Magnetic graphene-based airgel material with magnetic field and pressure sensing effect and preparation method thereof

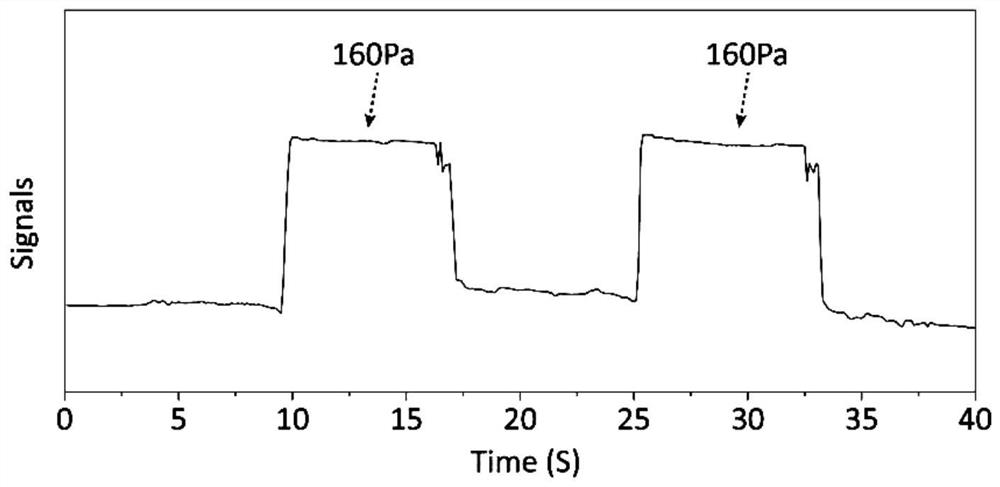

A magnetic graphene and aerogel technology, applied in the direction of the size/direction of the magnetic field, graphene, and the measurement of the change force of the magnetic property of the material caused by the applied stress, can solve the problem of inability to achieve fast response and high sensitivity , The magnetic field detection range is small, the resistance value change is small, etc., to achieve good magnetic field sensing performance, good electromagnetic performance and mechanical performance, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

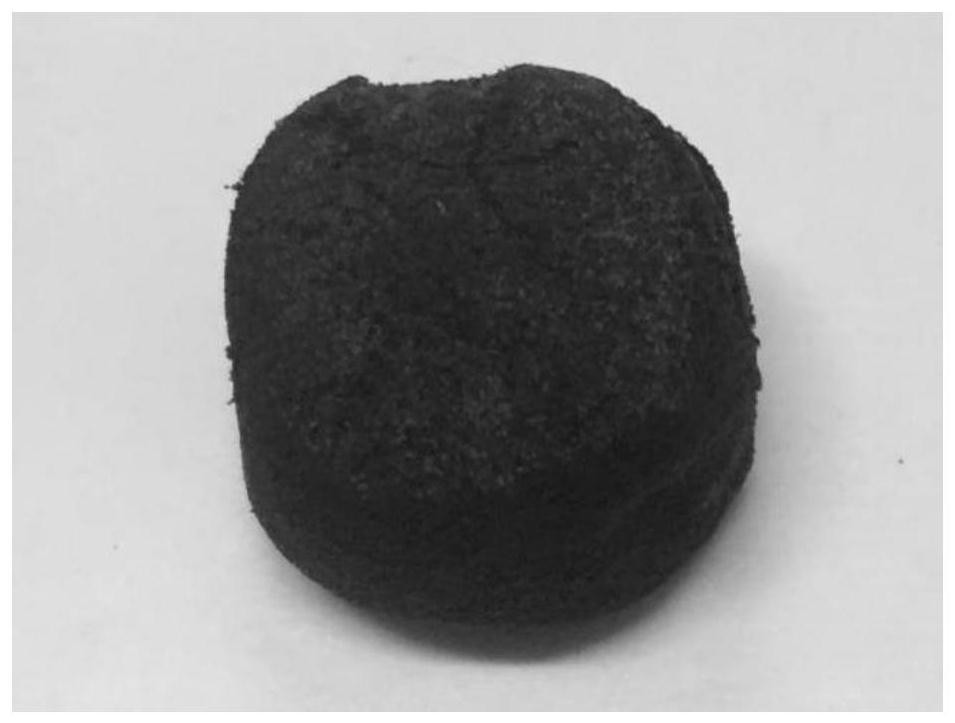

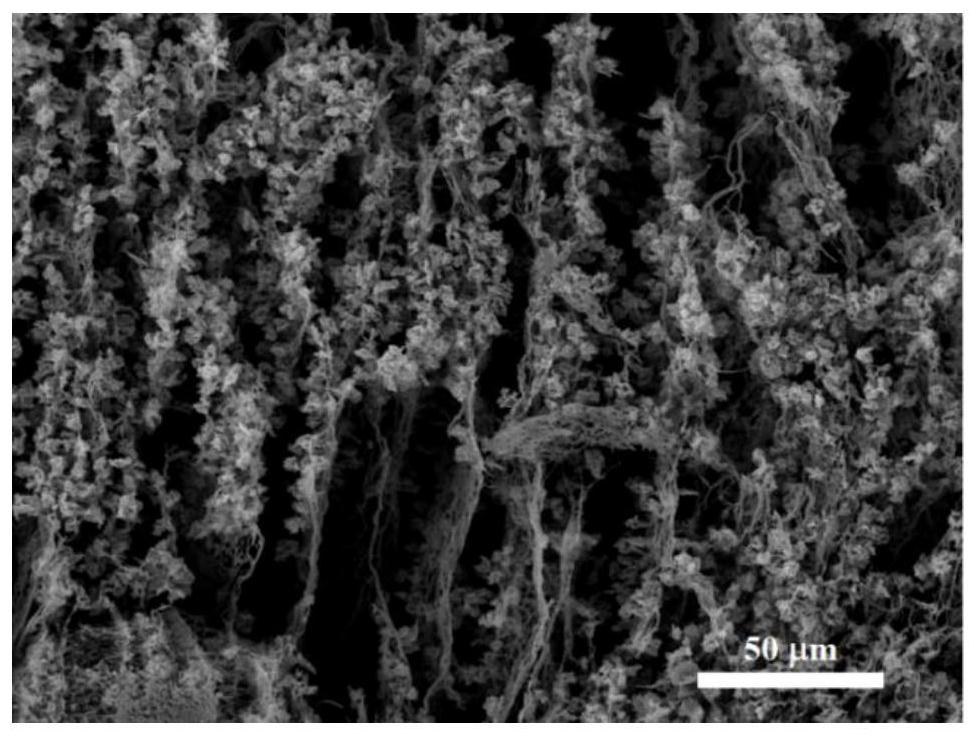

[0054] This embodiment provides a method for preparing a magnetic graphene-based airgel material, and the specific preparation process is as follows:

[0055] 1) Preparation of reduced graphene oxide solution: use natural graphite powder, concentrated sulfuric acid, potassium persulfate, phosphorus pentoxide, and potassium permanganate as raw materials to prepare graphene oxide through the improved Hummers method, and uniformly disperse it in deionized water A graphene oxide aqueous solution is obtained. Put the graphene oxide aqueous solution in a 500mL beaker, add ethylenediamine solution, heat it in a water bath to 60-90°C, reduce it under stirring for 1-6 hours, take it out and dialyze it with deionized water for 12-24 hours to obtain reduced graphene oxide solution.

[0056] 2) Preparation of nanofiber suspension: thermoplastic PVA-co-PE masterbatch and cellulose acetate butyrate (CAB) powder are mixed according to a certain quality and then melted and extruded to obtain...

Embodiment 2

[0061] This embodiment provides a method for preparing a magnetic graphene-based airgel material, and the specific preparation process is as follows:

[0062] 1) Preparation of reduced graphene oxide solution: use natural graphite powder, concentrated sulfuric acid, potassium persulfate, phosphorus pentoxide, and potassium permanganate as raw materials to prepare graphene oxide through the improved Hummers method, and uniformly disperse it in deionized water A graphene oxide aqueous solution is obtained. Put the graphene oxide aqueous solution in a 500mL beaker, add ethylenediamine solution, heat it in a water bath to 60-90°C, reduce it under stirring for 1-6 hours, take it out and dialyze it with deionized water for 12-24 hours to obtain reduced graphene oxide solution.

[0063] 2) Preparation of nanofiber suspension: thermoplastic PVA-co-PE masterbatch and cellulose acetate butyrate (CAB) powder are mixed according to a certain quality and then melted and extruded to obtain...

Embodiment 3

[0068] This embodiment provides a method for preparing a magnetic graphene-based airgel material, and the specific preparation process is as follows:

[0069] 1) Preparation of reduced graphene oxide solution: use natural graphite powder, concentrated sulfuric acid, potassium persulfate, phosphorus pentoxide, and potassium permanganate as raw materials to prepare graphene oxide through the improved Hummers method, and uniformly disperse it in deionized water A graphene oxide aqueous solution is obtained. Put the graphene oxide aqueous solution in a 500mL beaker, add ethylenediamine solution, heat it in a water bath to 60-90°C, reduce it under stirring for 1-6 hours, take it out and dialyze it with deionized water for 12-24 hours to obtain reduced graphene oxide solution.

[0070] 2) Preparation of nanofiber suspension: thermoplastic PVA-co-PE masterbatch and cellulose acetate butyrate (CAB) powder are mixed according to a certain quality and then melted and extruded to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com