Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

A composite material and fiber-reinforced technology, applied in drill pipe, drilling equipment, earth-moving drilling, etc., can solve the problem that the eccentric wear resistance of fiber fabric coating layer is not ideal, reduce the cost of continuous coating and process complexity, structure and The difficulty of material development and other problems can improve the continuous stability, avoid slippage and delamination, and reduce the probability of breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] By adopting the above-mentioned preparation device, realizing the preparation method of the present invention is specifically:

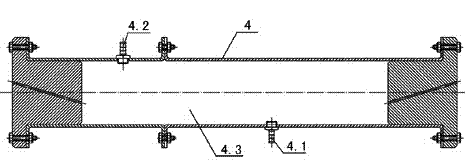

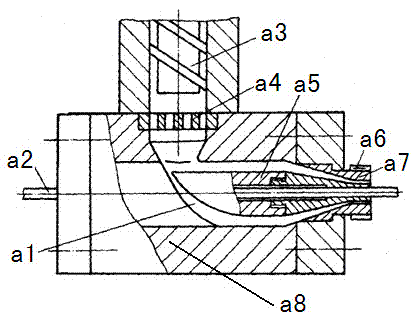

[0031] (a) A plurality of bundles of fibers (glass fiber, carbon fiber or basalt fiber) are drawn from the drawing frame 1, and are pretreated by the heating furnace 2 under the traction of the traction device 10. The atmosphere is air, and the furnace temperature is between 80 and 150°C. The traction speed is between 0.08-1.5 m / min, and the passage time is 1.0-12.5 minutes; the fibers coming out of the heating furnace 2 enter the injection mold 4, and the injection mold 4 is filled with the resin matrix glue 4.3 injected by the injection machine 3, and the resin matrix Epoxy, vinyl ester or polyurethane resins.

[0032] (b) The fiber bundles impregnated with the glue in the injection mold 4 are then solidified and formed by the pultrusion mold 6. A mold cooling device 5 is provided at the entrance of the pultrusion mold 6 to reduce the mold i...

Embodiment 1

[0037] Multiple bundles of carbon fiber filaments enter the surface treatment furnace through the wire hole of the wire rack. The furnace temperature is 120°C and the traction speed is 1.0 m / min. The carbon fiber after heat treatment enters the injection mold, which is filled with the resin injected by the injection machine The ratio of glue and resin glue is polyol:isocyanate=100:121. The dipped carbon fiber enters the pultrusion die, and the entrance of the pultrusion die is cooled to room temperature by circulating water cooling, but after the water cooling, the mold is heated in three stages by the mold heating device, and the temperature is 110°C, 135°C, and 155°C. The formed composite material rod continues to advance at a speed of 1.0 m / min, and passes through a post-curing heating furnace with a length of 2 meters and a temperature of 150°C for post-curing treatment. After being fully cooled by air, the rod body passes through a tractor and enters as a core wire. Plast...

Embodiment 2

[0038] Example 2: According to implementation 1, the carbon fiber in the pultrusion process is changed to high-strength glass fiber, the furnace temperature of fiber heat treatment is 100 ° C, the traction speed is 0.2 m / min, and the injection resin is changed to epoxy resin, wherein E-51: methyl tetrahydro Phthalic anhydride: DMP-30: Zinc stearate in parts by weight of 100:85:2.0:1, the pultrusion die is heated in two stages, and the temperature is 120°C and 160°C. The formed sucker rods are processed through a post-curing furnace with a temperature of 160 °C and a length of 3 m. After cooling, use a plastic extruder to continuously extrude a nylon (PA) wear-resistant layer with a thickness of 4mm within a length of 1202m to 1295m. After sufficient cooling, a fiber-reinforced composite material with a length of 73m wear-resistant layer The continuous sucker rod is wound onto a disc with a diameter of 3m. According to the needs of the oil well, when the length is 1521m, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com