Spunlace non-woven material containing natural dry petals and preparation method thereof

A spunlace non-woven and petal technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of natural flowers and plants falling off, short shelf life of products, not easy to store, etc., and achieve the effect of natural and soft colors and good health care functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] A preparation method of a spunlace nonwoven material containing natural dried petals comprises the following steps:

[0071] 1) Pre-treat the natural dried petals so that the moisture content of the petals is 50-80%.

[0072] 2) Preparation of wet mixed fiber web:

[0073] 2.1) Send ultra-short textile fibers of one or more components into the discharge tank, complete the uniform dispersion of the fibers under the agitation of the propeller, and finally make a fiber suspension with a concentration of 0.1 to 1%. The fiber suspension is fed into the working pool.

[0074] 2.2) Send the pretreated petals and fiber suspension into the mixing tank and mix thoroughly, so that the natural dried petals are evenly distributed in the fiber suspension and then sent to the pre-copy tank.

[0075] 2.3) The petal mixed slurry in the forebay goes through high-speed stirring, slit filter device and two times of dilution, and then enters the inclined wire former through the slurry pum...

Embodiment 1

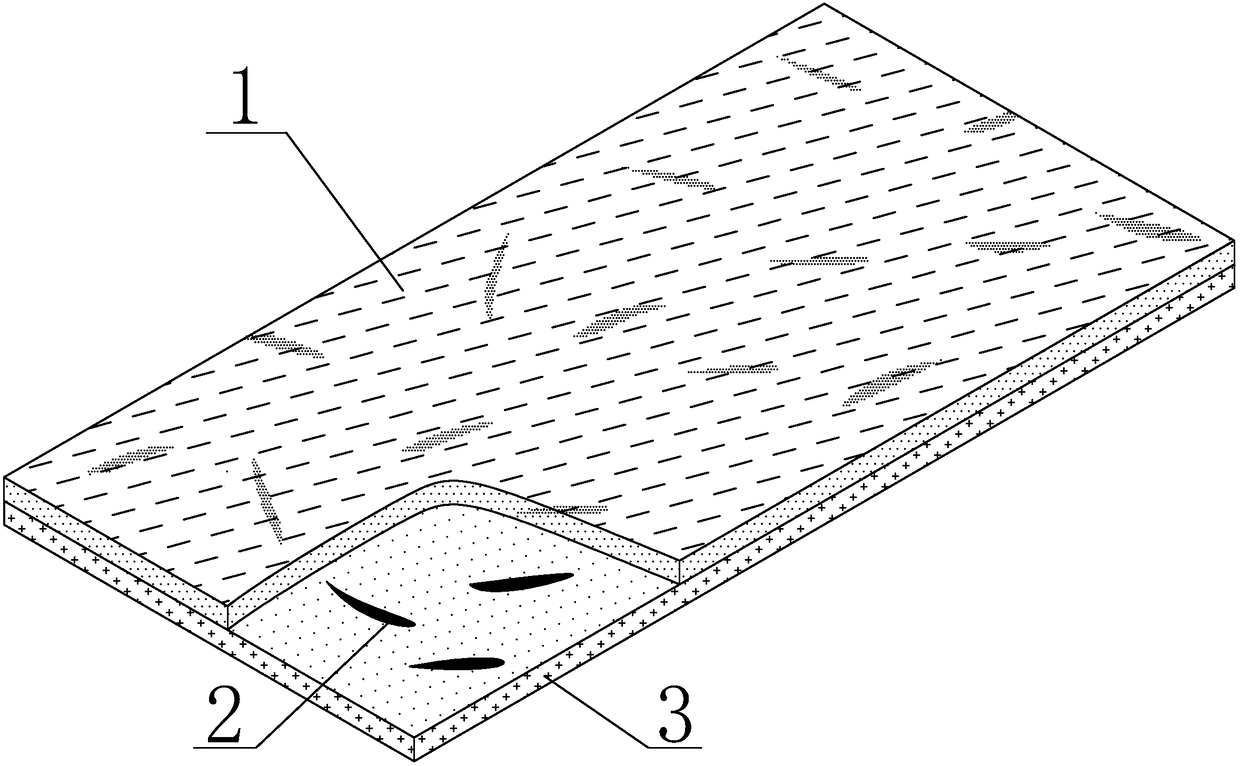

[0089] Such as figure 1 Shown, a kind of spunlace non-woven material containing natural dried petals comprises dry-laid fiber web 3, wet-laid fiber web 1 and some calendula natural dried petals 2, and described calendula dried flower petal is positioned at wet-laid fiber web and dry-laid fiber web.

[0090] Wherein, the mass percentage of the dry-laid fiber web is 50%, the mass percentage of the wet-laid fiber web is 49%; the mass percentage of the petals is 1%.

[0091] The dry-laid fiber web is made of 100% viscose fiber, and its specification is 1.67dtex×38mm.

[0092] The wet-laid fiber web viscose ultra-short fiber has a specification of 2.0 dtex×5 mm.

[0093] The petals of the dried calendula are whole petals with a natural shape; the moisture content of the petals is 6.5%, the length of the petals is 13-20 mm, the width is 3-4 mm, and the thickness of the petals is <1 mm.

[0094] Described a kind of preparation method that contains calendula petal spunlace nonwoven...

Embodiment 2

[0107] A spunlace non-woven material containing natural petals comprises a dry-laid fiber web, a wet-laid fiber web and several natural wild chrysanthemum petals, and the natural wild chrysanthemum petals are located between the wet-laid fiber web and the dry-laid fiber web.

[0108] Wherein, the mass percentage of the dry-laid fiber web is 49%, and the mass percentage of the wet-laid fiber web is 49%; the mass percentage of the wild chrysanthemum petals is 2%.

[0109] The dry-laid fiber web is made of 100% viscose fiber, and its specification is 1.67dtex×38mm.

[0110] The wet-laid fiber web viscose ultra-short fiber has a specification: 1.67 dtex×6 mm.

[0111] The petals of the natural wild chrysanthemum are whole petals with a natural shape; the moisture content of the petals is 6.8%, the length of the petals is 10-13 mm, and the width is 3-4 mm; the thickness of the petals is less than 1 mm.

[0112] Described a kind of preparation method that contains natural wild chry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com