Method for machining and manufacturing electric folding gate by adopting hot dip galvanizing static plastic spraying pipe

A technology of electric telescopic and electrostatic spraying, which is used in gates/doors, devices for coating liquids on surfaces, pre-treatment surfaces, etc. problem, to achieve the effect of high anti-fouling performance and surface self-cleaning performance, improving the overall aesthetics, and the color will not fade for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

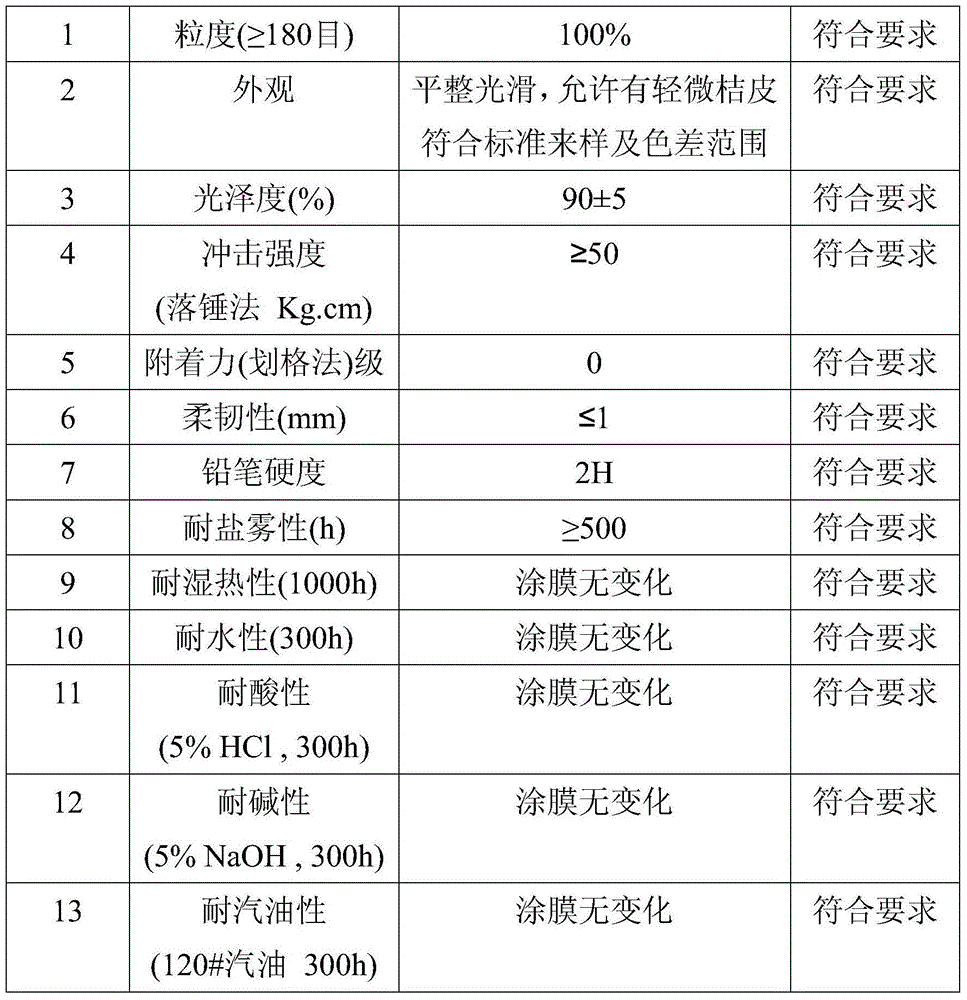

[0025] A method for processing and producing electric telescopic doors by using hot-dip galvanized electrostatic spray pipes, the specific steps are as follows:

[0026] (1) The outer surface of the steel pipe used must not be sticky with oil, and must not have uneven corrosion. It is not allowed to stick markers on the inner and outer walls of the steel pipe, and the steel pipe must not be artificially bent during transportation;

[0027] (2) Use 18-20% hydrochloric acid aqueous solution to pickle 2-5 tons of steel pipes for 5-15 minutes. When the pipe is lowered into the acid tank, the steel pipe is inclined at 15°. Lift one side of the steel pipe for 3 times before lifting the other side for 3 After repeating twice, lift the steel pipe. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com