Anti-corrosion composite coating for rail fastener clips and bolt spikes, preparation method and coating method thereof

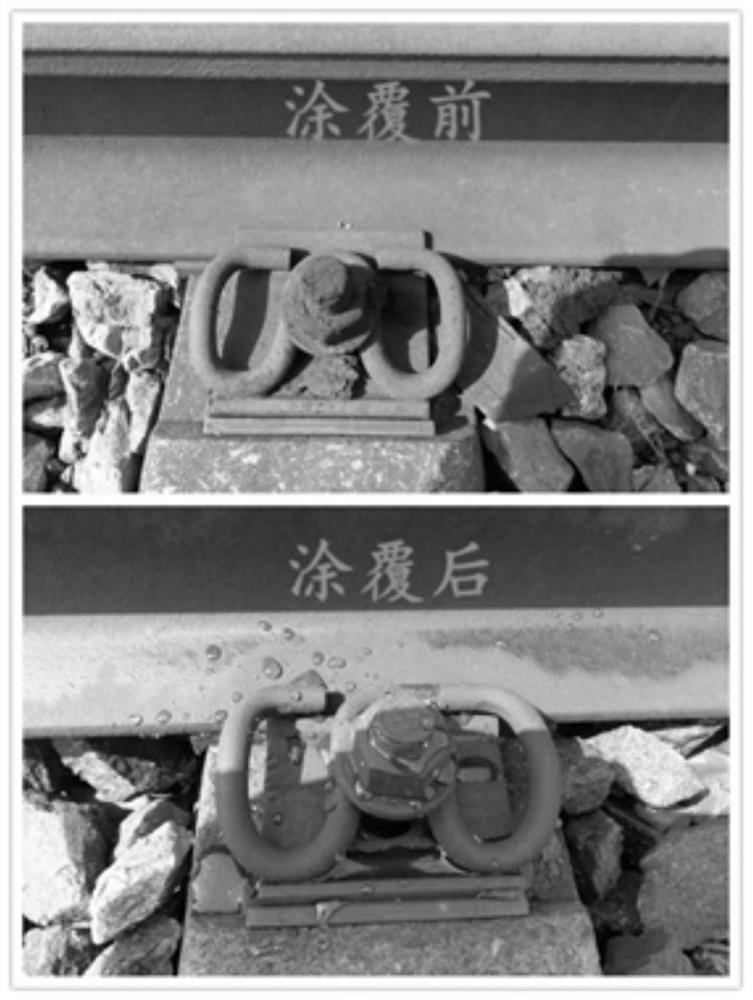

A composite coating and anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, coatings, and devices for coating liquid on the surface, and can solve the problems of low bonding force between anti-corrosion grease and rail substrate, low coating efficiency, and poor coating quality , to achieve the effect of reducing the coating workload and labor intensity, good anti-corrosion effect, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

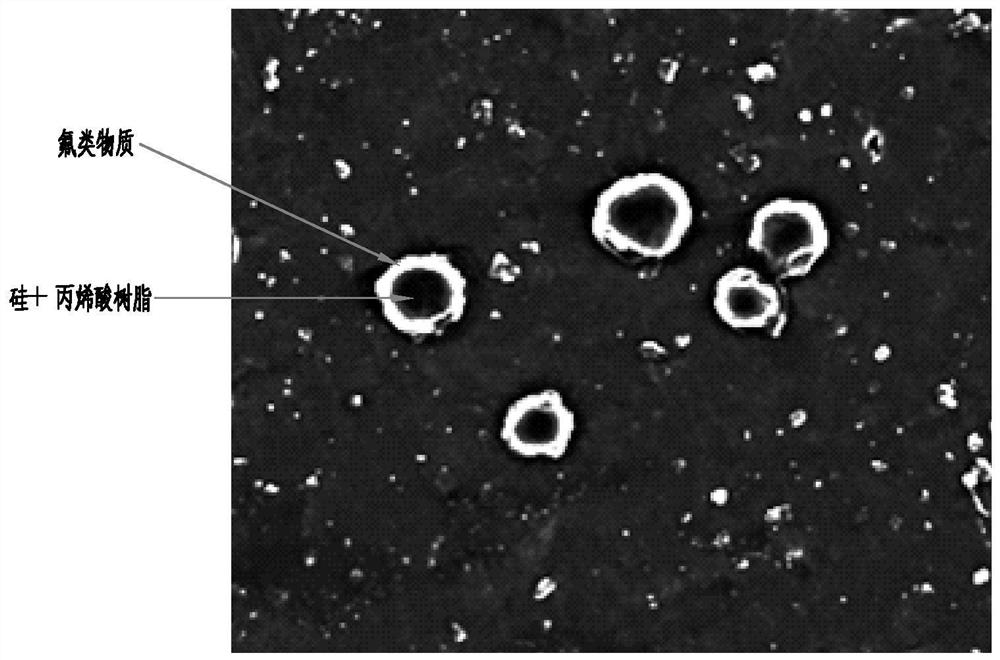

[0053] (1) Configure modified fumed silica:

[0054] In a 500ml three-necked flask, add 300ml of xylene, 14g of gas phase white carbon black, 0.56g of water, stir at room temperature for 1 hour, add 2.52g of hexamethyldisilazane, heat and stir, and control the temperature at 110 to 130 degrees to react. After 2 h, the temperature was lowered, the xylene was evaporated under reduced pressure, the product was poured out, dried and used for later use.

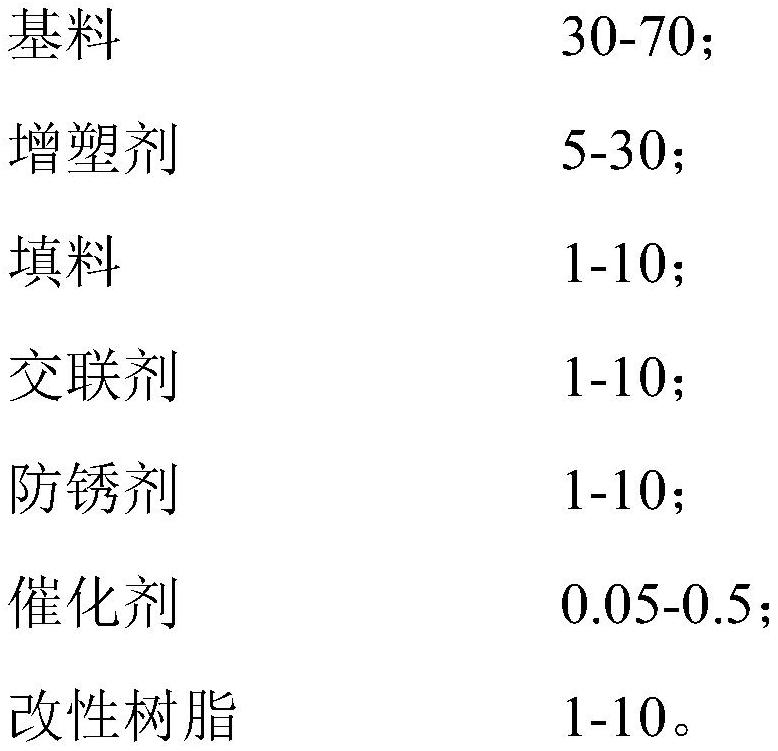

[0055] (2) Configure the primer:

[0056] Heat and mix 30g of α,ω-dihydroxy polydimethylsiloxane with a viscosity (25°C) of 8000cs and a hydroxyl content of 0.004mol / 100g and 5g of silicone oil 201, keep at 160±10°C for 1.5 hours, add 2g of modified resin EVA, stirred for half an hour, then added 1g of barium petroleum sulfonate, stirred for half an hour, then cooled to 50°C, added 0.5g of vinyltributanone oximinosilane, mixed for 15min, and added 0.5g of methyl triacetate. Butanone oxime silane, plus 0.05 g of dibutyltin dilaur...

Embodiment 2

[0063] Step (1) is the same as Example 1

[0064] (2) Configure the primer:

[0065] Heat and mix 40g of α,ω-dihydroxy polydimethylsiloxane with a viscosity (25°C) of 8000cs and a hydroxyl content of 0.004mol / 100g and 10g of silicone oil 201, keep at 160±10°C for 1.5 hours, add 5g of modified resin EVA, stirred for half an hour, then added 2g of barium petroleum sulfonate, stirred for half an hour, then cooled to 50°C, added 1g of vinyltributanone oximosilane, mixed for 15min, and added 2g of methyltributanone The oxime silane was added with 0.1 g of dibutyltin dilaurate, mixed uniformly, stirred for half an hour, decompressed for about 5 minutes, and removed air bubbles to obtain a primer modified silicone rubber.

[0066] (3) Configure the surface coating:

[0067] Pass N in the reactor for 30min 2 , add 13g acrylic resin, 70g n-butanol, 1g silicone defoamer, turn on the reflux device, stir and heat up to 70±10°C, add 13g acrylic resin, 1g benzoyl peroxide, 7g vinyltrimet...

Embodiment 3

[0070] Step (1) is the same as Example 1

[0071] (2) Configure the primer:

[0072] Heat and mix 50g of α,ω-dihydroxy polydimethylsiloxane with a viscosity (25°C) of 8000cs and a hydroxyl content of 0.004mol / 100g and 15g of silicone oil 201, keep at 160±10°C for 1.5 hours, add 7g of modified resin EVA, stirred for half an hour, then added 5g of barium petroleum sulfonate, stirred for half an hour, then cooled to 50°C, added 1g of vinyltributanone oximosilane, mixed for 15min, and added 3g of methyltributanone The oxime silane was added with 0.2 g of dibutyltin dilaurate, mixed uniformly, stirred for half an hour, and decompressed for about 5 minutes to remove air bubbles to obtain a primer modified silicone rubber.

[0073] (3) Configure the surface coating:

[0074] Pass N in the reactor for 30min 2 , add 15g acrylic resin, 80g n-butanol, 1g silicone defoamer, turn on the reflux device, stir and heat up to 70±10℃, add 15g acrylic resin, 1g benzoyl peroxide, 8g vinyltrimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com