Patents

Literature

31results about How to "Simple coating method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

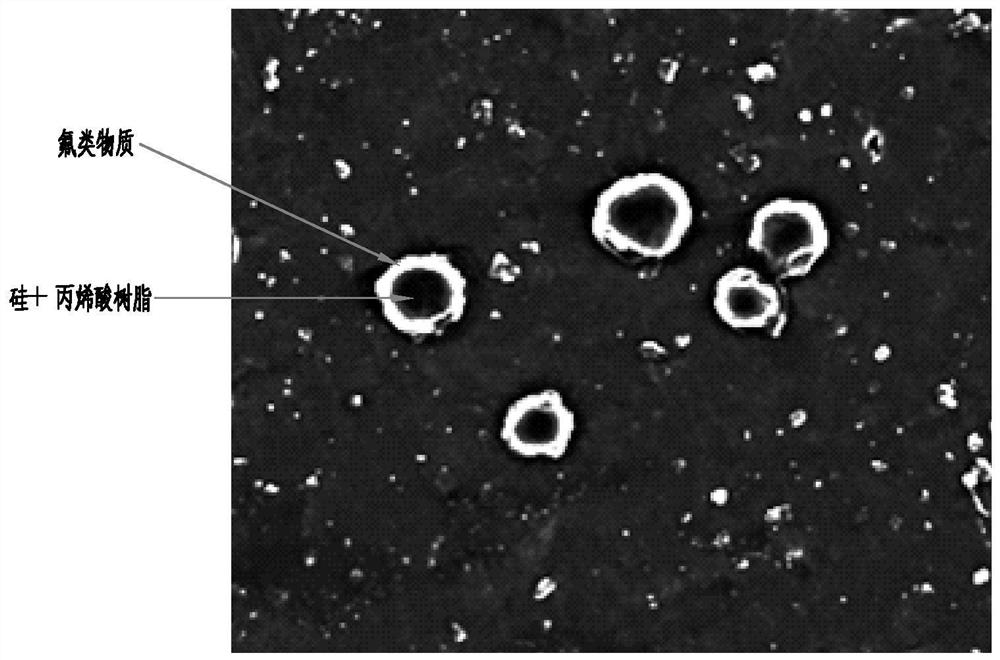

Super-hydrophobic coating with raspberry-like structured composite particles and preparation method thereof

InactiveCN106905795ASimple and fast operationUniversalCoatingsMicroballoon preparationMicrosphereMaterials science

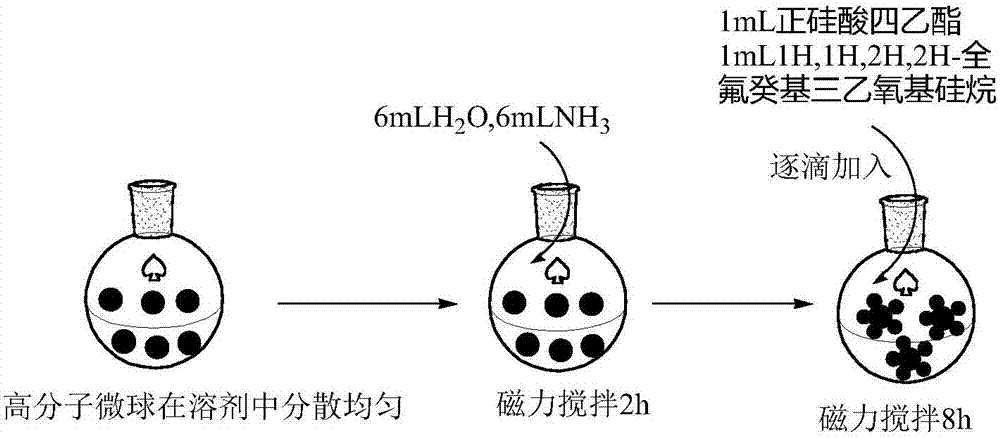

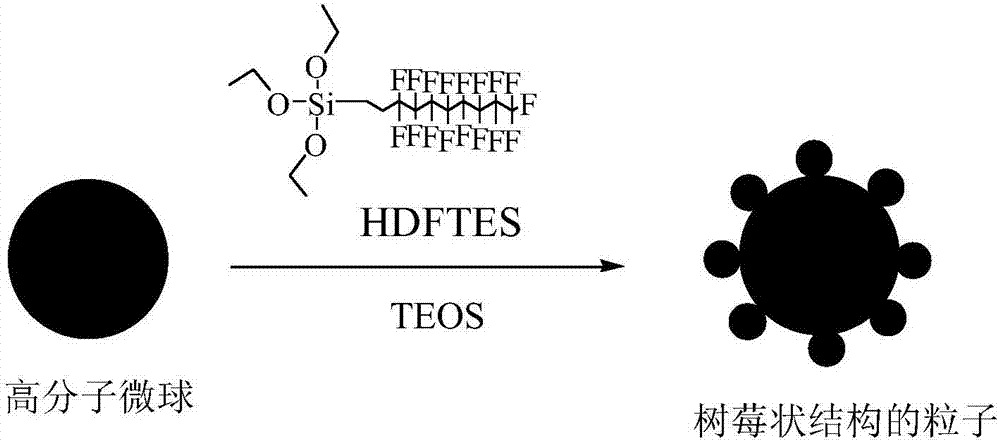

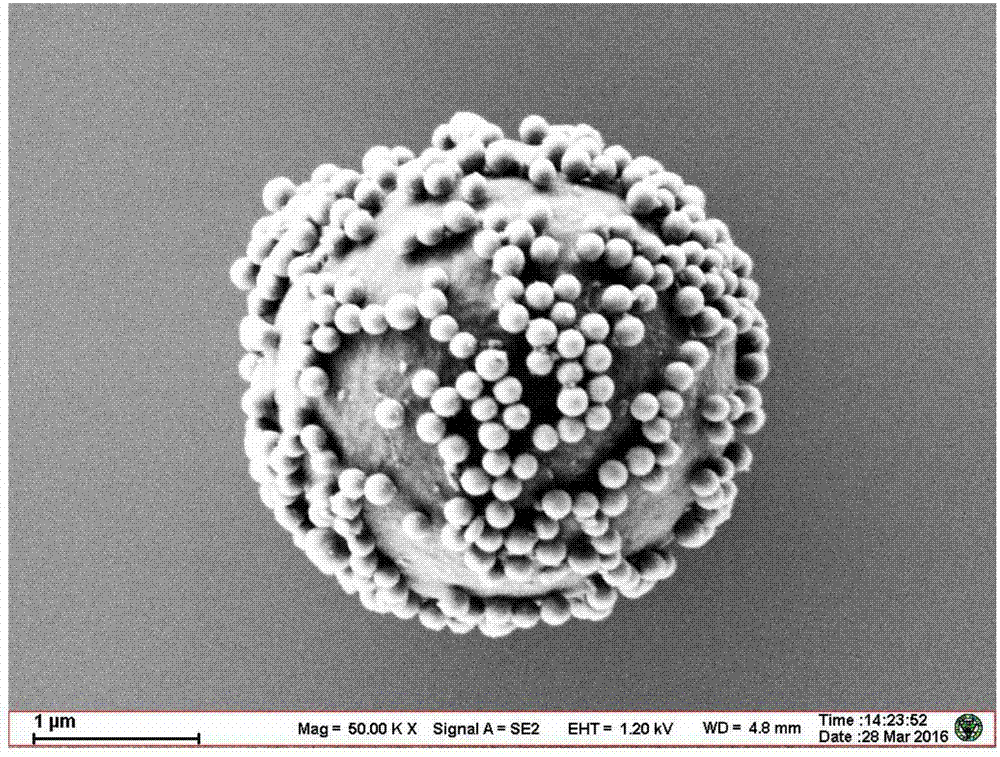

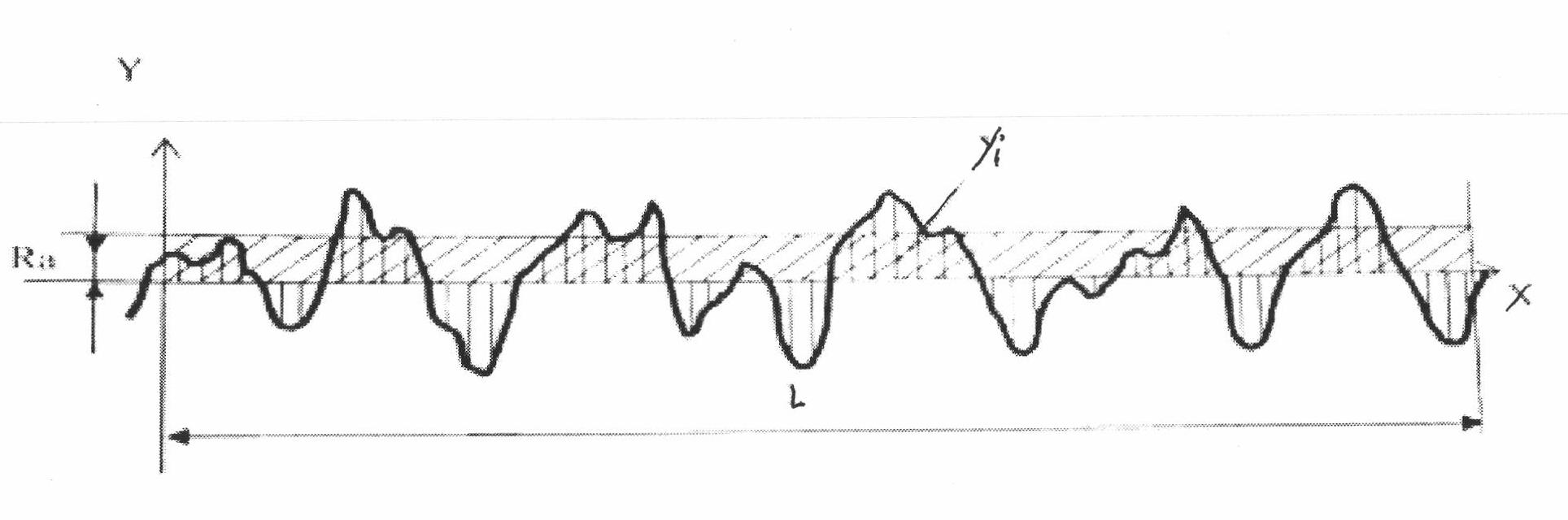

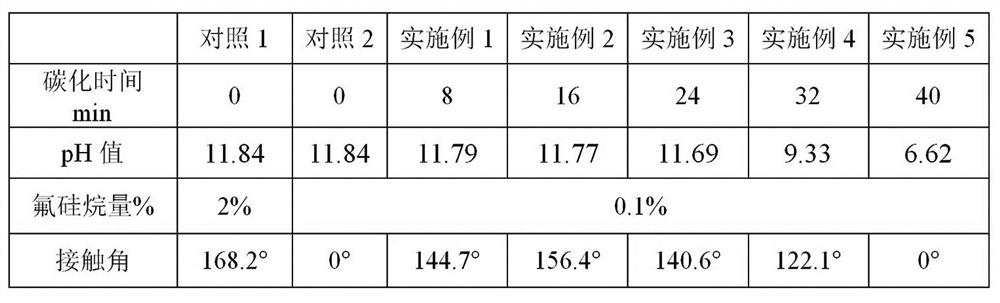

The invention discloses a superhydrophobic coating with a raspberry-like structure composite particle and a preparation method thereof. The superhydrophobic composite raspberry particle has a two-level hierarchical structure, and is composed of a polymer nanoparticle with a diameter of 10nm to 1000nm. The spherical core is composed of multiple smaller inorganic nanospheres attached to it. Among them, the organic spherical core refers to the polymer nanosphere with a diameter of 10nm to 1000nm, and the inorganic pellet is formed by the reaction of the following main raw materials on the spherical core according to the mass percentage: organic solvent: 70.02-90.75%; catalyst: 5.18-8.85% %; water: 5.85-8.89%; silicate: 1.12-2.02%; fluorine-containing silane coupling agent: 0.14-1.54%. Because the composite raspberry particles of the invention have a secondary hierarchical structure, the surface roughness can be increased; and the fluorine-containing silane coupling agent can effectively reduce the surface free energy, and finally a superhydrophobic coating can be prepared. The superhydrophobic coating of the present invention can be coated by various methods, including spraying, scraping, and soaking, without affecting its superhydrophobicity.

Owner:SOUTHEAST UNIV

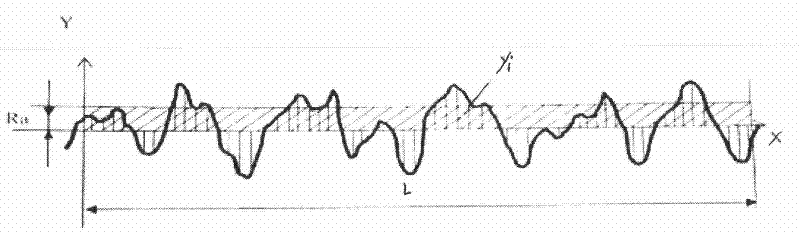

Method for preparing aluminum plate base for inkjet computer to plate and hydrophilic coating

ActiveCN102102214AAbsorbentImprove wear resistanceAnodisationPrinting pre-treatmentHydrophilic coatingComputer to plate

The invention belongs to a method for preparing an aluminum plate base for printing, and relates to a method for preparing an aluminum plate base for inkjet computer to plate and a hydrophilic coating for coating the surface of the aluminum plate base. The method for preparing the aluminum plate base comprises the steps of deoiling the aluminum plate base, performing electrolysis, dedusting, performing anodic oxidation and the like, and coating the hydrophilic coating on the treated aluminum plate base. The electrolysis and anodic oxidation processes in the prior art are improved, so that a nanometer and micrometer structure can be constructed on the surface after the aluminum plate base is subjected to the anodic oxidation; the diffusion behavior of ink droplets is controlled, and the hydrophilic coating is coated on the surface of the aluminum plate base, so that the aluminum plate base has certain roughness, ink absorption property and high wear resistance simultaneously; printing ink is sprayed on the aluminum plate base coated with the hydrophilic coating by an inkjet computer to plate technology so as to form a text area; and by adjusting the preparation process of the plate base and coating the hydrophilic coating, contrast between the text area and a non-text area during printing is increased, and text resolution is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

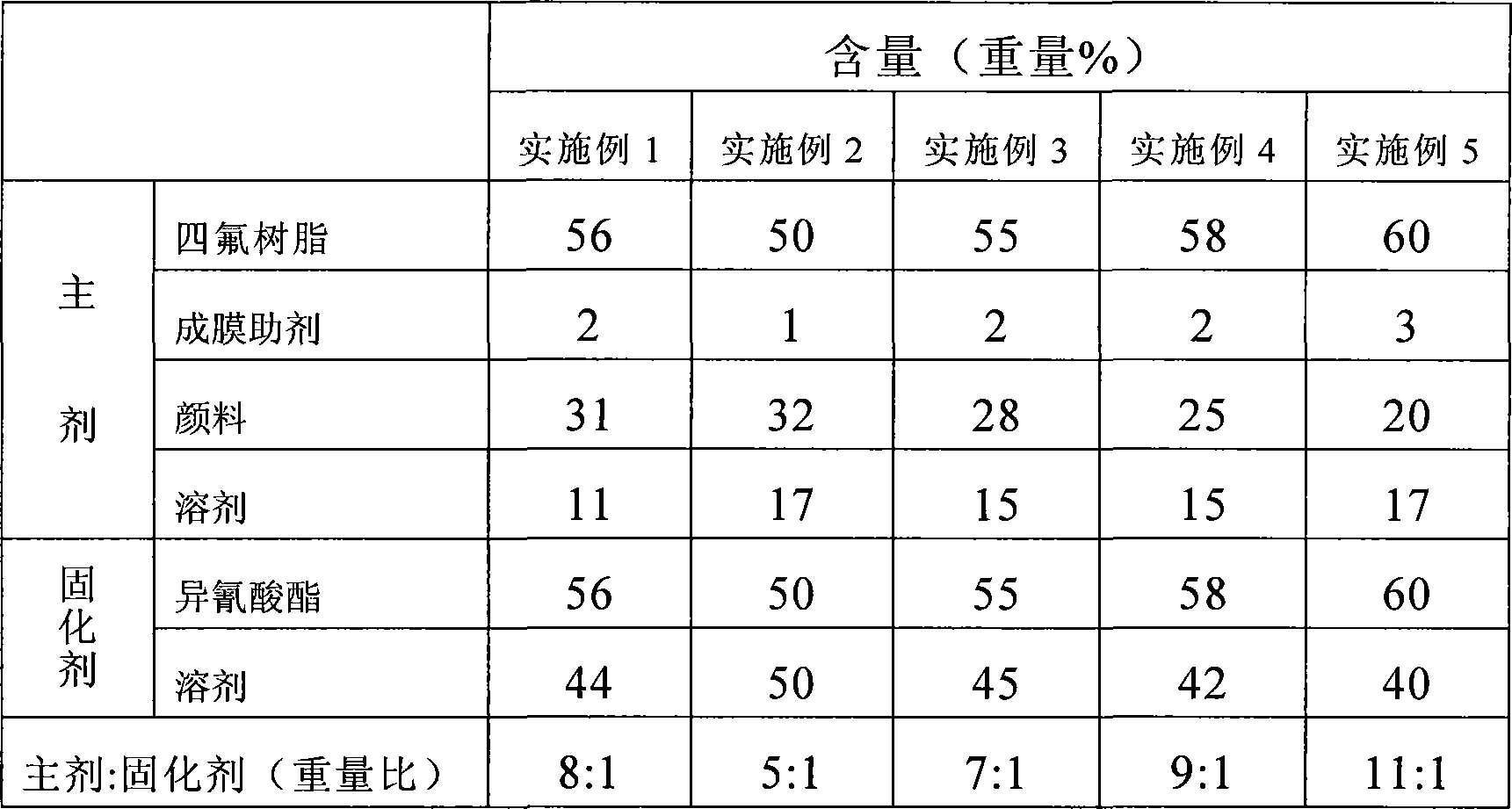

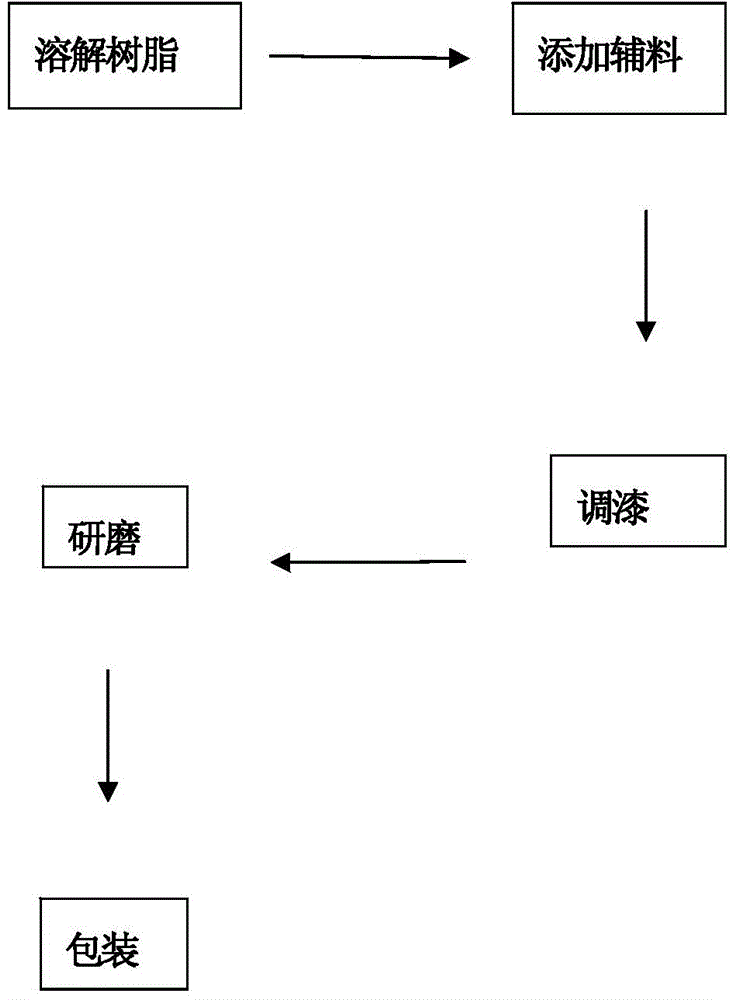

Tetrafluoroethylene resin coating

InactiveCN101608084AGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsResin coatingSolvent

The invention relates to a tetrafluoroethylene resin coating, which comprises a main agent and a curing agent, wherein the weight ratio of the main agent to the curing agent is 5-11:1; the main agent comprises the following components in percentage by weight: 50 to 60 percent of tetrafluoroethylene resin, 1 to 3 percent of film-forming auxiliary agent, 20 to 32 percent of pigment, and the balance of solvent; and the curing agent comprises the following components in percentage by weight: 50 to 60 percent of polyisocyanate, and the balance of solvent. Compared with the prior art, the tetrafluoroethylene resin coating is prepared by using isocyanate to cure hydroxyl-contained normal temperature crosslinking type tetrafluoroethylene fluorocarbon resin as the main film forming object compounded with other auxiliary agents, has the excellent characteristics of weatherability, corrosion resistance, chemical resistance, salt fog resistance, easy cleaning and the like, has a simple coating method and good drying property without dying by high-temperature baking, can performing coating on various base materials and under various environments, and has wide application range.

Owner:中涂化工(上海)有限公司

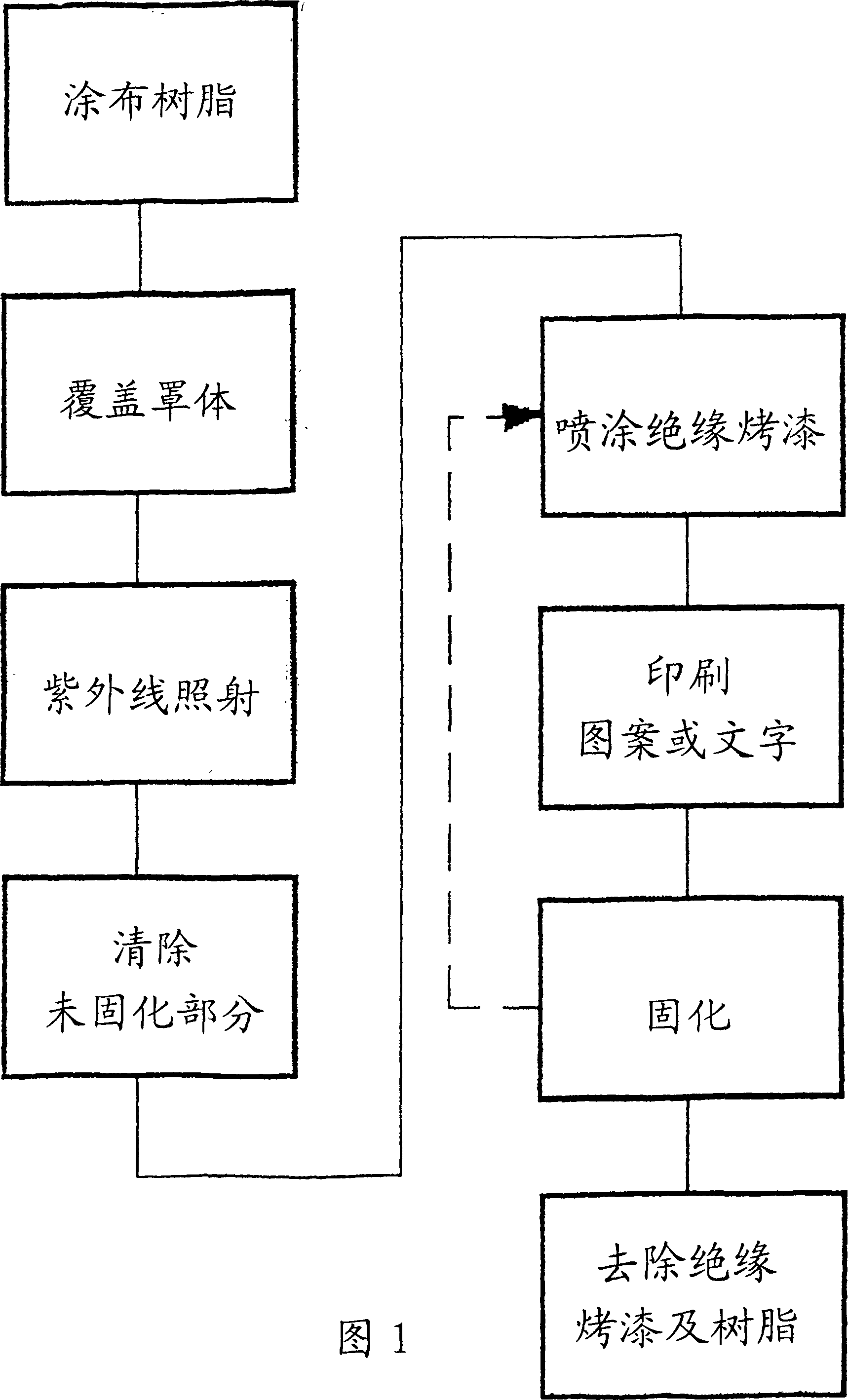

Anti-welding procedue of PCB

InactiveCN1835659AImprove impact resistanceUniform thicknessNon-metallic protective coating applicationSolder maskUltraviolet

The invention provides an improved solder mask structure to prevent the variation of electrical character and comprises: the step of coating the resin, making a steel plate with a large hole on the portion to be exposed, the resin is coated on the contact portion to be exposed and totally covers the contact portion; the step of covering mask, making a steel plate for coverage on which a hole in a designed size is opened, and covering the steel plate for coverage on the coated resign; the step of ultraviolet radiation, after ultraviolet radiation, the resin on the portion of opening hole is solidified; the step of spraying insulation finish, spraying the insulation finish on the PCB, and then solidifying it; the step of removing the insulation finish and resin, removing the insulation finish and resin on contact portion to be exposed using dull polish or sand blast; after washing, the contact portion is kept an exposing state, and other portion of the PCB is covered by the insulation finish.

Owner:杨合卿

Tin-free and copper-free environment-friendly marine antifouling coating as well as preparation method and application thereof

InactiveCN106281020ALarge range of inhibition of biological speciesExtended service lifeLiquid surface applicatorsAntifouling/underwater paintsSodium BentoniteFuel oil

The invention provides tin-free and copper-free environment-friendly marine antifouling coating. The tin-free and copper-free environment-friendly marine antifouling coating is prepared from the following components according to the ratio: xylol, PMA (Polymethyl Acrylate), rosin resin, chlorinated polyether resin, soybean lecithin, talcum powder, zinc oxide, ferric oxide red, medium yellow, bentonite, an antifouling agent, a plasticizer and a light aromatic solvent. The tin-free and copper-free environment-friendly marine antifouling coating provided by the invention particularly still has an obvious antifouling effect under a static state of a ship, and has tin-free and copper-free properties; the tin-free and copper-free environment-friendly marine antifouling coating has no pollution to the sea; the antifouling coating also has a large biological species inhibition range and the releasing speed of the antifouling agent is stable; the antifouling coating has the characteristics that the antifouling coating is not easy to precipitate, the service life is long and the like; the navigational speed of the ship is indirectly increased and fuel oil is saved.

Owner:上海新健利新材料科技有限公司

Coating material composition and coating material system containing coating material composition

InactiveCN109836980ASimple coating methodGood initial peelabilityPolyurea/polyurethane coatingsOrganic solventMaterials science

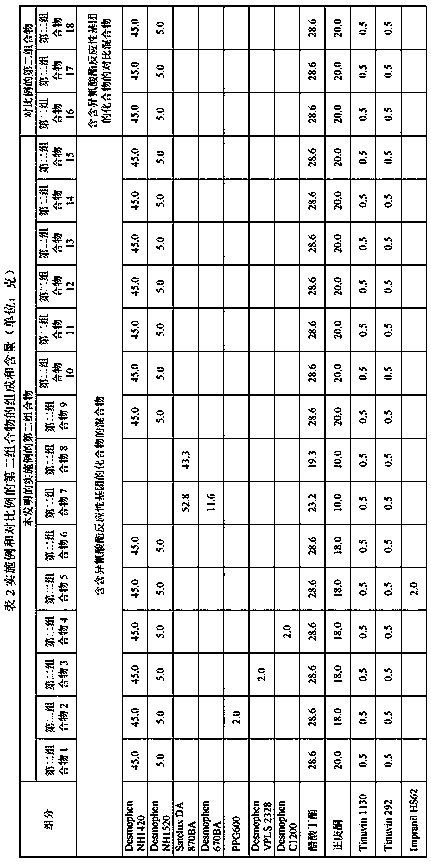

The present invention relates to a coating material composition and a coating material system containing the coating material composition, more particularly to a coating material composition, a peelable coating material system containing the coating material composition, a coating method and applications of the coating material system, and a product obtained by coating with the coating material system, wherein the coating material composition contains: a compound containing an isocyanate reactive group, a polyisocyanate and an organic solvent, the isocyanate group functionality of the polyisocyanate is not less than 2.8, and an equivalent ratio of the isocyanate group to the isocyanate reactive group is 0.5:1-10:1.

Owner:COVESTRO DEUTSCHLAND AG

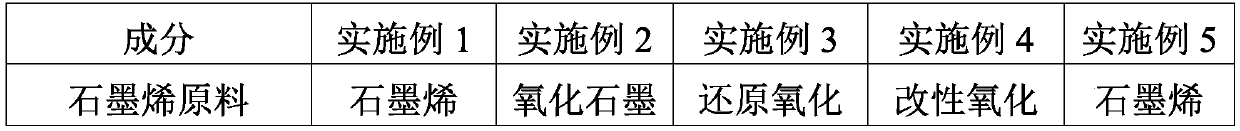

Graphene fabric coating and coating method thereof

InactiveCN108677550ASimple coating methodEfficient coating methodTextiles and paperPolyolefinMetallurgy

The invention discloses a graphene fabric coating and a coating method thereof. The coating layer is prepared from the following preparation materials in percentage by mass: 0.1 to 5 percent of graphene, 3 to 5 percent of polyolefin, 0.3 to 0.9 percent of dibenzoyl peroxide, 1.5 to 6.0 percent of bonding agents, 0.4 to 0.6 percent of ethanol, 1.5 to 1.8 percent of N-hydroxymethyl acrylamide, 4 to5 percent of emulsifiers, 0 to 5.5 percent of inorganic pigments and the balance of deionized purified water. The invention also provides the coating method of the graphene fabric coating. The graphene fabric coating layer and the coating method of the coating layer provided by the invention have the advantage that the antibacterial function, the UV resistant function, the far infrared heating function and the like are given to fabrics.

Owner:湖北联庄科技有限公司

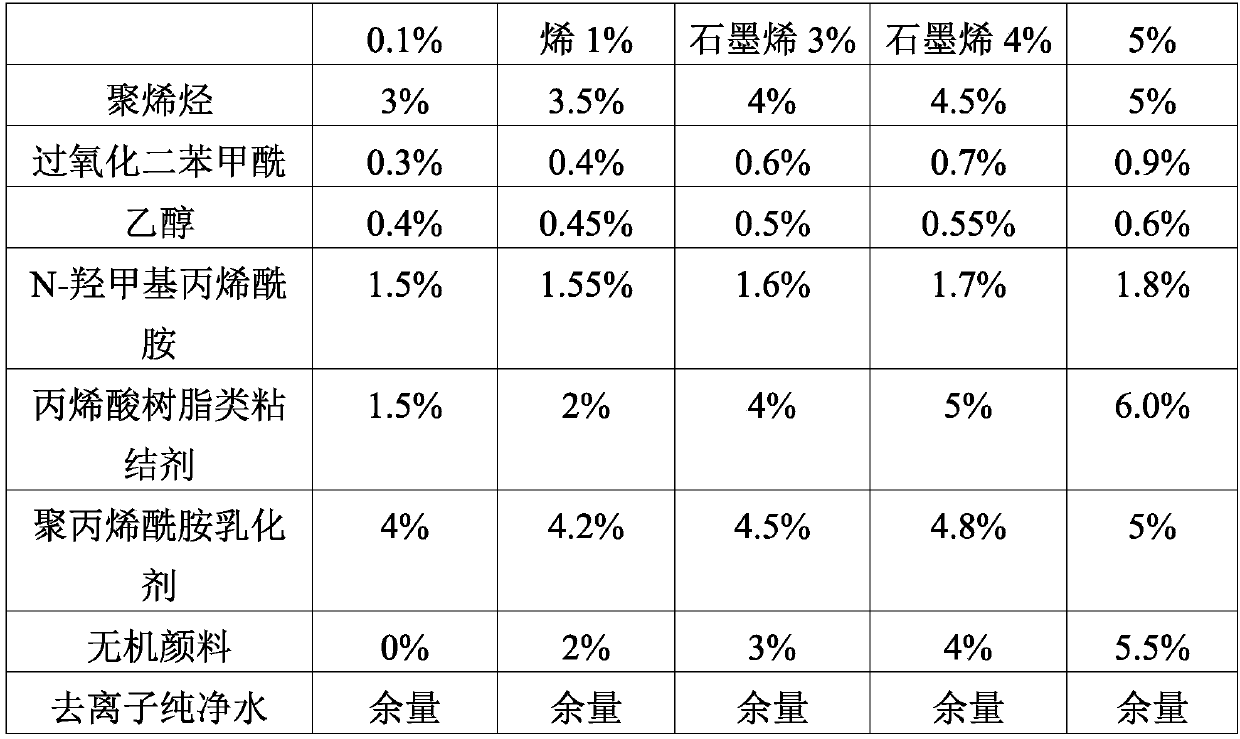

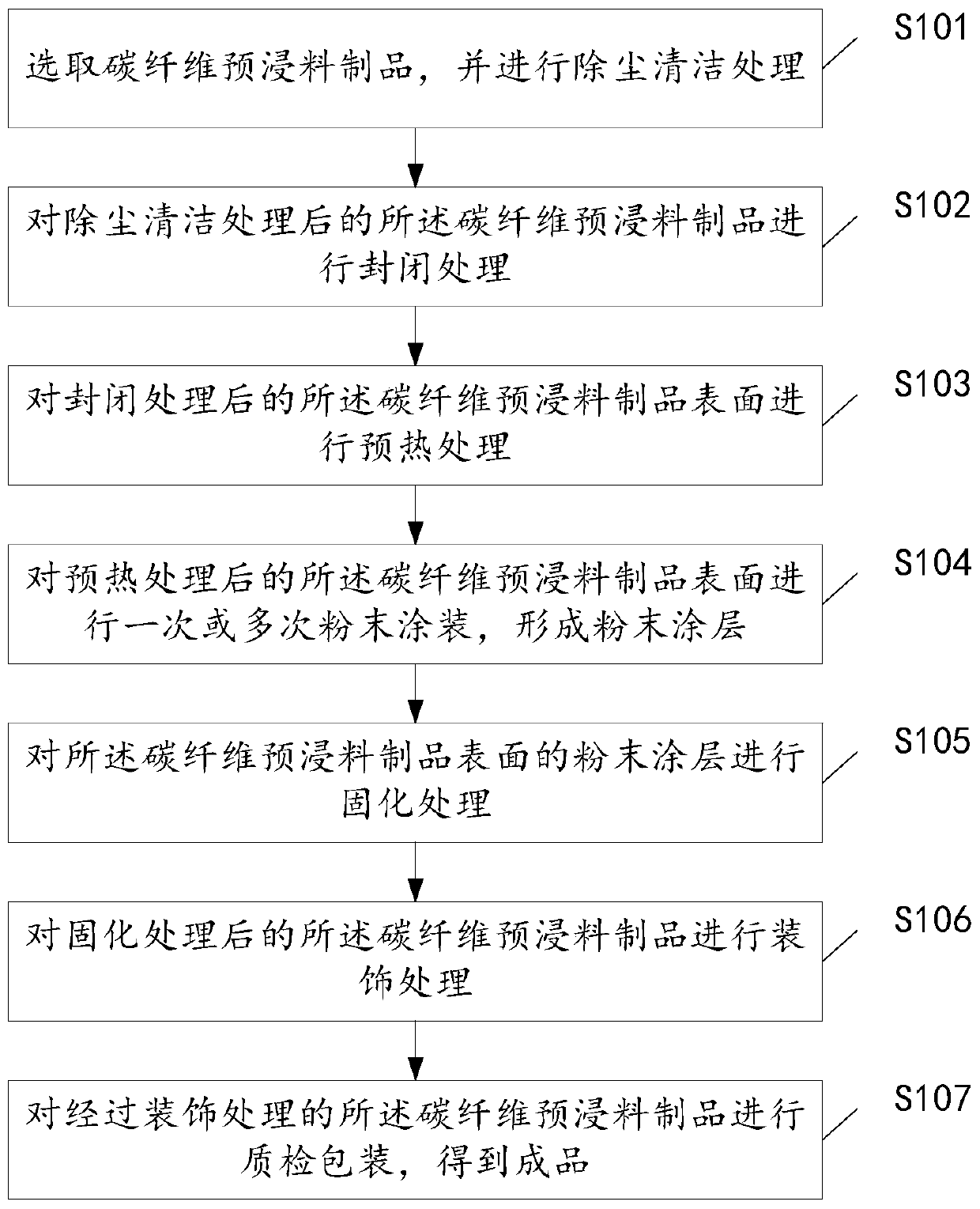

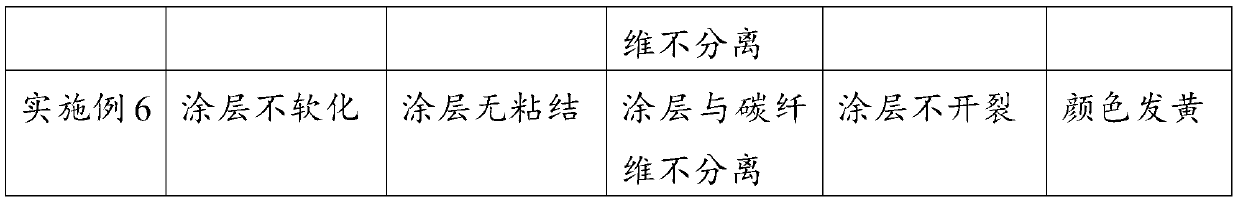

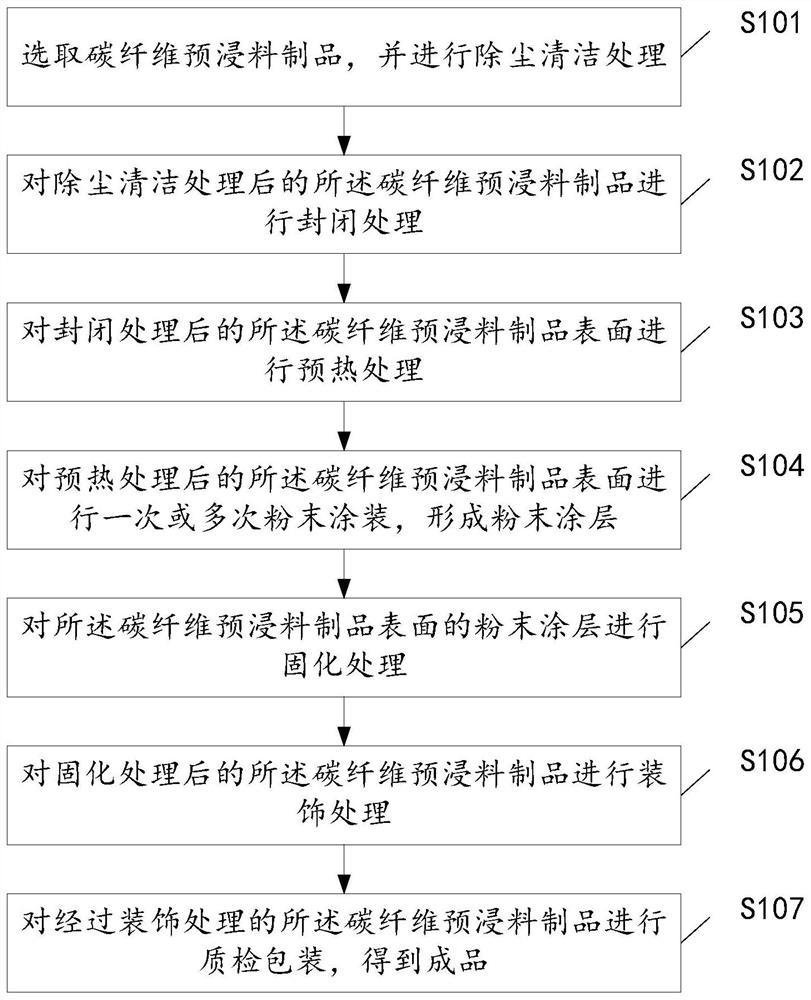

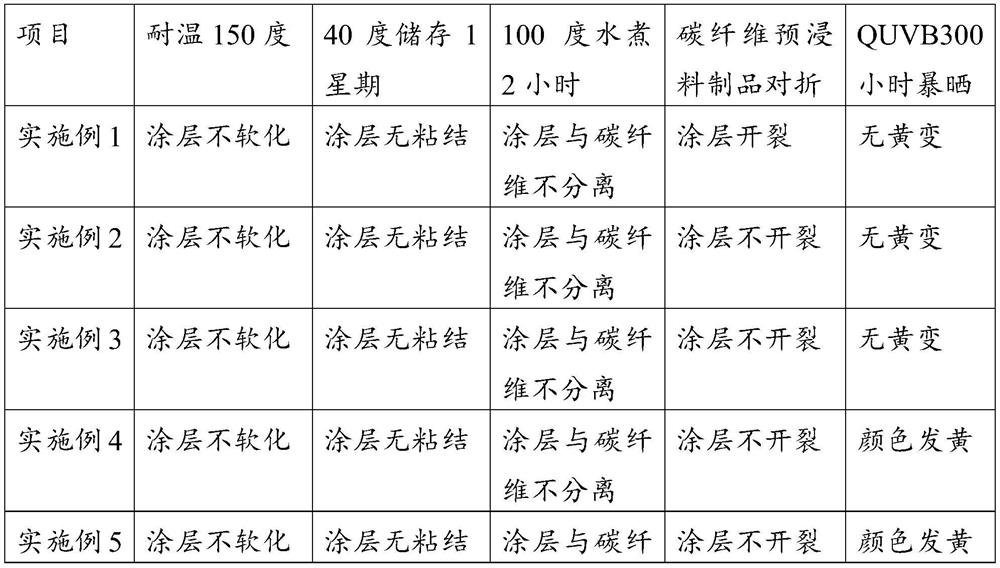

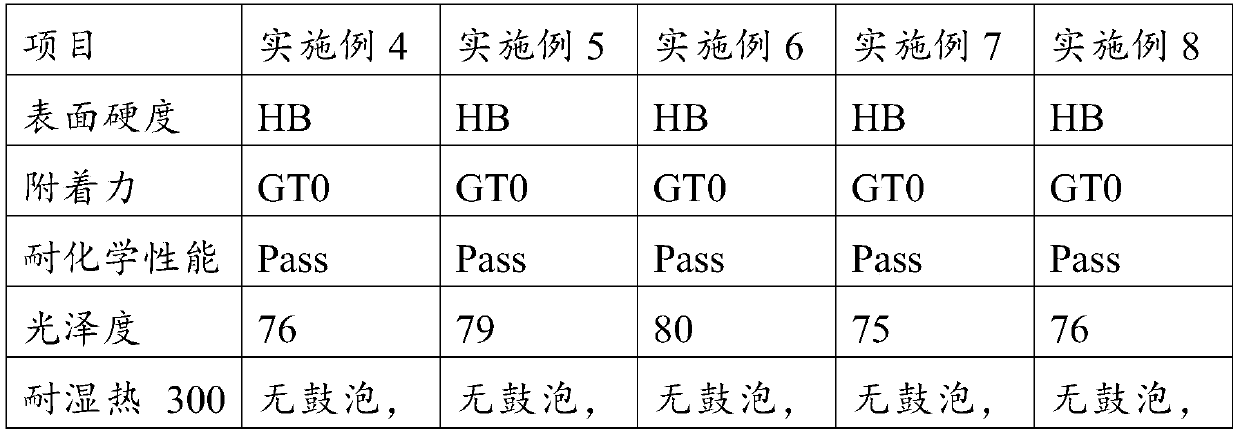

Carbon fiber prepreg product and coating method thereof

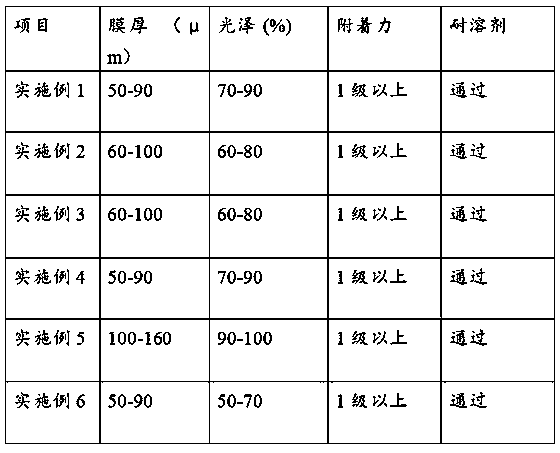

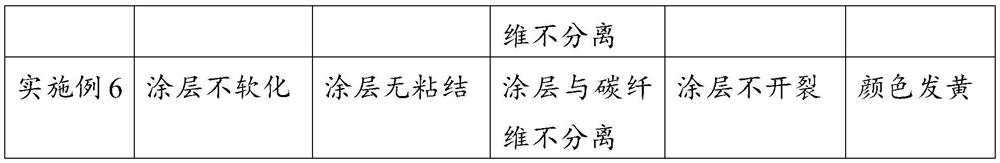

ActiveCN110628066AGloss can be adjusted freelyImprove the decorative effectPowdery paintsEpoxy resin coatingsFiberCarbon fibers

The invention discloses a coating method of a carbon fiber prepreg product. The coating method comprises the following steps: (1) selecting a carbon fiber prepreg product, and carrying out dust removal cleaning treatment; (2) carrying out sealing treatment on the carbon fiber prepreg product; (3) preheating the surface of a sealed carbon fiber prepreg product; (4) carrying out one time of a plurality of times of powder coating on the surface of the preheated carbon fiber prepreg product to form a powder coating layer; (5) carrying out curing treatment on the powder coating layer on the surfaceof the carbon fiber prepreg product; (6) carrying out decoration treatment on the cured carbon fiber prepreg product; and (7) carrying out quality inspection packaging on the decorated carbon fiber prepreg product to obtain a finished product. Correspondingly, the invention also provides the carbon fiber prepreg product prepared by the method. The method is simple, the process is controllable, nosolvent participates in the reaction, VOCs are not released, and no waste is generated.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

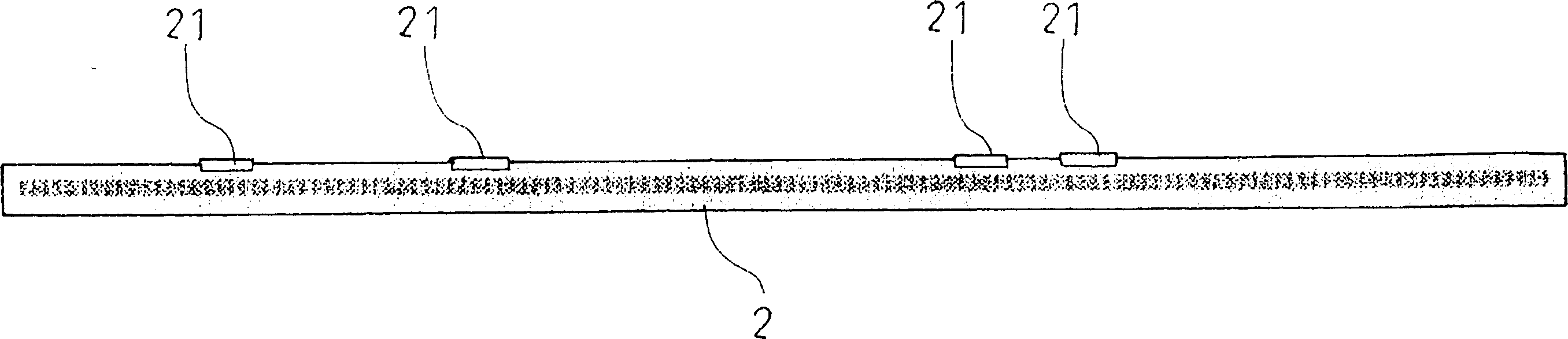

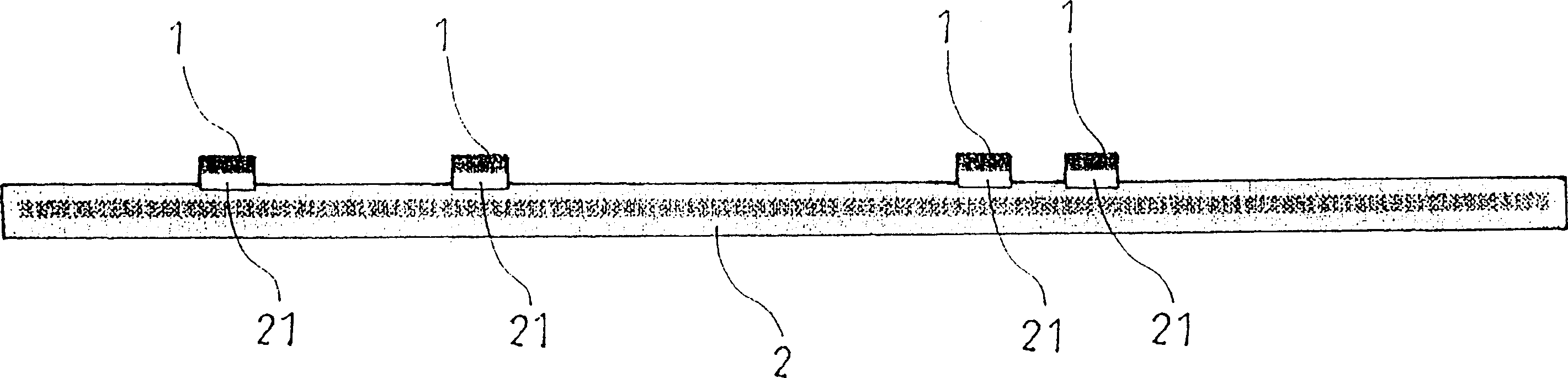

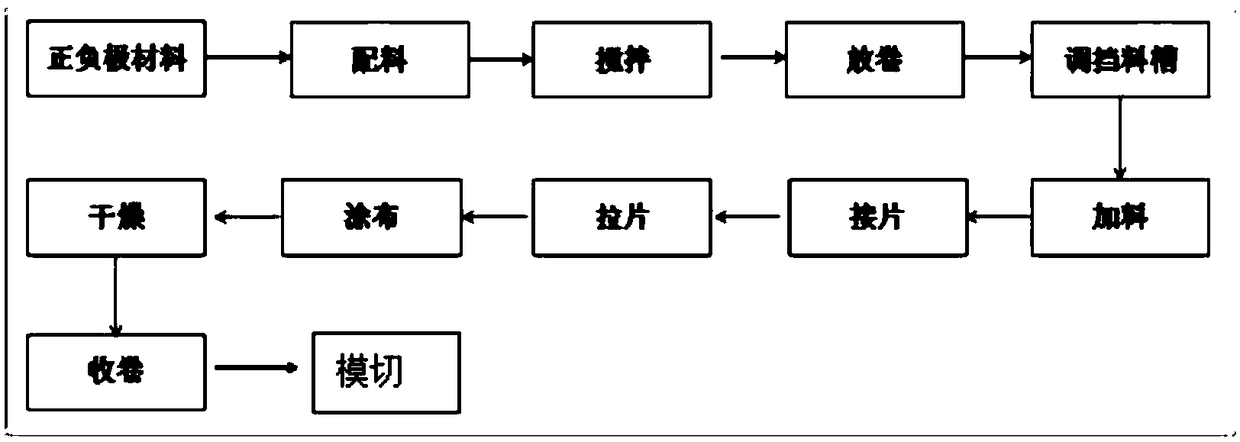

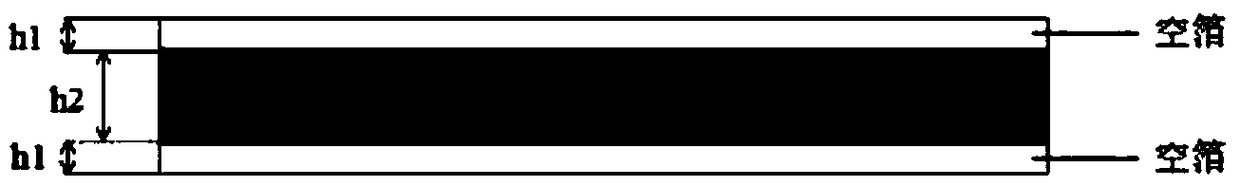

Coating process suitable for production of lithium battery

InactiveCN108520940AIncrease productivityPromote innovationElectrode collector coatingMaterials preparationMetallurgy

The invention discloses a coating process suitable for production of a lithium battery, which includes the steps of: material preparation, stirring, unreeling, adjustment of baffles of a material trough, material addition, joint of sheets, pulling of sheets, coating, drying, reeling and mold-cutting. In the coating step, a void foil remains between foil materials of electrode sheets, so that aftercoating and drying, the product can be directly mold-cut, thus omitting a cutting step. The coating process is subjected to creative modification; the modified coating method is simple and has convenience in mold-cutting, so that the coating process has better effect on lithium batteries, can save use amount of a foil material, reduces cost and increases production efficiency.

Owner:桑顿新能源科技(长沙)有限公司

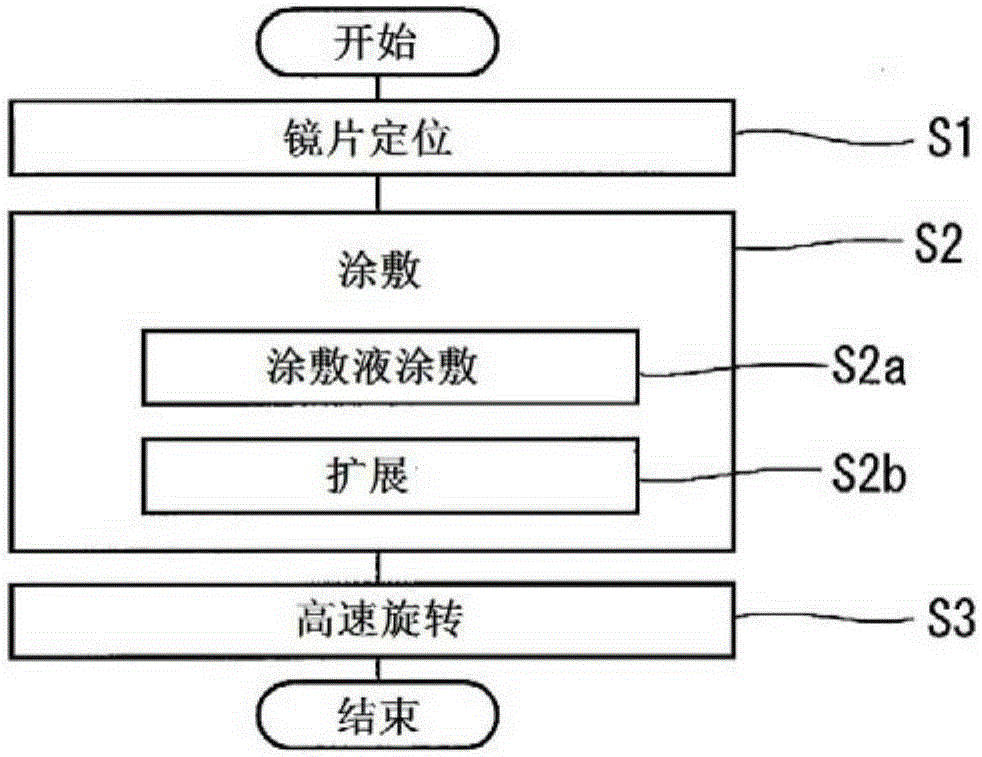

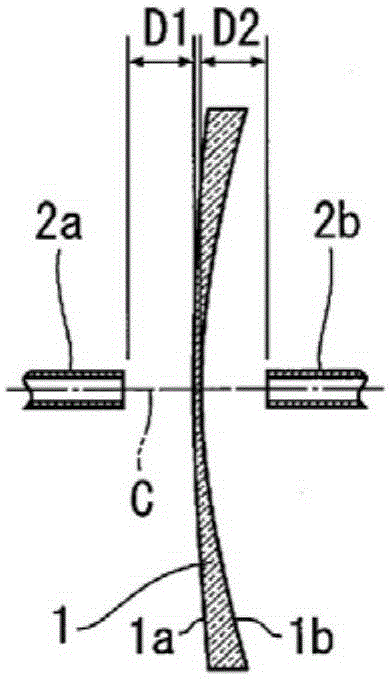

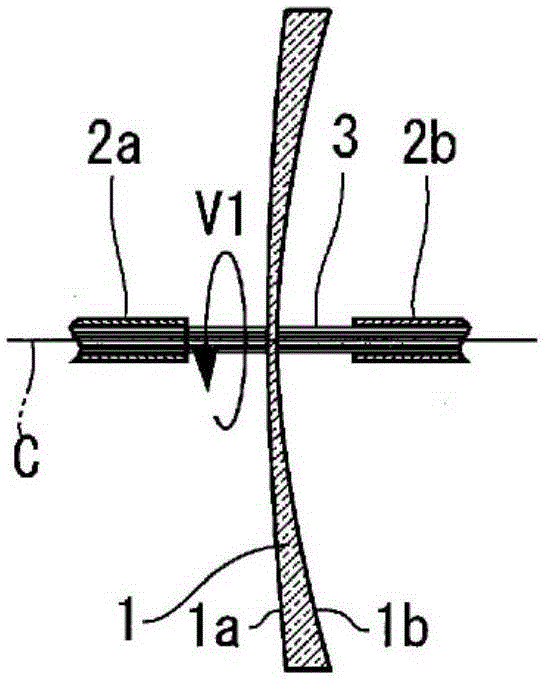

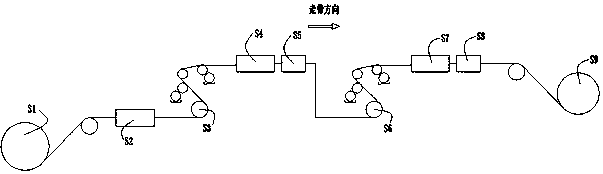

Method for manufacturing spectacle lens and coating device for coating liquid for base material of spectacle lens

InactiveCN105229495ALittle effect of gravityImprove uniformitySpectales/gogglesLiquid surface applicatorsCentre of rotationEngineering

A coating liquid (3) is horizontally jetted from nozzles (2a, 2b) so that lens surfaces (1a, 1b) of a spectacle lens base material (1) arranged so that the optical axis (C) is oriented in the horizontal direction are coated with the coating liquid (3) (step (S2a)). The spectacle lens base material (1) is rotated at a first rotational speed with the optical axis (C) as the rotational center, thus using centrifugal force to coat and spread the coating liquid (3) over the lens surface (step (S2b)). The spectacle lens base material (1) is rotated at a second rotational speed higher than the first rotational speed, thus using centrifugal force to splash the excess (3a) of the coating liquid (3) outside the spectacle lens base material (1) (step (S3)). Thus, a highly uniform film can be formed over the lens surface of a spectacle lens.

Owner:HOYA CORP

Seal coating process and manufacturing method of wood furniture

The invention relates to a seal coating process and a manufacturing method of wood furniture. The seal coating process includes the steps of 1), using, by weight, 10-35% of air-drying resin, 60-85% o plastics and 5-30% of a thinner to blend brushing plastics; 2), coating the brushing plastics on a work piece with the coating weight controlled within 80-120g / m<2>; 3), starting a movable-type UV (ultraviolet) drier, and drying the plastics through motion of the movable-type UV drier; 4), diluting the sealing plastics to coat the same on the work piece; 5), starting the movable-type UV drier, and drying the plastics through motion of the movable-type UV drier. The coating process has the advantages of operation easiness; environment pollution, production space, polishing manpower, paint consumption, damages to human health, time on the coating process can all be reduced and the like.

Owner:JIANGMEN GUOMEI CHEM

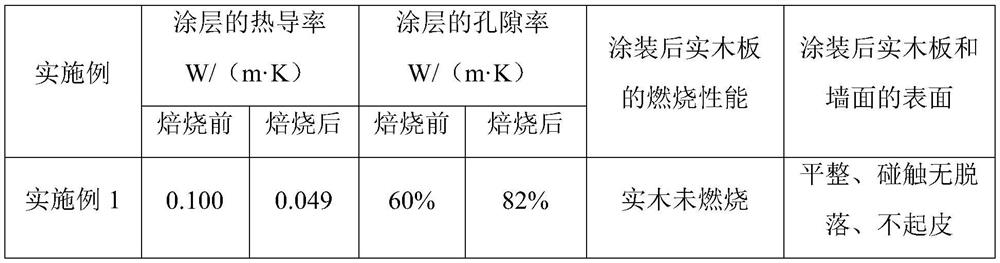

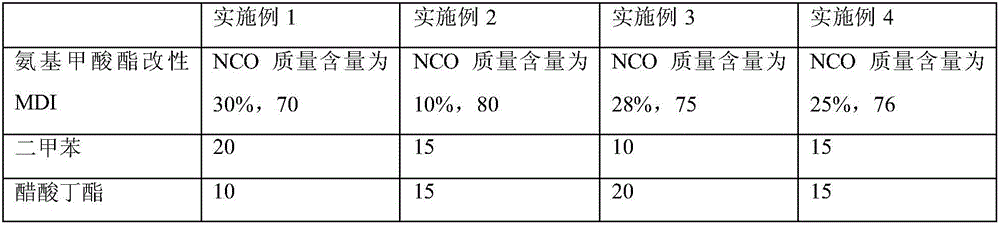

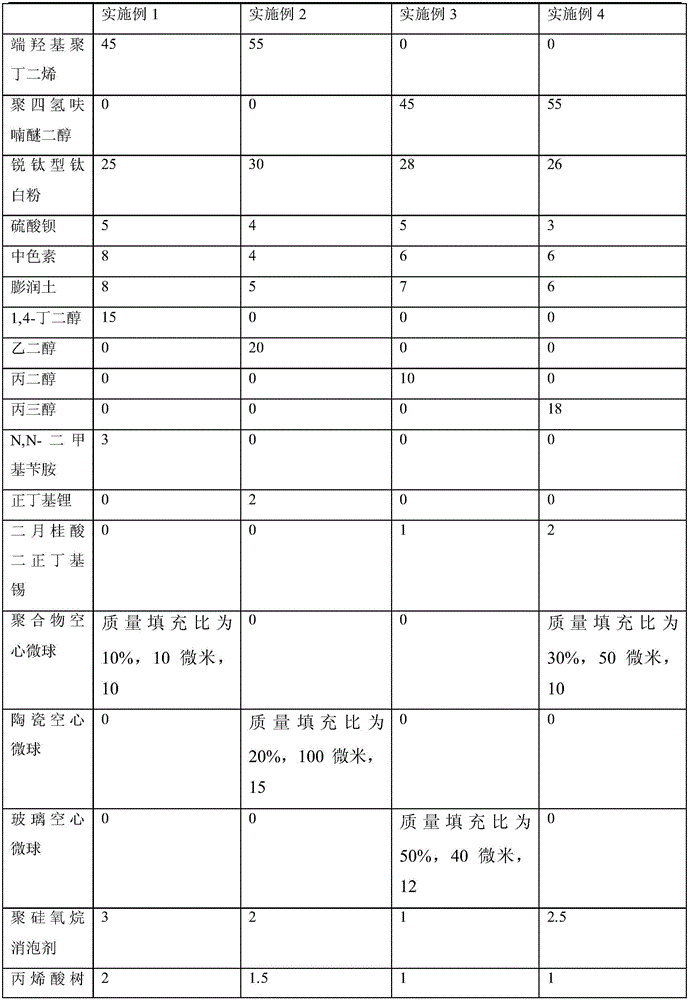

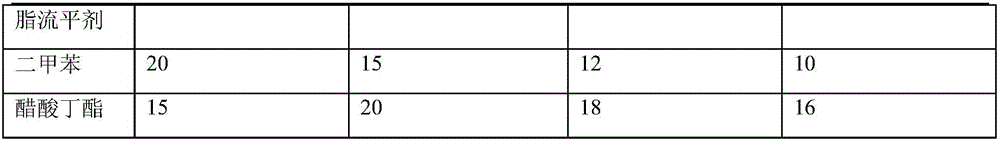

Flame-retardant and heat-insulating nano high-build coating and coating method thereof

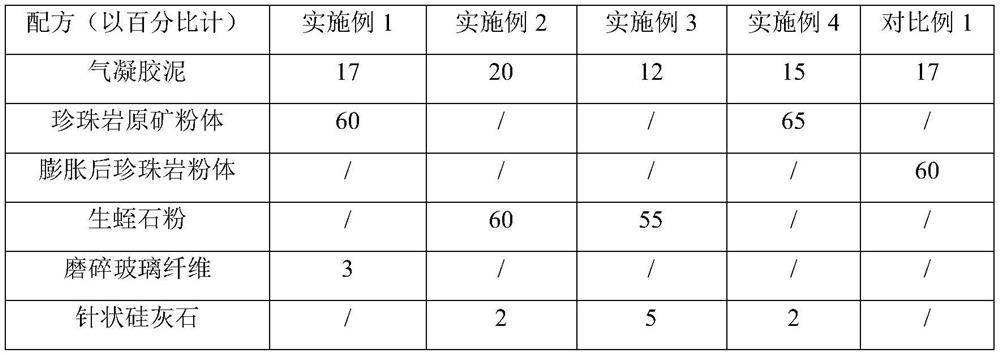

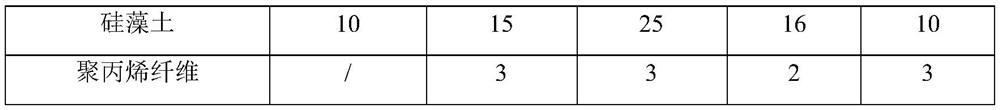

PendingCN114231070AImprove flame retardant performanceImprove insulation effectFireproof paintsSpecial surfacesFiberAdhesive

The invention provides a flame-retardant thermal-insulation nano thick paste coating. The flame-retardant thermal-insulation nano thick paste coating comprises an inner-layer coating and a surface-layer coating, the inner-layer coating comprises inner-layer powder, an adhesive and a regulator; the inner-layer powder comprises aerogel, an expandable inorganic silicate powder material, diatomite, inorganic fibers or / and organic fibers; the surface layer coating comprises surface layer powder, an adhesive and a conditioning agent, and the surface layer powder comprises calcium powder, diatomite and sericite powder. The aerogel daub and the diatomite serve as a heat-preservation flame-retardant layer in a coating outside a workpiece or a wall surface, in a fire environment, the aerogel and the diatomite wrap the surface layer of the ceramic powder which is not expanded, fire is retarded and isolated, along with temperature rise and heat conduction, the ceramic powder is preheated until expansion, the expanded coating is kept intact and does not crack due to fibers, and the thermal insulation effect is achieved. And the coating has the effects of high temperature resistance and flame retardance. Therefore, the nano high-build coating disclosed by the invention has very good flame-retardant and heat-insulating properties. The coating method is simple, the construction controllability is high, and use is convenient.

Owner:苏州正乙丙纳米环保科技有限公司

Coating method for high-speed rail concrete surface strong waterproof thin coating type polyurethane paint

ActiveCN106085192AAchieve thin coatingImprove waterproof performanceIn situ pavingsAnti-corrosive paintsPolyolFilm-forming agent

Owner:TIANJIN CHANGYUAN ELECTRONICS MATERIAL

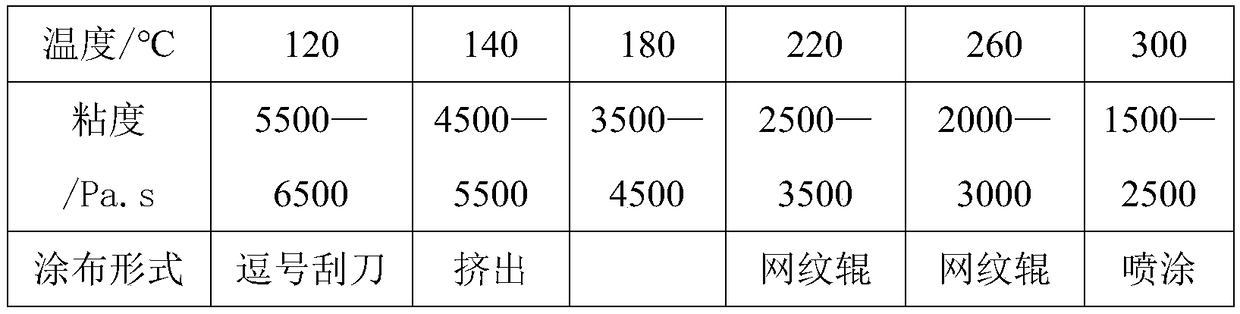

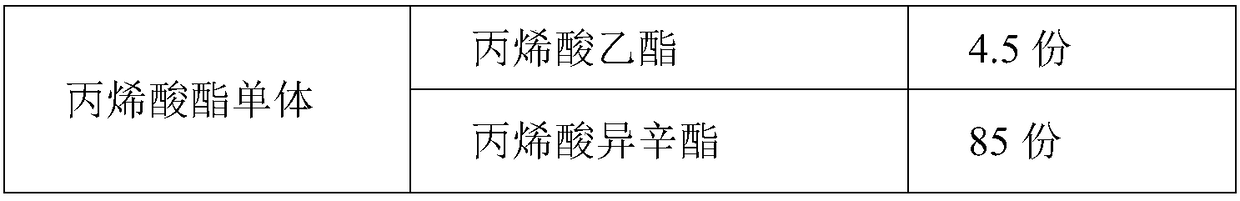

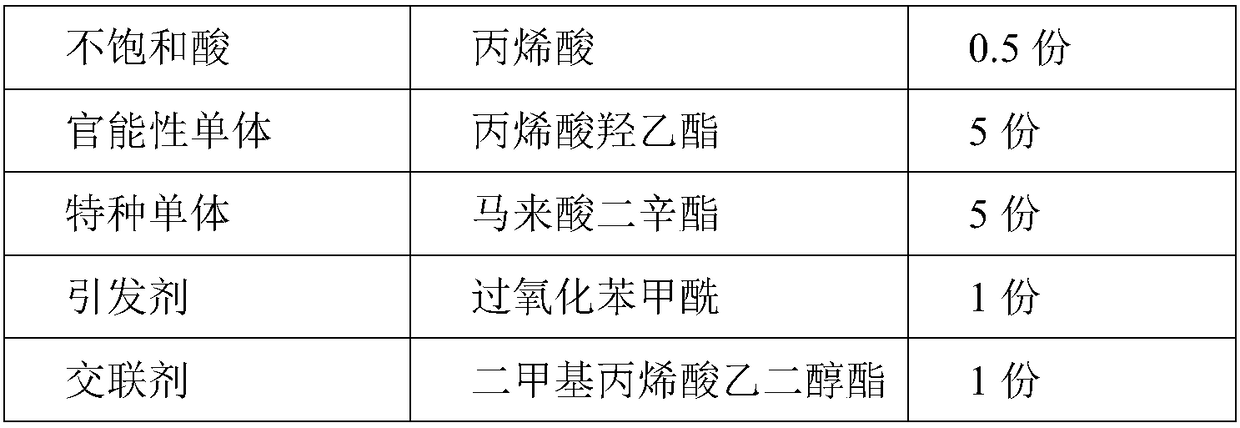

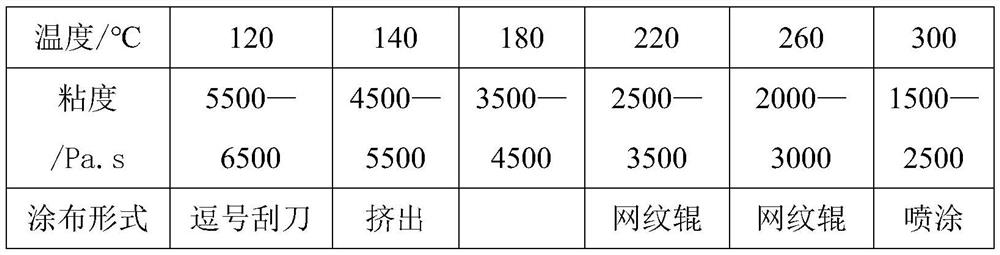

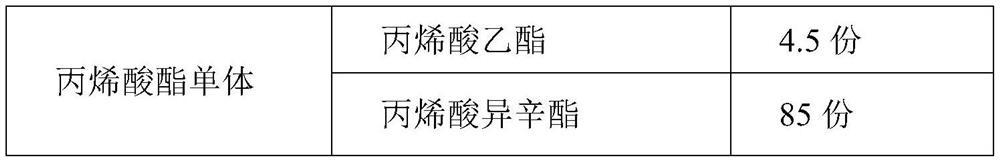

Acrylic ester solid restickable adhesive and preparation and coating method thereof

ActiveCN109321177AExcellent adhesionStrong initial adhesionFilm/foil adhesivesEster polymer adhesivesFunctional monomerAdhesive

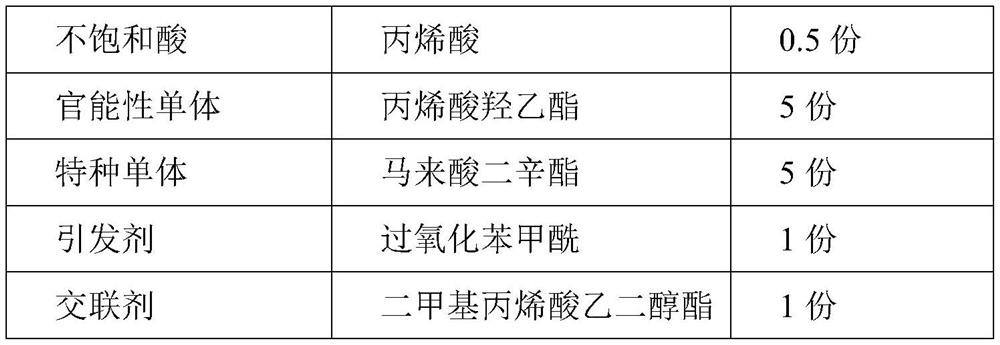

The invention discloses an acrylic ester solid restickable adhesive and a preparation and coating method thereof. The acrylic ester solid restickable adhesive is prepared from the following raw materials in parts by weight: 60-95 parts of acrylic ester monomer, 0-6 parts of unsaturated acid, 0-6 parts of functional monomer, 1-20 parts of special monomer, 0.5-3 parts of an initiator and 0.1-1 partof a crosslinking agent. The preparation method of the acrylic ester solid restickable adhesive comprises the following steps of (1) mixing; (2) first-stage reaction; (3) second-stage reaction; and (4) solidification. The coating method of the acrylic ester solid restickable adhesive comprises the following steps that (1) the acrylic ester solid restickable adhesive is heated to 120-350 DEG C to become fluid by using a hot melting box; and (2) a base material is coated with the acrylic ester solid restickable adhesive at the fluid state obtained in the step (1), and the adhesive is solidifiedat the room temperature.

Owner:深圳市久久天一纸制品有限公司

Method for preparing aluminum plate base for inkjet computer to plate and hydrophilic coating

ActiveCN102102214BAbsorbentImprove wear resistancePrinting pre-treatmentHydrophilic coatingElectrolysis

The invention belongs to a method for preparing an aluminum plate base for printing, and relates to a method for preparing an aluminum plate base for inkjet computer to plate and a hydrophilic coating for coating the surface of the aluminum plate base. The method for preparing the aluminum plate base comprises the steps of deoiling the aluminum plate base, performing electrolysis, dedusting, performing anodic oxidation and the like, and coating the hydrophilic coating on the treated aluminum plate base. The electrolysis and anodic oxidation processes in the prior art are improved, so that a nanometer and micrometer structure can be constructed on the surface after the aluminum plate base is subjected to the anodic oxidation; the diffusion behavior of ink droplets is controlled, and the hydrophilic coating is coated on the surface of the aluminum plate base, so that the aluminum plate base has certain roughness, ink absorption property and high wear resistance simultaneously; printing ink is sprayed on the aluminum plate base coated with the hydrophilic coating by an inkjet computer to plate technology so as to form a text area; and by adjusting the preparation process of the platebase and coating the hydrophilic coating, contrast between the text area and a non-text area during printing is increased, and text resolution is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

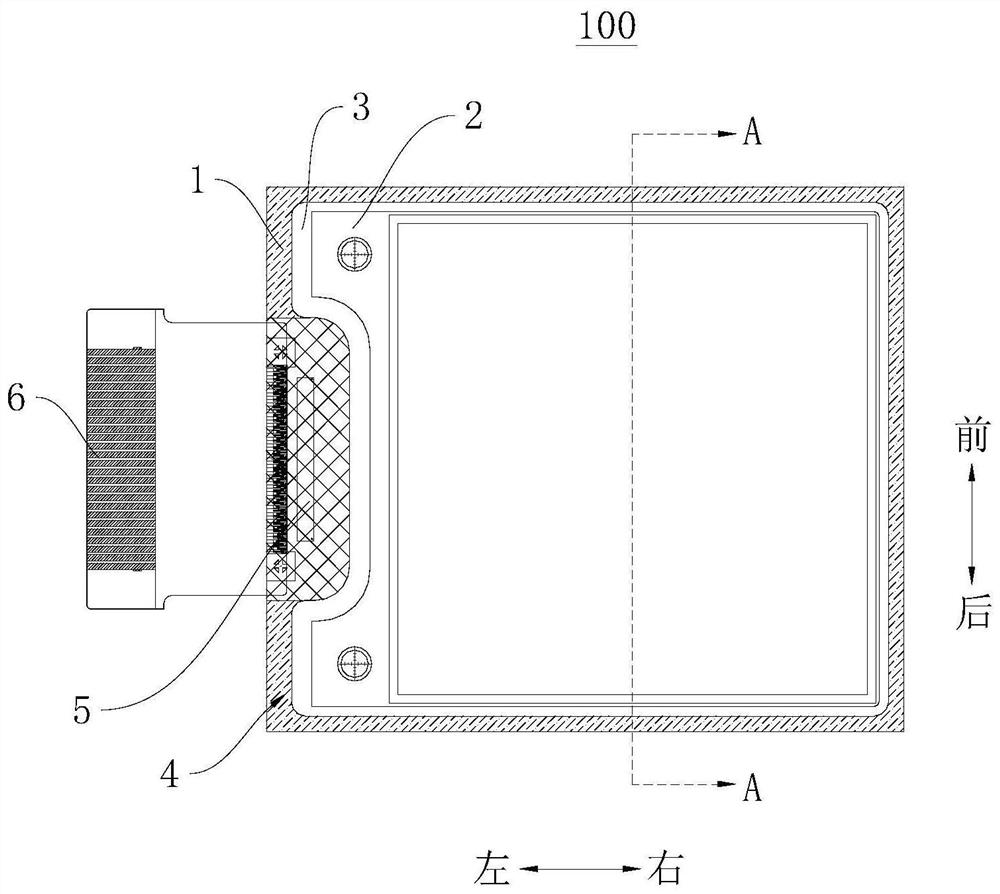

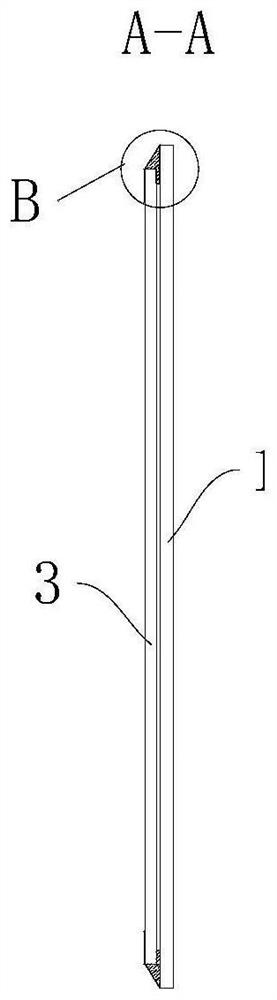

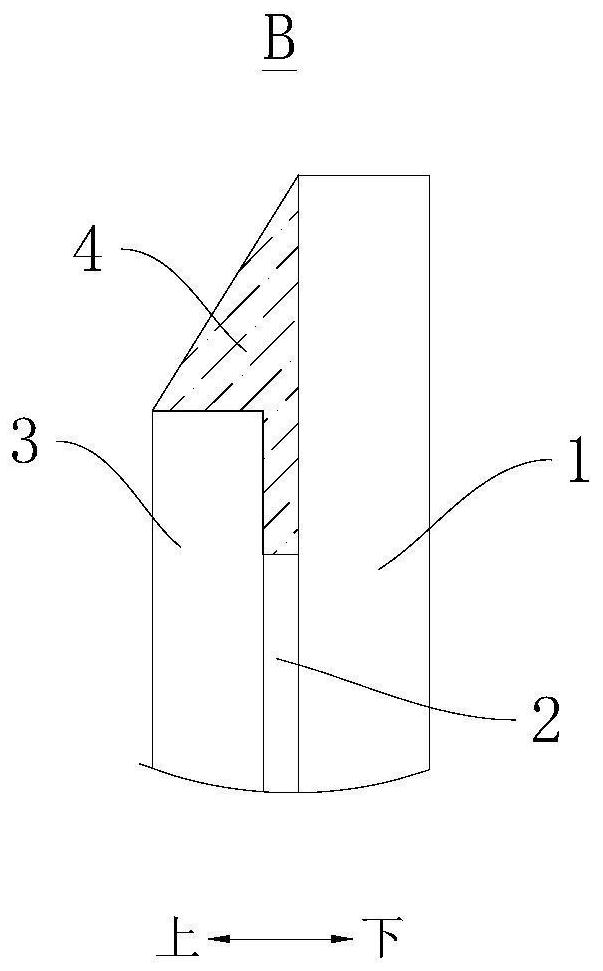

Display module, electronic device and method for manufacturing display module

ActiveCN111402757BPlay a protective effectPhenomena that are not easily damagedIdentification meansEngineeringProtection layer

The invention discloses a display module, an electronic device and a manufacturing method of the display module. The display module includes: a substrate; , the projection of the display layer is located in the projection of the substrate; the protective layer, the protective layer is arranged on the side of the display layer away from the substrate, and at least part of the protective layer extends beyond the peripheral wall of the substrate, in a plane parallel to the substrate, the display layer is The projection is located in the projection of the protective layer; the sealing layer, the sealing layer includes a first sealing part and a second sealing part connected, the first sealing part is provided on the part of the protective layer beyond the outer peripheral wall of the substrate, and the second sealing part is provided on between the substrate and the protective layer and on the periphery of the display layer. According to the display module of the present invention, the protective layer can protect the substrate to a certain extent, so that the substrate is not easily damaged due to bumping.

Owner:CHONGQING BOE SMART ELECTRONICS SYST CO LTD +1

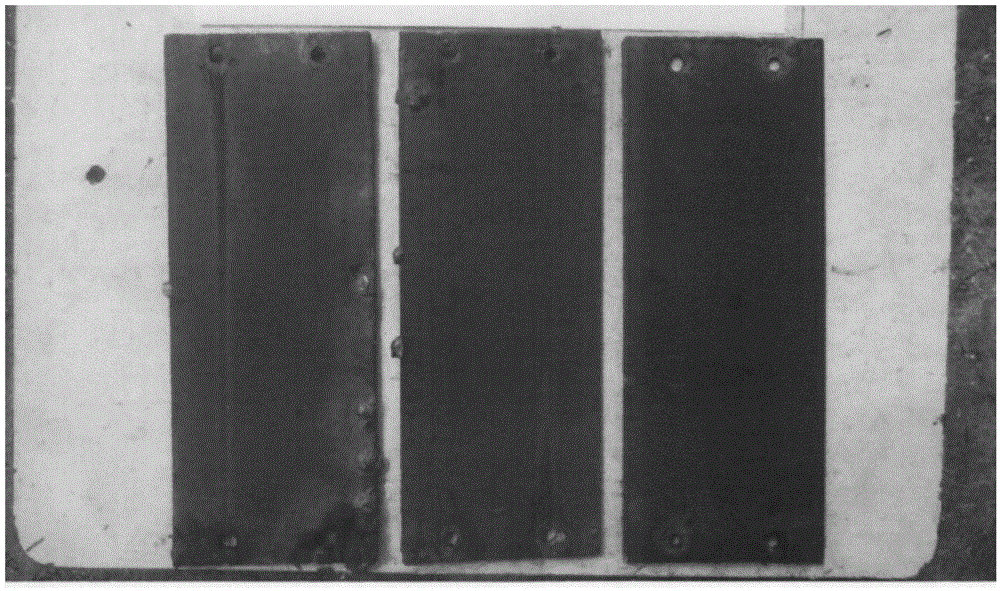

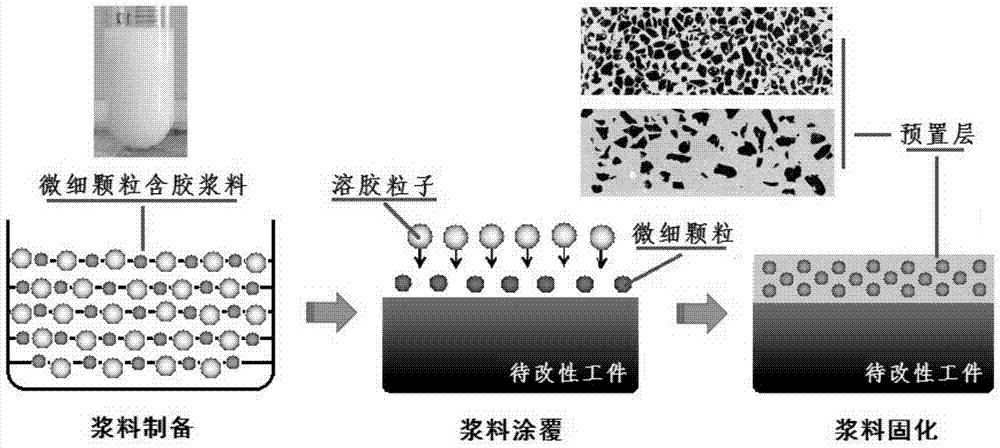

Coating method of high-dispersion, strong adhesion, light-transmitting fine particle pre-coating method for laser melting

ActiveCN105603419BTranslucentImprove adaptabilityMetallic material coating processesFine structureSlurry

The invention discloses a coating method of a high-dispersion strong-adhesion light-permeable fine particle preset layer for laser melt injection. The coating method is characterized by comprising the steps of preparing fine particle glue-containing slurry from fine powder, preheating a to-be-modified workpiece, coating the workpiece with the fine particle glue-containing slurry, drying and curing a preset layer, and the like. The preset layer prepared by virtue of the coating method has light translucency and can well adapt to a laser melt injection particle-reinforced surface modification technique; and meanwhile, fine particles are diffused and distributed in the preset layer in a high dispersion manner and have uniform thickness, and the preset layer has well adhesion with the surface of a to-be-modified material. The coating method is not limited by the size, shape and weight of the to-be-modified workpiece, can be applied to the coating of fine particle preset layers with complex shapes and fine structures and has very strong engineering applicability.

Owner:JIANGSU UNIV

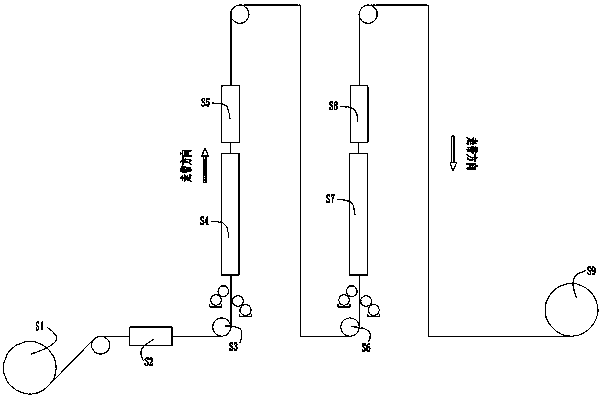

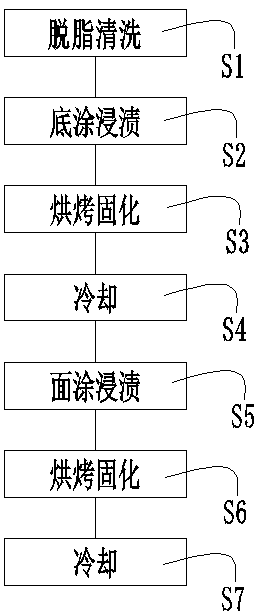

Anticorrosive wetting coating material and method and condensing unit heat exchanger

InactiveCN110684412AExtended service lifeIncrease the wetted areaEvaporators/condensersPretreated surfacesAcrylic resinFirming agent

The invention discloses an anticorrosive wetting coating material. The anticorrosive wetting coating material comprises a primer coating material and a finishing coating material, wherein the primer coating material is prepared from the following raw materials in percentage by weight: 30%-60% of modified resin, 0-40% of water, 6%-10% of an alcohol ether solvent, 1%-7% of a curing agent and 0.05%-0.5% of a defoaming agent; the finishing coating material is prepared from the following raw materials in percentage by weight: 9%-15% of modified acrylic resin, 12%-22% of modified polyacrylamide resin, 4%-8% of an alcohol ether solvent, 0.05%-0.5% of a defoaming agent and 0-80% of water; and the primer coating material is enabled to have excellent anti-corrosion performance, interlayer compositeforce between the coating and the coating is improved, meanwhile, the finishing coating material is enabled to have good hydrophilic performance, the wetting effect of the finishing coating material is improved, the situation of "dry spots" is reduced, and the heat exchange effect is improved.

Owner:GREE ELECTRIC APPLIANCES INC

A kind of acrylate solid repositionable adhesive and its preparation and coating method

ActiveCN109321177BExcellent adhesionStrong initial adhesionFilm/foil adhesivesEster polymer adhesivesPolymer scienceFunctional monomer

The invention discloses an acrylate solid repositionable adhesive and a preparation and coating method thereof. The acrylate solid repositionable adhesive comprises the following raw materials in parts by weight: 60-95 parts of acrylate monomer, 0-95 parts 6 parts of unsaturated acid, 0-6 parts of functional monomer, 1-20 parts of special monomer, 0.5-3 part of initiator, 0.1-1 part of crosslinking agent. The preparation method of the acrylate solid repositionable adhesive comprises the following steps: (1) mixing; (2) first-stage reaction; (3) second-stage reaction; (4) solidification. A method for coating an acrylate solid repositionable adhesive, comprising the following steps: (1) heating the acrylate solid repositionable adhesive to a fluid state after being heated to 120-350° C. through a hot melt box; (2) ) coating the fluid state acrylate solid repositionable adhesive obtained in step (1) on the substrate, and curing at room temperature.

Owner:深圳市久久天一纸制品有限公司

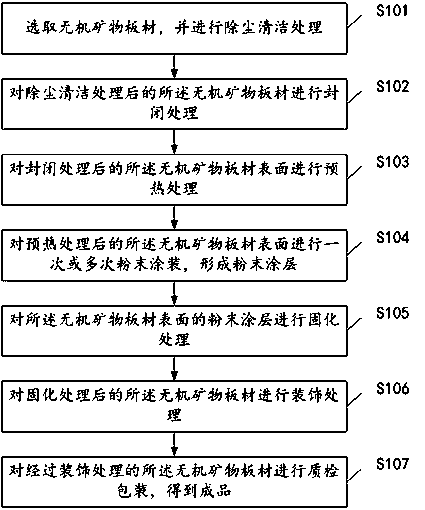

A kind of inorganic mineral plate and coating method thereof

ActiveCN110252632BGloss can be adjusted freelyImprove the decorative effectDecorative surface effectsSpecial ornamental structuresSurface conductivityPhysical chemistry

The invention discloses a coating method of an inorganic mineral plate. The coating method comprises the following steps of (1) selecting the inorganic mineral plate and carrying out dust removal and cleaning treatment, (2) sealing the inorganic mineral plates, (3) preheating the surface of the inorganic mineral plate to improve the surface conductivity of the inorganic mineral plate, (4) coating the surface of the inorganic mineral plate with ultra-low temperature powder paint for one or more times to form a powder coating, (5) curing the powder coating on the surface of the inorganic mineral plate, (6) decorating the inorganic mineral plate, and (7) carrying out quality inspection and packaging on the inorganic mineral plate to obtain a finished product. The invention further provides an inorganic mineral plate prepared by the coating method. With the adoption of the coating method, the method is simple, the process is controllable, various decorative effects can be achieved on the surface of the inorganic mineral plate by using the powder coating, and the problem that the powder coating and the inorganic mineral plate are difficult to match is solved.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

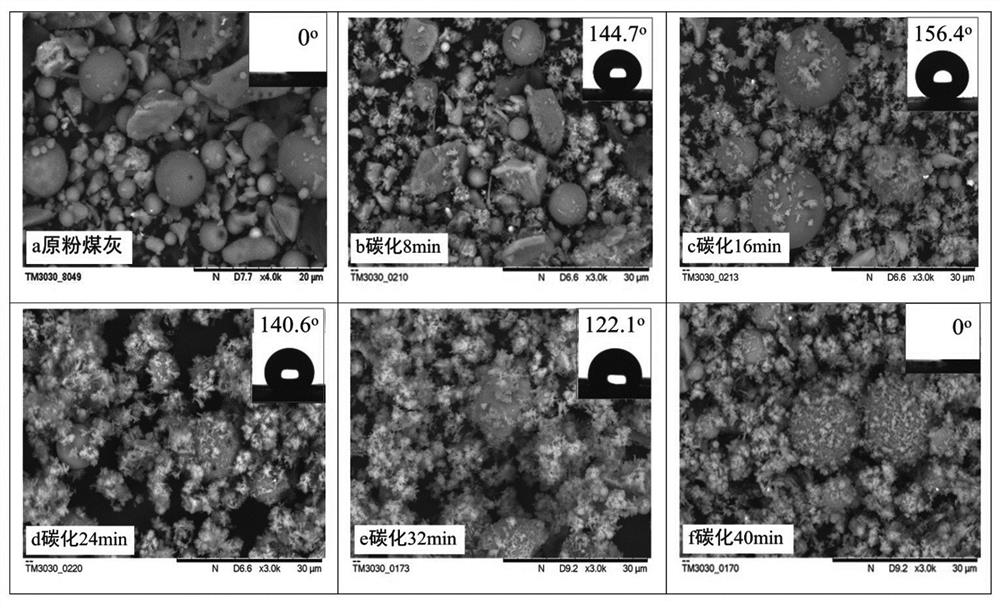

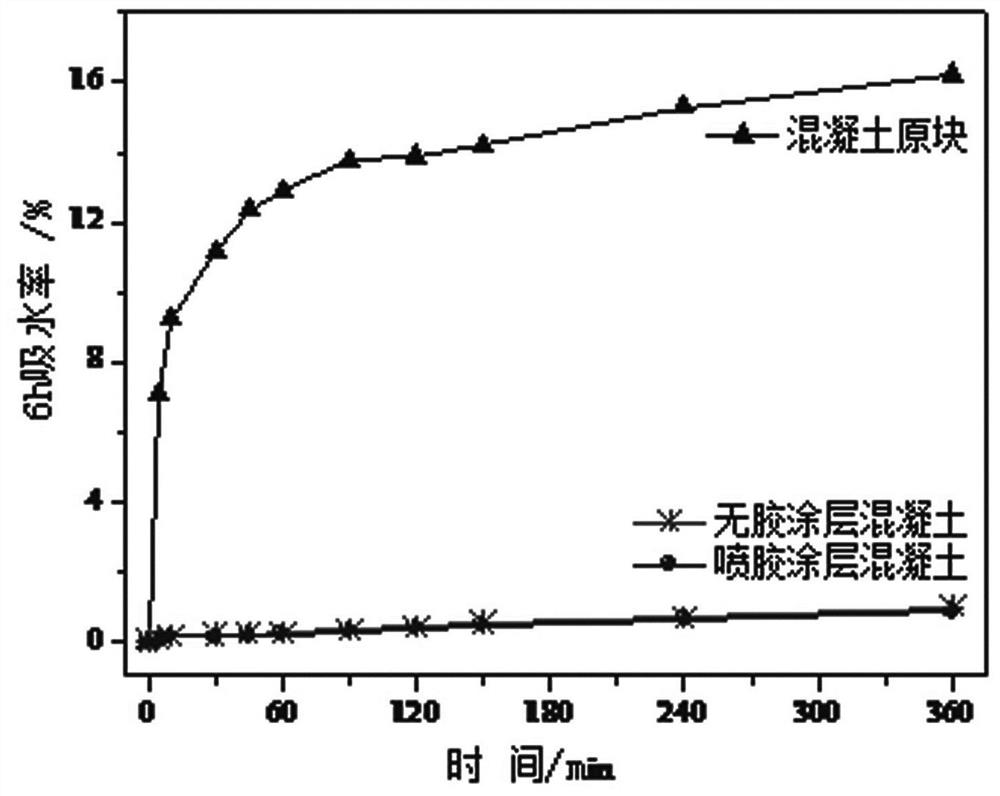

A kind of solid waste base superhydrophobic coating and coating method thereof

The invention relates to the technical field of coating, and in particular to a solid waste based super-hydrophobic coating and a coating method thereof. The solid waste based super-hydrophobic coating has the advantages that ethyl alcohol is adopted as a diluting dispersant, utilization of volatile organic solvents is avoided, and the waterproof coating is enabled to be environment-friendly; by utilizing solid waste granules, cost can be reduced, and waste can be turned into wealth; manufacturing steps are simple and easy to control, large-scale industrial production is benefited, and the coating method is simple and easy to generalize.

Owner:SHANXI UNIV

Waterborne epoxy floor coating

InactiveCN111234649AHigh bond energyImprove aging resistanceFireproof paintsAnti-corrosive paintsChemical industryPolymer science

The invention provides a waterborne epoxy floor coating, and relates to the technical field of coatings in the field of chemical industry. The waterborne epoxy floor coating comprises a component A and a component B. The component A comprises a high-performance silicone acrylic modified aqueous epoxy emulsion, a pigment filler, an auxiliary agent and deionized water, and the component B is a mixedmodified amine curing agent. According to the invention, the high-performance silicone acrylic modified waterborne epoxy emulsion is used as a basis; a mixed modified amine compound is used as a curing agent; the film-forming comprehensive performance can be matched with that of solvent type epoxy resin, wherein silicon-oxygen bonds in the system have relatively large bond energy and relatively small surface energy, so that the aging resistance, heat resistance, oil resistance, water resistance, precipitation resistance, medium resistance and electrical property of a polymer coating are improved, and the prepared anticorrosive coating reaches and exceeds corresponding indexes of common solvent-based coatings, and is an environment-friendly terrace coating.

Owner:卢列定

Carbon fiber prepreg product and coating method thereof

ActiveCN110628066BGloss can be adjusted freelyImprove the decorative effectPretreated surfacesPowdery paintsFiberCarbon fibers

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

A kind of preparation method of silver nanowire film with high transmittance and low resistance

ActiveCN106504829BLower resistanceImprove conductivityTransportation and packagingMetal-working apparatusMetalIon

The invention discloses a method for preparing a silver nanowire film with high transmittance and low resistance. 1~0.5mol L-1 silver nitrate alcohol solution; b) dissolving the surfactant in the polyol to obtain a substance concentration of 0.05mol L-1~0.5mol L-1 surfactant alcohol solution; c) mix the silver nitrate alcohol solution and the surfactant alcohol solution in a volume ratio of 4:5, add the metal ion control agent, then heat up and let it stand to obtain the silver nanowire mother liquor; d) prepare the silver nanowire mother liquor in step c The silver nanowire mother liquor was washed, centrifuged, and dispersed with a dispersant after removing impurities to obtain a silver nanowire dispersion with a mass volume ratio of 0.2 mg·mL‑1~20mol·L‑1, and the length of the silver nanowire was 80um~200um , with a diameter of 40nm to 100nm; e) Put the cleaned substrate into a spin coater, drop the silver nanowire dispersion liquid prepared in step d on the surface of the substrate, and after the coating is completed, dry it naturally to obtain silver nanowire film.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

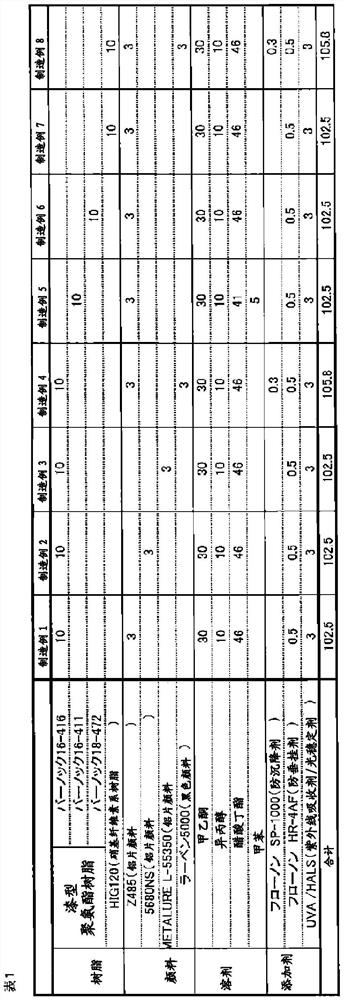

metal coating composition

ActiveCN110072955BEqual brightnessImprove concealmentSynthetic resin layered productsPolyurea/polyurethane coatingsMetal coatingPhotopigment

The present invention provides a metal coating composition, which maintains the same brightness as the metal coating film obtained by the conventional 3C3B coating method, and has no surface unevenness of the coating film, and can be used in a simplified coating method. There is no color clouding and diffuse reflection of the painted film, and the light fastness of the painted film is excellent. Specifically, a metal coating composition is provided, which includes: (1) a scaly bright pigment, (2) a resin with a weight average molecular weight of 40,000 to 60,000 and a glass transition temperature (Tg) of -25 to 40°C, and (3) Solvent.

Owner:DAI NIPPON TORYO CO LTD

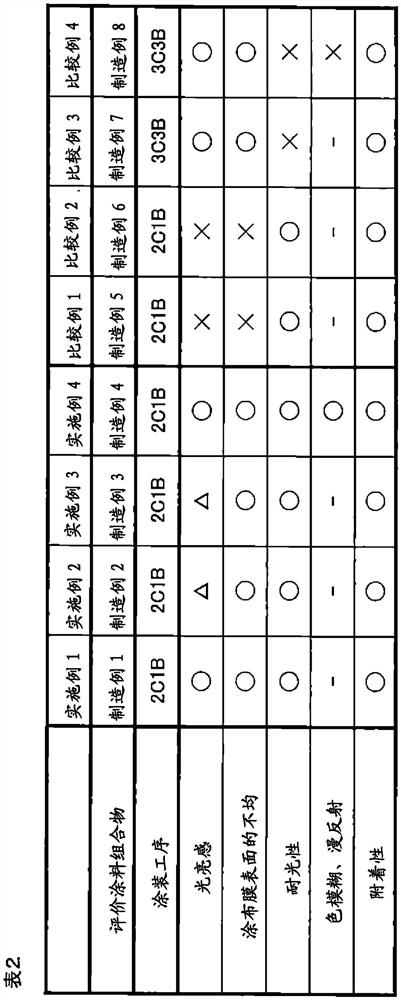

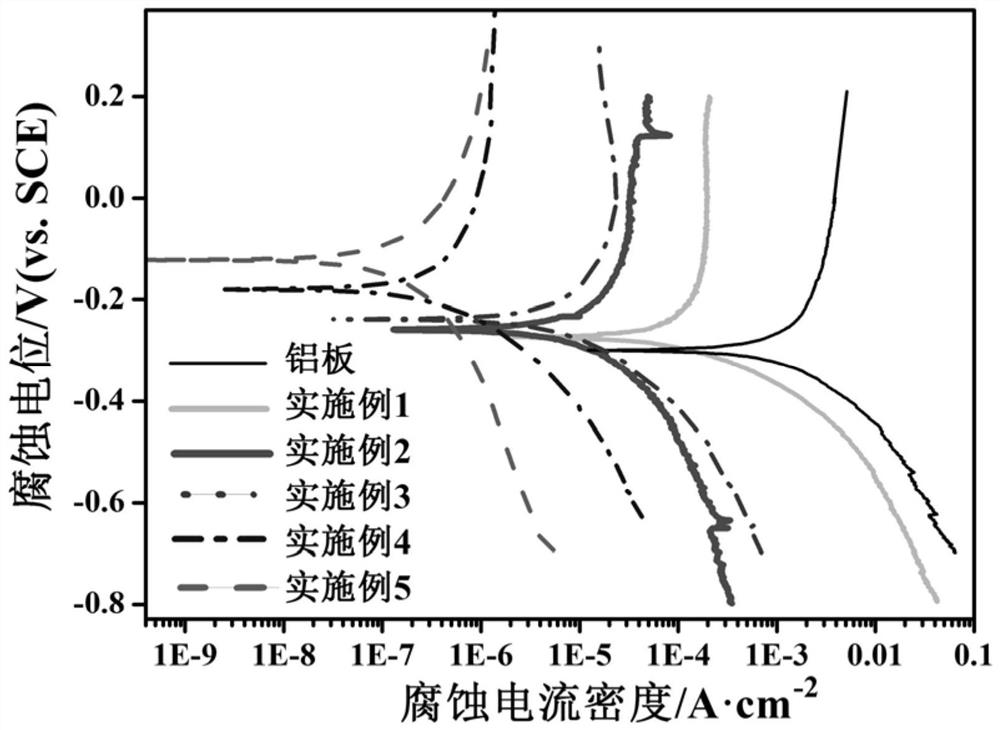

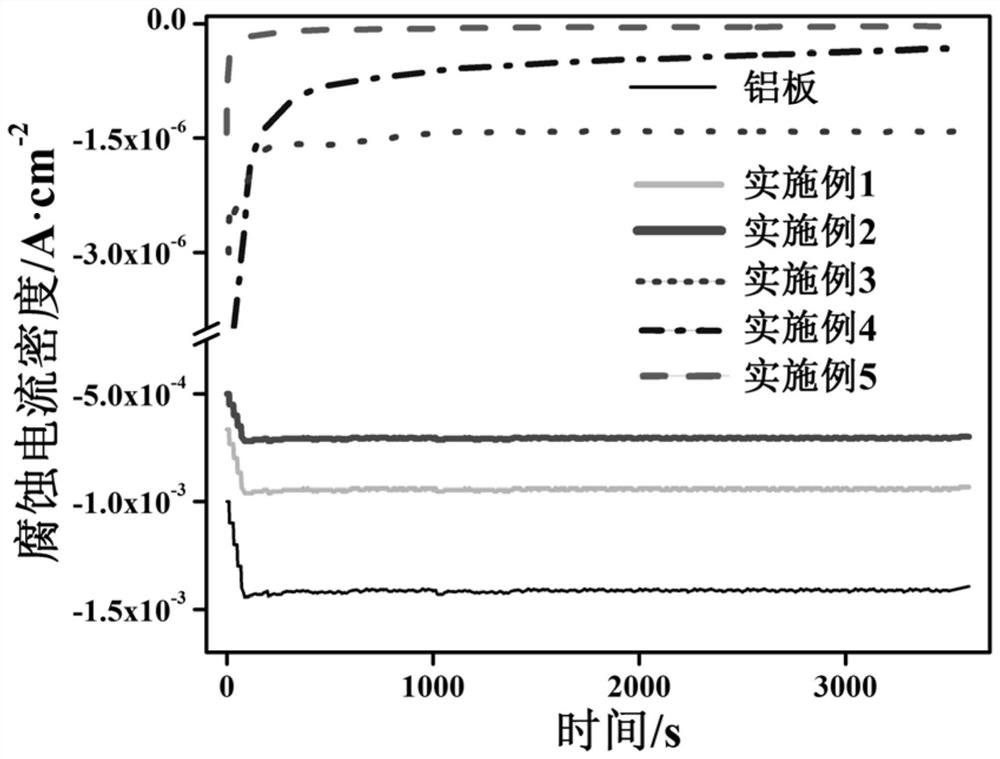

A conductive anti-corrosion coating process for aluminum flow field plate

ActiveCN107425209BImprove bindingFulfil requirementsCollectors/separatorsElectrical resistance and conductanceSodium Hypophosphite Monohydrate

The invention belongs to the technical field of a fuel cell, and discloses a conductive anti-corrosive coating process for an aluminium flow field plate. The conductive anti-corrosive coating process comprises the steps of firstly, carrying out preprocessing of polishing, precision polishing, ultrasonic cleaning, alkali cleaning, washing and the like on the aluminium flow field plate; then placing the preprocessed aluminium flow field plate into aqueous solution of graphene oxide, which contains tetrahydroxy aluminate ions, to impregnate, and after impregnation, cleaning with deionized water and carrying out normal temperature drying; and then impregnating in sodium hypophosphite solution to carry out processing, and after processing, cleaning with the deionized water and carrying out normal temperature drying. According to the invention, one compact graphene coating is coated on the surface of the aluminium flow field plate by adopting a chemical impregnation method which is simple to operate, low in cost, green and environmental-friendly. Conductivity and corrosion resistance testing results show that compared to an uncoated aluminium flow field plate, the coated aluminium flow field plate is obviously improved in corrosion resistance and is not reduced in conductivity, and thus, the requirements of the aluminium flow field plate for high corrosion resistance, high conductivity and low contact resistance in a fuel cell environment can be met.

Owner:TIANJIN UNIV

A closed coating process and manufacturing method for wooden furniture

The invention relates to a seal coating process and a manufacturing method of wood furniture. The seal coating process includes the steps of 1), using, by weight, 10-35% of air-drying resin, 60-85% o plastics and 5-30% of a thinner to blend brushing plastics; 2), coating the brushing plastics on a work piece with the coating weight controlled within 80-120g / m<2>; 3), starting a movable-type UV (ultraviolet) drier, and drying the plastics through motion of the movable-type UV drier; 4), diluting the sealing plastics to coat the same on the work piece; 5), starting the movable-type UV drier, and drying the plastics through motion of the movable-type UV drier. The coating process has the advantages of operation easiness; environment pollution, production space, polishing manpower, paint consumption, damages to human health, time on the coating process can all be reduced and the like.

Owner:JIANGMEN GUOMEI CHEM

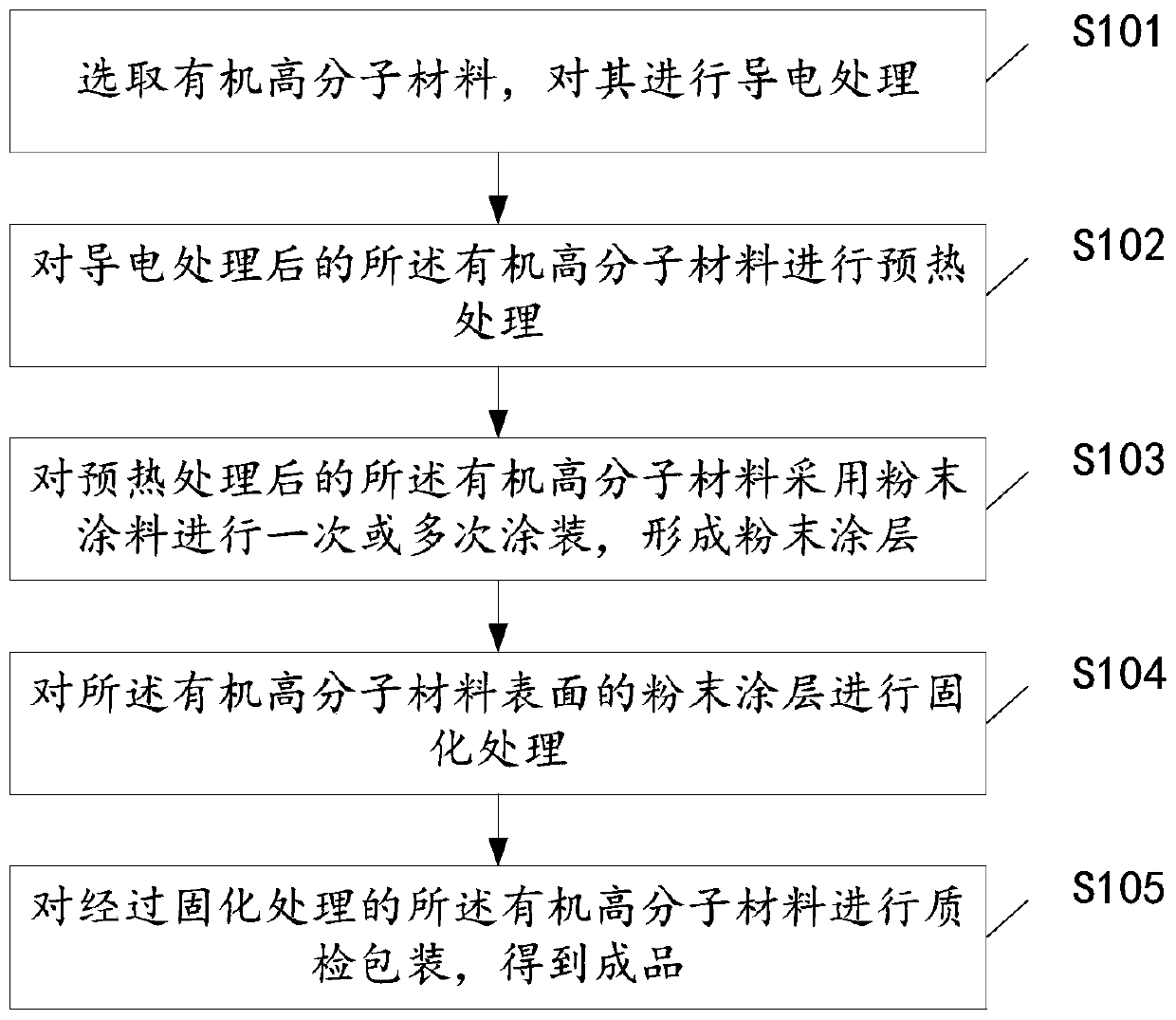

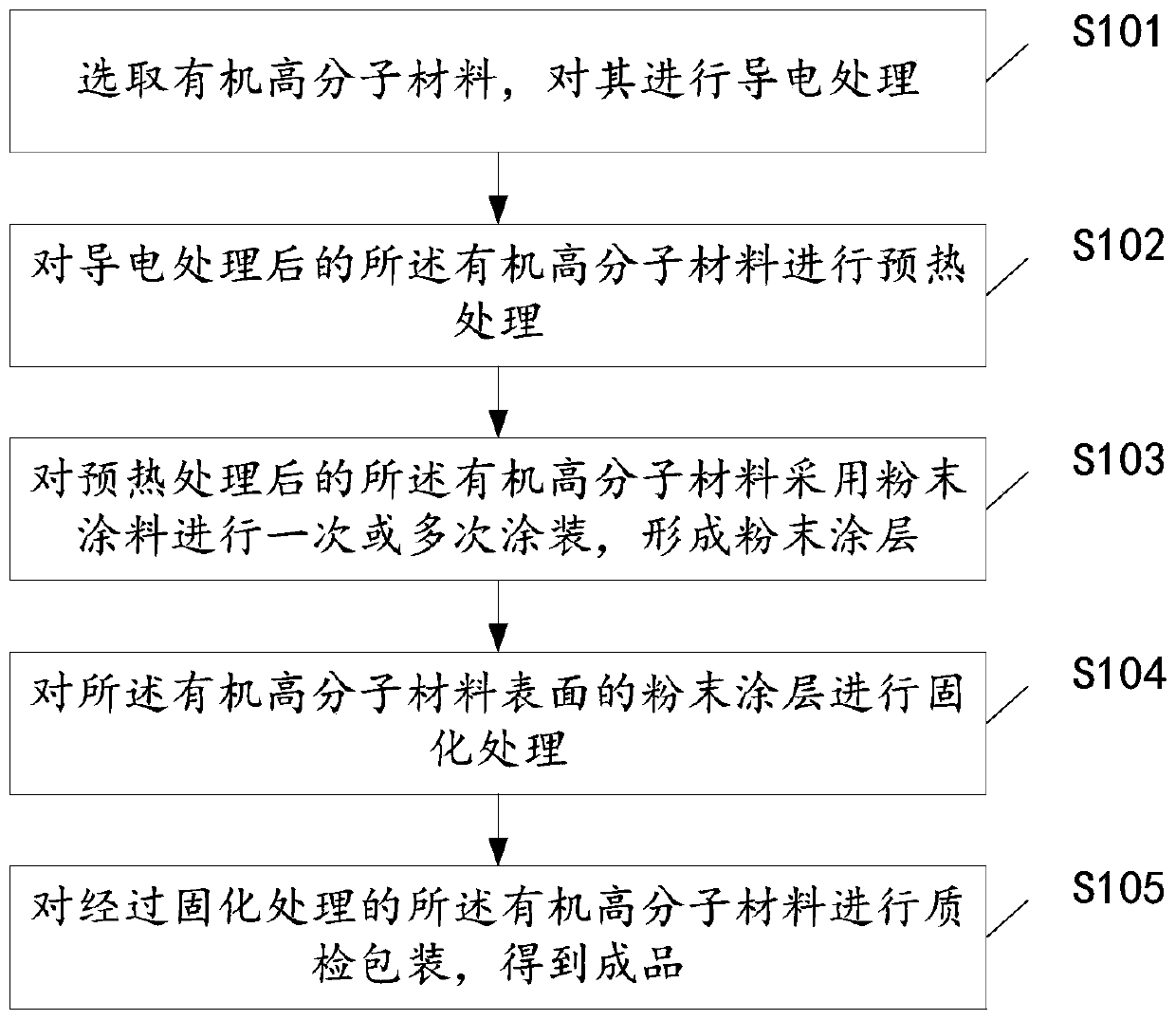

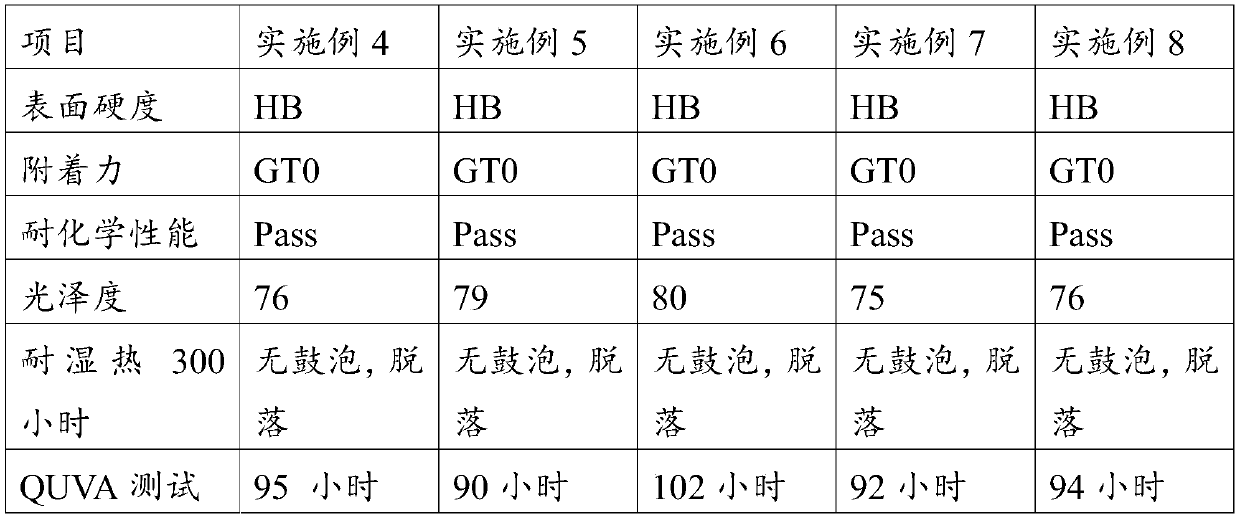

A kind of organic polymer material and coating method thereof

ActiveCN110577660BHigh resistivityImprove coating efficiencyPretreated surfacesPowdery paintsPolymer sciencePolymer chemistry

The invention discloses a coating method of an organic polymer material, and the method comprises the following steps:(1) selecting the organic polymer material and carrying out electric conduction treatment on the organic polymer material; (2) carrying out preheating treatment on the organic polymer material subjected to the electric conduction treatment; (3) coating the preheated organic polymermaterial with a powder coating for one or more times to form a powder coating layer; (4) carrying out curing treatment on the powder coating layer on the surface of the organic polymer material; and(5) carrying out quality inspection and packaging on the cured organic polymer material to obtain a finished product. Correspondingly, the invention also provides the organic polymer material preparedby the coating. The method is simple, controllable in process, high in efficiency, environmentally friendly, capable of saving energy and rich and diverse in decoration effect.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

Organic polymer material and coating method thereof

ActiveCN110577660AImprove coating efficiencyIncrease resistancePretreated surfacesPowdery paintsPowder coatingMaterials science

The invention discloses a coating method of an organic polymer material, and the method comprises the following steps:(1) selecting the organic polymer material and carrying out electric conduction treatment on the organic polymer material; (2) carrying out preheating treatment on the organic polymer material subjected to the electric conduction treatment; (3) coating the preheated organic polymermaterial with a powder coating for one or more times to form a powder coating layer; (4) carrying out curing treatment on the powder coating layer on the surface of the organic polymer material; and(5) carrying out quality inspection and packaging on the cured organic polymer material to obtain a finished product. Correspondingly, the invention also provides the organic polymer material preparedby the coating. The method is simple, controllable in process, high in efficiency, environmentally friendly, capable of saving energy and rich and diverse in decoration effect.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

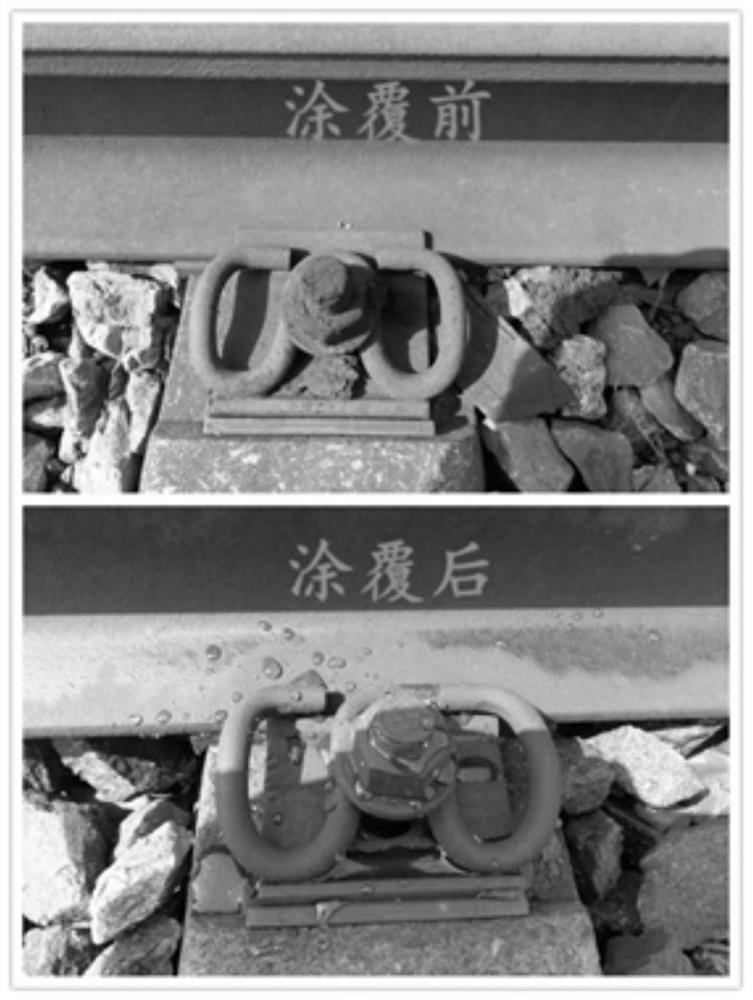

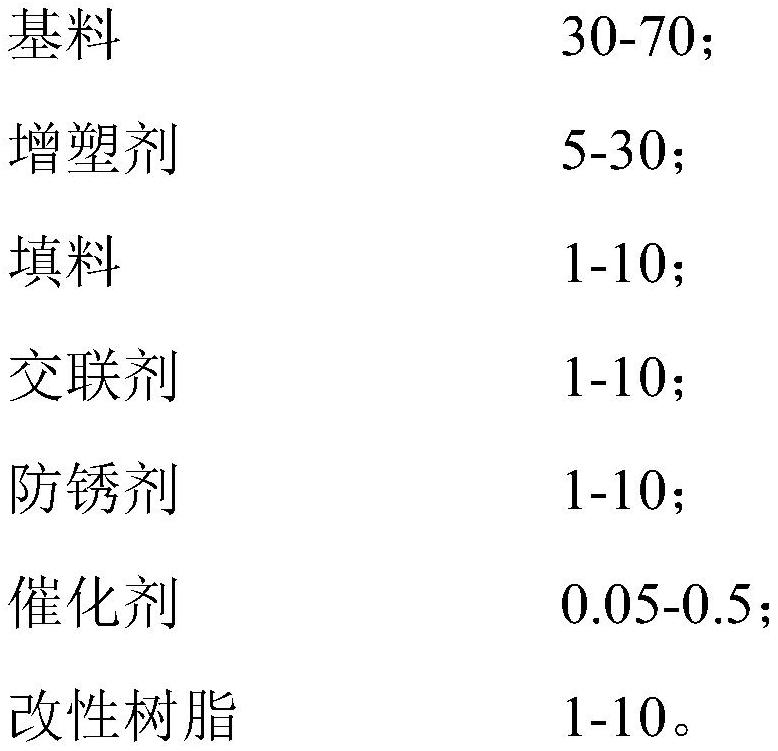

Anti-corrosion composite coating for rail fastener clips and bolt spikes, preparation method and coating method thereof

ActiveCN113185916BAchieving hydrophobic self-cleaningAchieving UV resistanceLiquid surface applicatorsAnti-corrosive paintsPtru catalystAcrylic resin

The invention discloses an anti-corrosion composite coating for rail fastener clips and bolt spikes and a preparation method and a coating method thereof. The composite coating includes a bottom layer and a surface layer, the bottom layer is modified silicone rubber, and the surface layer is modified fluorosilicon rubber. permanent acrylic resin. The preparation method is as follows: (1) Configure the primer: heat and mix the base rubber, plasticizer and filler, add modified resin and antirust agent to stir, then lower the temperature, add crosslinking agent and catalyst in sequence, and obtain modified silicone rubber ; (2) Configure the surface coating: fluorine-silicon modified acrylic resin is that the acrylic resin is first modified by silicon and then modified by fluorine. The coating method is rust coating. The coating adopts two layers of materials and methods. The bottom layer achieves anti-corrosion performance and improves the adhesion to the surface of the rail; the surface layer realizes the hydrophobic self-cleaning and anti-ultraviolet properties of the coating surface; Layer migration performance, can be firmly attached to the track surface, good anti-corrosion effect; simple coating process, reducing coating workload.

Owner:ZHEJIANG BAOSHENG RAILWAYNEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com