Compact anti-coking nozzle type biomass burner

A burner and anti-coking technology, applied in the direction of combustion method, combustion equipment, solid fuel combustion, etc., can solve the problems of high equipment cost investment, poor continuous stability, poor applicability of working conditions, etc., to simplify the use difficulty and operation work The effect of small quantity, equipment volume and occupied area, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

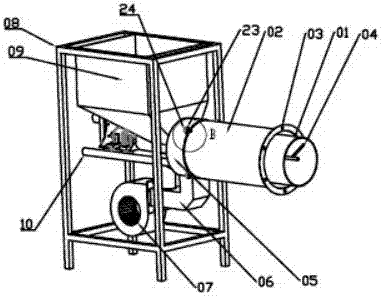

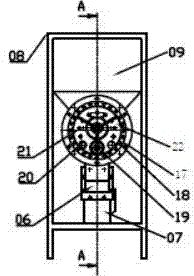

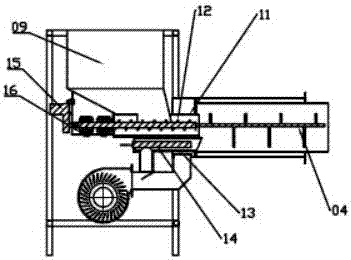

[0033] like figure 1 In the shown embodiment, the present invention provides a compact anti-coking nozzle type biomass burner. The main body of the burner includes a replaceable sleeve nozzle at the front, a comprehensive feeding device at the rear and an auxiliary comprehensive device for air distribution at the bottom. The main part, the three main parts are fixedly supported on the burner bracket (08), and the outer side of the burner bracket (08) can be added with an installation shell; the front replaceable sleeve nozzle consists of the nozzle inner wall tube (01), the nozzle outer wall tube ( 02), nozzle external flange (03), rotary fire ash removal device (04), sleeve nozzle connecting flange (23), in which the nozzle inner wall pipe (01) and the nozzle outer wall pipe (02) are aligned concentrically Welded on the sleeve nozzle connecting flange (23), the nozzle external flange (03) is concentrically welded to the other end of the nozzle outer wall pipe (02), and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com