Folding mechanism and folding overturning device for pull-ups and adult pull-ups production line

A technology of adult incontinence trousers and a turning device, which is applied in the field of a half-folding mechanism and a half-folding turning device, can solve the problems of high sliding friction between the product and the sheet metal folding plate, the production line speed of diapers cannot be too high, and the processing quality of diaper products is affected. Guaranteed continuous stability, smooth trajectory, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

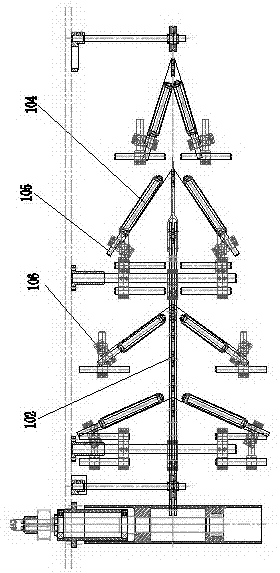

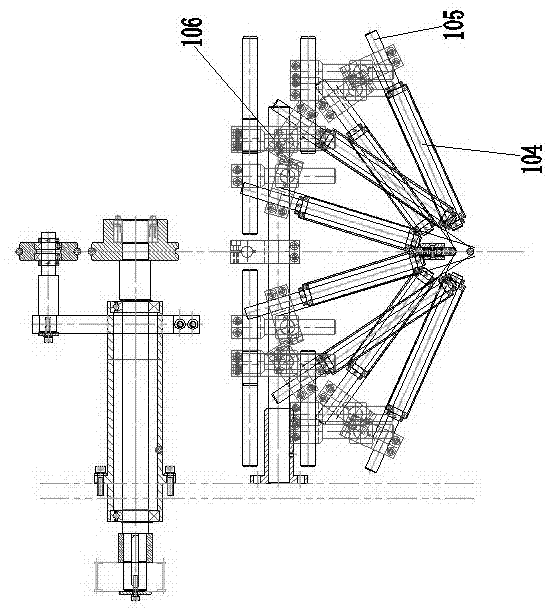

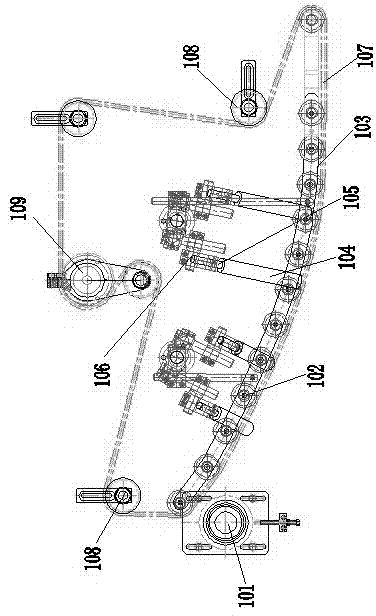

[0021] Embodiment 1: with reference to attached figure 1 , 1-1 and 1-2. A half-folding mechanism on the production line of pull-up pants and adult incontinence pants, which includes a half-folding driving wheel 101 fixed on a frame, a set of O-shaped wheels 102, and multiple sets of transition wheel rods 104; the half-folding driving wheel 101 is controlled by a servo Motor control, and the half-fold driving wheel 101 is arranged on the feed inlet side, docked with the output port of the previous processing procedure device on the production line; the rear of the half-fold driving wheel 101 is provided with a group of O-shaped wheels 101 arranged in an arc, and O The O-shaped belt 103 guided on the type wheel 101 is arc-shaped; the O-shaped wheel 102 arranged in an arc is gradually lowered from the half-folded driving wheel 101, and the O-shaped wheel 102 at the tail end of the O-shaped belt 103 is placed axially and horizontally ; The bottom of the O-shaped belt 103 is the ...

Embodiment 2

[0024] Embodiment 2: On the basis of Embodiment 1, a half-folding mechanism on the production line of pull-up pants and adult incontinence pants, each set of transition wheel rods 104 are alternately arranged on the inside and outside of the folded surface of the product; the product When alternately passing between the two transition wheel bars 104 of multiple sets of transition wheel bars 104, the multiple sets of transition wheel bars 104 generate a certain pulling force on the product, ensuring that the product is always kept flat during the half-folding process, effectively ensuring the half-folding position of the product accuracy.

Embodiment 3

[0025] Embodiment 3: on the basis of embodiment 1, with reference to appended Figure 4 . A half-folding and turning device on the production line of pull-up pants and adult incontinence pants, which includes the half-folding mechanism 1 described in Embodiment 1, and the rear of the half-folding mechanism 1 is sequentially provided with a pinch mechanism 2 and a turning mechanism 3; the half-folding mechanism The output port of 1 is docked with the input port of the pinch mechanism 2; the output port of the pinch mechanism 2 is docked with the input port of the turning mechanism 3; the output port of the turning mechanism 3 is connected with the input port of the next process such as a welding mechanism Docking; the folding mechanism 1, the pinch mechanism 2 and the turning mechanism 3 are all controlled by the PLC controller.

[0026] The half-fold flip method on the pull-up pants and adult incontinence pants production line, the unfolded product is horizontally conveyed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com