Method for manufacturing safety nets by waste polyester bottles

A production method, polyester bottle technology, applied in the direction of single-component polyester artificial filament, stretch spinning method, fire-resistant and flame-retardant filament manufacturing, etc., can solve the problems of poor weather resistance, easy oxidation, etc., and achieve anti-aging effect Good, good elasticity, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

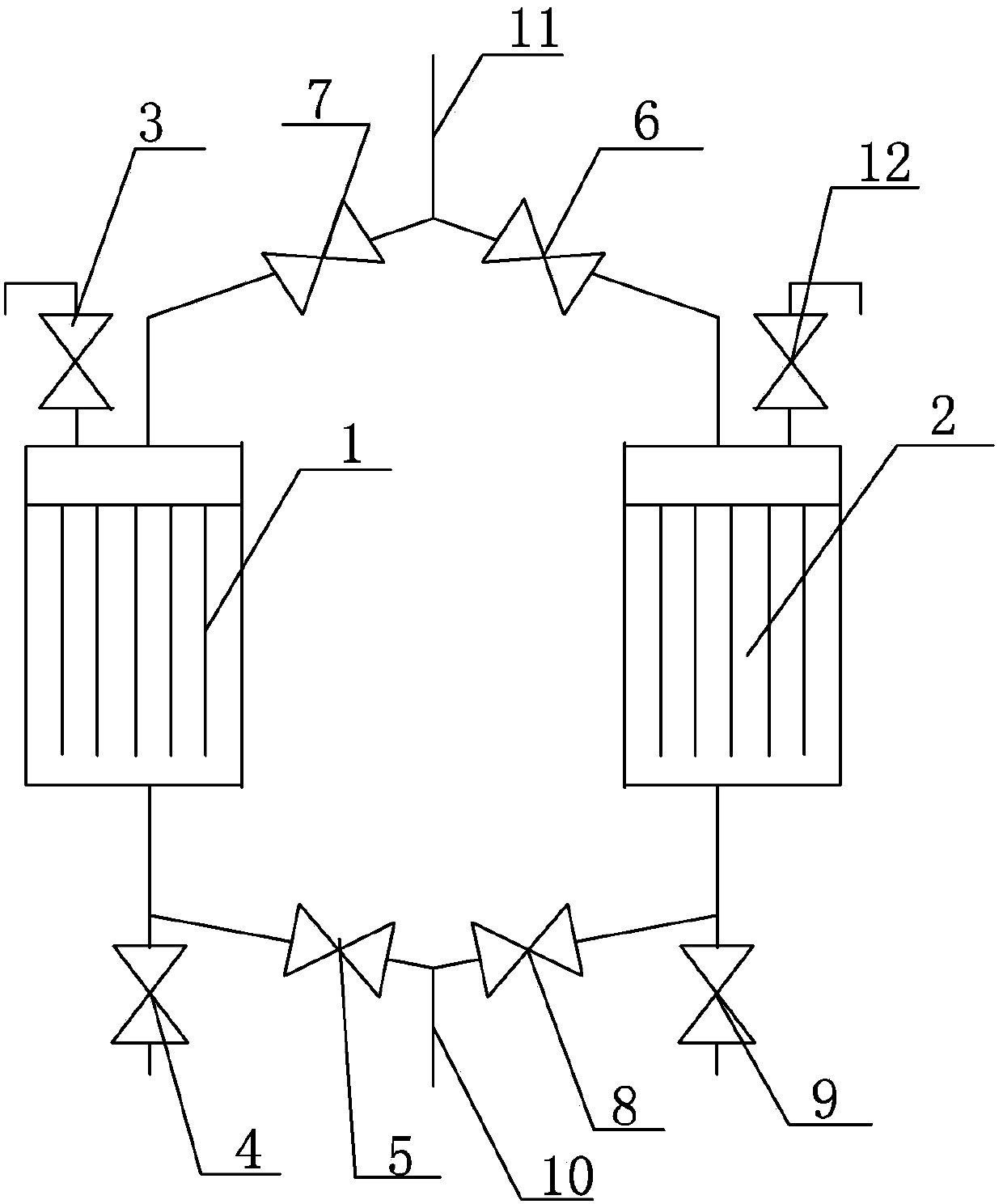

Method used

Image

Examples

Embodiment 1

[0040] (1) Crushing and cleaning: cut and crush PET recycled materials into bottle flakes with a diameter of about 12mm-14mm, and then hot wash with clean water (water temperature 85°C) and dehydrate;

[0041] (2) Ingredients: According to the ratio of PET recycled material 96%, masterbatch 3% (G4272A for polyester), flame retardant 1%, weigh 1500kg of raw materials (TA9098 halogen-free flame retardant);

[0042] (3) Crystallization drying: The raw materials are sent to the crystallization drying device (vacuum drum dryer) through the feeder and continuously rolled and stirred, heated to 140°C by the heat medium for crystallization for 2 hours, and then dried at this temperature for 4 hours. Hours, during which the vacuum pump is used to continuously evacuate, so that negative pressure is generated in the crystallization drying device, the pressure is 0.8mPa, and the moisture contained in the raw material and the smoke generated by impurities in the high temperature process are...

Embodiment 2

[0050] (1) Crushing and cleaning: Cut and crush PET recycled materials into bottle flakes with a diameter of about 12mm-14mm, then hot wash with clean water (water temperature 90°C), and dehydrate;

[0051] (2) Ingredients: According to the ratio of PET recycled material 97%, masterbatch 1% (G4272A for polyester), flame retardant 2%, weigh 1500kg of raw materials (TA9098 halogen-free flame retardant);

[0052] (3) Crystallization drying: The raw materials are sent to the crystallization drying device (vacuum drum dryer) through the feeder and continuously rolled and stirred, heated to 160°C by the heat medium for crystallization for 2 hours, and then dried at this temperature for 6 Hours, during which the vacuum pump is used to continuously evacuate, so that negative pressure is generated in the crystallization drying device, the pressure is 0.95mPa, and the moisture contained in the raw material and the smoke generated by impurities in the high temperature process are extracte...

Embodiment 3

[0060] Others are the same as Implementation 1, the difference is that in the step (1), the ratio of raw materials is: 98% of recycled PET, 1.5% of color masterbatch, 0.5% of flame retardant; Heating to 180°C; drying at 180°C in the step (4) and keeping it warm for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com