Method for Improving Chlorination Efficiency of Titanium-Containing Blast Furnace Slag

A technology of blast furnace slag and high efficiency, which is applied in the field of chemical engineering, can solve the problems of low titanium boiling chlorination rate in carbide slag particle size distribution, affecting the economy of the whole process, and affecting the efficiency of Ti recovery and utilization, so as to achieve a small footprint and improve recovery Good utilization efficiency and continuous stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

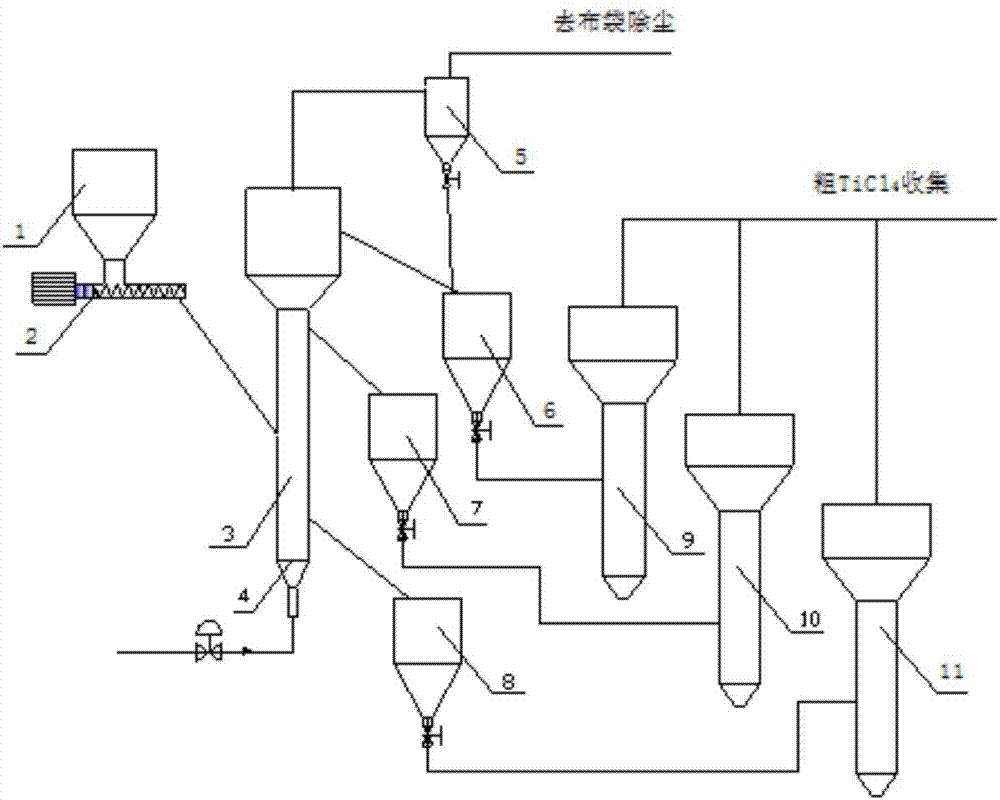

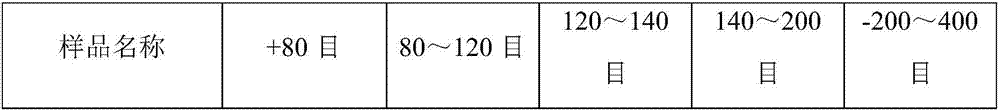

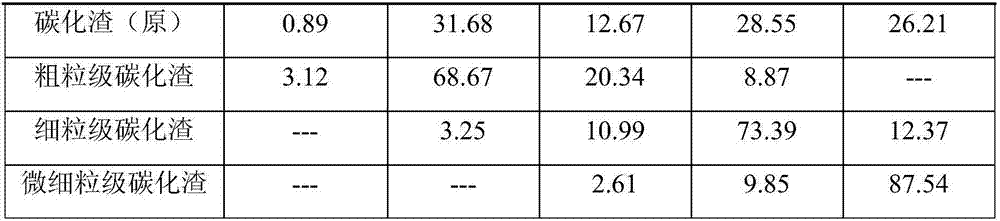

Embodiment 1

[0028] This example is a semi-industrial test, using a Φ100mm fluidized grading device, a Φ100mm quartz glass boiling chlorination reactor, and using a Roots blower to pressurize the air as the fluidization process wind. Blast furnace slag, treated with 10kt / aTiCl 4 On the industrial demonstration line, the electric furnace is used for high-temperature reduction and crushed into 80-400 mesh carbide slag. Its typical particle size distribution is shown in Table 1. Mainly select ≥140 mesh carbonized slag and enter the coarse-grained fluidized chlorination furnace for boiling chlorination; ≤200 mesh fine-grained carbonized slag is selected and enter the fine-grained chlorination furnace for boiling chlorination; 120-200 mesh The fine-grained carbide slag is selected for boiling chlorination in a fine-grained fluidized chlorination furnace. By classifying and adjusting different boiling chlorination process operating conditions, boiling chlorination of carbide slag with differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com