A kind of preparation method and application of modified nano-calcium carbonate for rubber

A nano-calcium carbonate, modification technology, applied in nanotechnology, calcium carbonate/strontium/barium, nanotechnology, etc. for materials and surface science, can solve the problem of small particle size, poor dispersion and compatibility of nano-calcium carbonate Insufficient and other problems, to achieve the effect of improving compatibility, promoting crystallization, and improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

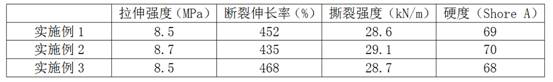

Examples

Embodiment 1

[0023] A kind of preparation method of modified nano calcium carbonate for rubber, it comprises the following steps:

[0024] (1) Take chlorella protein and deionized water and mix them evenly according to the mass ratio of 1:3, then add citric acid to adjust the pH value to 5, and then add protease and heat to 55 °C for 3 hours under stirring conditions to obtain a mixed solution A is for subsequent use; the ratio of the addition of the protease to the mass of the chlorella protein is 1500U:1g;

[0025] (2) Mix high-purity calcium oxide and deionized water with a mass ratio of 1:3 under stirring conditions at a speed of 300 r / min to obtain slurry A, pass the slurry A through a 100-mesh sieve, and filter and remove the slag. Then add 15 times the mass of deionized water to slurry A to dilute to obtain slurry B, then add mixed solution A obtained in step (1) to slurry B, heat to 85°C, and stir at constant temperature for 1.5h Slurry C is obtained; the mass ratio of the added a...

Embodiment 2

[0032] A kind of preparation method of modified nano calcium carbonate for rubber, it comprises the following steps:

[0033] (1) Take chlorella protein and deionized water and mix them evenly according to the mass ratio of 1:4, then add citric acid to adjust the pH value to 5.5, and then add protease and heat to 60 °C under stirring for 2.5 hours at a constant temperature to obtain mixing Liquid A is for subsequent use; the ratio of the addition of the protease to the quality of the chlorella protein is 1300U: 1g;

[0034](2) Mix high-purity calcium oxide and deionized water with a mass ratio of 1:4 under stirring conditions at a speed of 350 r / min to obtain slurry A, pass the slurry A through a 100-mesh sieve, and filter and remove the slag. Then, deionized water with 13 times the mass of slurry A was added to slurry A to dilute to obtain slurry B, and then mixed solution A obtained in step (1) was added to slurry B, heated to 80 °C, and stirred at constant temperature for 1...

Embodiment 3

[0041] A kind of preparation method of modified nano calcium carbonate for rubber, it comprises the following steps:

[0042] (1) Take chlorella protein and deionized water and mix them evenly according to the mass ratio of 1:2, then add citric acid to adjust the pH value to 6, then add protease and heat to 50 °C for 2 hours under stirring conditions to obtain a mixed solution A is for subsequent use; the ratio of the addition of the protease to the mass of the chlorella protein is 1200U:1g;

[0043] (2) Mix high-purity calcium oxide and deionized water with a mass ratio of 1:5 under stirring conditions at a speed of 400 r / min to obtain slurry A, pass the slurry A through a 100-mesh sieve, and filter and remove slag. Then, 14 times the mass of slurry A was added to slurry A to dilute with deionized water to obtain slurry B. Then, mixed solution A obtained in step (1) was added to slurry B, heated to 90°C, and stirred at constant temperature for 2 hours to obtain slurry B. Slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com