Wet etching apparatus and wet etching method

A technology of wet etching and equipment, which is applied in the field of wet etching equipment and wet etching, and can solve the problems of inability to meet large-scale continuous online production, inconsistent etching degree of etching products, poor continuous stability of etching production, etc. problems, to achieve the effect of adapting to large-scale continuous online production, improving continuous stability, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

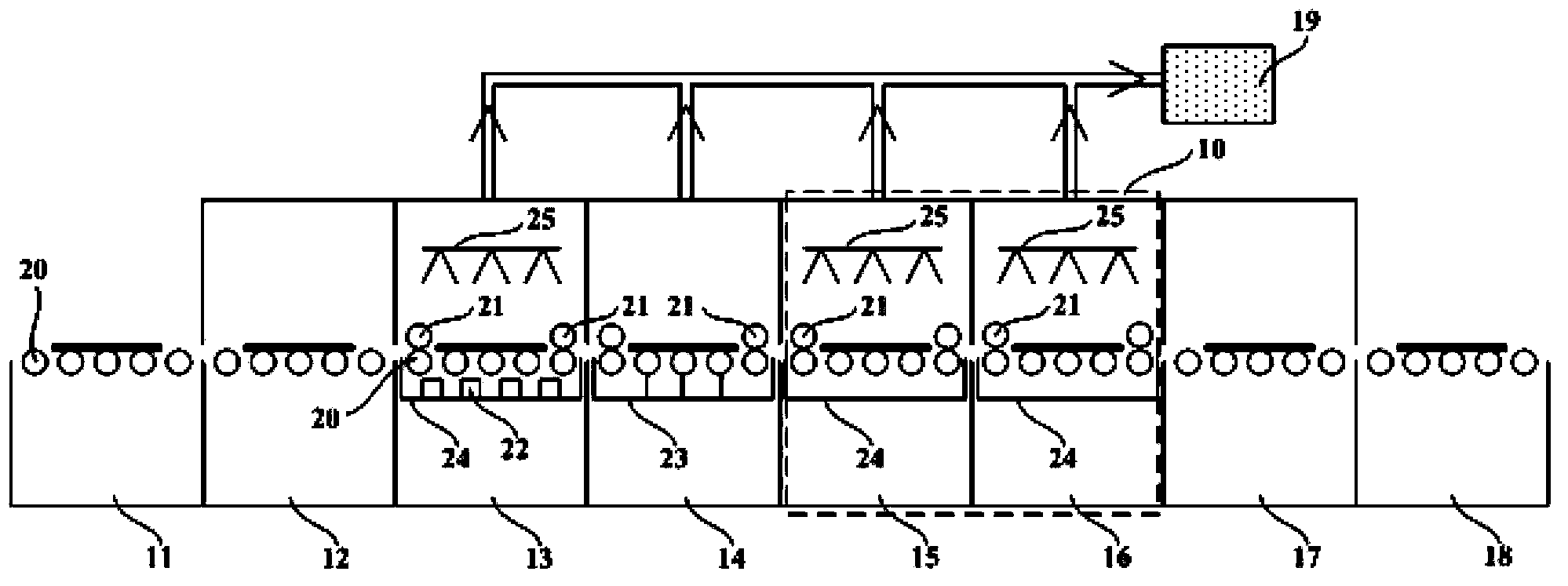

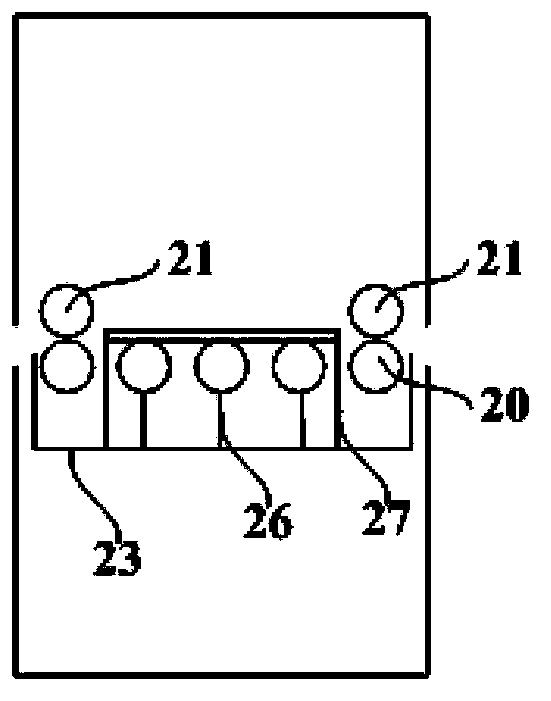

[0040] In order to solve the technical problem existing in the prior art that during wet etching, the temperature of the etching solution gradually rises, resulting in inconsistent etching degrees of each etching product, and ultimately leading to poor stability in continuous production, the present invention provides a A wet etching device and a wet etching method. In this technical solution, the temperature control system in the temperature control room is used to adjust the temperature of the etchant to the set temperature, so that the continuous production of multiple etch objects can eliminate the influence of temperature during etching, so that the temperature of each etched product The etching degree remains consistent, which improves the continuous stability of etching production. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com