Patents

Literature

272results about How to "Do not fade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous binding agent and preparation method thereof

ActiveCN101880512AGood storage stabilityEasy to storeMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesHot stampingEmulsion

The invention provides an aqueous binding agent which has washing resistance and is used for electrochemical aluminium hot stamping, and a preparation method thereof, belonging to a binding agent composition. The aqueous binding agent comprises 40-80 parts by weight of acrylic resin emulsion (with the solid content of 40-55%), 20-40 parts by weight of acrylic resin powder and 5-20 parts by weight of ethylene-vinyl acetate copolymer (EVA) emulsion (with the solid content of 40-60%). The binding agent does not contain organic volatile component, is harmless for the human body, is an environment-friendly electrochemical aluminium hot stamping binding agent, and is especially suitable for fabric which is needed to be printed and frequently washed.

Owner:浙江德尚化工科技有限公司

Digital reactive dye printing process for mulberry silk fabric

InactiveCN103451970AHigh color yieldIncrease color depthHeating/cooling textile fabricsDyeing processDigital printingUrea

The invention provides a digital reactive dye printing process for a mulberry silk fabric. The process comprises the following steps: carrying out textile sizing, drying, carrying out jet printing, steaming, washing by cold water, washing by hot water, washing by soap, washing by hot water, washing by cold water, and drying, wherein a sizing agent used in the textile sizing step comprises the following components in percentage by weight: 1%-3% of sodium sulfate powder, 0.5%-1% of sodium alginate, 3%-5% of urea, 0.5%-1.5% of sodium hydrogen carbonate, 1%-2% of modified starch, 5%-7% of electrolyte and the balance being water. By virtue of the process, the digital printing color yield of the mulberry silk fabric is increased, the inkjet printing color depth on a textile is increased, the color difference between a pattern on the textile and an electronic pattern is reduced, and the hand feel of the fabric is good.

Owner:SHIJIAZHUANG HEXI APPL TRADING

High-temperature steam endurance ink for spraying code and printing

The invention relates to high-temperature steam endurance ink for spraying code and printing, containing one or more organic solvents, resin and coloring agents. In addition, the consistency of the ink is 2.8-6.2CP / 25DEG C, the conductivity is 500-1,500muS and the surface tension is 27-30Dyn / cm. The high-temperature steam endurance ink for spraying code and printing can be applied to the surfaces of various packaged objects required to be treated at high temperature. The mark and the substrate adopting the high-temperature steam endurance ink have strong adhesive force and favorable adhesiveness and cannot fade, fall off, permeate and shift after being subjected to high-temperature digestion. The dried mark can be also scraped by a cleaning agent.

Owner:北京赛腾标识系统股份公司

Dispersion-reduction dyeing process for cotton-polyester blended fabric

ActiveCN106087463AImprove reducibilityImprove dyeing effectSucessive textile treatmentsDyeing processDisperse dyeVat dye

The invention discloses a dispersion-reduction dyeing process for a cotton-polyester blended fabric. The dispersion-reduction dyeing process comprises a disperse dyestuff treating procedure and a vat dye treating procedure which are successively carried out. The disperse dyestuff treating procedure comprises dyeing, reduction cleaning, washing and pickling; the vat dye treating procedure comprises dip padding with a vat dye suspension, dip padding with a reducing solution, steaming, oxidation, soaping, hot washing and drying; in the disperse dyestuff treating procedure, a disperse dyestuff microcapsule method is used for dyeing; and in the vat dyestuff treating procedure, vat dye wet rapid-steaming pad dyeing process is employed. The dispersion-reduction dyeing process for the cotton-polyester blended fabric has the advantages of good level dyeing effect, small chromatic aberration and high color fastness, and is simple in process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Chromatic composite rock slices and method for preparing same

The invention relates to a colorful composite rock sheet and a preparation process thereof. The composite rock sheet is prepared by raw materials with following proportion by weight, 60-65 parts of water-base resin, 5-8 parts of film-forming auxiliary agent and 30-35 parts of natural ore powder. The process comprises the following steps that firstly adding raw material in a burden charging barrel according to formulation, and conducting filter treatment after evenly mixing through stirring and dispersing, secondly conducting one-stage drying treatment after spraying into sheet shape with a spraying machine, wherein temperature is controlled within 50 DEG C-120 DEG C, thirdly immersing sheet-shaped material which is sprayed and dried into solvent for at least five minutes, then conducting with two-stage drying treatment, wherein temperature is controlled within 50 DEG C-120 DEG C, fourthly disintegrating into fragments with irregular size with a disintegrator, and obtaining finished products after screening. The beneficial effect of the invention is that the sheet is conducted with two times drying treatments and immersion treatment. The rock sheet has the characteristics of easy color matching, softness, non bonding and color fading, difficult solution and easily even dispersion when making up granite paint.

Owner:HANGZHOU SENLESHI COATING

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

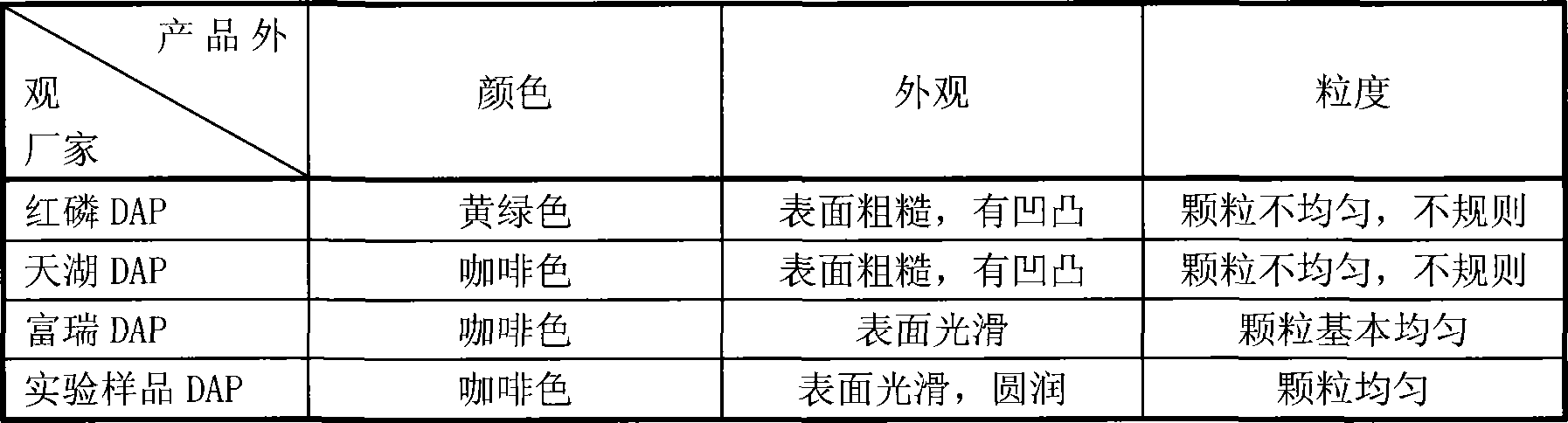

Method for dyeing phosphorus complex fertilizer

InactiveCN101234926AComponents that do not changeUniform colorFertiliser formsFertilizer mixturesDiammonium phosphatePhosphoric acid

The invention relates to a method for processing chemical fertilizer, in particular to a method for dyeing chemical fertilizer. The invention includes the preparation, addition, dyeing, and granulation of colorant, and comprises the following steps: A. adding weighted colorant into a phosphoric acid tank, an acid pump outlet or a pre-neutralization slot for producing phosphate compound fertilizer; B. mixing water solution with phosphate compound fertilizer for dyeing; C. spraying the slurry for granulation after dyeing. The method for dyeing chemical fertilizer is mainly used for appearance dyeing of various nitrogen and phosphate fertilizers and products, and can dye coffee on products evenly and effectively. The dyed products with high-quality appearance color do not have discoloration and color change so as to hit the target of unifying product color. Compared with that imported from America, diammonium phosphate dyed through the method for dyeing chemical fertilizer has the equal and even better color. As coffee color products sell well in the market, the invention can reduce sales cost.

Owner:云南云天化国际化工有限公司

Colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of colored oily fertilizer anti-caking agent

The invention relates to a colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of the colored oily fertilizer anti-caking agent. The colored oily fertilizer anti-caking agent comprises the following ingredients in percentage by mass: 2-4% of iron oxide red, iron oxide yellow, iron oxide blue, iron oxide green, iron oxide purple, iron oxide brown or iron oxide black and 98-96% of an oily anti-caking agent, and is prepared by uniformly milling and mixing such ingredients by adopting a horizontal mill. The colored oily fertilizer anti-caking agent is applied to fertilizer coating, and 1.0-1.6 kilograms are used in each ton of a fertilizer, so that a corresponding color of red, yellow, blue, green, purple, brown or black is shown in the appearance of the fertilizer. The colored oily fertilizer anti-caking agent with the corresponding color of red, yellow, blue, green, purple, brown or black is provided for fertilizers with different appearance colors, so that inside and outside colors of the fertilizer are consistent, color difference and materials with inconsistent colors are avoided; the colored oily fertilizer anti-caking agent is stable and uniform in color, strong in coating capability, resistant to light and heat, colorfast and non-discoloring, can also be used as a fertilizer variety distinguishing and anti-counterfeiting mark, and is low in use cost and good in anti-caking performance.

Owner:HUBEI FORBON TECH

Colored glazed quartz colorful sand and preparation method thereof

The invention discloses colored glazed quartz colorful sand and a preparation method thereof. The colored glazed quartz colorful sand is prepared by mixing the following raw materials in parts by weight: 1000 parts of quartz sand, 10-20 parts of an inorganic pigment, 10-20 parts of a middle / low-temperature glaze, 5-10 parts of a high-temperature-resistant adhesive, 5-8 parts of nanometer barium sulfate powder, 1-3 parts of nanometer silver powder, 2-5 parts of a dispersant, and 20-40 parts of water. The produced colored glazed quartz colorful sand has the advantages of abundant color, lifelikeness, no fading, good weatherability and the like.

Owner:宜兴市双志陶瓷科技有限公司

Dyeing technology for polyester cotton according to dispersive bath method

The invention discloses a dyeing technology for polyester cotton according to a dispersive bath method. The technology comprises the following steps: 1) treating disperse dyes, wherein the step of treating the disperse dyes comprises immersing and rolling the disperse dyes, preliminarily drying the disperse dyes which are immersed and rolled with infrared rays, drying the disperse dyes which are preliminarily dried with hot air, conducting hot melt baking on the disperse dyes which are dried and cooling the disperse dyes which are hot melt baked; 2) treating reduced dyes, wherein the step of treating the reduced dyes comprises immersing and rolling suspended substances of the reduced dyes, preliminarily drying the suspended substances which are immersed and rolled with the infrared rays, drying the suspended substances which are preliminarily dried with a drying cylinder, immersing and rolling a reduction solution, steaming the reduced solution which is immersed and rolled, drip washing the reduced solution which is steamed, oxidating the reduced solution which is drip washed, washing the reduced solution which is oxidated with water, washing the reduced solution which is washed with soap, washing the reduced solution which is washed with the water and drying the reduced solution which is washed. The technology disclosed by the invention adopts the dispersive bath method to treat dyeing, according to the method, the dyeing effect is good, the level dyeing degree is high, the dyeing fastness is high, the situation of color fading is avoided, and the quality is good.

Owner:常熟市立丹纺织品有限公司

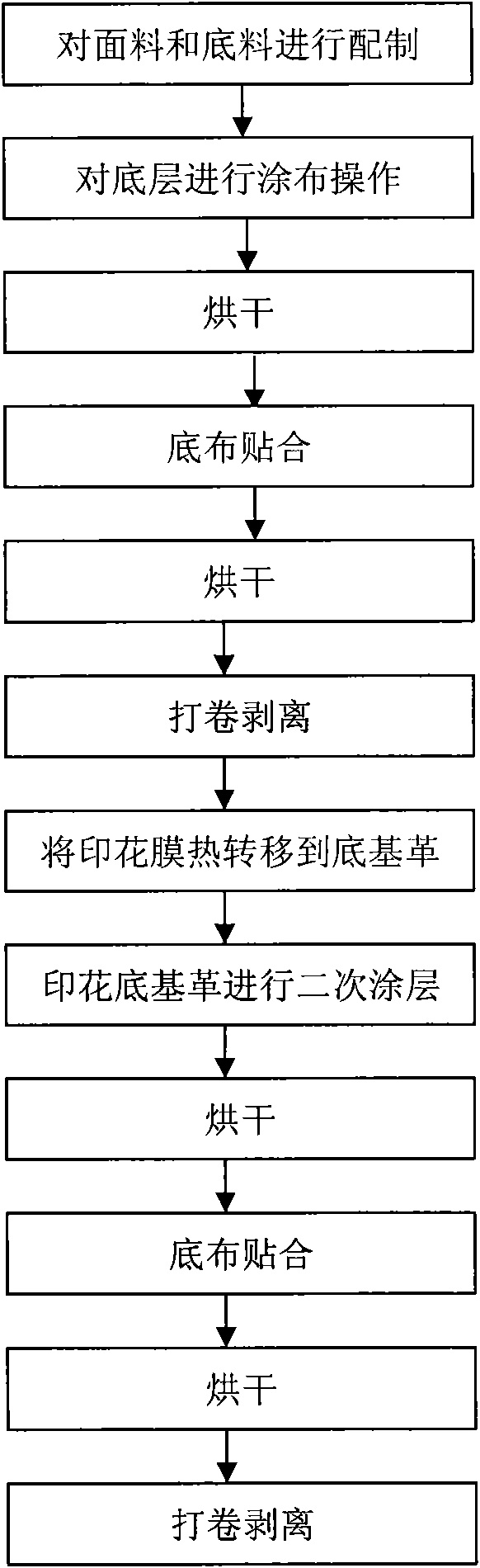

Novel PU printing waterproof and anti-crease fabric and preparation method thereof

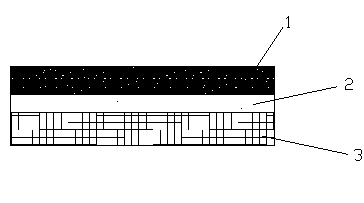

InactiveCN101660277AImprove the three-dimensional effectRemove tensionSynthetic resin layered productsDyeing processDisperse dyeAlcohol

The invention discloses a novel PU printing waterproof and anti-crease new fabric, which comprises three layers: the first layer is PU surface layer mainly comprising PU polyurethane; the second layeris printing dyes; the third layer is a PU surface layer mainly comprising PU polyurethane. The printing dyes in the second layer are ink disperse dyes made of disperse dyes and water-soluble carrier,or ink disperse dyes made of the disperse dyes and alcohol-soluble carrier, or ink disperse dyes made of the disperse dyes and oil-soluble resin. The invention also discloses a method for preparing the novel PU printing waterproof and anti-crease fabric, comprising the following steps: firstly, preparing a shell fabric and a backing material; secondly, carrying out coating operation; thirdly, performing the backing lamination; fourthly, drying, rolling and stripping; fifthly, thermally transferring a printing film to base leather; and sixthly, performing the secondary coating on the printingbase leather. The novel PU printing waterproof, anti-crease fabric has advantages of terrific tensile strength and hydrostatic pressure, and is durable in use, fastness to washing, colorfast; and thepreparation method is easy to operate.

Owner:仪征新天地织物面料实业有限公司

Multifunctional plastic additive and preparation method thereof

The invention relates to the field of plastic processing and in particular relates to a multifunctional plastic additive and a preparation method thereof. The multifunctional plastic additive comprises the following components in parts by weight: 70-89 parts of light calcium carbonate powder, 10-15 parts of stearate, 1.0-1.8 parts of mica powder, 3-5 parts of light magnesium oxide powder, 1-2 parts of organic tin, 2-3 parts of glass fiber powder, 1-2 parts of methacrylate, 1.0-1.5 parts of a coupler and 2-4 parts of a lubricant. The preparation method comprises the following steps: pre-modifying the light calcium carbonate powder by stearate, mixing the pre-modified light calcium carbonate powder, the mica powder, the light magnesium oxide powder and the glass fiber powder at a low speed, adding other formulation components, producing a high-temperature and low-speed stirring reaction, and discharging to obtain the multifunctional plastic additive. The preparation process is simple, and the prepared plastic additive can be used for improving the tensile strength, the strength, the pressure resistance and the like of a PVC (polyvinyl chloride) wood plastic composite material and a PVC engineering plastic.

Owner:汕头市亨德利塑胶有限公司

Decorative material and prepn. thereof

ActiveCN1834056ACrystal clear textureSmooth textureMohs scale of mineral hardnessAlkaline earth metal

This invention relates to a kind of decoration material and its preparation method, which is attributed to the field of inorganic nonmetallic materials. Counting in terms of oxide net content, the terminal product comprises: 45~72% SiO2, 2~20% R2O, 5~40% RO and 0~10% Al2O3, where R2 represents alkali metals and R represents alkaline metals. It can also contains 0.0001~7% Fe2O3, 0~7% ZnO, 0~7% BaO, 0~7% TiO2, 0~8% ZrO2, 0~2% HfO2, 0~7% B2O3 and some fluoride. Thanks to reasonable composition and compact texture, properties such as modulus of rupture, compression strength after drying and Mohs' hardness of the decoration materials are better than those of granite and marble.

Owner:JIUJIANG GOLDEN PHOENIX DECORATION MATERIAL CO LTD

Exterior decoration mortar and productive construction technology thereof

InactiveCN101224970AImprove compactnessImprove waterproof performanceSolid waste managementEmulsionShrinkage rate

The invention discloses an exterior wall decoration mortar which comprises white cement, fly ash and granulating slag. Each constituent comprises the following components by weight per 1,000 portion of mortar: 110-150 of fly ash, 185-285 of white cement, 220-290 of granulating slag for Phi 0.1-0.7 mm, 190-240 for Phi 0.2-0.6 mm, 100-160 for Phi 0.4-1.0 mm, 50-100 for Phi 1.2-1.6 mm. The invention adopts the homogeneous materials of decoration mortar and base layer of the wall surface, both mortars have identical dry shrinkage rate and physical and chemical index; the decoration mortar has good compactness once being finished according to the requirement of construction characteristics, thus the water proof performance is good; adequate redispersible emulsion powder allowing for anti-cracking requirement is blended when the mortar is prepared to lead the mortar to have a certain flexibility to overcome the disadvantage that the anti-cracking performance is not satisfactory when the mortar is resisting the cement material with high rigidity, thus the weatherability of the mortar is greatly enhanced. The test result indicates that the invention provides a mortar that can be fadeless and can not be damaged for 50 years.

Owner:GESHAN CONSTR GROUP

Nano water-based functional ceramic composite coating and preparation method thereof

ActiveCN103588443AGood physical and chemical stabilityExcellent abnormal temperature mechanical propertiesEmulsionPliability

The invention discloses a nano water-based functional ceramic composite coating which comprises raw materials in parts by weight as follows: 10-35 parts of silicate inorganic adhesives, 10-35 parts of main filler, 2-10 parts of stabilizing materials, 5-20 parts of toughness-enhancing emulsion type binding agents, 3-10 parts of film forming assistants and 5-25 parts of water. A preparation method comprises the steps as follows: the silicate inorganic adhesives and diluent are poured into a container and stirred at 350-400 r / min for 10-20 min, so that a mixed liquid is obtained; the main filler and the stabilizing materials are added to the mixed liquid, and the mixture is stirred at 350-400 r / min for 50-60 min; and the toughness-enhancing emulsion type binding agents and the film forming assistants are added sequentially, and the mixture is filtered by gauze with 400-600 meshes, so that the composite coating is obtained. A film of the coating is formed at the normal temperature, and the nano water-based functional ceramic composite coating has the characteristics of infiltration, large adhesive force, high density, stone hit resistance, impact resistance, high and low temperature resistance, superior abrasion resistance, washing resistance and good flexibility.

Owner:WUHAN ZHUOYI TECH DEV CO LTD

Mosquito repelling cloth art curtain fabric

InactiveCN102806730ASoft textureUnique functionSynthetic resin layered productsAnimal repellantsYarnEngineering

The invention provides a mosquito repelling cloth art curtain fabric, which adopts a multi-layer fabric structure design and comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is a terylene fabric layer, the fabric of the middle layer contains functional yarn strips with a mosquito repelling function, the inner layer is a terylene and spandex blended fabric layer, and the outer layer and the inner layer are formed on both surfaces of the middle layer by using a knitting process. According to the present invention, the mosquito repelling cloth art curtain fabric is disclosed; the fabric has soft texture and a unique function; the fabrics of the inner layer and the outer layer have characteristics of bright color, waster washing resistance, no color fading, elasticity, and obstruction of a certain ultraviolet radiation; with the special mosquito repelling component in the fabric of the middle layer, mosquito can be prevented from flying into the room so as to form a natural barrier, such that the fabric is particularly suitable for use in summer.

Owner:KUSN HUAHONG IMPORTS & EXPORTS

Bactericidal acaricidal laundry detergent

InactiveCN104877805AMild formulaStrong decontaminationAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBetainePotassium

The invention discloses a bactericidal acaricidal laundry detergent which is composed of the following components in percentage by weight: 20-24% of 60% LAS solution, 8-12% of laurylamidopropyl betaine, 10-15% of 6501 alkylolamide, 5-8% of potassium coconut oil fatty acid glycinate, 4-8% of cocinic acid acetal, 2-6% of polystyrene latex, 0.2-0.5% of essence. 6-10% of Chinese soapberry peel, 0.1-0.3% of citric acid, 0.2-0.3% of sodium chloride, 0.1-0.3% of pigment, 5-8% of bactericide and 20-30% of rice washing water. The bactericidal acaricidal laundry detergent has the advantages of mild formula, high detergent power, abundant foam, high rinsability, favorable bactericidal and acaricidal effects, no side effect, no fading of clothing, no irritation to skin and no pollution.

Owner:潘月娥

Four sides elasticity chamois flannel

InactiveCN101191273AEasy to stretchEasy to replyMonocomponent polyurethanes artificial filamentWoven fabricsFiberExtensibility

The invention relates to a neoprene suede nap and belongs to the textile fabric technical field. The invention is mainly characterized in that: warp threads are wrapped yarns taking sea-island filament as urethane elastic fiber core yarns, and the sea-island filament is made to become elastic sea-island filament; weft yarns are wrapped yarns taking PTT polyester as urethane elastic fiber core yarns, thereby the PTT is made to have good tension and restoring force and advanced performances like softness, fluffiness, easy dyeing, easy washing and so on are fully displayed; because a little urethane elastic fiber is arranged inside the PTT, resilience of the PTT is strengthened. The invention utilizes stain resistance better than chinlon fiber, antistatic property better than nylon, fluffiness, resilience, chromaticity, good stain removal and antifouling properties, easy dyeing, soft hand feeling, abundance in elasticity, and extensibility same as urethane elastic fiber of the PTT fiber to prepare the suede nap through coating according to mixture ratio; advantages of the two fibers are given full play; due to addition of the PTT fiber, the cost of raw materials and processing costs like energy consumption and so on can be reduced; due to addition of the urethane elastic fiber, the resilience can be guaranteed; by weaving of the suede nap, disadvantages of thin fabrics are avoided.

Owner:YANGZHOU JIYUAN TEXTILE

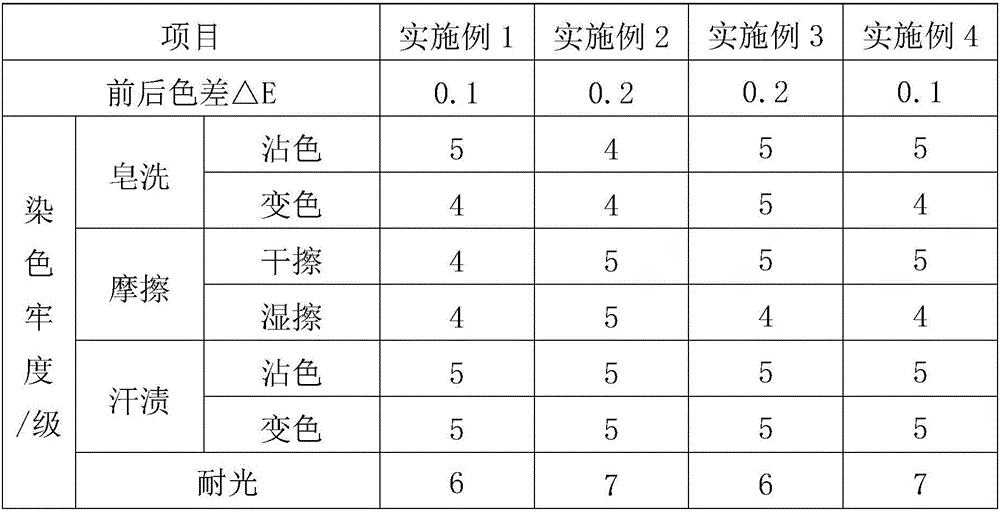

Digital printing process for real silk fabric

InactiveCN106758384AHigh color yieldIncrease color depthUltrasonic/sonic fibre treatmentDyeing processWarm waterEngineering

The invention provides a digital printing process for a real silk fabric. The digital printing process comprises the following procedures: real silk fabric preparation; low-temperature plasma processing; pretreatment liquid padding; drying; inkjet printing; drying; dry heat fixation; cold water flushing; warm temperature washing; soaping; warm water cleaning; and drying, wherein pretreatment liquid in the pretreatment liquid padding contains the following components by contents: 5g / L-10g / L of sodium alginate, 30g / L-50g / L of baking soda, 30g / L-50g / L of urea and 5g / L-15g / L of a defoaming agent. By virtue of the digital printing process, the tinctorial yield of the digital printing of a silkworm silk fabric is increased, the color depth of the digital printing on a textile is increased, and the chromatic aberration with an electronic pattern is reduced; and furthermore, the color fastness is high, and multiple experiments prove that the fabric does not fade or lose color even at relatively hostile experimental environments.

Owner:顾朝晖

Cloud wire coating and preparation method thereof

The invention relates to a cloud wire coating and a preparation method of the cloud wire coating. The cloud wire coating comprises the following raw constituents by weight: 4-7 parts of cellulose, 1-4 parts of AMP-95, 1-4 parts of wetting agent, 15-25 parts of coalescing agent, 1-3 parts of preservatives, 8-20 parts of ethylene glycol, 1-4 parts of defoamer, 150-240 parts of pearl powder, 350-500 parts of emulsion, 2-6 parts of thickeners, 3-9 parts of dispersing agent and 200-40 parts of deionized water. The cloud wire coating disclosed by the invention is fine and smooth in quality, and prevents the phenomena of wire fracture and tearing during wire drawing; with the coating, a film can be well adhered, and the seaming, the peeling and the cracking are prevented; and particularly, the coating has strong scrub resistance, water resistance and alkali resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

High-temperature-resistant water-borne coating and preparation method thereof

InactiveCN105176386ALow toxicityReduce surface tensionAnti-corrosive paintsEpoxy resin coatingsAcrylic resinKaolin clay

The invention discloses a high-temperature-resistant water-borne coating and a preparation method thereof. The high-temperature-resistant water-borne coating consists of the following materials in parts by weight: 82 to 85 parts of epoxy-modified organic silicone resin, 30 to 38 parts of bisphenol-A epoxy resin, 11 to 13 parts of water-based acrylic resin, 18 to 24 parts of graphite powder, 10 to 13 parts of polydimethylsiloxane, 5 to 8 parts of calcium carbonate, 8 to 10 parts of titanic oxide, 60 to 65 parts of deionized water, 10 to 12 parts of peal powder, 5 to 8 parts of titanium dioxide, 8 to 12 parts of kaolin, 5 to 8 parts of Rhine powder as release agent, 3 to 5 parts of thermal carbon black MT and 3 to 5 parts of toluene. Not only is the corrosion resistance of the water-borne coating good, but also the adhesion is good, so the water-borne coating cannot easily shed; moreover, colors are diversified; the service life is long, and problems, such as blistering, cracking, whitening and even leafing, cannot take place after the water-borne coating is used for a long time.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

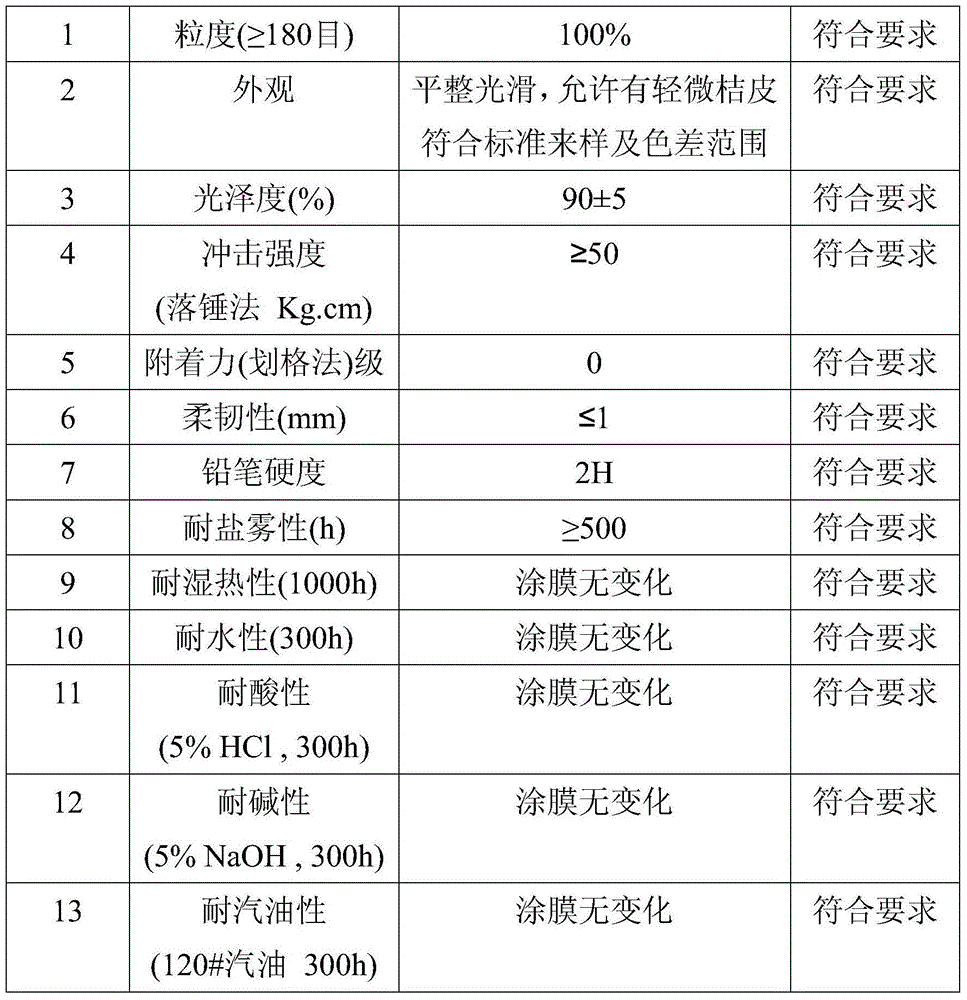

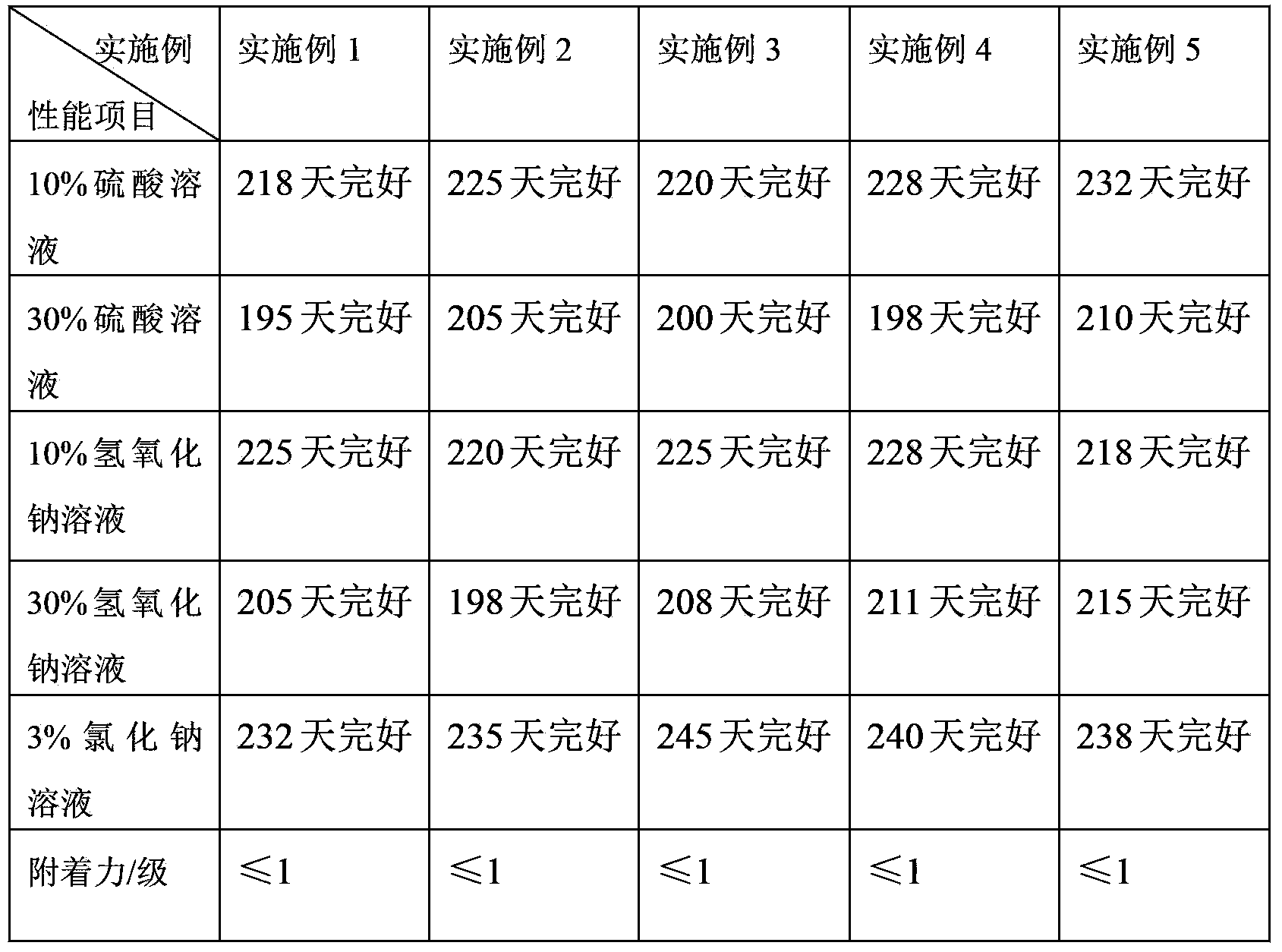

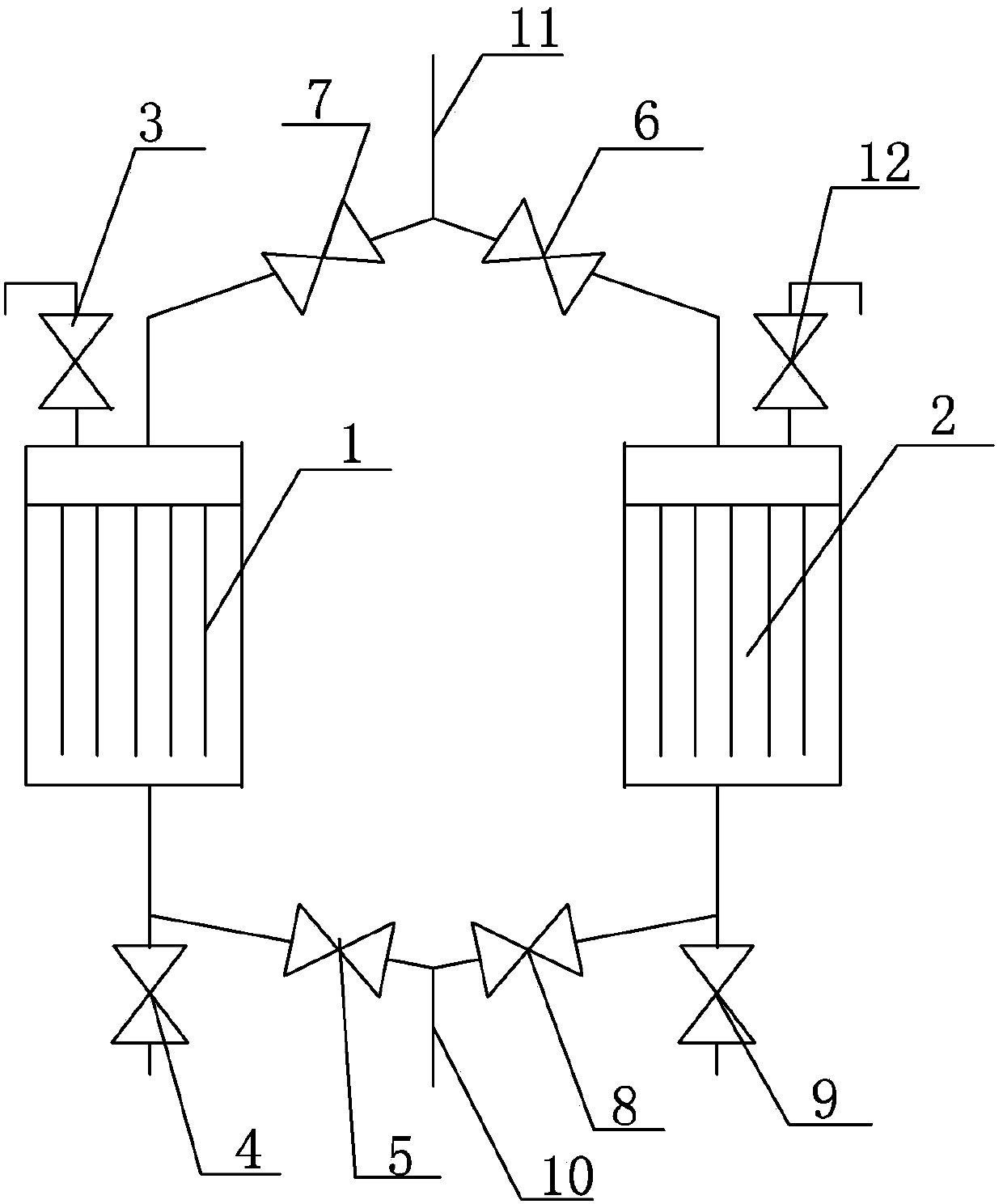

Method for machining and manufacturing electric folding gate by adopting hot dip galvanizing static plastic spraying pipe

ActiveCN104895479AStrong anti-corrosion performanceStrong UV resistanceGates/doorsPretreated surfacesSteel tubePolyester

The invention discloses a method for machining and manufacturing an electric folding gate by adopting a hot dip galvanizing static plastic spraying pipe, and relates to the technical field of electric folding gate manufacturing. The method comprises the steps of a hot dip galvanizing technology of a steel pipe, spraying of a hot dip galvanizing pipe, blanking of a finished product pipe and assembling of an electric gate. According to the method, the electro-chemical protection effect can be achieved through the hot dip galvanizing technology, rusting caused by the electro-chemical corrosion is avoided, spraying can be carried out on a galvanized pipe by adopting polyester type color powder coating, a formed coating film has the advantages of being high in anti-corrosion performance, striking-resistant and scraping-resistant, and the cost of the manufactured electric folding gate has the market competitiveness.

Owner:ANHUI PIONEER DOOR IND TECH

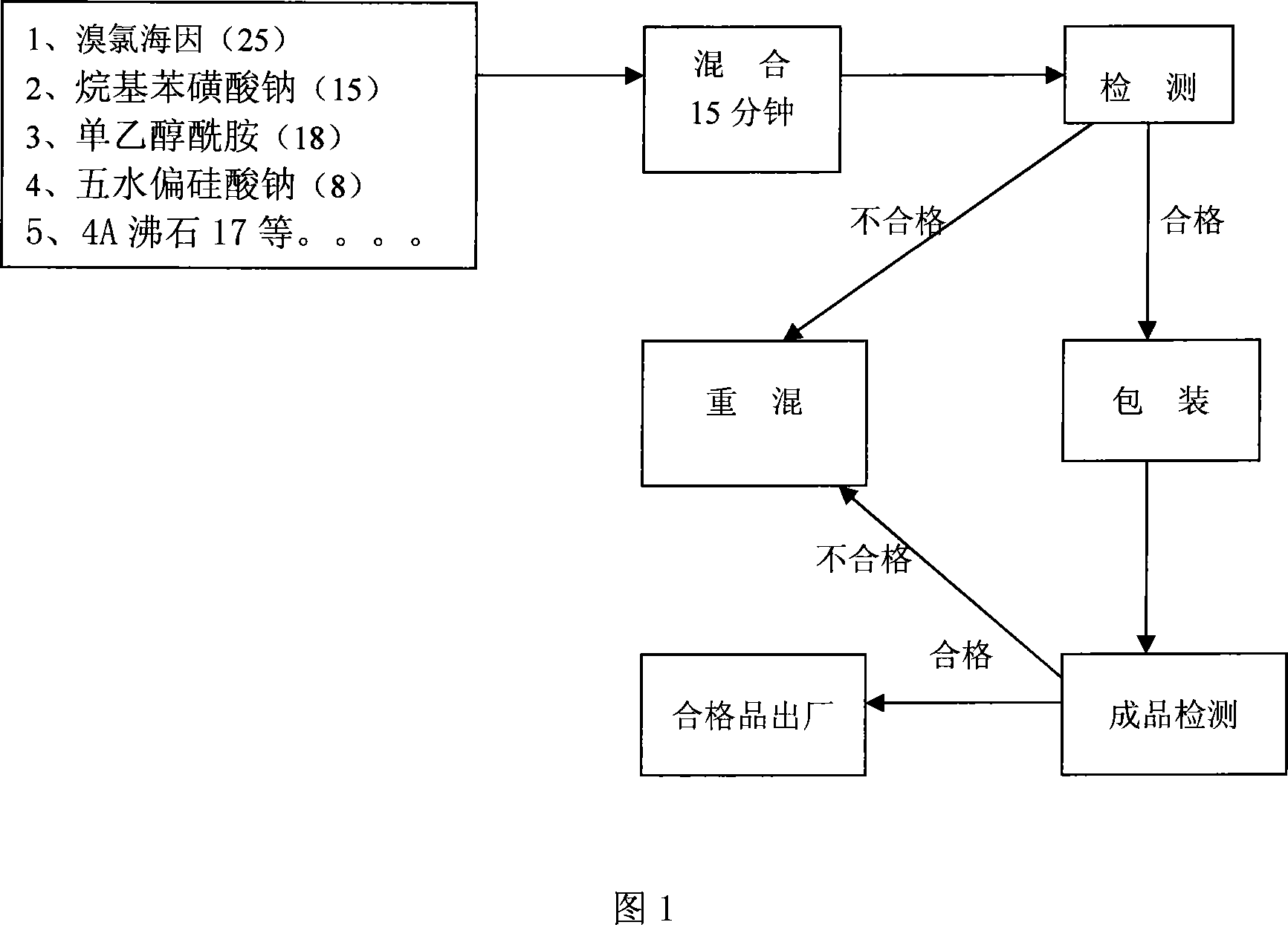

Detergent containing bromochlorohydantoin

InactiveCN101148634AAchieve whiteningTo achieve the effect of deodorizationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydantoin

Owner:广东欧替克生物医学科技有限公司

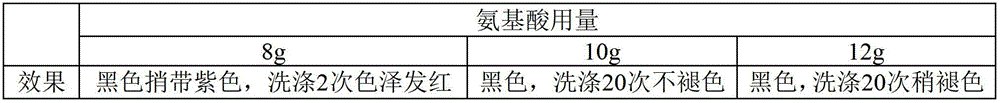

Pure cotton colouring agent and preparation method thereof

ActiveCN103343462ADo not fadeDoes not change colorTransfer printing processDyeing processChemistryGlycerol

The invention discloses a pure cotton colouring agent and a preparation method thereof. The pure cotton colouring agent disclosed by the invention is prepared from the following raw materials: de-ionized water, ethanol, glycerol, amino silicon oil, polyving akohol, hydrogen peroxide, salicylic acid, debonding agent L-303, isotridecyl alcohol polyoxyethylene ether, pigment, hexadecylpyridinium chloride, polyurethane thickening agent, silicone softening agent and polyquaternium-10. According to the invention, patterns can be transferred on pure cotton and polyester cotton by using sublimation transfer paper; the patterns are fadeless, non-discoloring, free from washing and bright-coloured and clear in colour; in addition, after being transferred, cloth is soft and has high colour fastness.

Owner:泗县恒星烫画机械股份有限公司

Scrub resistant diatom ooze coating

InactiveCN105645861AGood water resistance and friction resistanceExtended service lifeCalcium carbonateTitanium oxide

The invention relates to a scrub resistant diatom ooze coating. Raw materials of an existing diatom ooze coating are many, processing and selling costs are high, and coated walls are easy to stain and fall off, easily drop powder, is not resistant to scrubbing and has short service life. By the use of diatomite, sierozem, heavy calcium carbonate powder, white cement, HPMC, redispersible latex powder, titanium oxide and sodium chloride, the coating is manufactured with advantages as follows: raw materials are few; energy is saved and the environment is protected; operation is easy; processing method is simple; cost is low; water resistance is strong; the coating is scrub resistant; no powder drops; durability is good; and the coating is non-toxic and odourless, and has strong covering power, soft color and good decorative effect.

Owner:重庆发顺化工有限责任公司

Method for archaizing and aging wood for buildings

InactiveCN109015995AReduce usageSimple preparation processWood treatment detailsPressure impregnationWaxVacuum pressure

The invention discloses a method for archaizing and aging wood for buildings, relates to the technical field of wood processing technology for the buildings, and aims to solve the problems that the whole wood aging process is uncontrollable, aging treatment is carried out on specific parts with difficulty, and the aging degree is difficult to control meanwhile. The method for archaizing and agingwood for the buildings comprises the technical points that S1, base material treatment is carried out; S2, dipping liquid preparation is carried out; S3, the old part of the wood which needs to be aged is waxed, and the wood stands at normal temperature until the wax is solidified and formed; S4, the remaining part of the wood in the step S3 is coated with preservative, and the aged part of the wood in the step S3 is dewaxed; S5, the whole wood is immersed in the dipping liquid for soaking treatment for 1-2 hours by adopting a vacuum pressure-increasing dipping method; S6, cleaning is carriedout; S7, plasma treatment is carried out; S8, secondary grinding is carried out; and S9, the wood is soaked in an urea aqueous solution and the wood is allowed to dry naturally until the water contentis below 15%. According to the method for archaizing and aging wood for the buildings, the aging effect is uniform and natural, the treatment is deeper and more thorough, and the aging treatment timecan be greatly shortened.

Owner:南通市紫石古典园林建筑工程有限公司

Preservative resin coating

InactiveCN103360936AQuality improvementEasy to useAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention discloses a preservative resin coating. The preservative resin coating comprises the following components in percentage by weight: 60-80% of component A and 20-40% of component B, wherein the component A comprises the following components in parts by weight: 40-50 parts of polyester resin, 14-19 parts of epoxy resin, 8-12 parts of coloring pigments, 5-10 parts of rust-proof pigments, 5-7 parts of filler, 0.5-2 parts of auxiliary agents and 0.5-2 parts of a mixed solvent, the mixed solvent comprises xylene and butyl acetate, and the auxiliary agents include a defoaming agent, an anti-settling agent and a thixotropic agent; and the component B the following components in parts by weight: 0.5-1 part of plasticizer, 3-8 parts of tricarboxymethyl propane, 8-15 parts of butyl acetate, 15-25 parts of toluene diisocynate, 6-15 parts of xylene, 1-3 parts of cyclohexanone and 0.5-2 parts of polyurethane dehydrant. According to the preservative resin coating disclosed by the invention, the quality is stable, the polyester resin and the epoxy resin are taken as base materials to form an interpenetrating polymer network to endow the coating with compactness, the preservative property and the adhesive force are greatly improved, and the preservative resin coating cannot blister, rust, fade and fall in a long time.

Owner:南京市荣达树脂有限公司

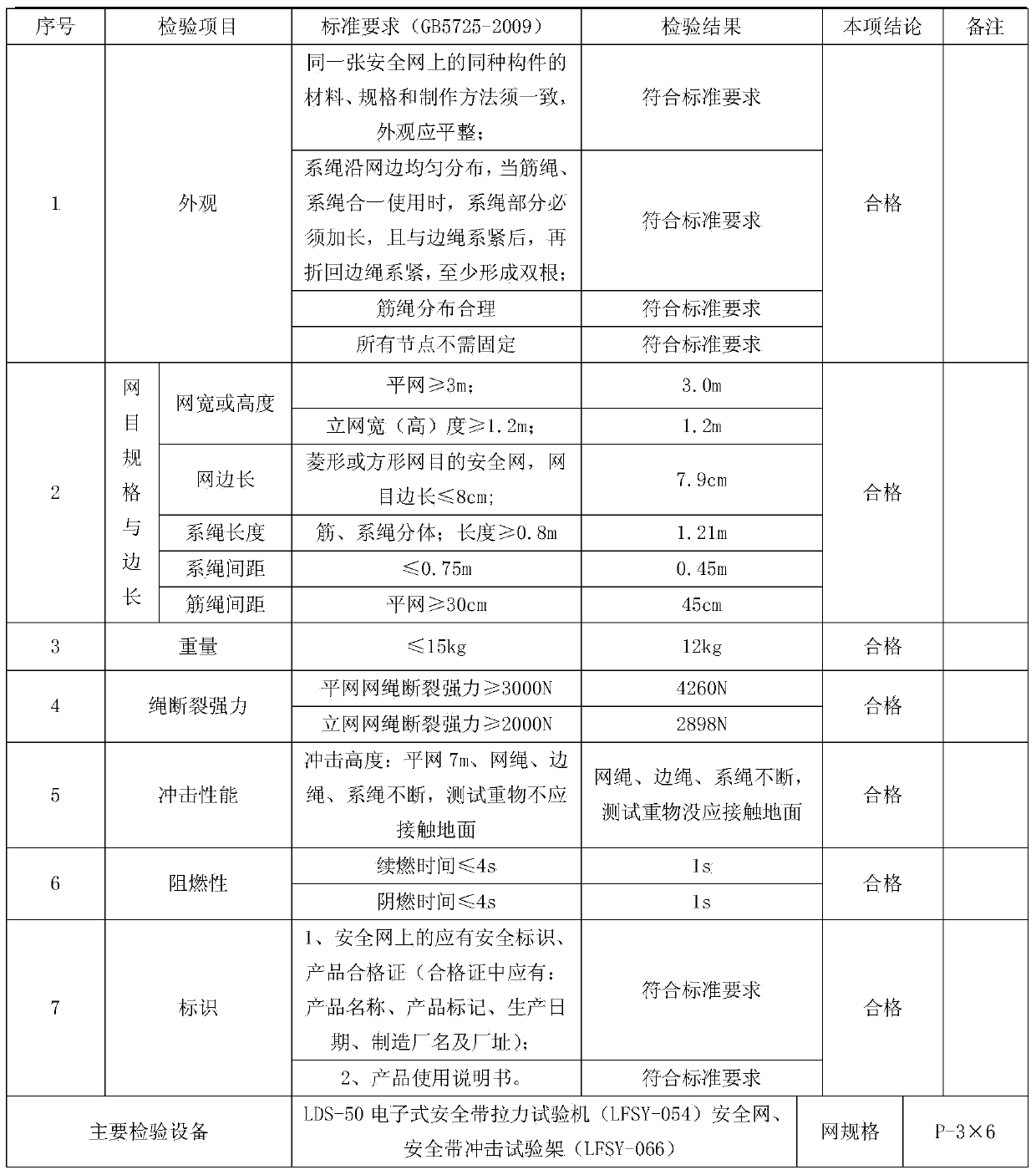

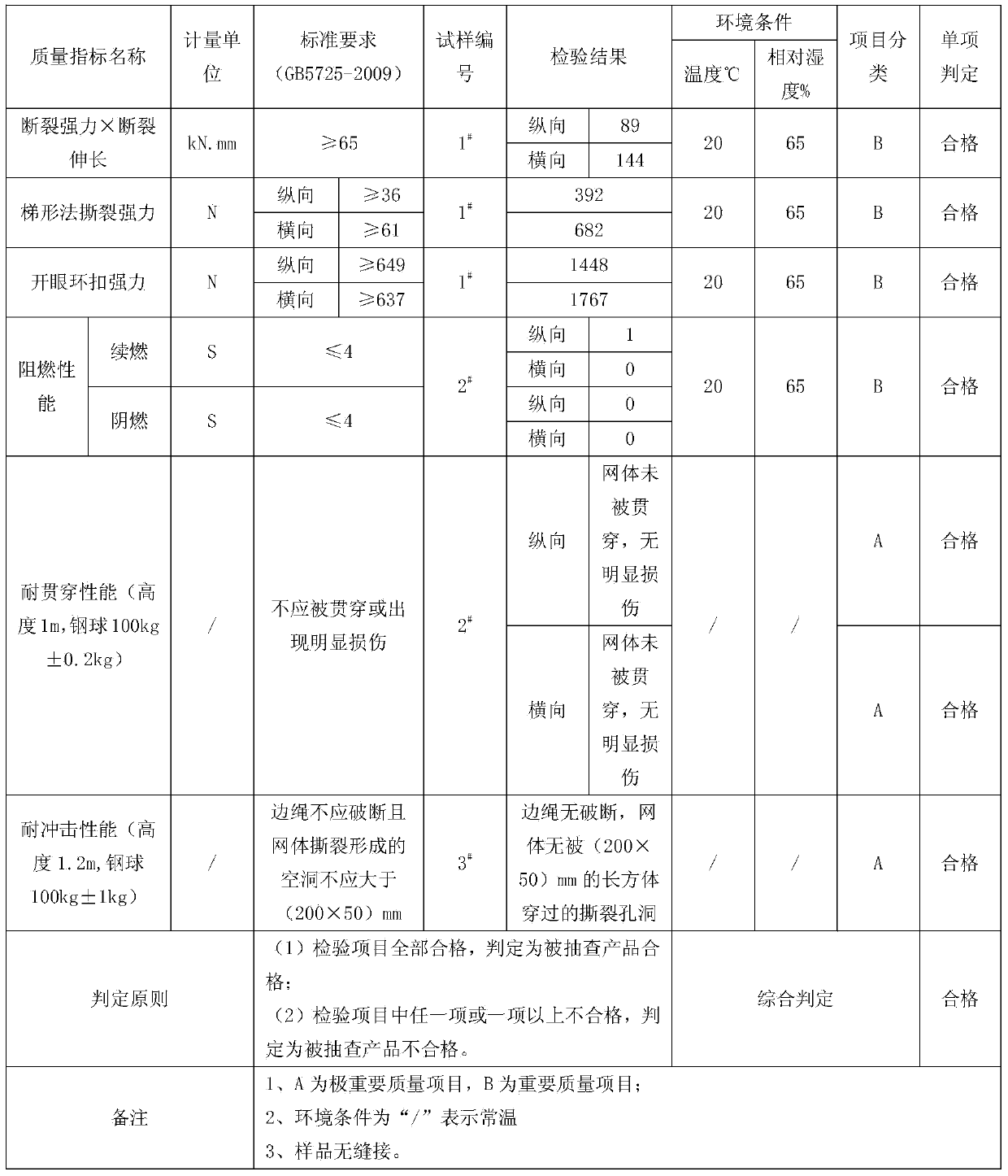

Method for manufacturing safety nets by waste polyester bottles

ActiveCN104178841AImprove performanceIncrease elasticityFlame-proof filament manufacturePigment addition to spinning solutionPolyesterSafety net

The invention relates to the technical field of safety net manufacturing technology and particularly relates to a method for manufacturing safety nets by waste polyester bottles. By improvements on a technological process, technological conditions, equipment and the like, different types of safety nets, such as a horizontal safety net, a vertical safety net and a fine-mesh vertical safety net, can be obtained according to different warp knitting approaches. The safety nets obtained by virtue of the method have good strength performance and a good anti-aging effect; besides, the waste polyester bottles are used to replace polypropylene (PP) resin as a raw material for producing the safety nets, not only is the energy saved, but also the production cost is lowered, and the method conforms to national industrial policy requirements and has an outstanding substantive characteristic and remarkable progress.

Owner:山东滨州波涛化纤制品有限公司

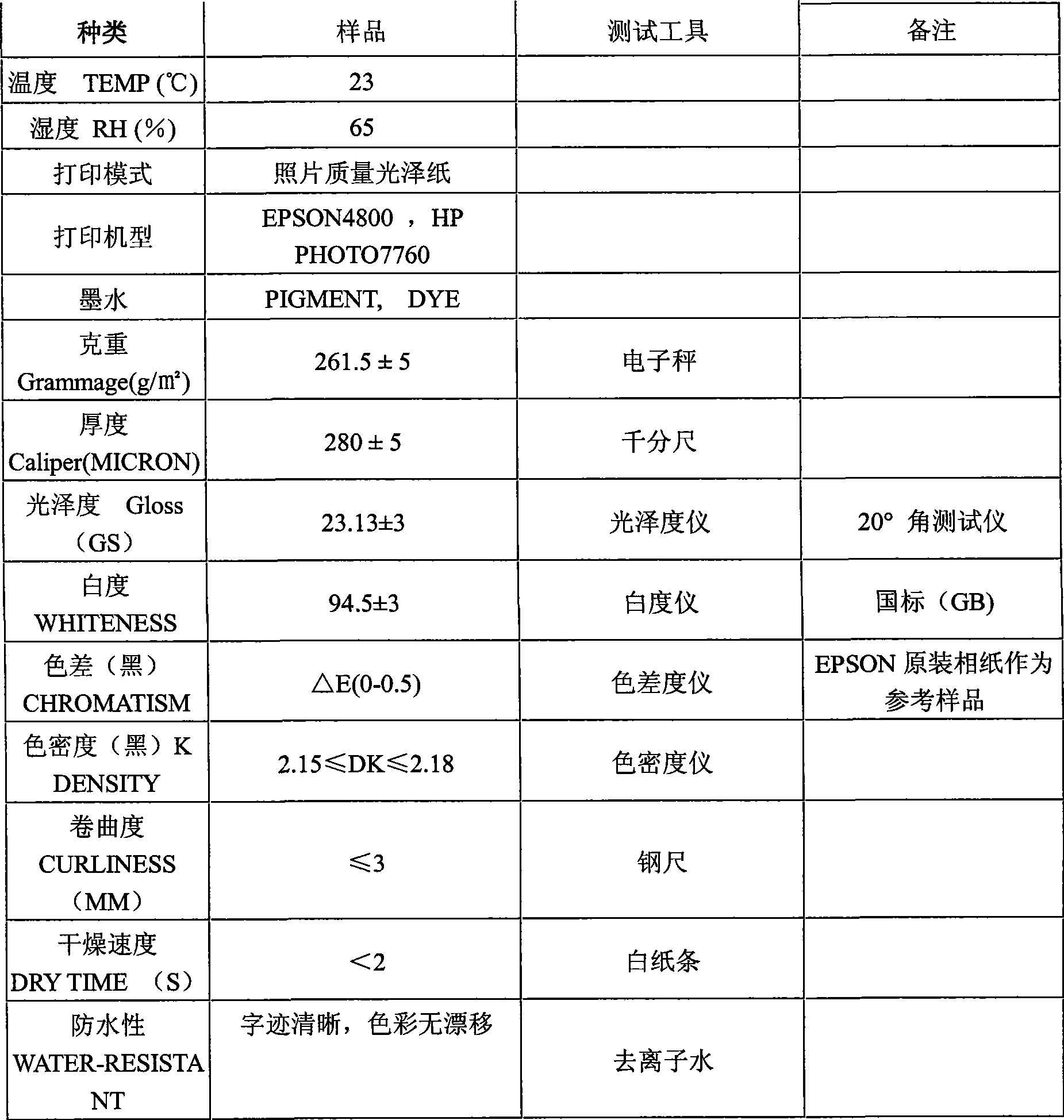

A silicon oxide ink-jet coating and a manufacturing method thereof

InactiveCN101544143ASolve problems that are prone to reunionImprove surface smoothnessCoatingsWhitening AgentsPolyvinyl alcohol

The invention relates to a silicon oxide ink-jet coating and a manufacturing method thereof. The coating comprises the components of 50 to 52 weight ratios of silica sol, 0.1 to 0.3 weight ratios of cross linker, 29 to 31 weight ratios of water, 12 to 14 weight ratios of isopropanol, 1 to 3 weight ratios of polyvinyl alcohol, 0.05 to 0.15 weight ratios of surface active agent, 3 to 4 weight ratios of cationic coloring stabilizer and 0.17 to 0.23 weight ratios of liquor whitening agent. The method includes the following steps of sequentially mixing, stirring and cutting the silica sol, water, isopropanol, cross linker and polyvinyl alcohol, adding and cutting the surface active agent, liquor whitening agent and the cationic coloring stabilizer, filtering and standing to eliminate bubbles and getting the finished product. The coating and manufacturing method solve the problem of easy glomeration of nanometer materials and the coating has high surface smoothness, glossiness and fine water resistance. Printed images are bright in color and high in temperature resistance and do not fade after being saved for a long time. The whole manufacturing is simple and suitable for quantity production.

Owner:惠州艺都文化用品有限公司

All natural ingredient hair dye and preparation method thereof

InactiveCN102871932ASafe and non-toxic side effectsGood hair dyeing effectCosmetic preparationsHair cosmeticsHerbSide effect

The invention discloses all natural ingredient hair dye which comprises dyeing combination drug, pretreating agent and dye mordant. The dyeing combination drug comprises fleece-flower root, prepared rehmannia root, henna, indigofera tinctoria and herb of yerbadetajo. The all natural ingredient hair dye has good hair-dyeing effect and a natural color, the color can not fade after long term washing, and the dyeing recipe is safe and does not have toxic or side effects.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com