Novel anti-coking intelligent efficient biomass heating furnace

A heating furnace and anti-coking technology, which is applied to household furnaces/stoves, furnaces/stoves with hot water devices, heating methods, etc. and other problems, to achieve the effect of strong appearance structure and environmental embedding, prolonging equipment life and prolonging flue gas stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

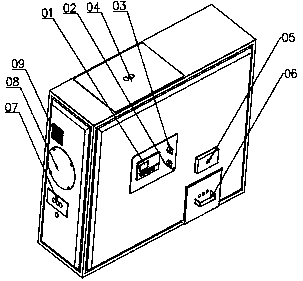

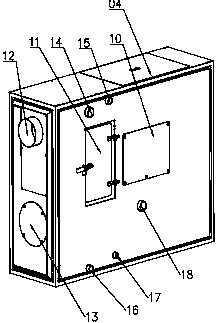

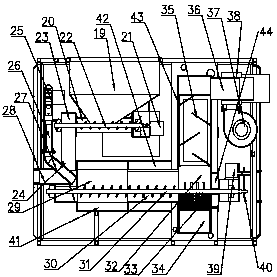

[0039] as attached figure 1 , attached figure 2 , attached image 3 The specific embodiment shown in the present invention is a novel anti-coking intelligent high-efficiency biomass heating furnace. The gas post-processing device, dynamic combustion and slag removal transmission device, intelligent control device, and maintenance and repair device are composed of seven parts. The main body of the heating furnace is fixed on the furnace body bracket. The panel housing is snapped on.

[0040] Preferably, combined with image 3 , attached Figure 5 The feed ignition device in this specific embodiment is mainly composed of a feed device and an ignition device, wherein the feed device is mainly composed of a feed bin (19), a feed pipe (20), a feed motor (21), a feed twist Long (22), blanking bin (23), blanking bin drainage plate (24), etc., the feeding pipe (20) is welded and connected at the bottom of the feeding bin (20), and the feeding motor (21) passes through the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com