Carbon fiber continuouspimping rod and preparation device and method thereof

A technology for preparing device and carbon fiber, applied in the direction of fiber chemical characteristics, drill pipe, earthwork drilling, etc., can solve problems such as corrosion and eccentric wear, and achieve the effect of increasing fluidity, improving infiltration effect, and avoiding delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

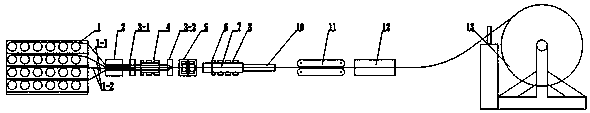

[0041] A kind of preparation method of carbon fiber continuous sucker rod of the present invention is characterized in that comprising the following steps to make:

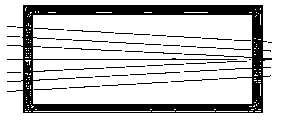

[0042] (a) A plurality of bundles of carbon fibers are drawn from the wire rack 1, wherein the carbon fiber reinforced layer A and the high modulus glass fiber layer B pass through the carbon fiber glue tank 3-1 under the traction of the traction device 11, and are soaked in the resin matrix glue solution. The resin matrix is Multi-functional epoxy resin system; pre-cured by heating in the small mold 4, and mold heating devices are distributed around the small mold, heating in two stages, and the heating temperature is 90-160°C;

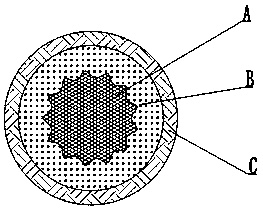

[0043] (b) In the small mold, the carbon fiber reinforced layer A is covered with high-modulus glass fiber layer B and high-strength glass fiber, and the fiber braided wear-resistant layer C in the multi-bundle carbon fiber is drawn from the wire rack 1 through the braiding machine, Use ...

Embodiment 1

[0048] Example 1: First, 242 bundles of T300-12K fibers are drawn from the wire drawing frame 1, and after preheating treatment, they pass through the carbon fiber glue tank 3-1 under the traction of the traction device 11, and soak in the resin matrix glue liquid, and the resin matrix is multifunctional. Epoxy resin system, the glue ratio is resin:curing agent=100:113;

[0049] The carbon fiber passes through the small mold 4 and is heated in two stages in the small mold. The temperature of the two zones is 90°C and 160°C for pre-curing;

[0050] 150 bundles of WS3000-2400tex glass fibers drawn from the wire drawing frame 1 pass through the inner hole of the braiding machine 5, and enter the outer layer glue tank together with the braided layer formed by 22 pieces of 1100dtex aramid fiber 1414, and soak the resin matrix glue solution. The resin matrix is Multifunctional epoxy resin system, the glue ratio is resin: curing agent: wear-resistant filler = 100:113:5; under the t...

Embodiment 2

[0053] Embodiment 2: according to embodiment 1, resin is replaced with four-functional epoxy resin, improves temperature resistance, the resin in the small glue tank 3-1: curing agent=100:126, the resin in the outer layer glue tank 3-2 : curing agent: wear-resistant filler = 100:126:5, the heating temperature of the dipping device is 40°C;

[0054] The die temperature is controlled at 110°C, and the pultrusion die with a hole diameter of 22mm is heated in 7 stages, the temperature is 130°C, 230°C, 250°C, the pultrusion speed is 0.27m / min, and the composite material rod is pultruded; The rod body of the composite material that is produced enters the post-curing heating furnace 10 for thermal stress treatment and post-curing. The post-curing heating furnace 10 is heated in three stages, and the temperature is 230°C, 195°C, and 120°C; the solidification becomes a three-layer structure with a diameter of 22mm Eccentric wear-resistant carbon fiber reinforced composite continuous su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com