Dispersion-reduction dyeing process for cotton-polyester blended fabric

A technology of polyester-cotton blending and disperse dyes, applied in the field of printing and dyeing, which can solve problems such as fading, unusable clothing, and unsatisfactory dyeing effect, and achieve good quality, good dyeing effect, and good level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

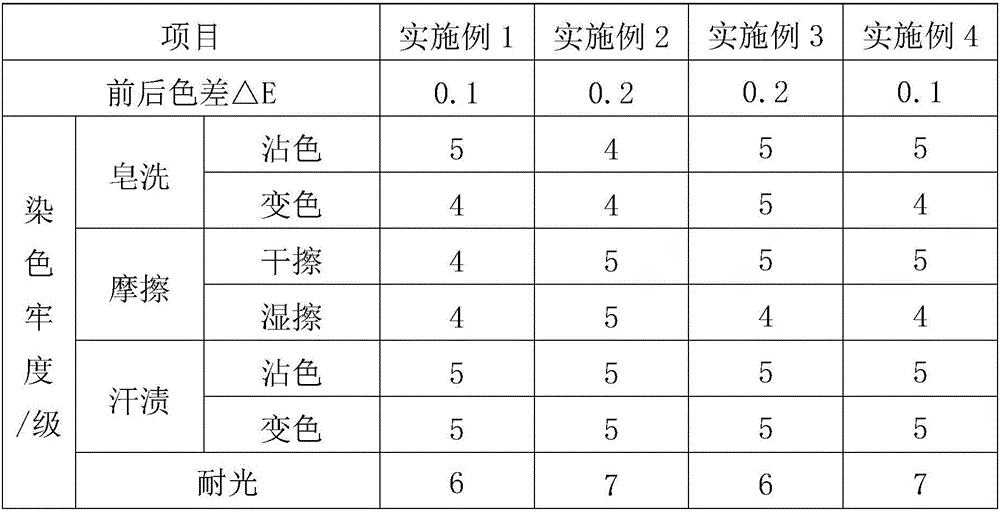

Examples

Embodiment 1

[0022] In this embodiment, a disperse vat dyeing process for polyester-cotton blended fabrics includes sequentially performing a disperse dye treatment process and a vat dye treatment process; the disperse dye treatment process includes dyeing, reduction cleaning, water washing and pickling; the vat dye The treatment process includes padding of vat dye suspension, padding of reducing solution, steaming, oxidation, soaping, hot washing and drying;

[0023] In the disperse dye treatment process, the disperse dye microcapsule method is used for dyeing, and the dye solution formula includes: disperse dye microcapsule body 2.5% (owf), glacial acetic acid 2g / L, sodium acetate 1g / L, leveling agent 2g / L, adjusting the bath ratio to 1:25, dipping the polyester-cotton blended fabric into the dyeing liquor for dyeing, entering the dyeing at 36°C, raising the temperature to 68°C at a speed of 2.3°C / min, keeping it warm for 8min, and then dyeing at 1.3°C Raise the temperature to 115°C at a...

Embodiment 2

[0026] In this embodiment, a disperse vat dyeing process for polyester-cotton blended fabrics includes sequentially performing a disperse dye treatment process and a vat dye treatment process; the disperse dye treatment process includes dyeing, reduction cleaning, water washing and pickling; the vat dye The treatment process includes padding of vat dye suspension, padding of reducing solution, steaming, oxidation, soaping, hot washing and drying;

[0027] In the disperse dye treatment process, the disperse dye microcapsule method is used for dyeing, and the dye solution formula includes: disperse dye microcapsule body 1% (owf), glacial acetic acid 2g / L, sodium acetate 1g / L, leveling agent 2g / L, adjusting the bath ratio to 1:15, dipping the polyester-cotton blended fabric into the dyeing liquor for dyeing, entering the dyeing at 40°C, raising the temperature to 75°C at a speed of 2°C / min, keeping it warm for 5min, and then dyeing at 1.5°C Raise the temperature to 100°C at a speed...

Embodiment 3

[0032] In this embodiment, a disperse vat dyeing process for polyester-cotton blended fabrics includes sequentially performing a disperse dye treatment process and a vat dye treatment process; the disperse dye treatment process includes dyeing, reduction cleaning, water washing and pickling; the vat dye The treatment process includes padding of vat dye suspension, padding of reducing solution, steaming, oxidation, soaping, hot washing and drying;

[0033] In the disperse dye treatment process, the disperse dye microcapsule method is used for dyeing, and the dye solution formula includes: disperse dye microcapsule body 3% (owf), glacial acetic acid 1g / L, sodium acetate 2g / L, leveling agent 1g / L, adjust the bath ratio to 1:30, dip the polyester-cotton blended fabric into the dyeing liquor for dyeing, enter the dyeing at 30°C, raise the temperature to 65°C at a speed of 2.5°C / min, keep it warm for 10min, and then dye it at 1°C Raise the temperature to 120°C at a speed of 1 / min, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com