High-temperature coating method of graphene anti-corrosion layer of copper alloy composite material

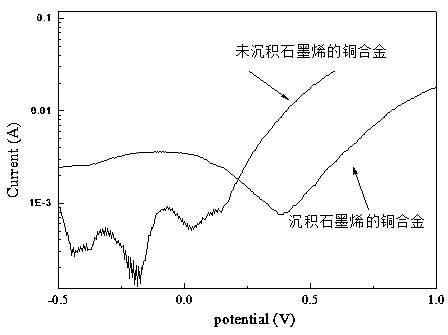

A technology of composite materials and copper alloys, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems such as the difficulty of graphene coating, field and quantity limitations, easy softening and falling off, etc. to improve anti-corrosion requirements. Achieve the effects of strong anti-corrosion performance, continuous performance, stable material, and remarkable high-temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

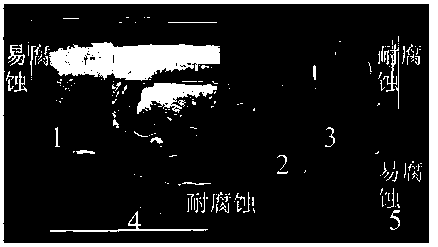

Image

Examples

Embodiment 1

[0030] A high-temperature coating method of a graphene anticorrosion layer of a copper alloy composite material, the steps are as follows:

[0031] (1) Pre-treatment of copper alloy coating:

[0032] Put the BFE10-1-1 copper alloy sheet into acetone and ultrasonically vibrate for 5 minutes to clean its surface and dry it with nitrogen, then put it into deionized water and ultrasonically vibrate for 5 minutes to clean its surface and dry it with nitrogen;

[0033] Soak in 2 mol / L dilute hydrochloric acid for 10 minutes, then soak in deionized water for 10 minutes and dry;

[0034] The surface was cleaned by ultrasonic vibration in acetone for 5 min and dried with nitrogen gas.

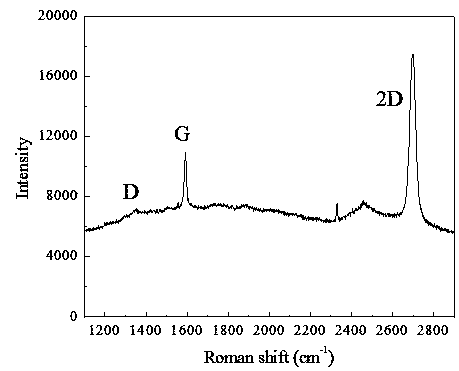

[0035] (2) High temperature coating of graphene anti-corrosion coating:

[0036] Put the treated copper alloy sheet into a sealed tube furnace, and pass in hydrogen gas, the gas flow rate is 500 sccm, the pressure is 0.5 Pa, heated from room temperature to 700 ° C, the heating rate is 5 ° C / min, and...

Embodiment 2

[0039] This embodiment adopts the same preparation method as that of Embodiment 1, the difference being that the temperature of graphene high-temperature coating is 1000°C.

Embodiment 3

[0041] This embodiment adopts basically the same preparation method as that of Embodiment 1, except that the temperature of graphene high-temperature coating is 1200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com