A device and process for producing chlorinated high polymer

A technology of chlorinated high polymer and high polymer, applied in chemical/physical process, chemical/physical/physical chemical process, chemical/physical/physical chemical process of applying energy, etc. The problems of uneven chlorination and effective transfer of heat can achieve the effects of controlling reaction temperature, expanding production scale, and strengthening heat dissipation and heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

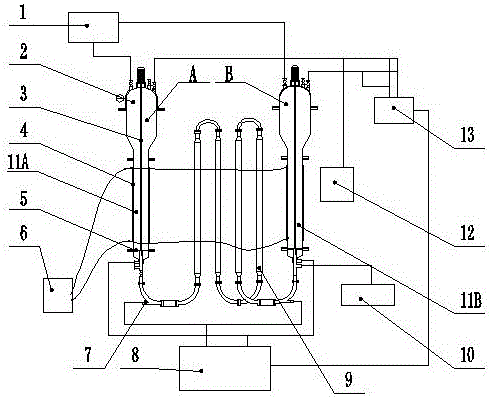

[0037] Refer to the attached figure 1 ; The raw material bin 1 is pressurized, and the high polymer flows into the amplification section 2 and then falls into the fluidized bed reactor 11A. Turn on the vacuum device 12 to vacuumize the high polymer to remove gaseous impurities attached to the high polymer. The mixed gas of chlorine gas and hydrogen chloride gas or inert gas passes through device 8 for impurity removal, deoxidation, and heating, and the gas heating temperature is 20-130°C. The heated gas enters the fluidized bed reactor 11A through the fluidizing gas device 5, and fluidizes the high polymer. After prechlorination for 10-60 minutes, the heating system 6 is turned on, and the fluidized bed reactor and the riser Heating is carried out at a temperature of 20-130°C. The pressure of 11A and the fluidized bed reactor 11B is adjusted by the pressure regulating device 13 to increase the internal pressure of the fluidized bed reactor 11A. The flow aid gas enters the b...

Embodiment 2

[0039] Refer to the attached Figure 5 ; The raw material bin 1 is pressurized, and the high polymer flows into the amplification section 2 and then falls into the fluidized bed reactor 11A. Turn on the vacuum device 12 to vacuumize the high polymer to remove gaseous impurities attached to the high polymer. The mixed gas of chlorine gas and hydrogen chloride gas or inert gas is removed and deoxidized through the gas impurity removal device 8, and the gas heating temperature is 25-160°C. The heated gas enters the fluidized bed reactor 11A through the fluidizing gas device 5, and fluidizes the high polymer. After prechlorination for 10-60 minutes, the heating system 6 is turned on, and the fluidized bed reactor and the riser Heating is carried out at a temperature of 25-160°C. The pressure of the fluidized bed reactor 11A is adjusted by the pressure regulating device 13 to increase the internal pressure of the fluidized bed reactor A. The flow-aid gas enters the bottom of the...

Embodiment 3

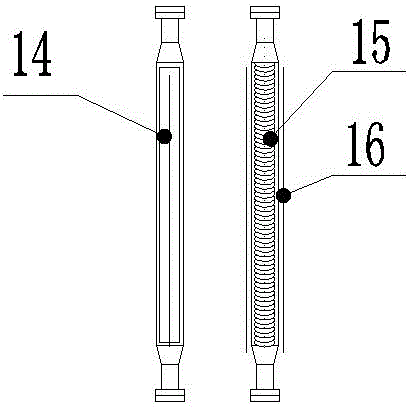

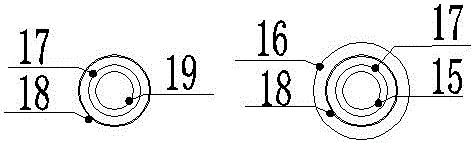

[0041] Refer to the attached figure 1 with 2 The difference between embodiment 3 and embodiments 1 and 2 is the structure of the riser 9, one is the riser 14 of the ultraviolet lamp mechanism, and the other is the plasma inner electrode 15 and the plasma outer electrode 16 and the quartz tube 17 , Outer pipe jacket 18 is formed as attached to the instruction manual figure 2 , 3 The annular gap plasma generator shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com