System and method for controlling cigarette transportation and storage

A cigarette and electrical control technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of unstable cigarettes in memory, affecting the quality of cigarettes, and many monitoring components, etc., to achieve continuous stability, Increase the human-machine interface and reduce the effect of detection components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

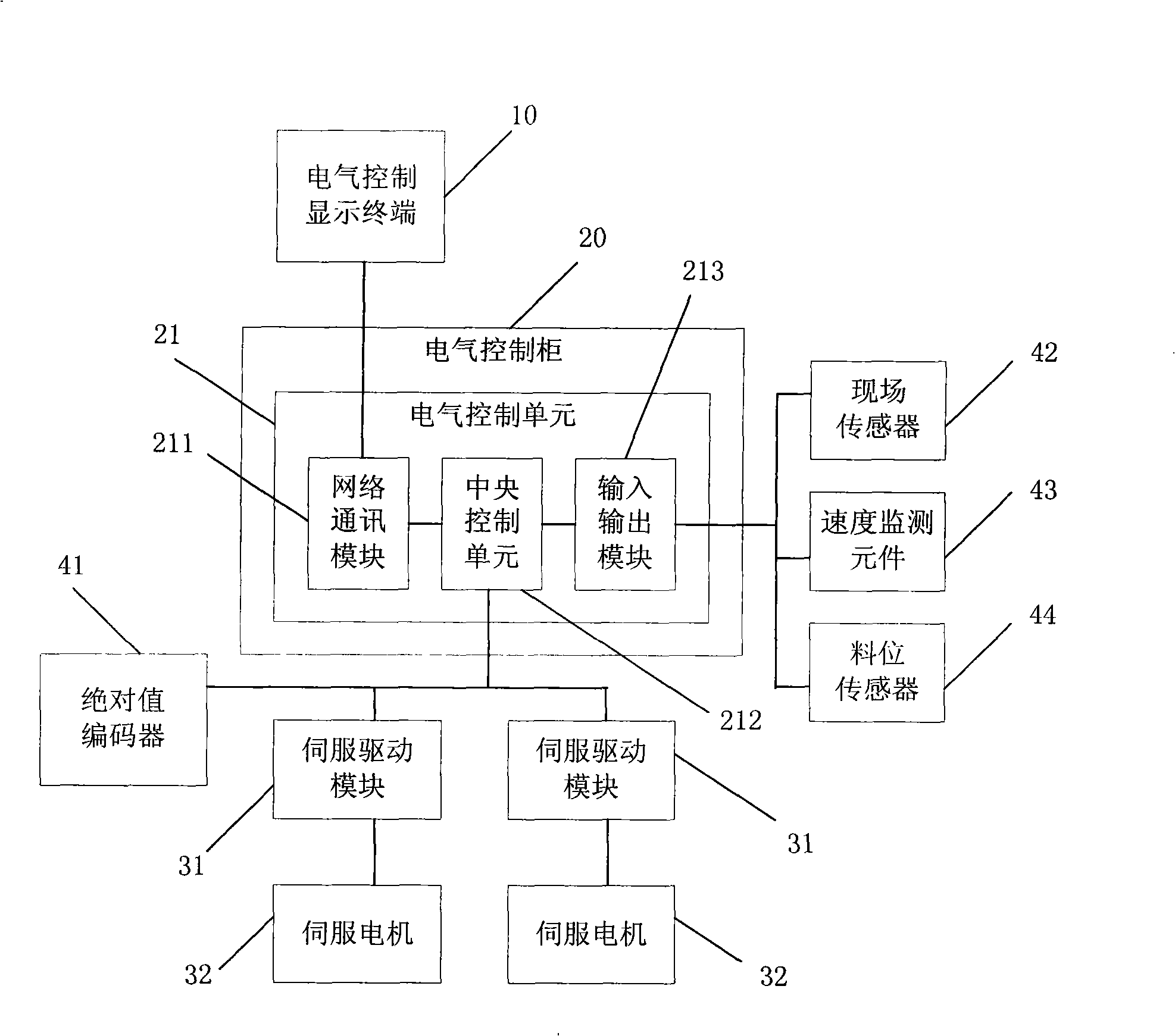

[0032] figure 1 It is a structural schematic diagram of a system for controlling cigarette delivery and storage in a specific embodiment of the present invention. like figure 1 As shown, the cigarette delivery and storage control system includes an electrical control cabinet 20, an electrical control display terminal 10, a control network, a storage and delivery servo drive device, an electrical actuator and on-site monitoring components. Among them, the electrical control cabinet includes an electrical control unit 21, and the electrical control unit further includes a central control unit 212, an input and output module 213, and a network communication module 211; the storage and delivery servo drive device further includes no less than two servo drive modules 31; the electrical execution The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com