A kind of process method for preparing nano-silver solder paste based on inverse microemulsion system

A technology of inverse microemulsion and process method, which is applied in the field of preparation of nano-silver solder paste based on inverse microemulsion system, which can solve the problems of insufficient stability of inverse microemulsion system and easy agglomeration of nanoparticles, and achieve stability Insufficient, solving reunion, enhancing the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

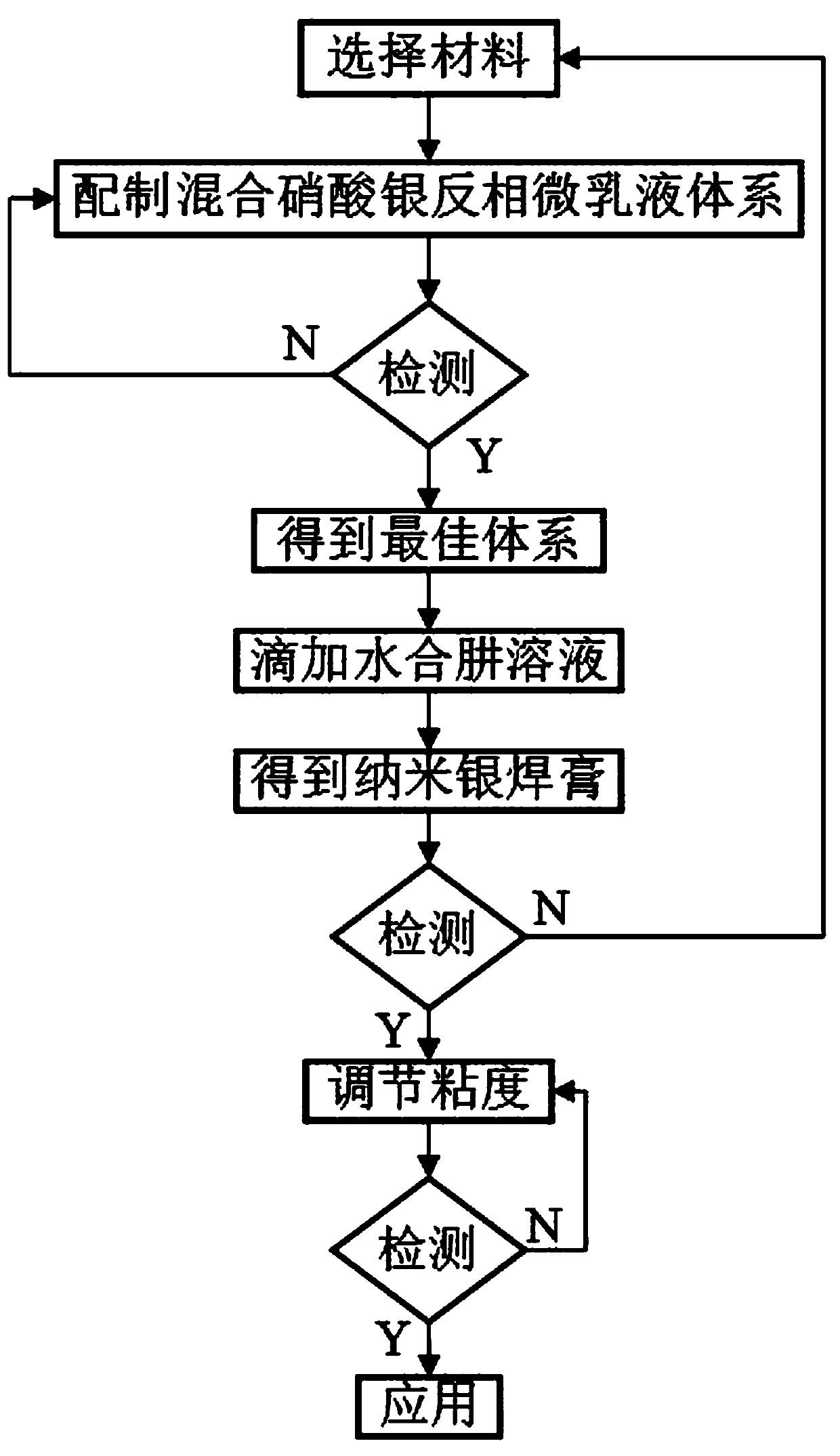

Image

Examples

preparation example Construction

[0030] (1) Preparation of mixed silver nitrate aqueous solution, dissolving silver nitrate particles in distilled water to prepare a certain concentration of silver nitrate aqueous solution, adding dropwise polymer electrolytes of different qualities, to prepare mixed silver nitrate aqueous solutions containing different polymer electrolyte mass percentages;

[0031] (2) Preparation of hydrazine hydrate solution, dissolving the hydrazine hydrate solution in distilled water to obtain a certain concentration of hydrazine hydrate solution;

[0032] (3) Prepare polymer electrolyte aqueous solution inverse microemulsion and draw pseudo-ternary phase diagram;

[0033] Set the amount of surfactant, co-surfactant and oil phase organic matter as m1, m2, m3 respectively, and take different m1 / m2 values, first assume (m1+m2): m3=1:1 is the best ratio, and the surface activity Agent, co-surfactant and oil-phase organic matter were added to the beaker in turn, and mixed silver nitrate aque...

Embodiment 1

[0045] A preparation process of nano-silver solder paste, comprising the steps of:

[0046] 1) Preparation of mixed silver nitrate aqueous solution: Dissolve silver nitrate particles in distilled water to prepare a silver nitrate aqueous solution with a concentration of 0.1mol / L, and add polyethyleneimine (PEI) of different qualities to the silver nitrate aqueous solution to prepare polyethyleneimine containing Imine mass percent is respectively 0.1%, 0.5%, 1%, 5%, 10% mixed silver nitrate aqueous solution;

[0047] 2) Preparation of hydrazine hydrate solution: Dissolve hydrazine hydrate solution in distilled water to obtain 0.5mol / L hydrazine hydrate solution;

[0048] 3) Prepare polymer electrolyte aqueous solution inverse microemulsion and draw pseudo-ternary phase diagram:

[0049]Record the mass of Triton X-100, n-hexanol and n-heptane as m1, m2 and m3 respectively, take m1: m2=(9:1, 8:2, 7:3, 6:4, 5:5, 4:6 , 3:7, 2:8, 1:9), (m1+m2): m3=1:1, add Triton X-100, n-hexanol ...

Embodiment 2

[0055] According to the same method as in Example 1, PVP was used instead of Triton X-100 as the surfactant, n-hexanol was used as the co-surfactant, n-heptane was used as the oil phase organic matter, and polyethyleneimine was used as the stabilizer to form a modified polymer electrolyte. Nano-silver solder paste was prepared from a permanent inverse microemulsion system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com