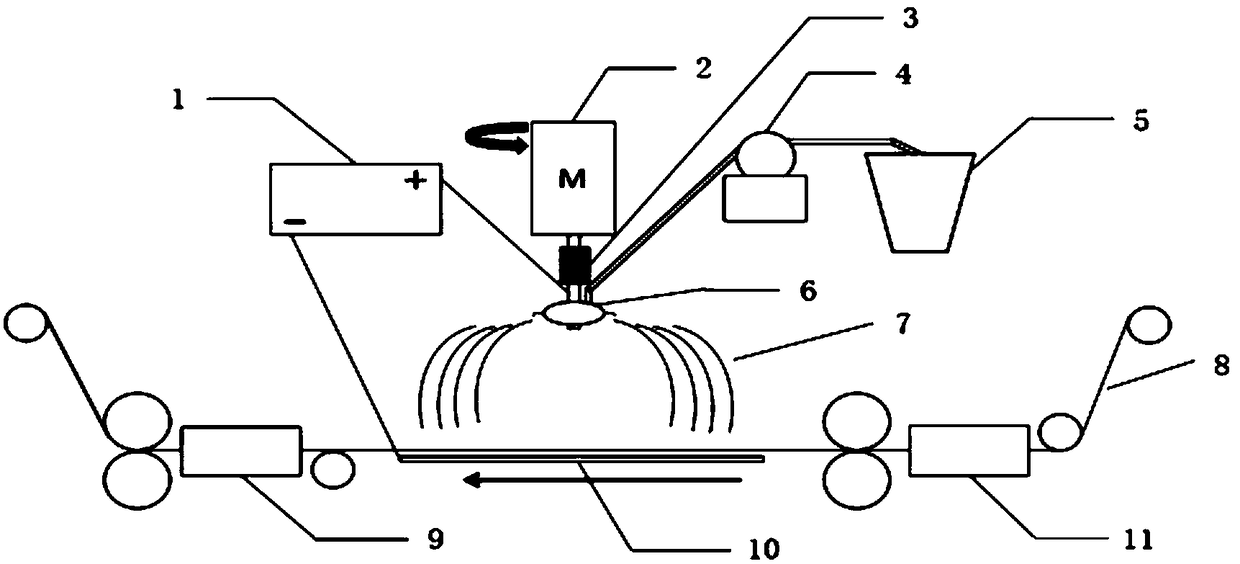

Device for continuously and efficiently forming yarn from reinforced nanofiber and spinning method

InactiveCN108796682AImprove production efficiencyMultiple choiceFilament/thread formingContinuous wound-up machinesYarnFiber

The invention relates to the technical field of textile processing, and aims to provide a device for continuously and efficiently forming yarn from reinforced nanofiber and a spinning method. The device comprises a vertically installed motor, and a rotating shaft at the bottom of the motor is connected with a spinneret through a coupler; a plurality of spinneret holes are uniformly distributed inthe circumferential direction of the spinneret; after the collected yarn is led out from a fixed yarn drum, the yarn sequentially passes through a twister and an untwister and is wound into a spool bya winding roller; a conductive plate is arranged below the collected yarn between the twister and the untwister in parallel, and is perpendicular to the rotating shaft of the motor; the conductive plate is connected to the negative electrode of an electrostatic generator through a cable; the spinneret made of metal is connected to the positive electrode of the electrostatic generator through a cable, so that the spinneret and the spinneret holes have electrical conductivity; the collected yarn is subjected to rough modification and charge addition treatment. The nanofiber in the method is obtained through an electrostatic centrifugal spinning method, and the preparation efficiency is high; the spinning raw materials are soluble and meltable, the conductivity requirement of a spinning solution is not high, the selectivity is higher, and the yield of the nanofiber yarn is high.

Owner:ZHEJIANG SCI-TECH UNIV

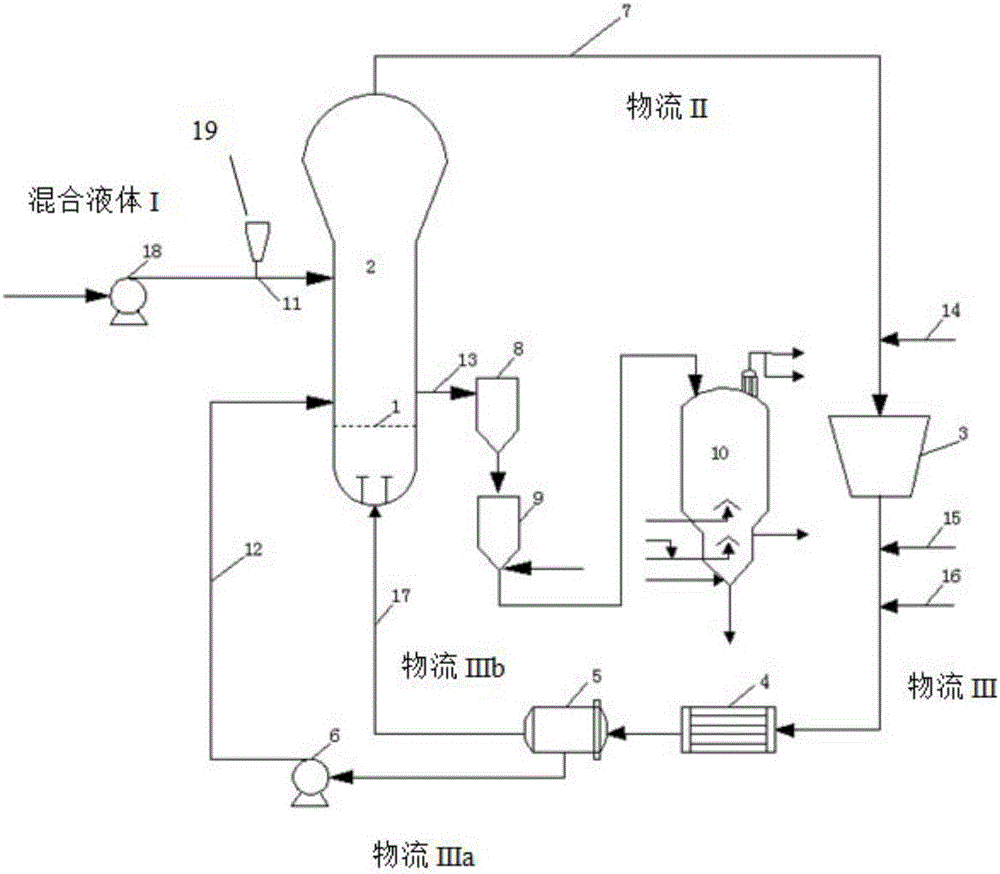

Preparation method and application of polyethylene film

ActiveCN105802033AUniform longitudinalUniform strengthSynthetic resin layered productsLabelsBlow moldingPolymer science

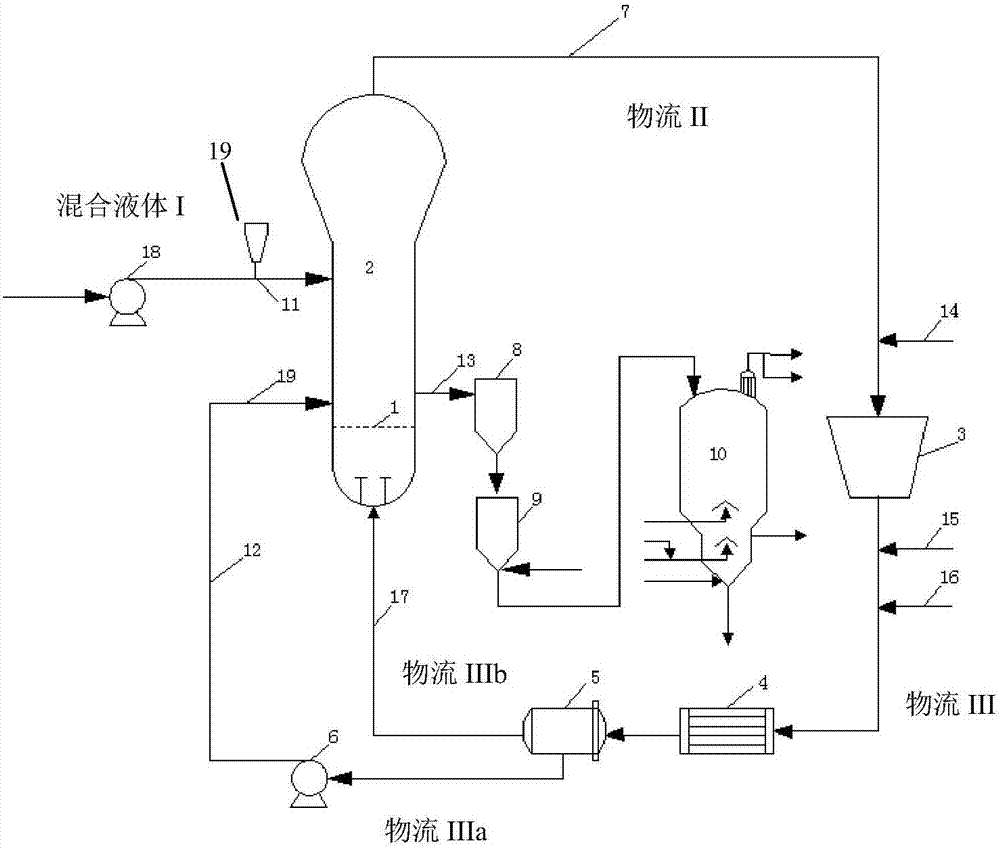

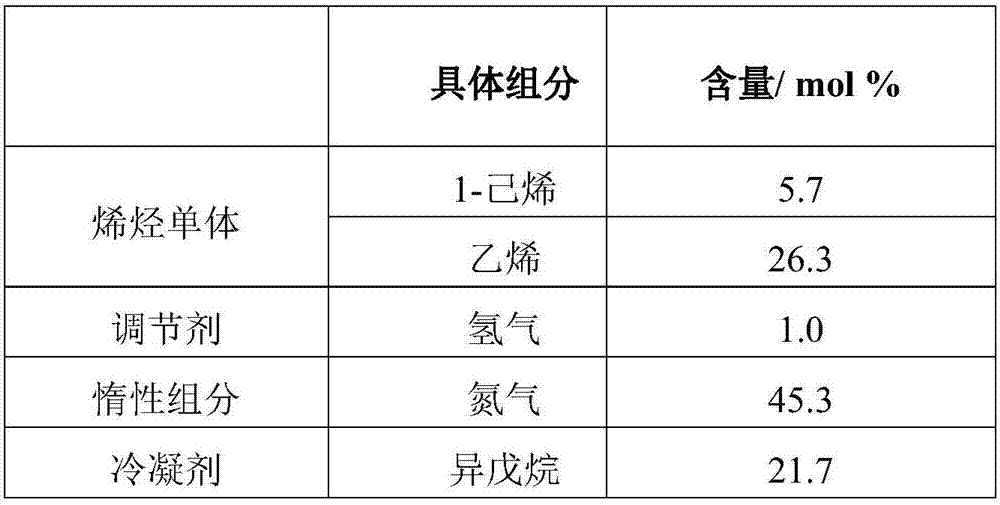

The invention discloses a preparation method of a polyethylene film.The preparation method comprises the following steps of 1, conveying a main catalyst in a catalyst system into a reactor with mixed liquor I as carrier material flow, wherein the mixed liquor I comprises alkene, olefin and promoter; feeding olefin to material flow II flowing out of the reactor for replenishment, so that material flow III is obtained, and dividing the material flow III into material flow IIIa and material flow IIIb, wherein the material flow IIIa and the material flow IIIb flow back to the side and the bottom of the reactor respectively; in the reactor, obtaining polyvinyl through polymerization, and discharging the material out of the reactor, wherein olefin comprises alpha-olefin and ethene, and the mole concentration ratio of alpha-olefin to ethene in the mixed liquor I is 1 or higher; 2, making polyvinyl obtained in step 1 be subjected to a blow molding process, so that the polyethylene film is obtained.By means of the method, longitudinal and transverse tensile strength of the film is improved, and uniform longitudinal and transverse tensile strength is achieved.

Owner:ZHEJIANG UNIV

Moth-resistant treating method for wicker straw

InactiveCN106272816AIncrease storage capacityHigh bonding strengthRadiation/waves wood treatmentWood treatment detailsMedicinePre treatment

The invention discloses a moth-resistant treating method for wicker straw. The method comprises the following steps: (1) pretreating straw raw materials; (2) preparing a moth-resistant treating solution; (3) modifying; (4) treating at low temperature; (5) repeatedly treating for the second time; (6) weaving at constant temperature. The straw treated according to the method provided by the invention has better moth-resistant and mold-proof characteristics, excellent flexibility, folding resistance, tensile strength and weaving property; the prepared products have the characteristics of environmental protection, safety and no harm to a human body; the service life of the products is 2-3 years longer than that of the products prepared according to the conventional method; the popularization value is higher.

Owner:FUNAN YONGXING ARTS & CRAFTS

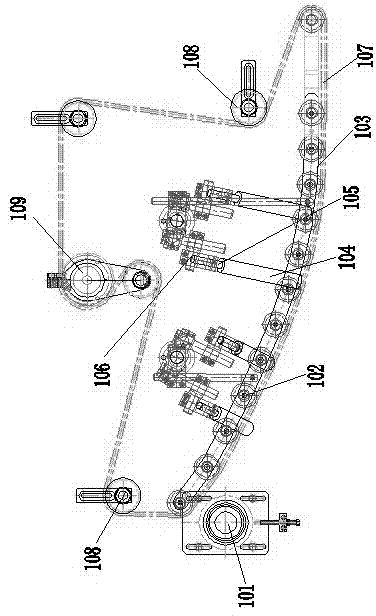

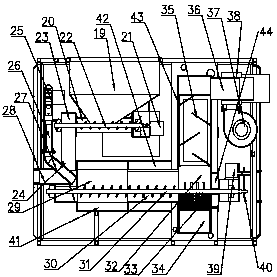

Folding mechanism and folding overturning device for pull-ups and adult pull-ups production line

ActiveCN103754689AImprove processing qualityImprove product qualityFolding thin materialsWebs handlingLeather beltManufacturing line

The invention relates to a folding mechanism and a folding overturning device for a pull-ups and adult pull-ups production line. The folding mechanism comprises an O-shaped belt guided by a group of O-shaped wheels, a plurality of groups of transition wheel rods are arranged above the O-shaped belt at intervals, each group comprises two transition rods arranged symmetrically, and the included angles between the transition wheel rods become smaller gradually. A product is folded in the middle on the O-shaped belt, under the guide of the transition wheel rods, two sides of the product are gradually overlapped, and the product is vertically delivered to a clamping mechanism. A product channel is formed between two conveying mechanism belts of the clamping mechanism, and a plurality of pairs of clamping transition wheels are arranged on the inner sides of the opposite belts. An overturning mechanism is in abutting connection with the output end of the clamping mechanism, a plurality of groups of overturning wheels gradually changing from the vertical direction to the horizontal direction are arranged between an upper support and a lower support. The product is output horizontally after overturned. The folding mechanism and the folding overturning device achieve automatic folding and overturning of the product, effectively reduce friction resistance generated in product folding and overturning and improve product machining quality.

Owner:ZHEJIANG YONGCHUANG MACHINERY

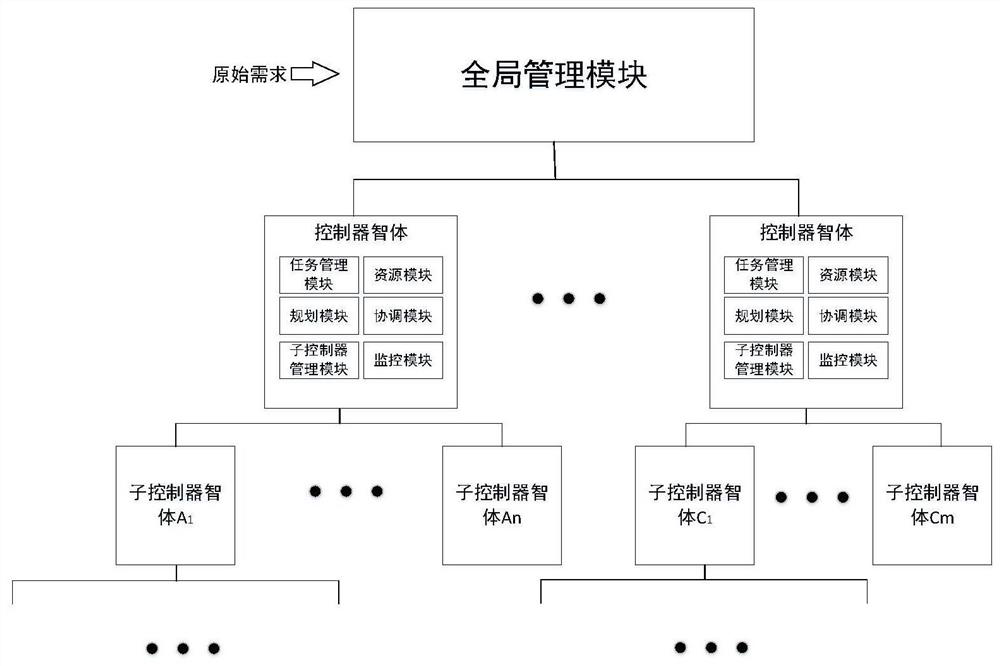

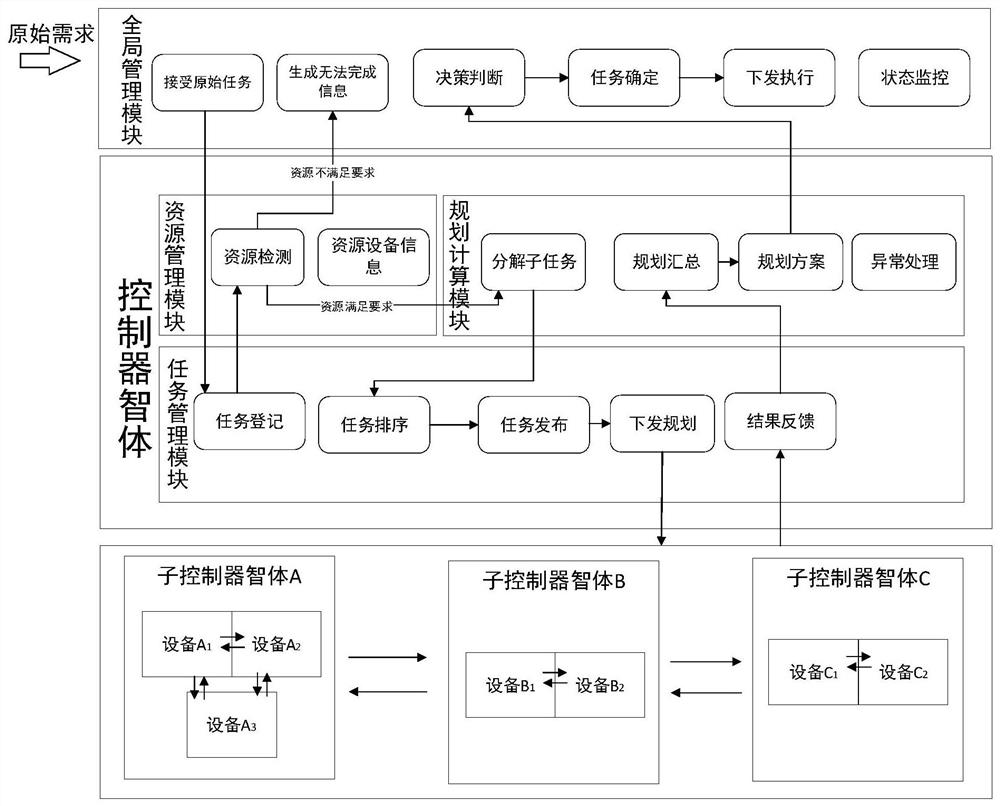

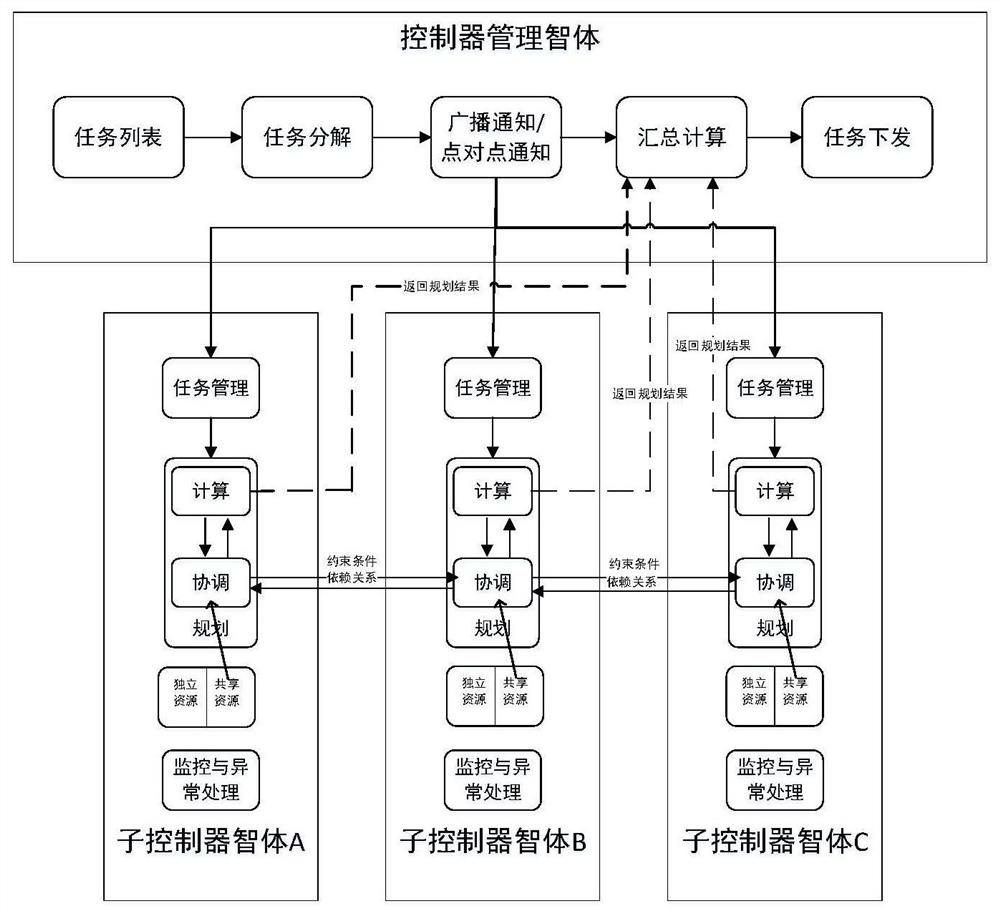

Production line scheduling system and method based on multiple intelligent bodies

ActiveCN111898908AReduce couplingGuaranteed independent operation abilityResourcesTotal factory controlResource informationComputer science

The invention belongs to the related technical field of production scheduling, and discloses a production line scheduling system and method based on multiple intelligent bodies. The production scheduling system comprises a global management module, a controller intelligent body and a sub-controller intelligent body, and the global management module is a manager of the highest level in the production scheduling system and has the highest management authority; the controller intelligent body is the core of the production scheduling system and comprises a resource module, a planning calculation module and a task management module, and the resource module is used for storing resource information of the sub-controller intelligent bodies; the planning calculation module decomposes the task and sends the task to the task management module; the task management module sorts the decomposition tasks according to a priority sequence and then distributes the decomposition tasks to the sub-controller intelligent bodies; and the sub-controller intelligent body is used for executing the task sent by the task management module. According to the invention, the independent operation capability of theintelligent body is ensured, and the working efficiency and management capability of the scheduling system are improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

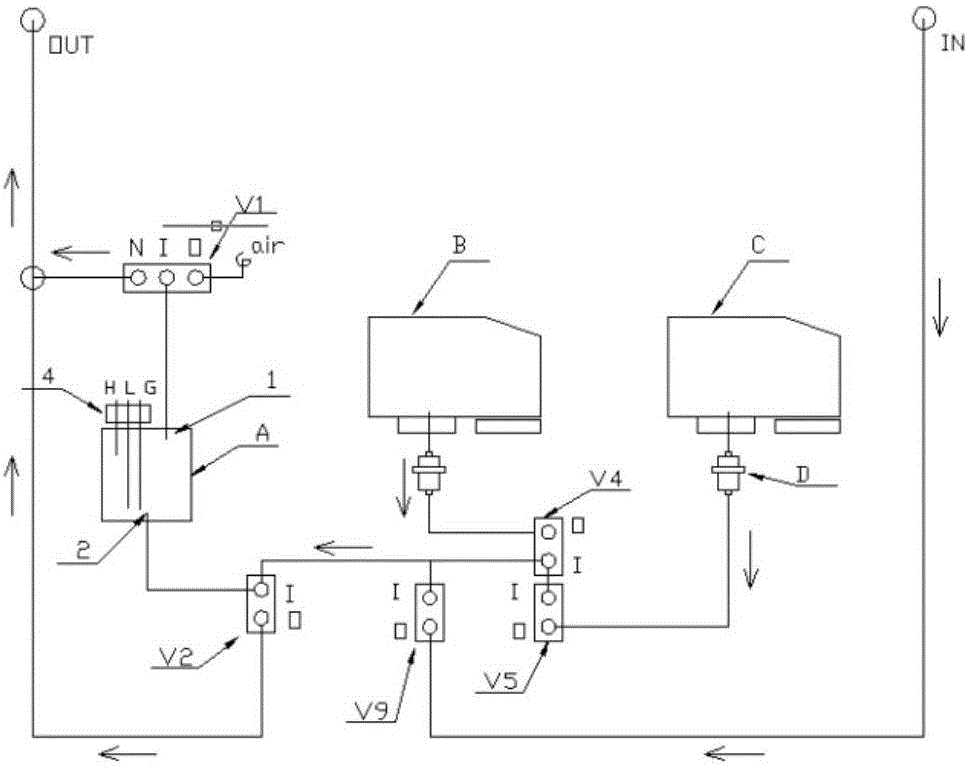

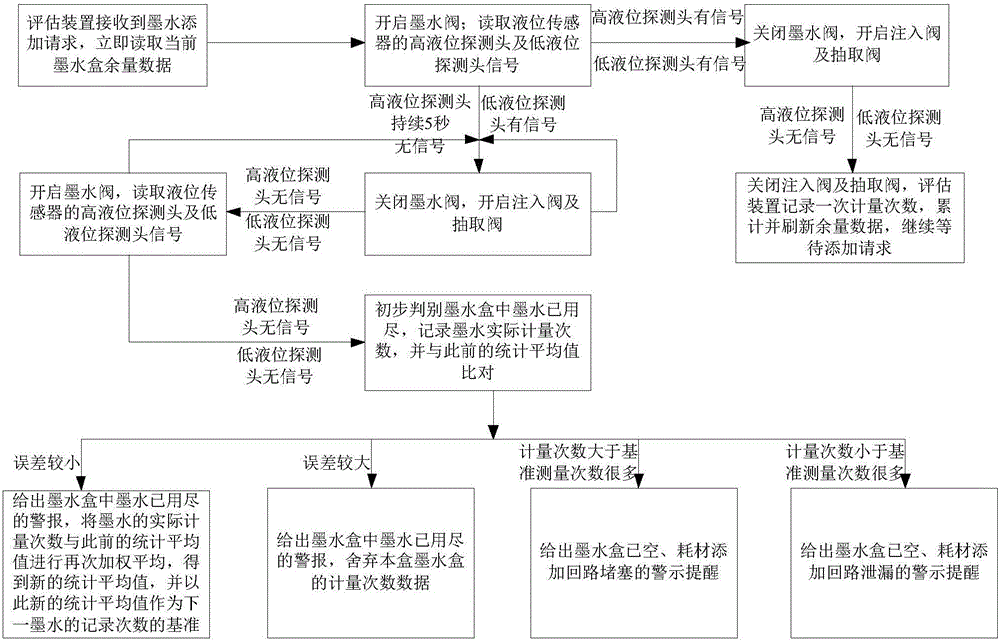

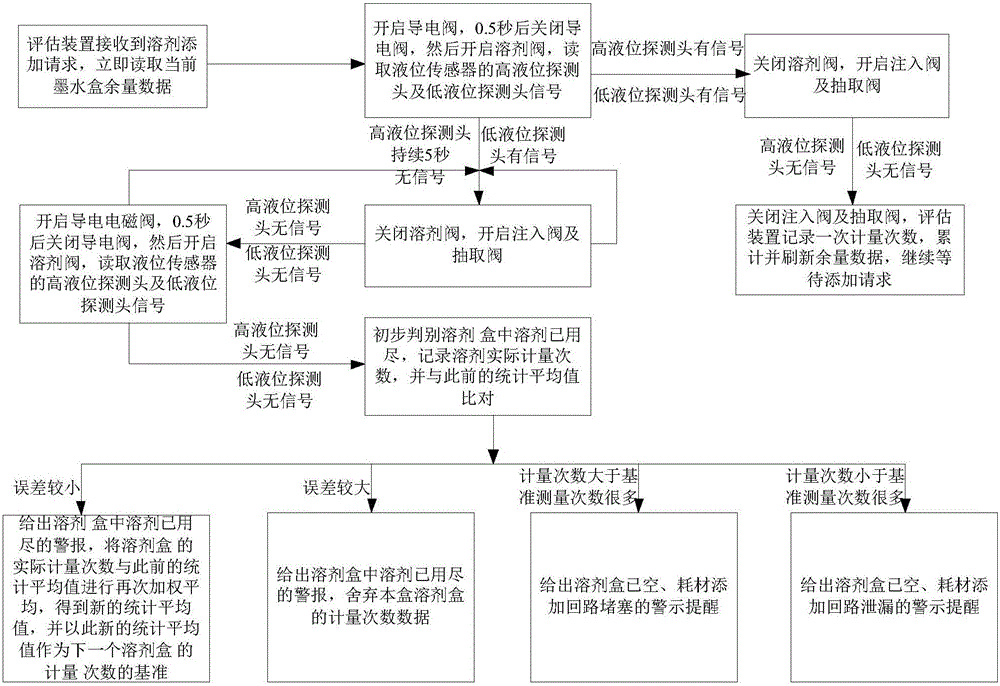

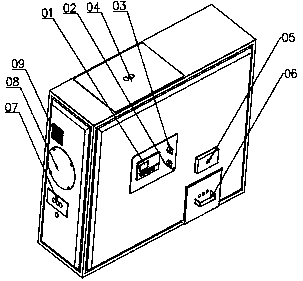

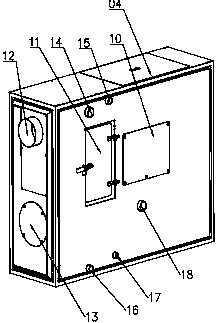

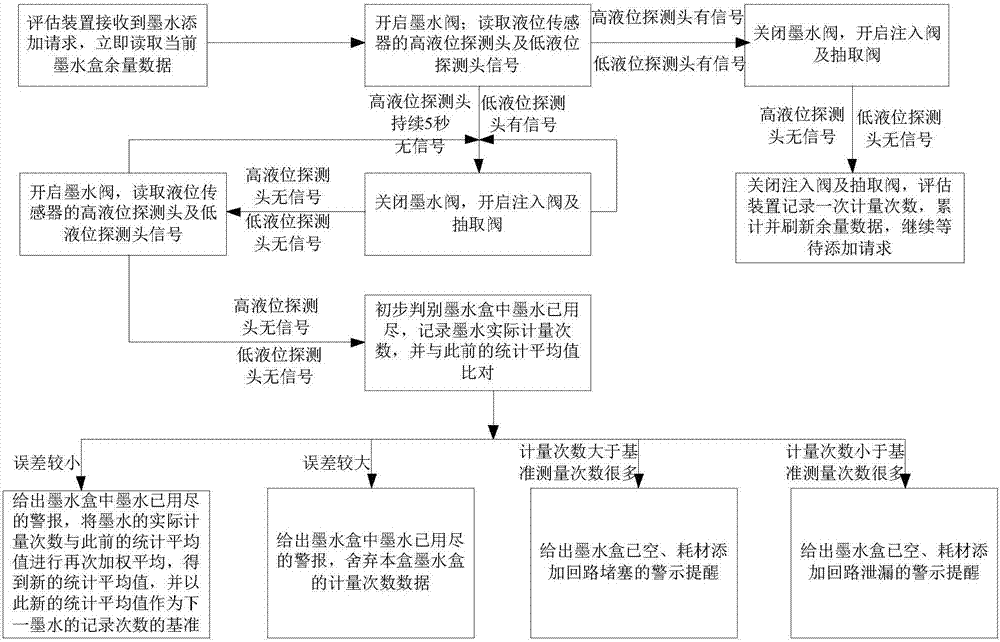

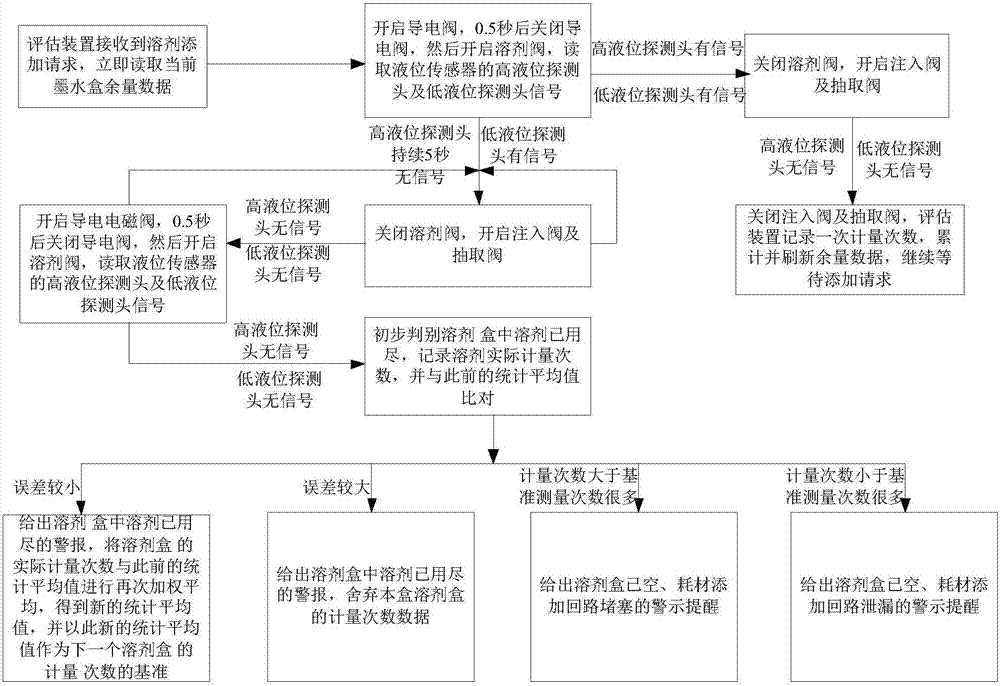

Monitoring method for consumable consumption of ink-jet printing machine

ActiveCN105966083AAccurately monitor real-time headroomAccurately grasp the consumption progressPrintingPulp and paper industryMonitoring methods

The invention provides a monitoring method for the consumable consumption of an ink-jet printing machine. The monitoring method comprises the steps that a metering device is connected to a consumable addition loop in series; consumables needing to be added from an ink box or a solvent box in the consumable addition loop flow through the metering device for being metered each time and then are added into an ink loop of the ink-jet printing machine. The amount of left consumables in the ink box or the solvent box is estimated in real time according to a metering result of the metering device. According to the monitoring method, the consumption progress condition of the consumables of the ink-jet printing machine can be accurately mastered without opening a machine case frequently and manually inspecting the machine case, hidden failures such as leakage and blockage of the whole ink addition metering loop can be judged, consumable supplementing plans and maintenance plans can be made in advance, machine halting and production halting caused by using up the consumables can be avoided, the use convenience of the ink-jet printing machine is greatly improved, and the continuous stability of production is greatly improved.

Owner:SHANGHAI HUAZHI ELECTRONICS EQUIP CO LTD

Novel anti-coking intelligent efficient biomass heating furnace

InactiveCN108105757AIncrease the itineraryReduced contentStove/ranges for heating waterSolid heating fuelProcess dynamicsCombustion chamber

The invention discloses a novel anti-coking intelligent efficient biomass heating furnace. The novel anti-coking intelligent efficient biomass heating furnace comprises a feed ignition device, a multi-chamber partition combustion chamber, a hot water output circulating device, a flame smoke aftertreatment device, a dynamic combustion deslagging transmission device, an intelligent control device and a maintenance device. The core of the novel anti-coking intelligent efficient biomass heating furnace is a three-chamber four-area segmentation gradual combustion chamber, and an auger and rake tooth whole-process dynamic structure is used for replacing a movable fire grate, so that the combustion efficiency is improved, and coking and slagging are prevented. A front-blowing back-leading micro-negative-pressure two-way ternary air distribution system is adopted. In addition, a high-temperature area of the heating furnace adopts an all water jacket structure; external heating output of circulating water is realized through smoke-water reverse heat exchange; operations are simplified through intelligent control and introduction of an automatic ignition system; and the heating furnace is excellent in fuel applicability and operation convenience, is dispersed heating equipment with cleanness, high efficiency, energy conservation and environmental protection, provides excellent heating solution schemes for national new urbanization, and is prominent in anticipant economy and social benefit.

Owner:联合优发生物质能源徐州有限公司

A method for preparing olefin polymers using multi-temperature reaction zones

The invention discloses a method for preparing olefin polymer by utilizing multiple temperature reaction areas. The method provided by the invention comprises the following step of forming a plurality of olefin polymer reaction areas with different temperatures in a fluidized bed reactor by utilizing a circulating medium, wherein the circulating medium comprises an olefin monomer and a condensing agent. By utilizing the method, preparation of high-performance olefin polymer product by utilizing a single reactor is realized. The method is high in heat transfer efficiency. The olefin polymer prepared by utilizing the method is low in density, wide in distribution, uniform in degree of crystallinity and the like and can be widely applied to various fields of thin-film materials and the like.

Owner:ZHEJIANG UNIV

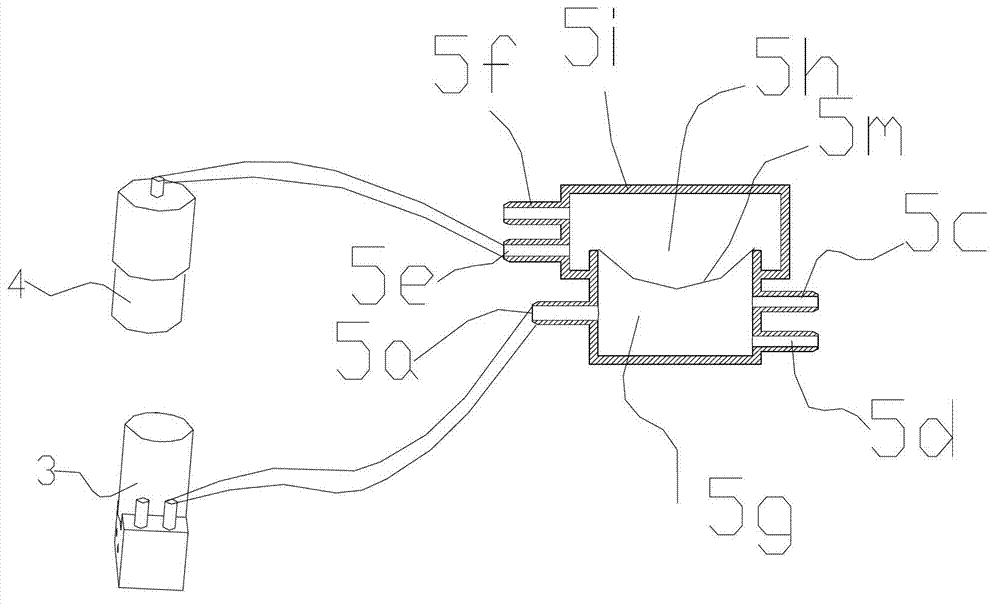

Constant-pressure buffer distributor of printer ink pipeline

The invention relates to the field of printer assemblies, in particular to a constant-pressure buffer distributor of a printer ink pipeline. The constant-pressure buffer distributor of the printer ink pipeline comprises an ink inlet, an ink outlet and a buffer groove. The ink inlet and the ink outlet are respectively communicated with the buffer groove. A sealing film and a buffer film subjected to deformation processing are arranged on the buffer groove and form an air sealing cavity with an air inflation port and an air outlet in a sealing mode, the buffer film is sealed above the buffer groove, and the air inflation port is connected with an air inflation pump. The air outlet is provided with a pressure sensor and an air release valve. The constant-pressure buffer distributor of the printer ink pipeline can produce constant pressure under the action of the air inflation pump, feeds ink with the constant pressure into a printing head through buffering effect of the ink buffer groove, can well overcome ink gravity and resistance in the pipeline and can ensure a printer to work normally, continuously and uninterruptedly.

Owner:HANGZHOU SPOTCOLOR DIGITAL TECH CO LTD

Method for preparing polyacrylonitrile bamboo charcoal composite fiber by in-situ polymerization

InactiveCN102002772BImprove continuous stabilityEasy to processMonocomponent synthetic polymer artificial filamentSpinning solutions preparationIn situ polymerizationSolvent

Owner:ZHONGYUAN ENGINEERING COLLEGE

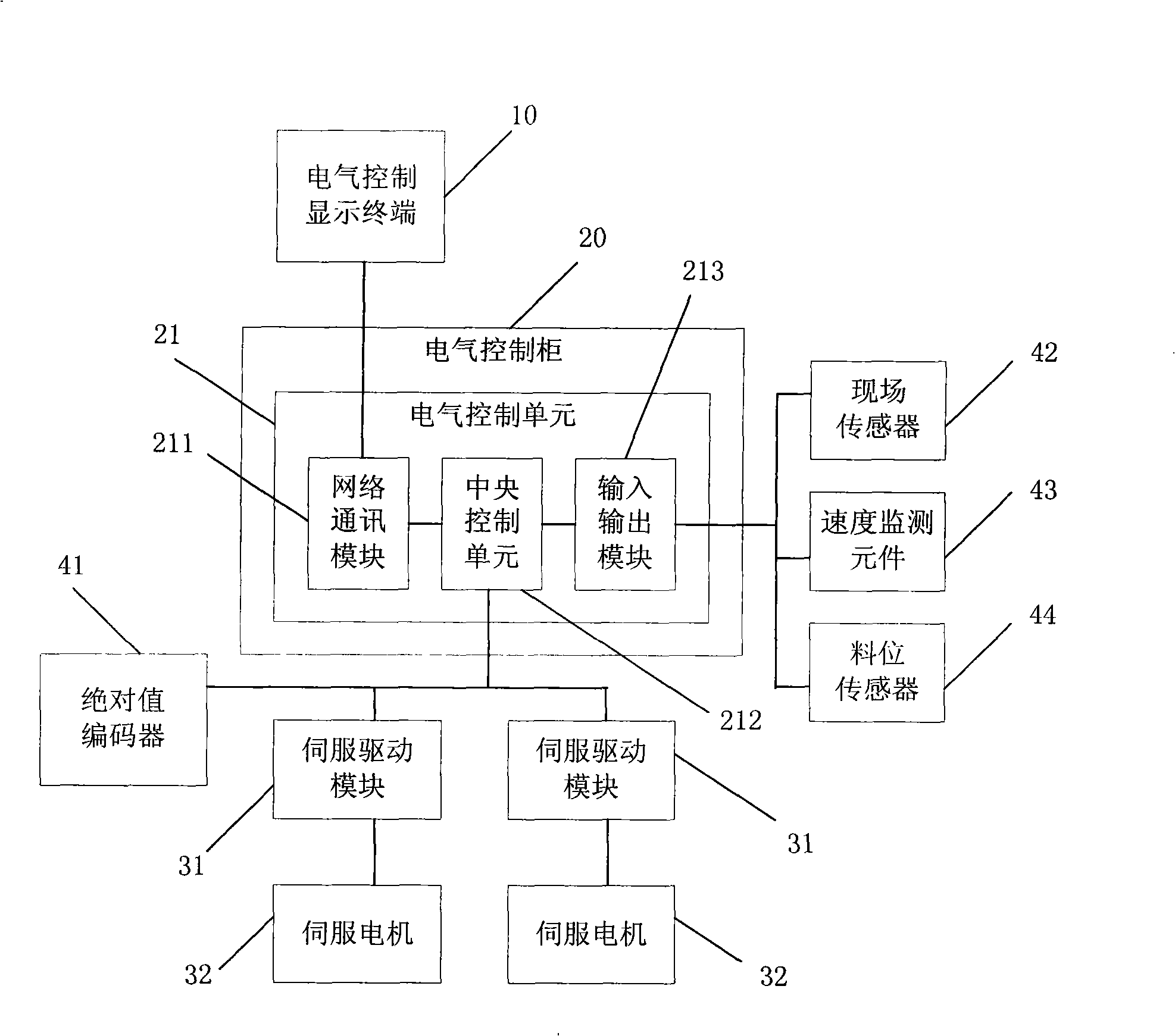

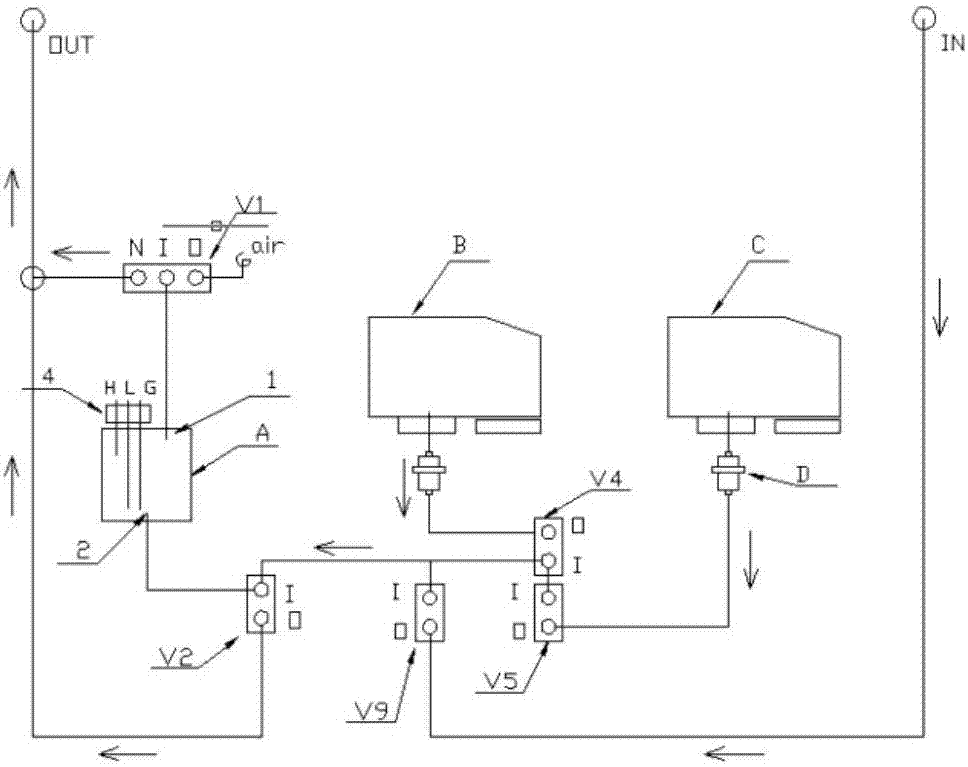

System and method for controlling cigarette transportation and storage

InactiveCN101349917ALow failure rateSimple actionTotal factory controlProgramme total factory controlTransfer procedureElectric control

The invention discloses a system for controlling the transmission and storage of cigarettes and a method, wherein an electric control display terminal is provided above an electric control cabinet comprising an electric control unit, a field detection unit is connected with the electric control unit for collecting and sending data to the electric control unit, the electric control unit via a control network is respectively connected with the electric control display terminal and a storage transmission servo drive device for sending the processing result of the electric control unit to the electric control display terminal and the storage transmission servo drive device, the storage transmission servo drive device is connected with an electric execution mechanism for controlling the electric execution mechanism. The technical scheme of the invention can accurately calculate the storage amount of cigarettes, has stable operation and low accident rate, can confirm the continuity and stability of cigarettes in transmission to confirm the quality of cigarettes.

Owner:ZHENGZHOU HAIYI TECH

A method for monitoring the consumption of consumables for inkjet printers

ActiveCN105966083BAccurately monitor real-time headroomAccurately grasp the consumption progressPrintingInk printerPulp and paper industry

The invention provides a monitoring method for the consumable consumption of an ink-jet printing machine. The monitoring method comprises the steps that a metering device is connected to a consumable addition loop in series; consumables needing to be added from an ink box or a solvent box in the consumable addition loop flow through the metering device for being metered each time and then are added into an ink loop of the ink-jet printing machine. The amount of left consumables in the ink box or the solvent box is estimated in real time according to a metering result of the metering device. According to the monitoring method, the consumption progress condition of the consumables of the ink-jet printing machine can be accurately mastered without opening a machine case frequently and manually inspecting the machine case, hidden failures such as leakage and blockage of the whole ink addition metering loop can be judged, consumable supplementing plans and maintenance plans can be made in advance, machine halting and production halting caused by using up the consumables can be avoided, the use convenience of the ink-jet printing machine is greatly improved, and the continuous stability of production is greatly improved.

Owner:SHANGHAI HUAZHI ELECTRONICS EQUIP CO LTD

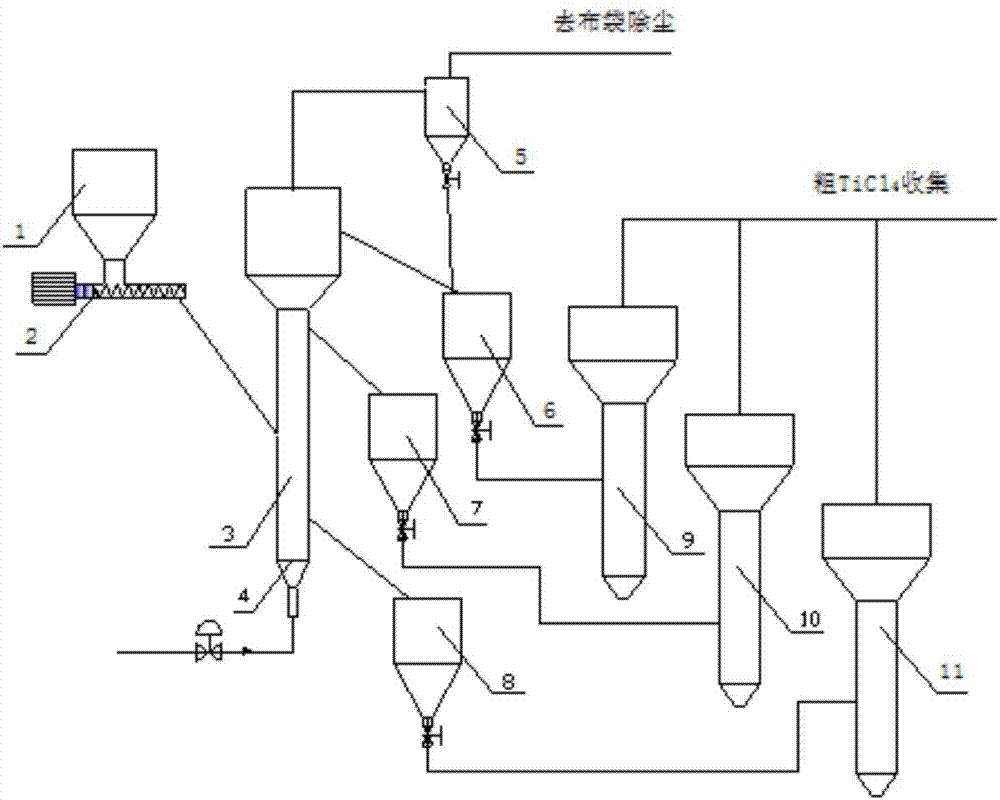

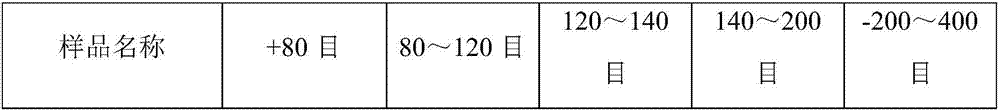

Method for Improving Chlorination Efficiency of Titanium-Containing Blast Furnace Slag

ActiveCN105819500BImprove chlorination efficiencyImprove recycling efficiencyTitanium tetrachlorideReduction treatmentSlag

The invention belongs to the field of chemical engineering, particularly relates to a method for improving the chlorinating efficiency of titanium-bearing blast furnace slag, and aims at solving the technical problems that at present, due to the fact that the low-temperature chlorination rate of carbide slag is low, the recycling efficiency of Ti is seriously affected, and the economical efficiency of the whole process is affected. The method for improving the chlorinating efficiency of the titanium-bearing blast furnace slag comprises the following steps that 1, the carbide slag which is subjected to high-temperature thermal reduction treatment and smashed into 80-400 meshes is divided into coarse fraction carbide slag, fine fraction carbide slag and micro-fine fraction carbide slag; 2, the coarse fraction carbide slag, the fine fraction carbide slag and the micro-fine fraction carbide slag are added into three boiling chlorination reactors for boiling chlorination respectively. According to the method, the chlorinating efficiency of blast furnace slag is effectively improved, and the recycling efficiency of Ti is greatly improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

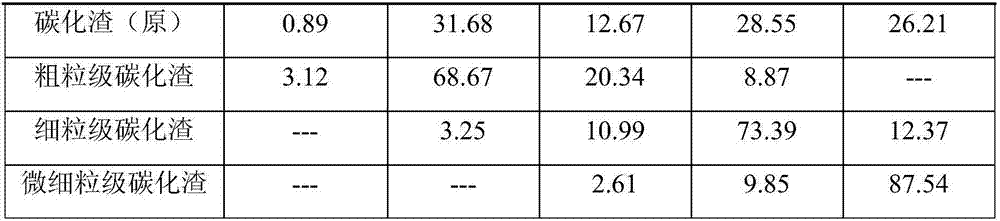

Special installation rod of U-type seat

ActiveCN105261996ASolve the problem of long power outages during installationSolve problems caused by multiple power outages, etc.Apparatus for overhead lines/cablesEngineeringLive-line working

Provided is a special installation rod of a U-type seat. An L-type support arm and a fixed pulley group are installed on left and right sides of a support bench. A through hole on which a rubber leather bowl is installed is arranged in a horizontal arm of the L-type support arm. The rubber leather bowl has a cone-shaped outer wall, a downward big end and a cone-shaped inner cavity. A chamber of the inner cavity is gradually shrunk from top to bottom. One end of a pull rope is fixedly connected with the rubber leather bowl and the other end is successively wound around a first pulley and a second pulley and then is freely hung from the second pulley. The support bench sleeves the upper end of an outer rod 1. An inner rod 1 is capable of performing axially linear movement relative to the outer rod 1 and axially rotating. The lower end of a fastening rod is threaded into an oil cavity of the outer rod 1 and then is fixedly connected with the upper end of the inner rod 1, so the fastening rod is capable of performing axially linear movement relative to the outer rod 1 and axially rotating. An axial hexagonal prism blind hole is arranged in the upper end face of the fastening rod. According to the invention, the special U-type seat on a bird repellent device is connected with and fixed on the L-type support arm via a cone-shaped column on the U-type seat, so live-line work and installation of the bird repellent device can be achieved and a problem of long time of power outage for installation of the bird repellent device is solved.

Owner:国网山东济南市历城区供电公司 +1

Method for removing formic acid online in the process of trioxymethylene synthesis

ActiveCN102702167AEasy to integrateMinor changesOrganic chemistryFractional distillationFormateSalt solution

The invention discloses a method for removing formic acid online in the process of trioxymethylene synthesis. The method is characterized in that the formic acid is removed by enabling reaction mixed gas to pass through basic salt solution to convert the formic acid into formate. The method can effectively remove the formic acid, is favorable for improving quality of trioxymethylene products, and promotes continuous stable production of the trioxymethylene products.

Owner:BEIJING RISUN TECH CO LTD

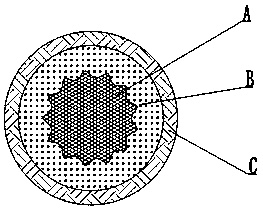

Carbon fiber continuouspimping rod and preparation device and method thereof

PendingCN108625794AIncrease contact areaImprove wear resistanceDrilling rodsLayered productsGlass fiberCarbon fibers

The invention discloses a carbon fiber continuouspimping rod and a preparation device and method thereof. The carbon fiber continuouspimping rod comprises a carbon fiber reinforcement layer, a high modulus glass fiber layer and a fiber-weave abrasion-proof layer. The high modulus glass fiber layer is arranged on the outside portion of the carbon fiber reinforcement layer in a covering mode; and the fiber-weave abrasion-proof layer is arranged on the outside of the high modulus glass fiber layer in a woven and coiling mode. Continuous acrylonitrile-based carbon fibers with longitudinal stretching modulus of more than 230 GPa are adopted for the carbon fiber reinforcement layer; high modulus glass fibers with longitudinal stretching modulus of more than 90 GPa are adopted for the high modulus glass fiber layer; and the coiled fiber-weave abrasion-proof layer is made of abrasion-proof high modulus aramid1414 fibers. The problems of corrosion and partial abrasion during oil field oil extraction production are solved; the problem of influence on rod bodies by high temperature well washing is solved; the problem of oil extraction in a deep well and an extra-deep well is solved; and the pumping rod with corrosion-proof and partial-abrasion-resisting performance, and a small piston effectand convenient operation and use is manufactured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ethylene polymer

ActiveCN107226876ALarge heat transferHigh latent heat of vaporizationSynthetic resin layered productsPolymer scienceEthylene Polymers

The invention relates to a preparation method of an ethylene polymer, and the method comprises the following steps: taking a mixed liquid I as a carrier flow to convey a main catalyst in a catalyst system into a reactor, wherein the mixed liquid I comprises alkane, alkene and a co-catalyst; adding supplementing alkene feedstock into a material flow II which outflows from the reactor to obtain a material flow III and dividing the material flow III into a material flow IIIa and a material flow IIIb, wherein the material flow IIIa and the material flow IIIb separately flow back to the lateral part and the bottom of the reactor; and performing polymerization in the reactor to obtain an ethylene polymer and performing discharging from the reactor. In the method, the alkene comprises alpha-alkene and ethylene, wherein the molar concentration ratio of the alpha-alkene and the ethylene is more than or equal to 1. The polymer prepared by the method has low haze and high self-adhesive property. The invention also relates to an application of the ethylene polymer prepared by the method which is provided by the invention to film products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cable connector

InactiveCN108155510ASimple structureEasy to useRelieving strain on wire connectionCouplings bases/casesButt jointEngineering

The invention provides a cable connector. The cable connector comprises a first joint and a second joint. The first joint is in butt joint with the second joint. A first cable is arranged in the firstjoint, and a first cable core of the first cable is arranged in a hollow structure in the first joint. A first joint cap is arranged at the end of the first joint, and the first cable penetrates thefirst joint cap. A second cable core is arranged in the second joint, and the second cable penetrates the end of the second joint. A locking nut and a cable pressing sleeve are arranged at the end ofthe second joint. The cable pressing sleeve sleeves the second cable, and is located in the second joint. The locking nut is locked at the end of the second joint in a threaded mode. The cable pressing sleeve is compressed at the second cable through the locking nut to lock the second cable at the second joint. The cable connector has the advantages of simple structure, convenience in use, and capability of improving connection stability at cable joints effectively and improving cable erection efficiency.

Owner:天津市小猫线缆股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com