A silicon oxide ink-jet coating and a manufacturing method thereof

A silicon oxide and silicon dioxide technology, applied in the coating and other directions, can solve the problems of far different printing effect, poor ink absorption performance, inability to waterproof, etc., and achieve the effect of bright color, long storage time and small environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be described in further detail below in conjunction with specific embodiments:

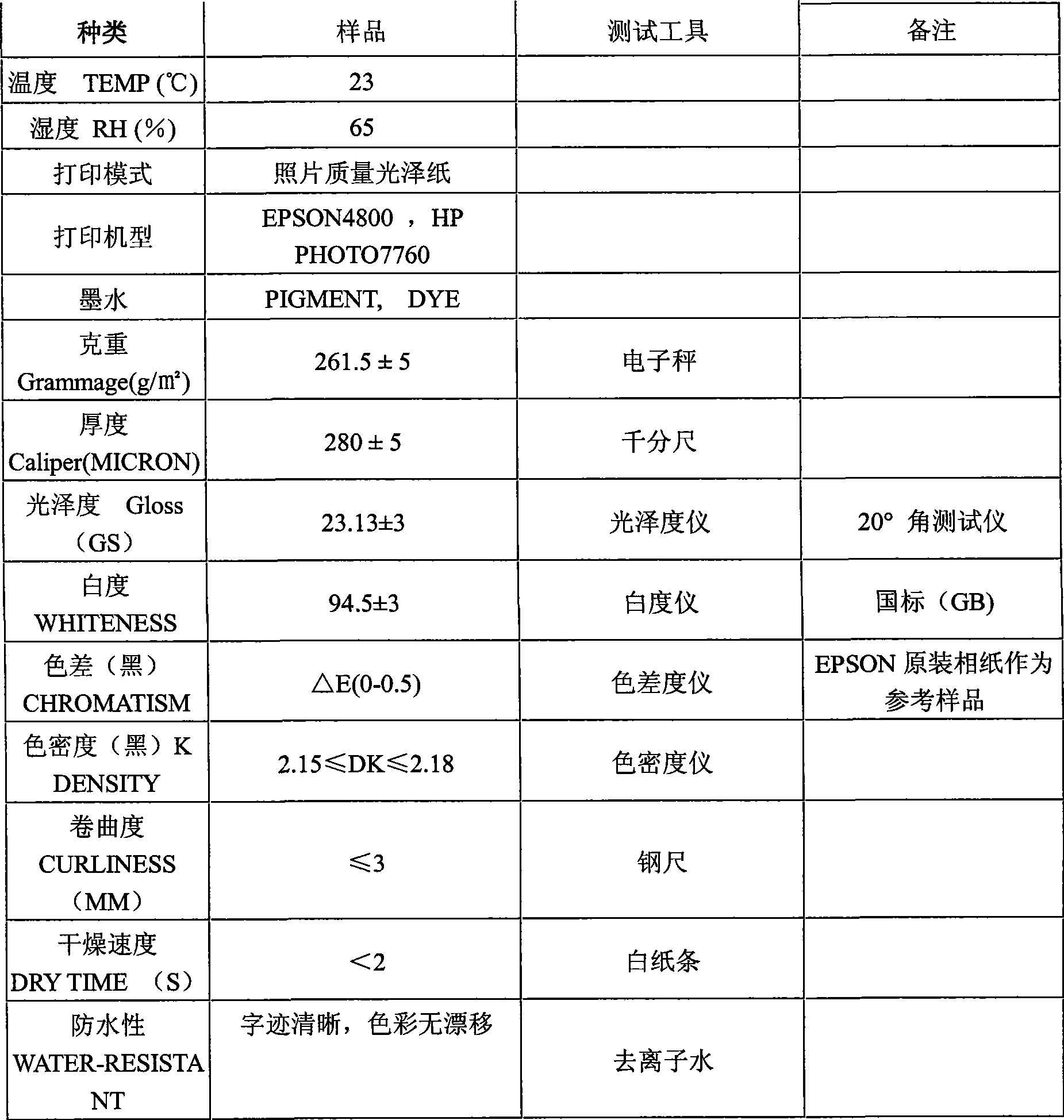

[0021] This embodiment discloses a silicon oxide inkjet coating. According to the weight ratio, the coating components are: 51 parts of silica sol, 0.2 parts of crosslinking agent, 30 parts of water, 13 parts of isopropanol, 2 parts of polyvinyl alcohol, surface 0.1 part of active agent, 3.5 parts of cationic color fixing agent, and 0.2 part of liquid whitening agent.

[0022] Wherein, the silica sol is a nano-scale silica sol. By adding a surfactant, the problem of easy agglomeration of nano-scale materials is solved, so that the coating has high surface smoothness and high gloss. The molecular formula of the silica sol can be expressed as mSiO2nH2O, Wherein the solid content of the silicon dioxide is 15%, and the particle size of the silicon dioxide is between 15 and 35 nanometers. The used s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com