Patents

Literature

43results about How to "Achieve hydrophobicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

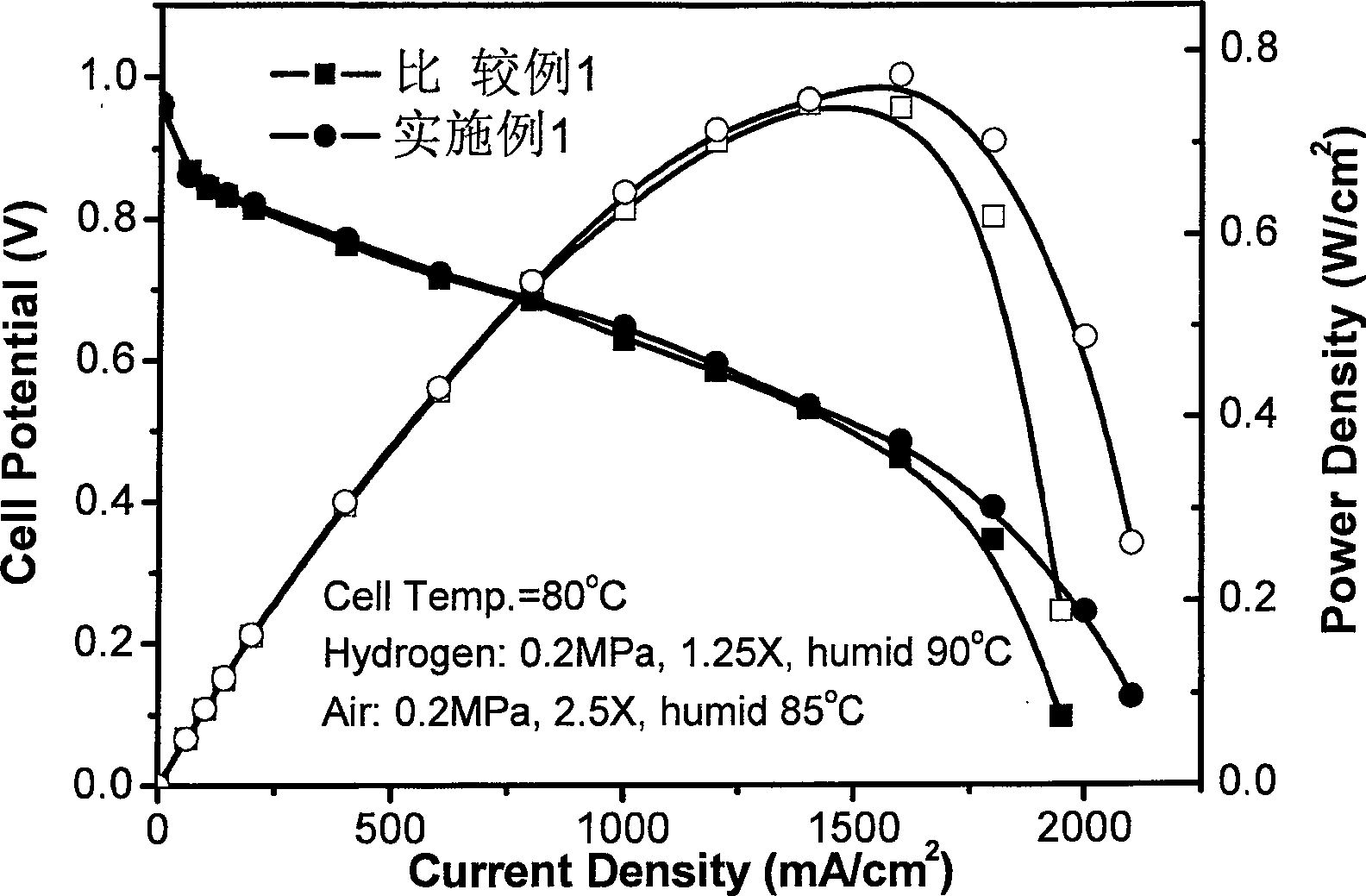

Gas diffusion layer for fuel cell and its production

InactiveCN101154733AGuaranteed hydrophobicityAchieve hydrophobicityCell electrodesFinal product manufactureFuel cellsElectrical battery

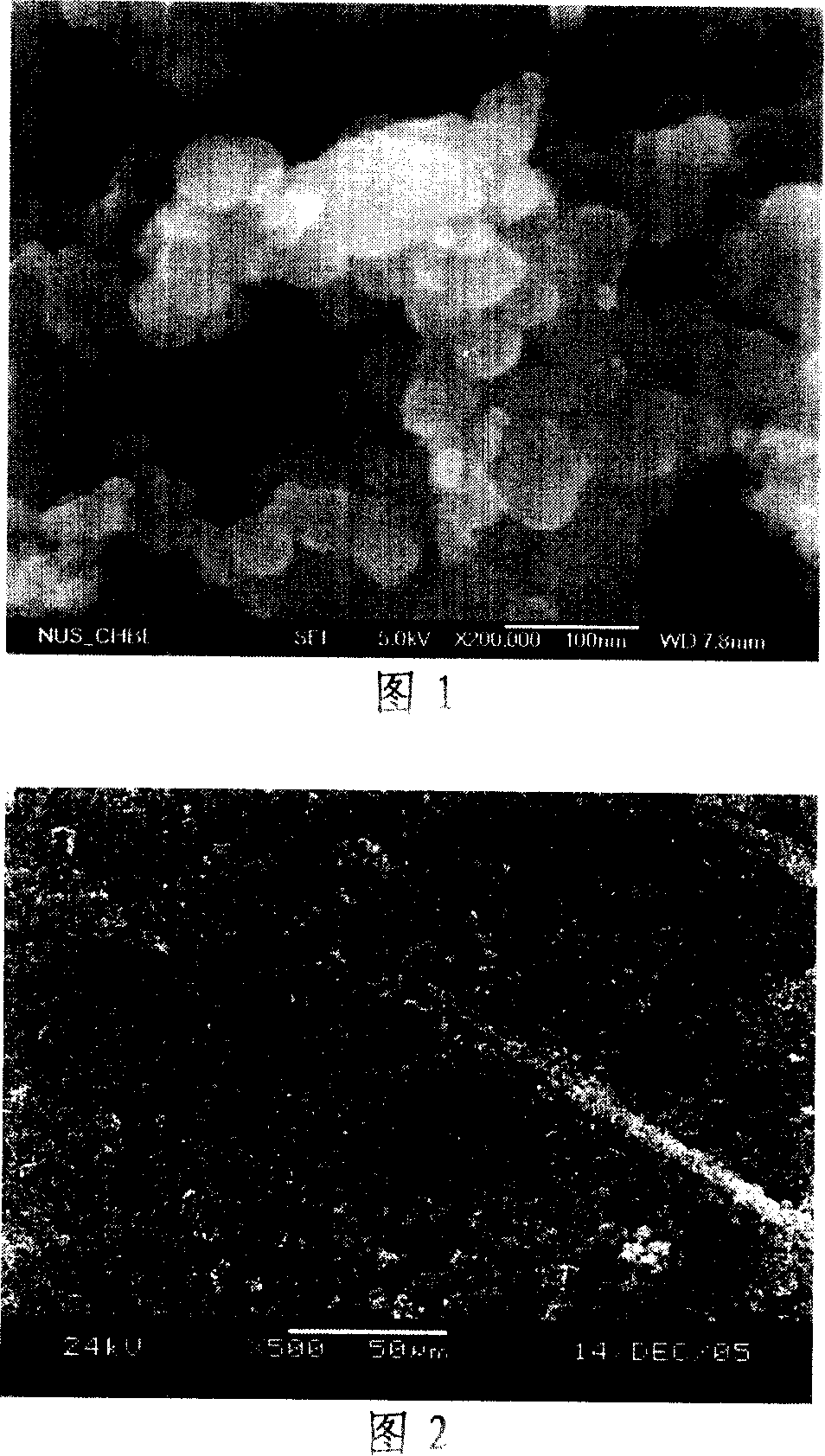

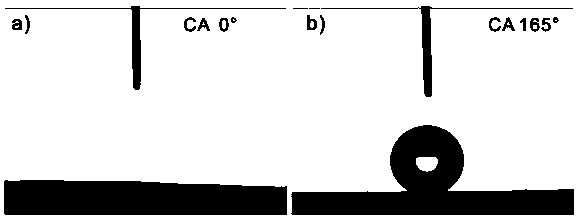

The invention relates to a fuel battery, in particular to a gas diffusing layer and the preparation for the fuel battery; the gas diffusing layer consists of basic bottom layer and a micro-hole layer, which is made by fabricating the micro-hole constructed by a water repellent agent / a composite powder body of electric conduction copper material at one side or two sides of a porous electric conduction basic bottom processed by a hydrophobic water; the water repellent agent / the composite powder body of electric conduction copper material is made by a microwave dielectric heating technology; because of the favorable water repellent performance and the grain diameter structure therefore, the gas diffusing layer to be fabricated has a strong and even water repellent performance and a suitable hole structure, so that the favorable mass transfer capability of the gas diffusing layer can be assured. The fuel battery assembled by the invention can show a better battery output performance, and is particularly suitable to be used in the fuel battery where the air is used as oxidizer with a strong practicality value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

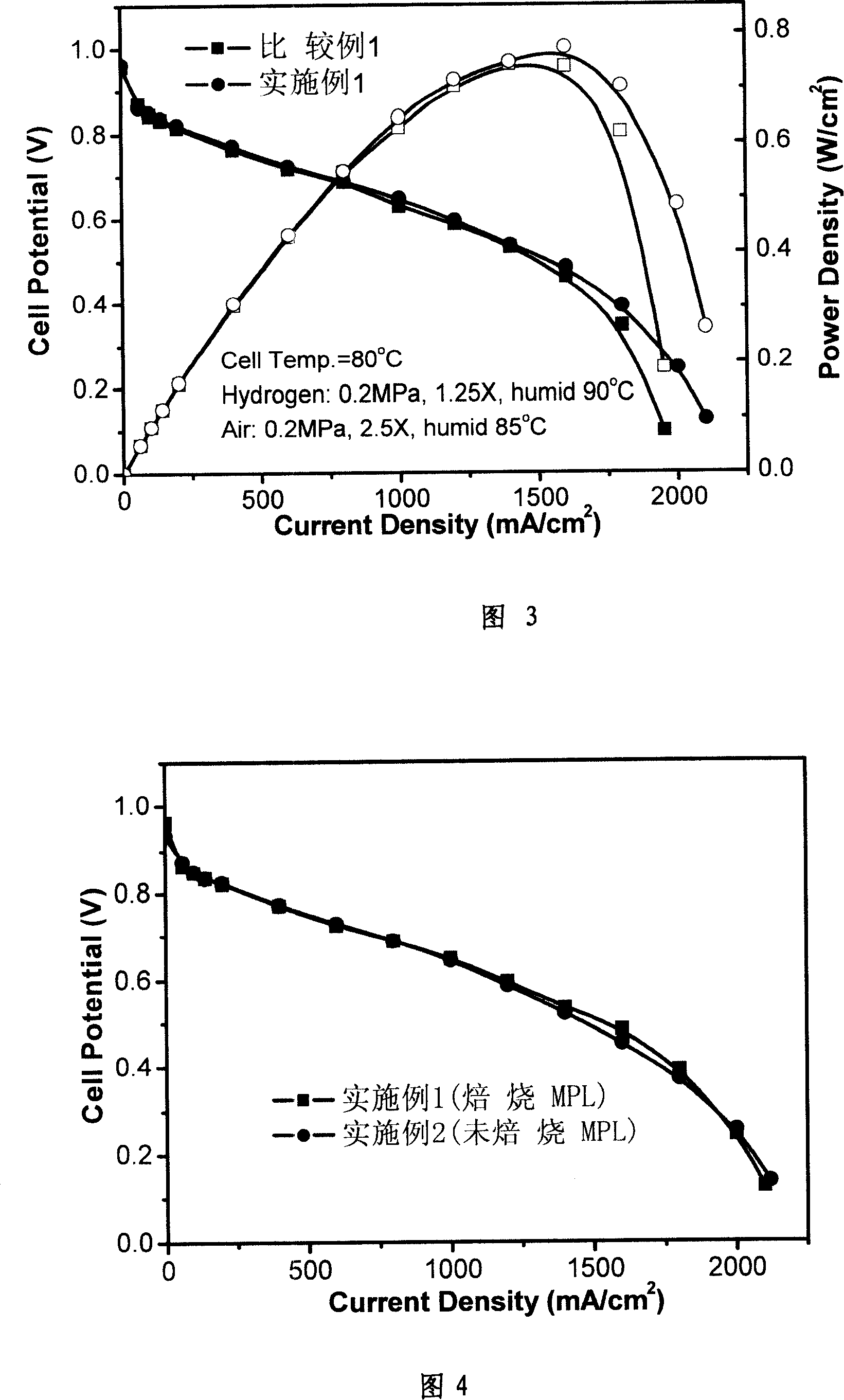

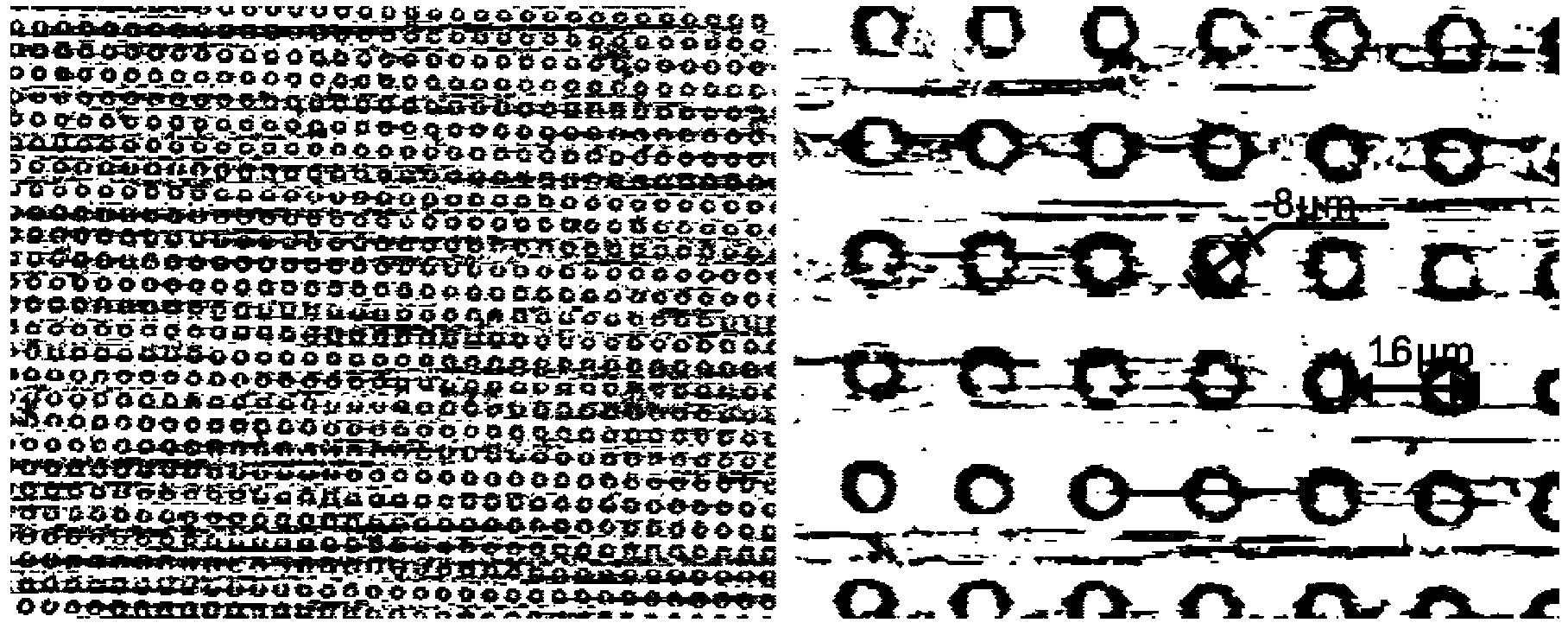

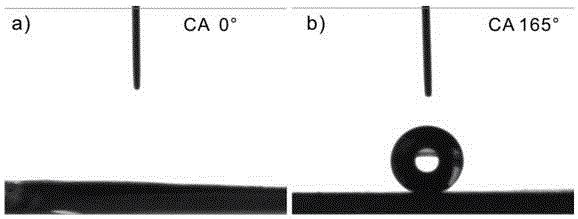

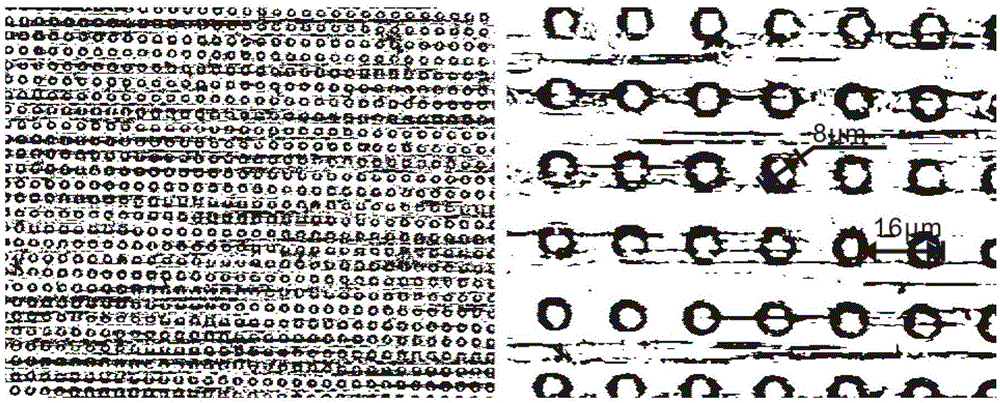

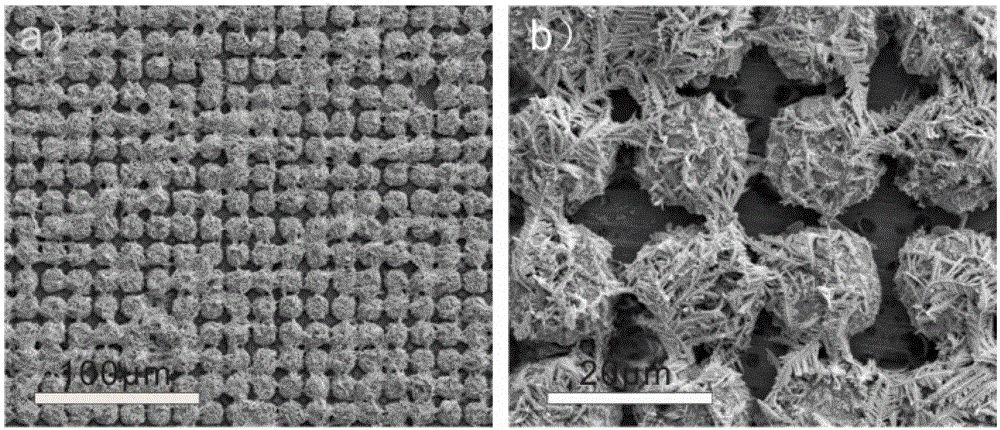

Manufacturing method for copper-based super-hydrophobic surface structure

InactiveCN103406248AShort preparation cycleEasy to operatePretreated surfacesSpecial surfacesScale structurePhotoresist

A manufacturing method for a copper-based super-hydrophobic surface structure mainly includes that step 1, a metal copper base is pre-processed; step 2, a layer of photoresist is coated on the surface of the processed copper base in a rotation mode, and the photoresist layer attached to the surface of the copper base forms a well-aligned porous array template through photoetching processing; step 3, the copper base with the well-aligned porous array template obtained in the step 2 is used as an anode and soaked in a CuSO4 solution to form a primary battery to conduct a reaction for 4-8 min; step 4, the copper base of the primary battery obtained in the step 3 after reaction is finished is soaked into an AgNO3 solution to conduct in-situ reduction for 30-70s; step 5, the copper base subjected to the reaction in the step 4 is subjected to silanization processing, and the copper-based super-hydrophobic surface structure is manufactured. By means of the method, two simple redox processes are utilized to obtain a layer of micro-nano dual-scale structure similar to the lotus leaf surface on the surface of copper metal, hydrophobe is achieved, the performance of the manufactured super-hydrophobic surface is stable, a contact angle between the super-hydrophobic surface and a water solution with a pH value ranging from 1 to 14 can be larger than 155 degrees, and the minimum rolling angle can be smaller than 1.5 degrees.

Owner:WUHAN UNIV OF TECH

Super-hydrophobic material and preparation method thereof

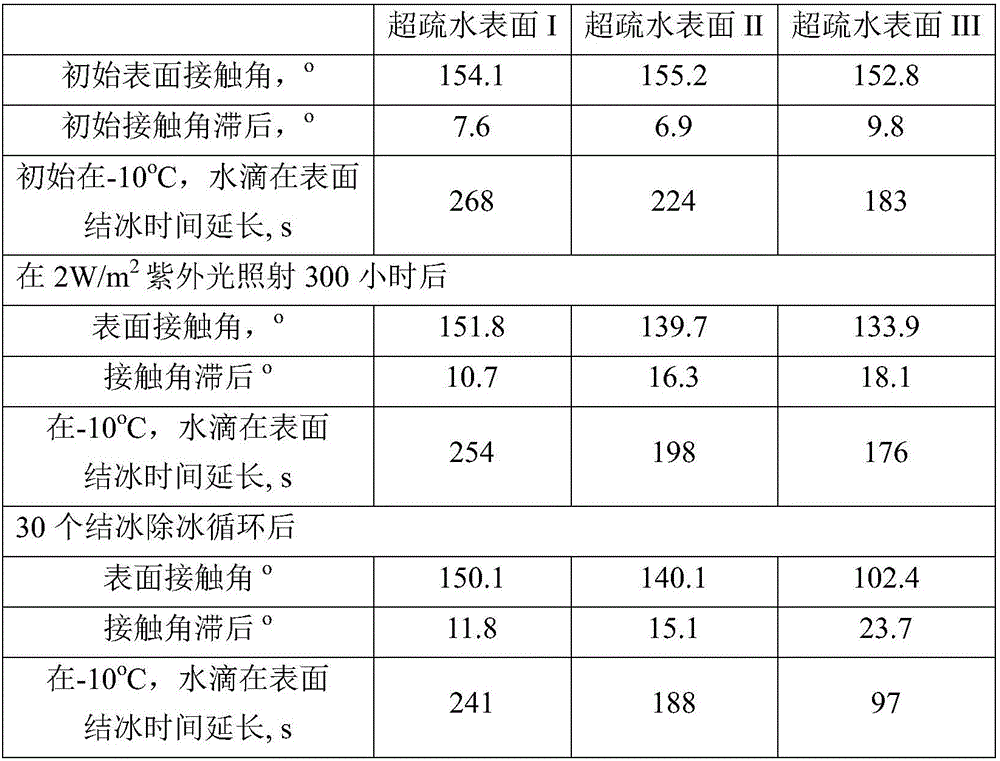

InactiveCN106752462AAchieve hydrophobicityAchieving UV resistanceCoatingsUltraviolet resistanceCoating

The invention discloses a super-hydrophobic material which comprises a substrate and a coating layer, wherein the coating layer comprises the following ingredients in parts by weight: 65-78 parts of resin and 8-16 parts of nano-particles. The invention also provides a preparation method of the super-hydrophobic material. The super-hydrophobic material prepared by the preparation method provided by the invention has the advantages that the ultraviolet resistance is strong, the material is wear-resisting, the freezing time on the surface can be effectively prolonged, etc.; meanwhile, the service life of the super-hydrophobic material is prolonged, and the super-hydrophobic material has wide market prospect.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

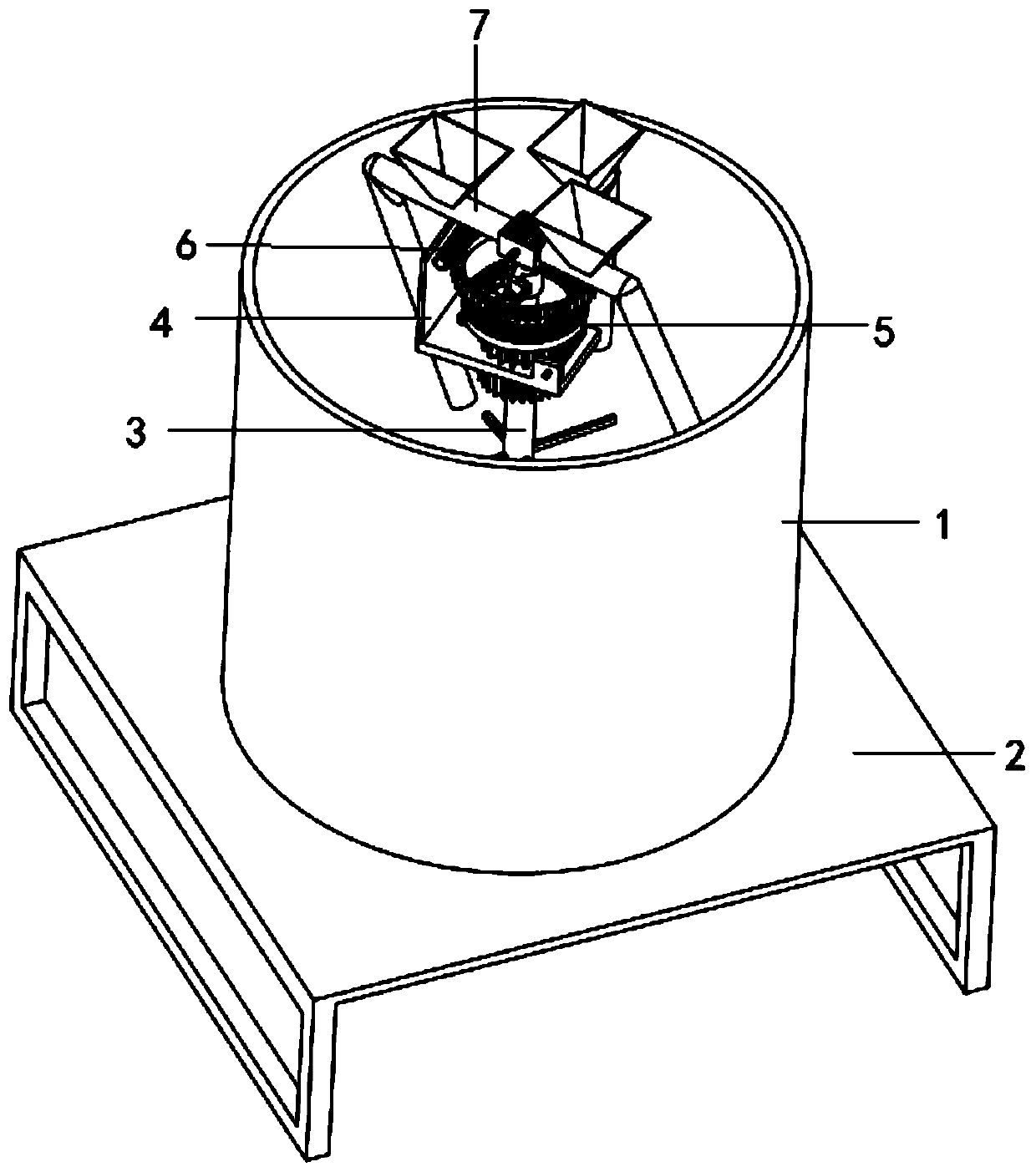

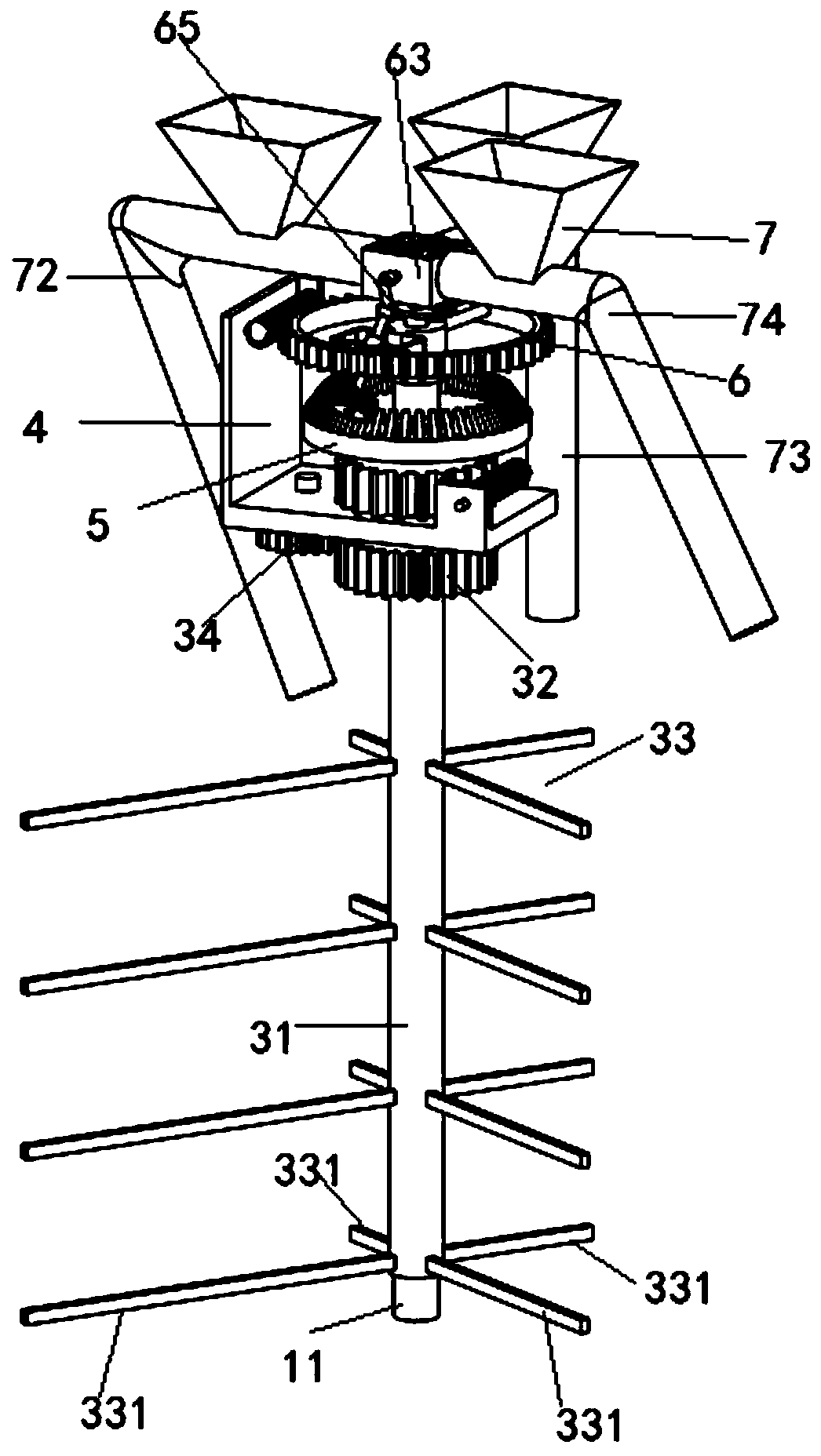

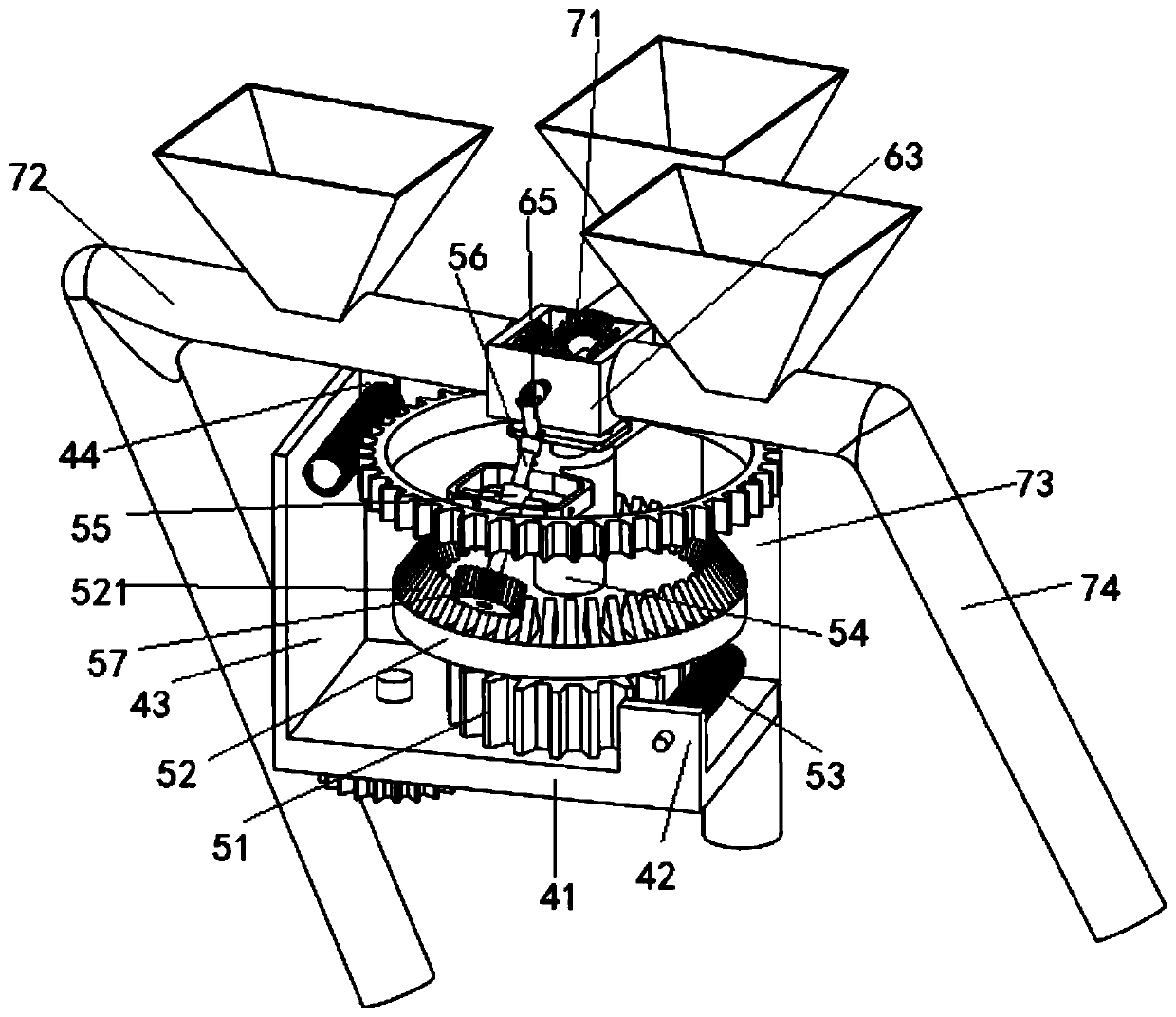

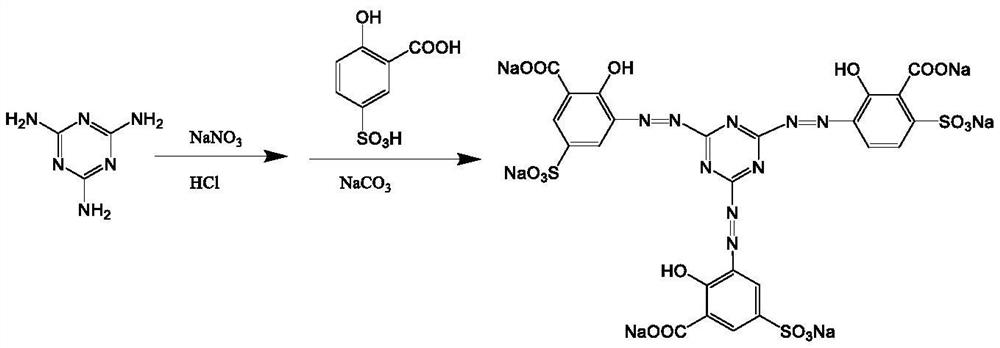

Preparation process of modified heavy calcium carbonate

ActiveCN111302373AAutomatic control timeAutomatically control the amount addedCalcium/strontium/barium carbonatesCosmetic preparationsPhysical chemistryInorganic chemistry

The invention discloses a preparation process of modified heavy calcium carbonate. The preparation process comprises the following steps: simultaneously adding a modified grafting agent and an ethanolsolution into a stirring reaction cylinder of a dispersive feeding type stirring device, simultaneously dividing heavy calcium carbonate into three equal parts, respectively adding the three equal parts into three dispersive feeding mechanisms, stopping stirring after the reaction is completed, discharging, filtering the obtained material, and drying to obtain the modified heavy calcium carbonate. In the process for improving heavy calcium carbonate, the dispersive feeding type stirring device is used, a first material guide cylinder, a second material guide cylinder and a third material guide cylinder in the device go deep into the three positions of the center edge side and the middle of the stirring reaction cylinder, materials are evenly added into the different positions of the stirring reaction cylinder, meanwhile, due to the fact that the whole dispersed feeding mechanism conducts feeding in the rotating process, stirring is conducted while feeding is conducted, and then sufficient mixing of the materials is achieved.

Owner:广西凤山县鑫峰矿业有限责任公司

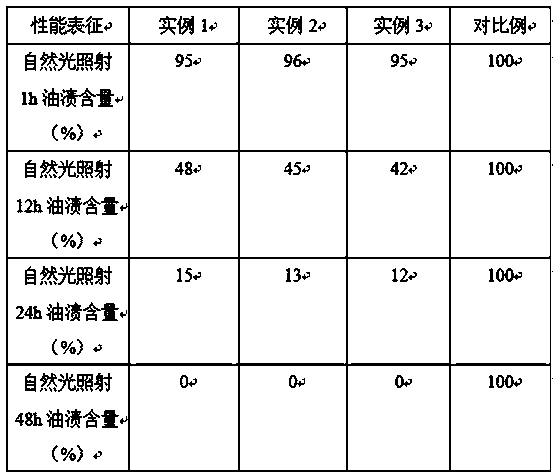

Nanometer self-cleaning coating and preparation method thereof

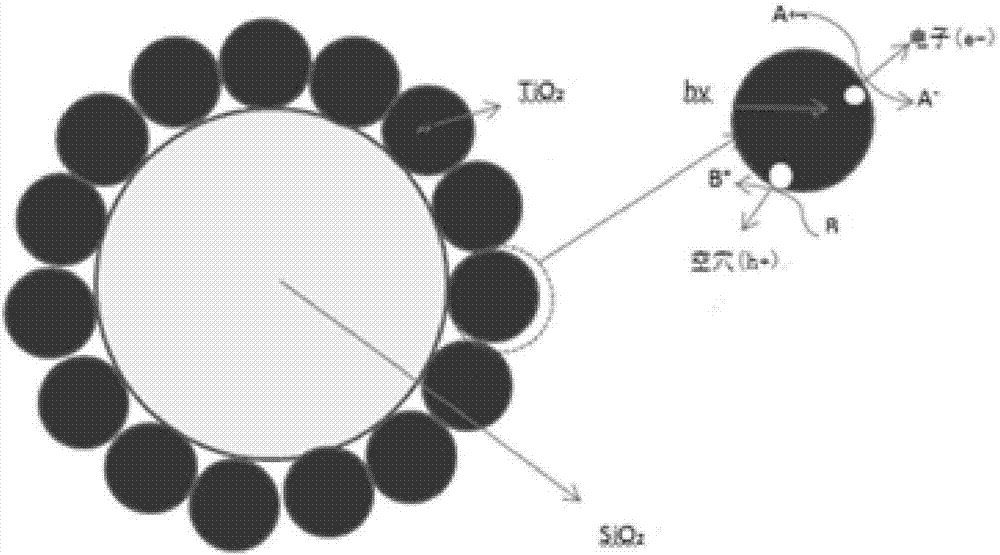

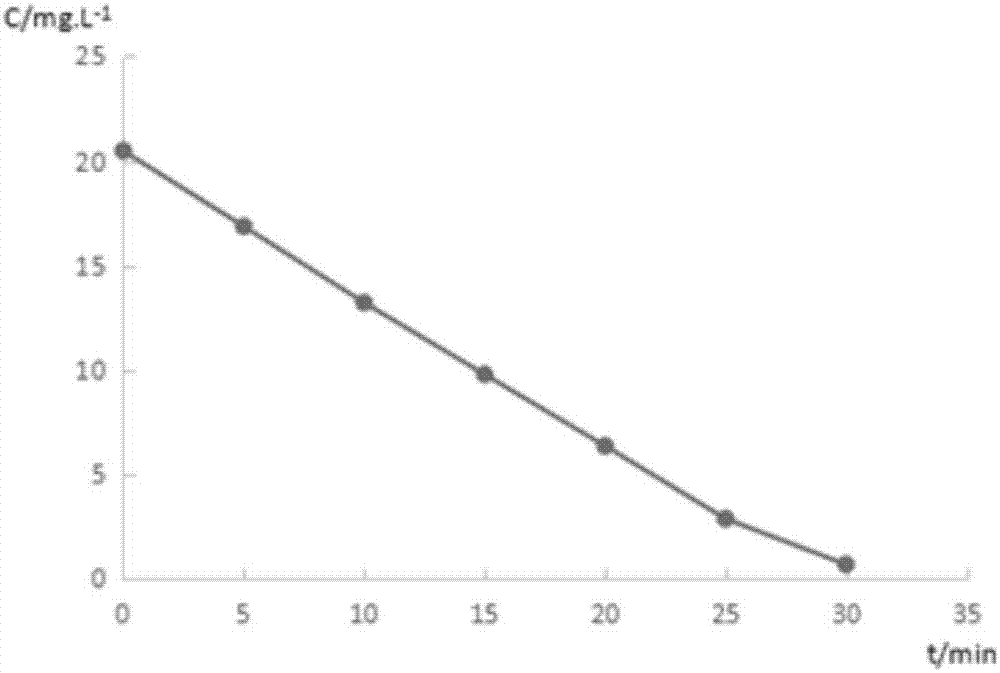

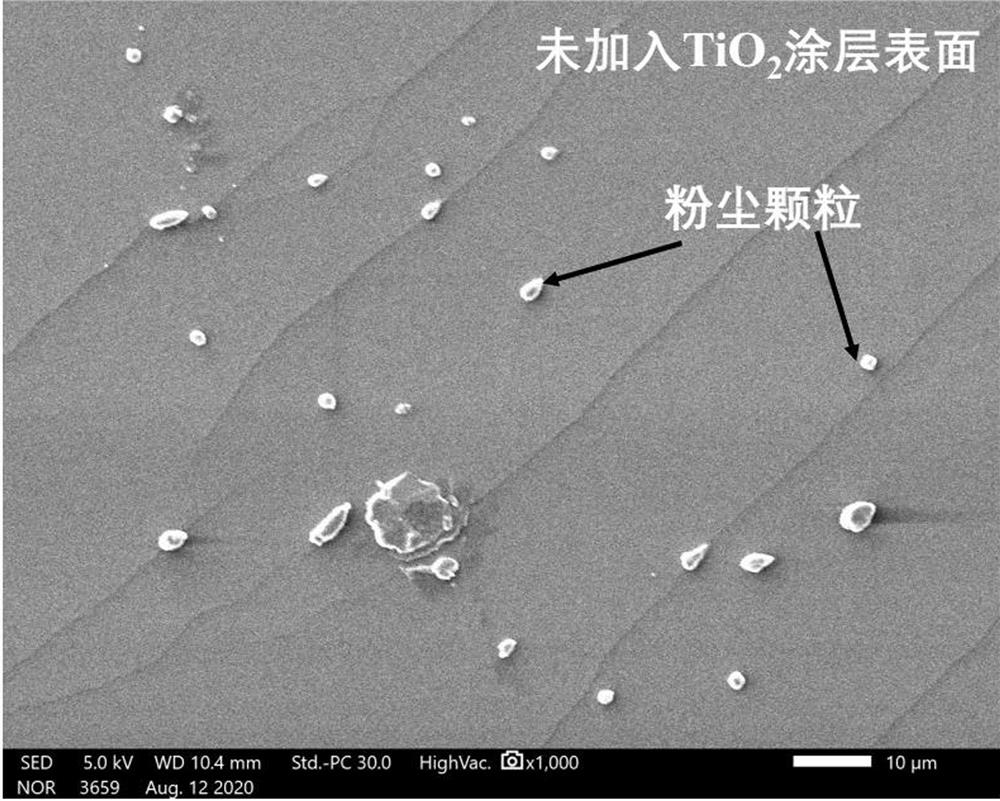

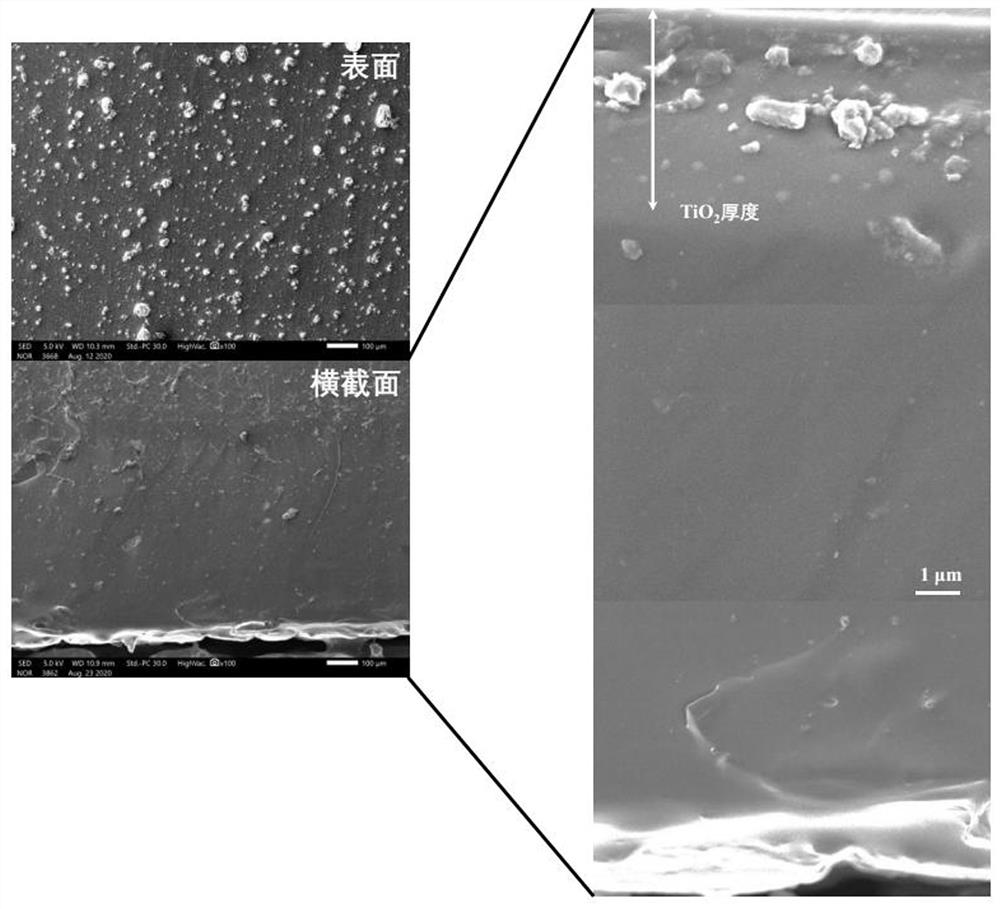

InactiveCN107474665AAchieve hydrophobicityStrong oxidation abilityCoatingsAcrylic resinComposite nanoparticles

The invention discloses a nanometer self-cleaning coating and a preparation method thereof. The preparation method comprises the following steps of: firstly synthesizing SiO2 by a hydrolyzation method, adding a nanometer photocatalyst in the synthetic process, preparing SiO2 / photocatalyst hydrophobic composite nanoparticles with a photocatalytic property, then polymerizing fluorine-containing function monomers and soft-hard monomers under the action of an inhibitor to form fluorine-modified acrylic resin, and finally adding the SiO2 / photocatalyst hydrophobic composite nanoparticles into the fluorine-modified acrylic resin, plating membranes by adopting a dipping-pulling method to prepare the nanometer self-cleaning coating. The nanometer self-cleaning coating and the preparation method disclosed by the invention have the advantages that the hydrophobic function and the photocatalytic function are achieved, organic dirt adhered on the surface of a basic material can be effectively decomposed into inorganic substances, and by combination of the hydrophobic function, the self-cleaning effect for the surface can be realized.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of durable hydrophobic anti-photoaging stone cultural relic sealing and protecting coating

The invention belongs to the technical field of preparation of a novel anti-photoaging stone cultural relic coating, and provides a preparation method of a durable hydrophobic anti-photoaging stone cultural relic sealing coating in order to overcome the defects that an existing anti-photoaging stone cultural relic sealing coating is poor in durability, prone to pollution, poor in anti-photoaging performance, low in strength and the like. According to the invention, fluorosilane and nano TiO2 are added into an isopropanol solution, and ultrasonic dispersion is carried out; a mixed solution of PDMS and a curing agent are prepared; and the fluorosilane grafted nano TiO2 is dried, the dried fluorosilane grafted nano TiO2 is added into a PDMS mixed solution, ultrasonic dispersion is carried out, the surface of the stone cultural relic is coated with the obtained product, vacuumizing is carried out, and curing is performed to obtain the durable hydrophobic anti-photoaging stone cultural relic sealing and protecting coating. Due to the fact that the nano TiO2 with the light shielding performance is enriched on the surface, the light aging resistance is improved. The fluorosilane-modifiednano TiO2 migrated to the surface reduces the surface energy of the coating, thereby enhancing the hydrophobicity. The preparation method is simple and easy to implement, short in period, suitable forlarge-scale production and applied to stone cultural relic protection.

Owner:TAIYUAN UNIV OF TECH

Pressure-resistant and weather-resistant light material containing loofah sponge and used for vehicle covering and preparation method

InactiveCN105200667AImprove stress resistanceEasy to carryFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsWeather resistanceSodium carboxymethylcellulose

The invention discloses a pressure-resistant and weather-resistant light material containing loofah sponge and used for vehicle covering and a preparation method. The light material comprises raw materials in parts by weight as follows: 100-200 parts of nano loofah sponge fiber, 40-80 parts of nano lotus leaf fiber, 30-50 parts of polypropylene staple fiber, 20-40 parts of sodium hydroxide, 3-7 parts of ultraviolet ray absorption polyester, 1-5 parts of a brominated flame retardant, 4-6 parts of nano hollow glass beads, 60-80 parts of epoxy resin, 5-7 parts of a coupling agent, 4-8 parts of phenyl silicone oil, 2-4 parts of carboxymethyl cellulose sodium, 70-80 parts of polystyrene, 15-25 parts of hydrochloric acid, 12-20 parts of ethanol and an appropriate amount of deionized water. An epoxy resin material is prepared from the low-density and light loofah sponge fiber with high toughness, high pressure resistance and high fracture resistance in cooperation with weather-proof materials such as ultraviolet ray absorption polyester, the brominated flame retardant, the nano hollow glass beads and the like; the pressure-resistant and weather-resistant light material has the advantages of lightweight, pressure resistance, weather resistance, convenience in carrying and use and the like; the hydrophobic lotus leaf fiber is adopted for graft modification of the loofah sponge fiber, and hydrophobicity is realized; the polypropylene staple fiber is adopted for graft modification of the loofah sponge fiber, and the fracture resistance of the material is realized.

Owner:FOSHAN LANTU TECH CO LTD

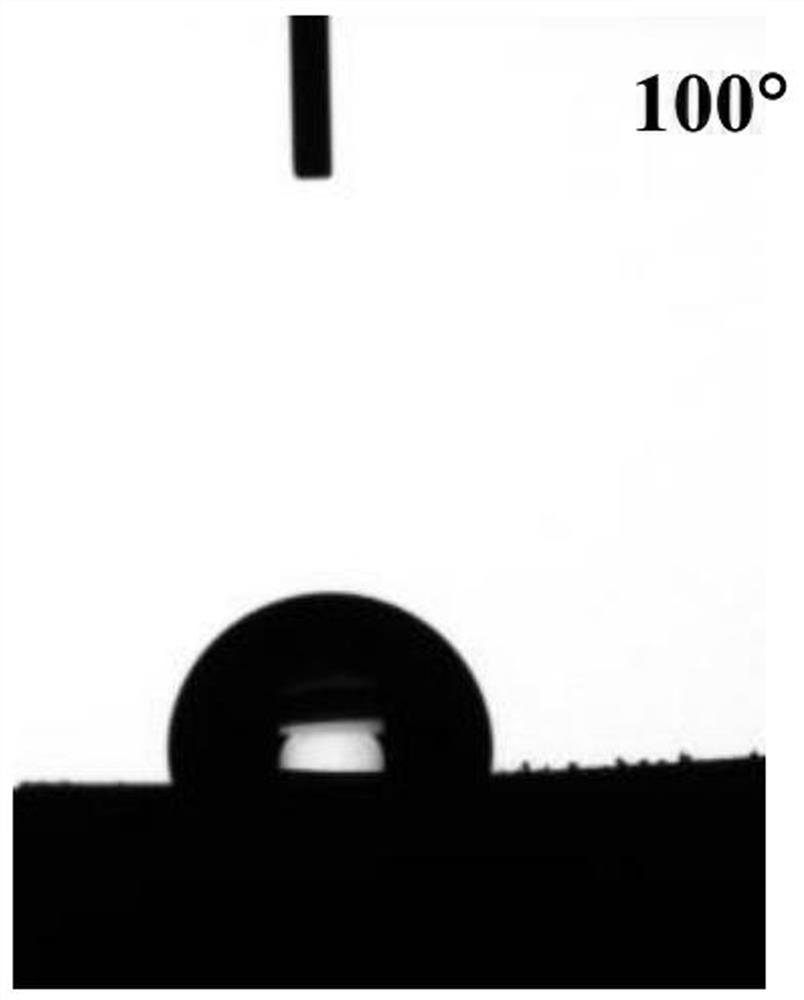

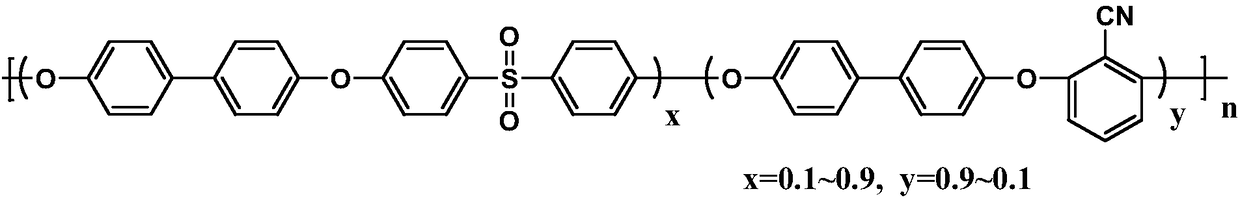

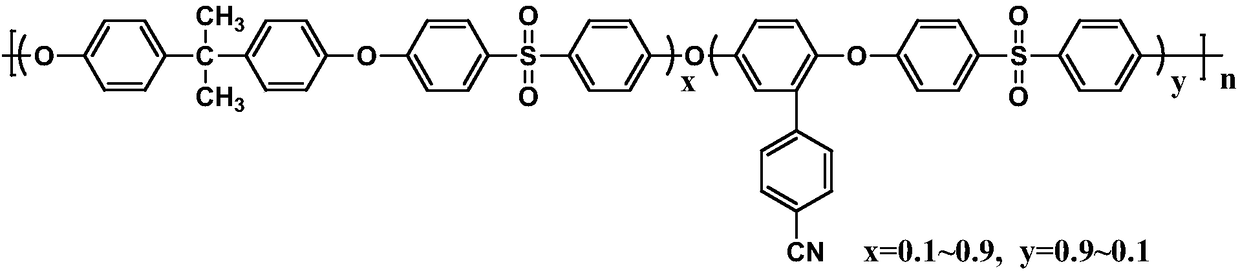

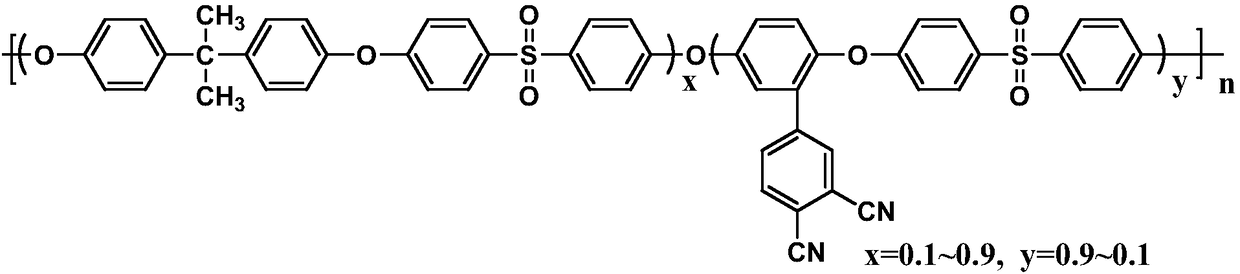

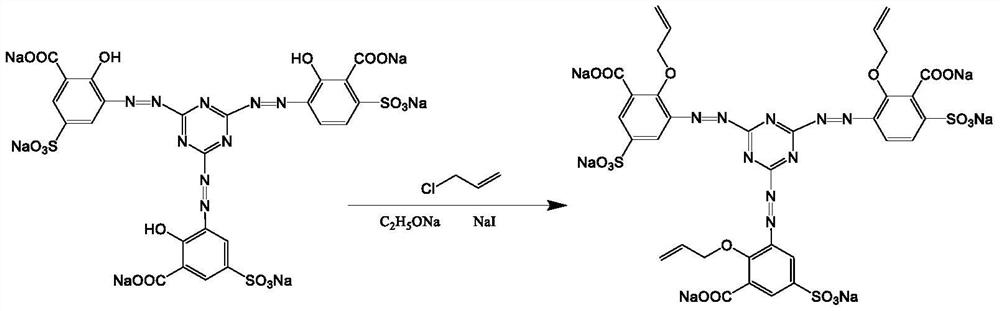

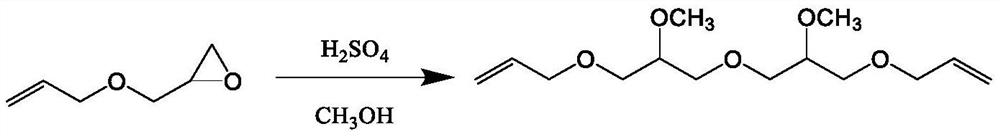

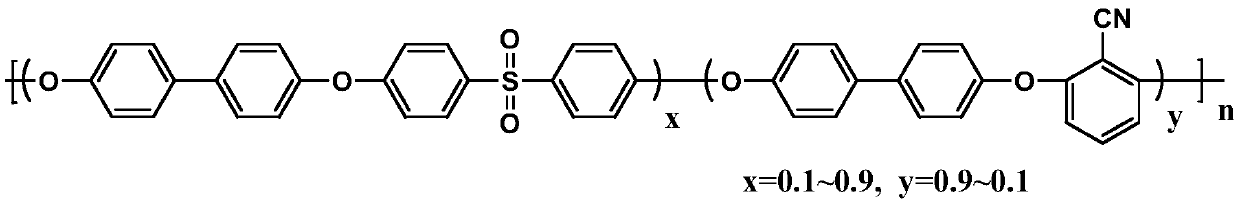

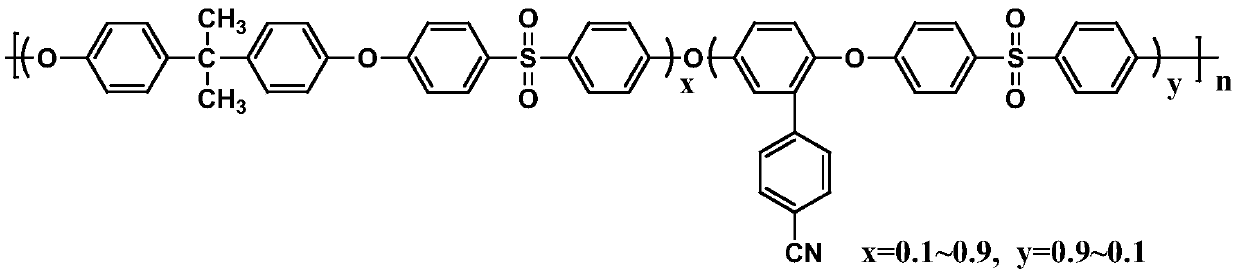

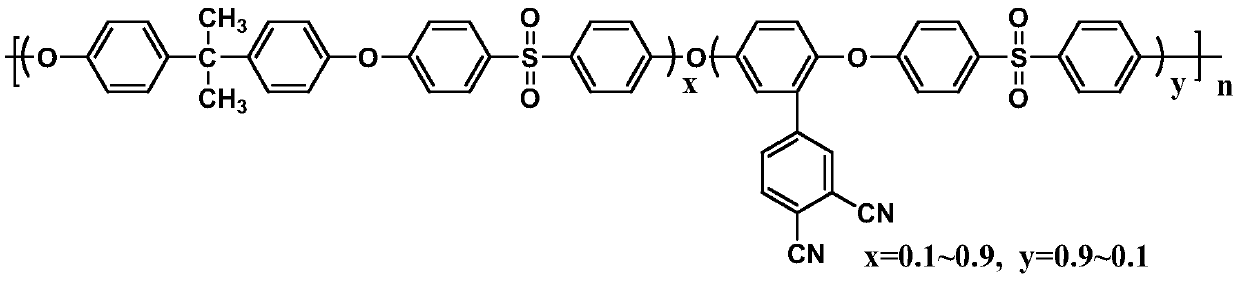

Cyano-containing polyarylethersulfone/polyethersulfone coating composition as well as preparation method and coating technology thereof

ActiveCN108314962AImprove adhesionExtended service lifeFireproof paintsPretreated surfacesButanoneToluene

The invention provides a cyano-containing polyarylethersulfone / polyethersulfone coating composition and a preparation method thereof and belongs to the technical field of coating. The cyano-containingpolyarylethersulfone / polyethersulfone coating composition takes a mixture of polyethersulfone resin and cyano-containing polyarylethersulfone resin as film-forming resin; a preparation technology comprises the following steps: dissolving the polyethersulfone resin and the cyano-containing polyarylethersulfone resin into a compound solvent composed of N-methylpyrrolidone, dimethylacetylamide, toluene, butanone and the like at a stirring peed of 3200 to 3800r / min; then adding components including pigment and filler and the like in sequence and grinding in a sand grinder for 2 to 6h. The preparation and coating technologies of the coating, provided by the invention, are simple to operate, production equipment is easy to realize and an applicable range is relatively wide; a prepared coating layer has good impact resistance, corrosion resistance and the like; meanwhile, the cyano-containing polyarylethersulfone is added, so that the attachment force of the coating layer is further improvedwhen being compared with that of a pure polyethersulfone coating layer.

Owner:JILIN UNIV

Super-hydrophobic microcapsule polymer cement-based anticorrosive coating as well as preparation method and application thereof

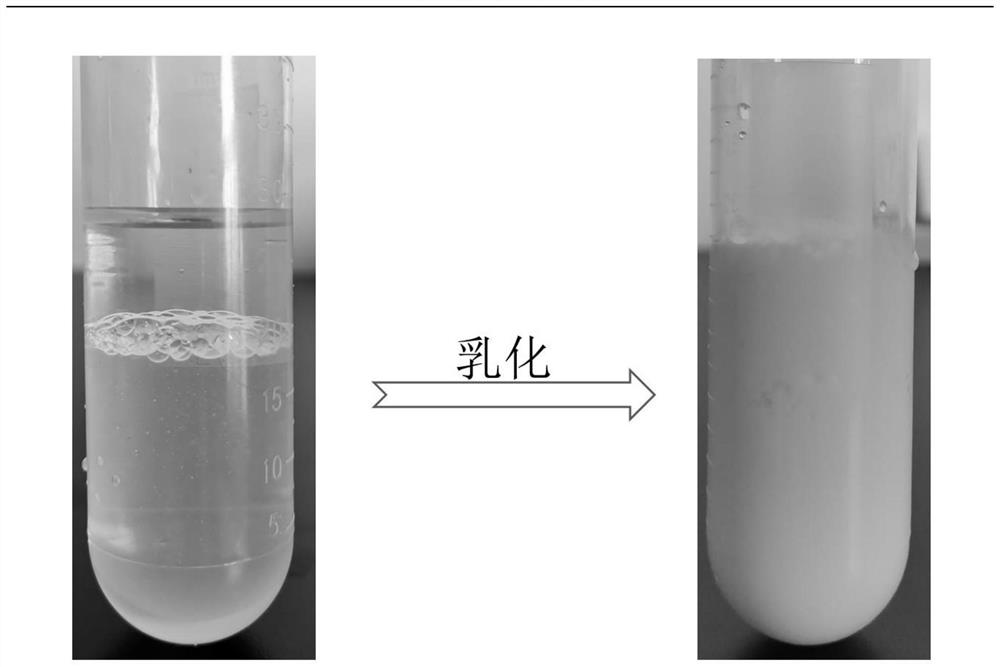

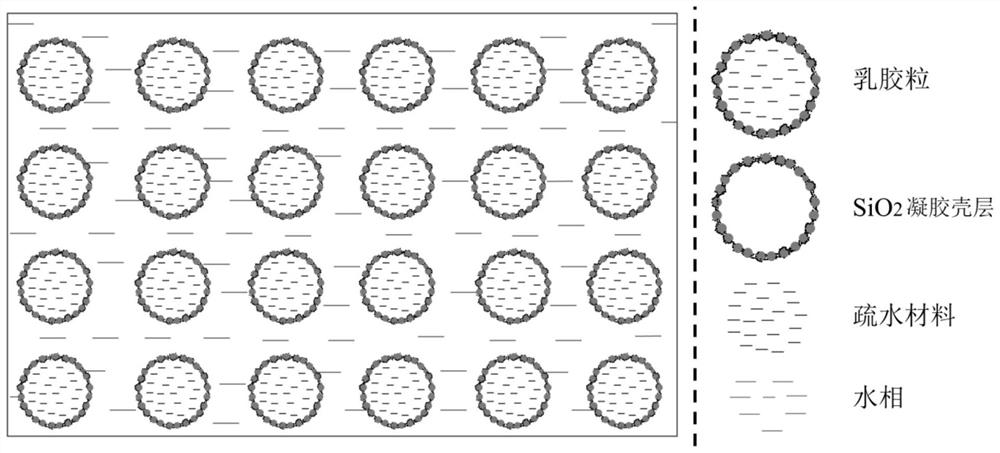

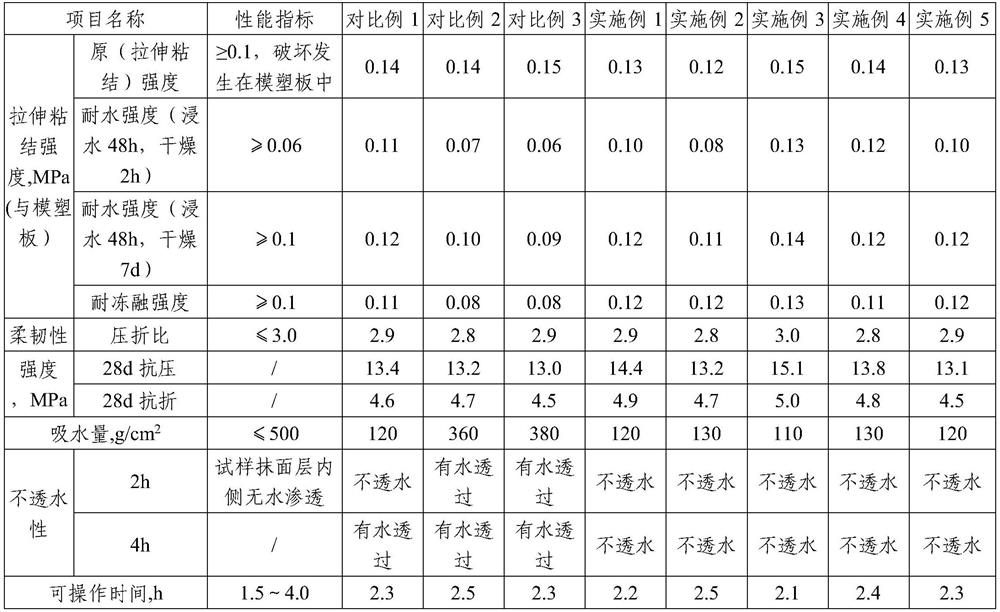

The invention relates to the field of cement anticorrosive coatings, in particular to a super-hydrophobic microcapsule polymer cement-based anticorrosive coating as well as a preparation method and application thereof. The coating is prepared from the following raw materials in parts by weight: 65-85 parts of cement, 65-70 parts of quartz sand, 0.5-1.0 part of a reinforcing agent, 0.17-0.32 part of a retarder, 45-55 parts of emulsion, 15-18 parts of water, 1.1-1.8 parts of a coalescing agent, 0.47-1.4 parts of a light stabilizer, 0.2-0.6 part of a preservative, 0.05-0.3 part of hydrophobic modified graphene oxide and 6-8 parts of a water-based microcapsule emulsion, wherein the water-based microcapsule emulsion is of a core-shell structure formed by taking a hydrophobic material as a coreand SiO2 gel as a shell layer. The anticorrosive paint provided by the invention avoids adverse effects on a cement hydration hardening process and a polymer film forming process, and effectively solves the problem of compatibility between a hydrophobic agent and emulsion as well as between the hydrophobic agent and cement.

Owner:UNIV OF JINAN

Gas diffusion layer for fuel cell and its production

InactiveCN100521328CGuaranteed hydrophobicityAchieve hydrophobicityCell electrodesFinal product manufactureElectricityFuel cells

The invention relates to a fuel battery, in particular to a gas diffusing layer and the preparation for the fuel battery; the gas diffusing layer consists of basic bottom layer and a micro-hole layer, which is made by fabricating the micro-hole constructed by a water repellent agent / a composite powder body of electric conduction copper material at one side or two sides of a porous electric conduction basic bottom processed by a hydrophobic water; the water repellent agent / the composite powder body of electric conduction copper material is made by a microwave dielectric heating technology; because of the favorable water repellent performance and the grain diameter structure therefore, the gas diffusing layer to be fabricated has a strong and even water repellent performance and a suitable hole structure, so that the favorable mass transfer capability of the gas diffusing layer can be assured. The fuel battery assembled by the invention can show a better battery output performance, and is particularly suitable to be used in the fuel battery where the air is used as oxidizer with a strong practicality value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Super-hydrophobic heat-resistant coating for aluminum alloy and preparation method of super-hydrophobic heat-resistant coating

InactiveCN114395326AAchieve superhydrophobicityAchieve heat resistanceMolten spray coatingPretreated surfacesThioureaCarboxylic acid

The invention discloses a super-hydrophobic heat-resistant coating for an aluminum alloy and a preparation method of the super-hydrophobic heat-resistant coating, and relates to the technical field of coatings. The heat-resistant coating is formed on the surface of the aluminum alloy through the spraying pretreatment process and the second-time spraying treatment in sequence, the heat-resistant coating and the aluminum alloy form a firm cross-linked interpenetrating network structure, the heat resistance of the coating is improved, and the phenomenon that the service life of the aluminum alloy is shortened in a high-temperature environment is reduced; and then third spraying treatment is conducted, a corrosion inhibitor serves as an inner core solution, stearic acid serves as a shell solution, a super-hydrophobic coating is formed through coaxial electrostatic spraying, the corrosion inhibitor is prepared from isoquinocarboxylic acid, dipropylene triamine and p-methoxyphenyl thiourea, the surface of the aluminum alloy is isolated from an environment medium, and corrosion of an acid medium and chloride ions is inhibited. The prepared super-hydrophobic heat-resistant coating for the aluminum alloy has the heat-resistant, super-hydrophobic and corrosion-resistant effects.

Owner:严平

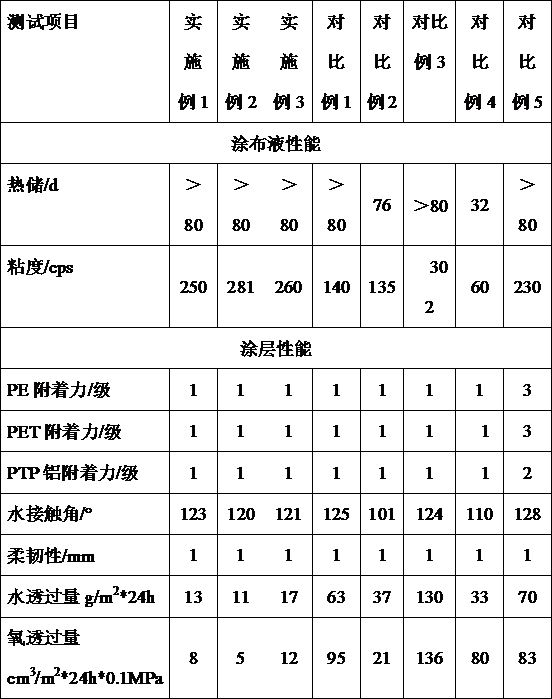

Coating liquid with high barrier property and application thereof

The invention discloses a coating liquid with high barrier property and application thereof, the coating liquid comprises, by weight, 40-60 parts of a water-based polyester emulsion, 2-10 parts of a nucleating agent, 5-15 parts of a nanoparticle dispersion liquid, 0.5-1 part of a dispersant, 0.1-1 part of a stabilizer, 2-10 parts of a curing agent and 30-40 parts of deionized water, and the water-based polyester emulsion comprises water-based crystalline resin. According to the coating liquid disclosed by the invention, through matching of the water-based crystalline resin and other raw materials, uniform coating and qualified adhesive force of the coating liquid on different base materials are met, so that high-efficiency application of the coating liquid to packaging of products with high barrier requirements is realized.

Owner:苏州瀚海新材料有限公司

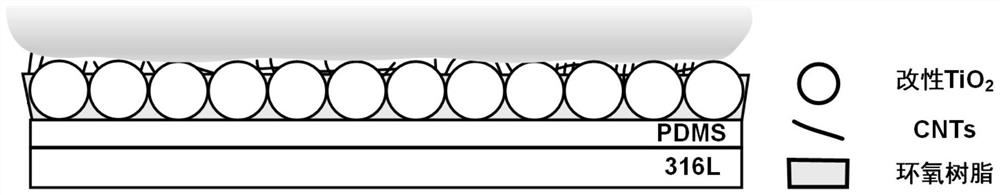

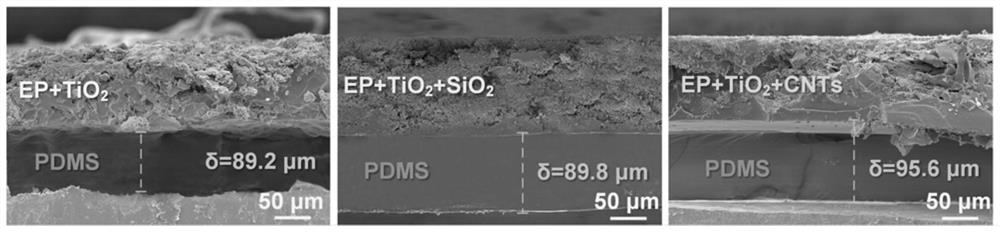

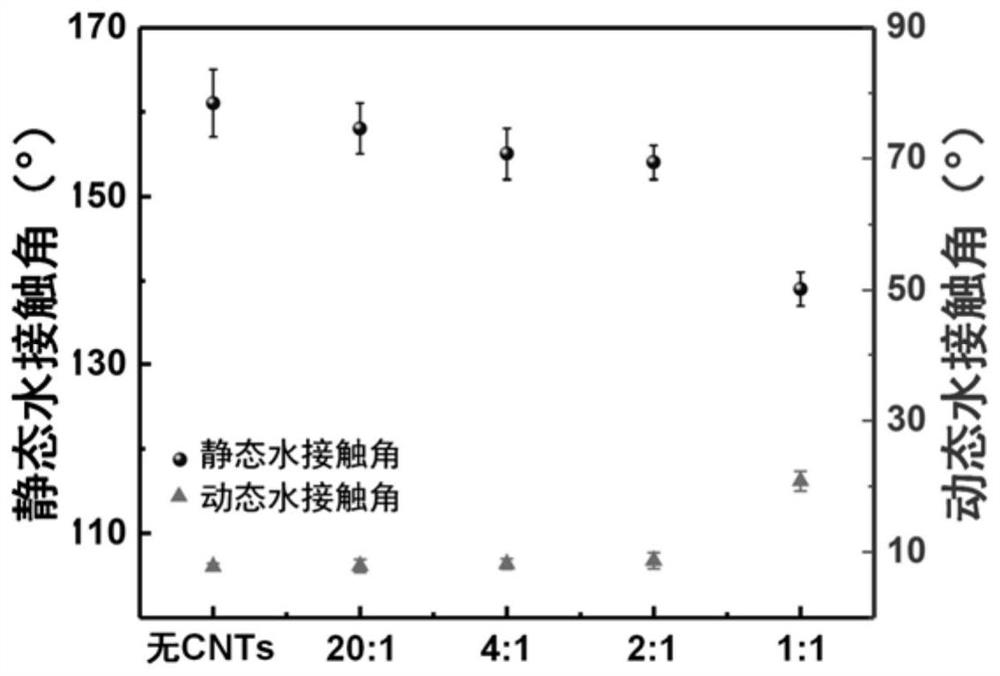

Preparation method of super-hydrophobic wear-resistant coating containing buffer structure

ActiveCN114535022AImprove wear resistanceHigh hardnessPretreated surfacesTitanium dioxideEpoxyAlcohol

The invention discloses a preparation method of a super-hydrophobic wear-resistant coating containing a buffer structure, which comprises the following steps: (1) dispersing lauric acid powder in absolute ethyl alcohol, firstly dropwise adding tetraethyl titanate, then adding deionized water and HCl, and magnetically stirring to prepare a modified TiO2 solution; carrying out centrifugal treatment on the modified TiO2 solution to obtain modified TiO2 particles, and carrying out vacuum drying for later use; (2) pre-cleaning the test piece, preparing a PDMS coating on the surface of the test piece, and carrying out high-temperature curing treatment; (3) precoating epoxy resin on the PDMS coating by using a spin coater; and mixing the modified TiO2 particles with carbon nanotubes, stirring and grinding, then spraying the mixture onto the PDMS coating by using a spray gun, and then putting the PDMS coating into a drying oven for high-temperature heavy pressing to obtain the super-hydrophobic wear-resistant coating. The prepared super-hydrophobic wear-resistant coating containing the buffer structure has excellent wear resistance, corrosion resistance and hydrophobic resistance reduction effects, is high in hardness, does not show brittle damage under particle impact, and can provide safety guarantee for submarine gas pipeline transportation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Treatment technology for preventing mildew and corrosion of fresh bamboo

InactiveCN108327017AAvoid carbonizationReduce moisture contentWood treatment detailsReed/straw treatmentWater contentCorrosion

The invention discloses a treatment technology for preventing mildew and corrosion of fresh bamboo. The treatment technology comprises the following steps A to C of: firstly, weighing heat conductionoil, heating to certain temperature, and maintaining for a period of time; adding the fresh bamboo into the heat conduction oil, and continuing to heat; specifically heating and warming by sections, performing heat treatment on the fresh bamboo by utilizing the self characteristics of the heat conduction oil, naturally cooling the heat conduction oil and the fresh bamboo, fetching out the fresh bamboo at certain temperature, draining water, and naturally cooling the fresh bamboo, so as to complete the heat treatment on the fresh bamboo. The treatment technology has the advantages that the nutritional matters in the fresh bamboo material are thoroughly modified; by performing the impregnating and heat treatment by the high-temperature heat oil, the hydrophilic groups of the structure in thebamboo fibers are destroyed and decomposed, so that the hydrophobicity of the material is reached, the water content is reduced, and the influence by outside humidity is avoided; the internal microorganisms are killed, so that the effect of preventing mildew and corrosion is reached, and the stability of the fresh bamboo material is improved.

Owner:赣州森泰竹木有限公司

Rainproof and fireproof ceramifiable polyolefin material and preparation method thereof

InactiveCN109762238AGuaranteed mechanical strengthGuaranteed porcelain performanceCross-linkPlatinum complex

The invention discloses a rainproof ceramifiable polyolefin material. The rainproof ceramifiable polyolefin material is prepared from 50-80 parts of polyolefin, 20-50 parts of rubber mixings of silicone rubber, 80-120 parts of high-temperature-resistant packings, 10-30 parts of a halogen-free flame retardant, 20-40 parts of a ceramic formation sintering aid, 0.01-1 part of a platinum complex or aplatinum compound (in terms of platinum), 1-5 parts of a compatilizer and 0.5-1 part of a cross-linking agent. The invention further discloses a preparation method of the material. The preparation method comprises following steps: polyolefin and silica gel are blended, and the various packings are mixed, aged and vulcanized. The rainproof ceramifiable polyolefin material has excellent mechanical strength and fireproof performance, the surface of formed ceramic is hydrophobic, water can be effectively prevented from permeating into the ceramic, reduction of insulating property due to water absorption after firing ceramic formation of the material can be prevented effectively, the cost of the material is lower than that of ceramifiable silicone rubber, the fireproof performance of the material is higher than that of a common ceramifiable polyolefin material, and the rainproof ceramifiable polyolefin material has great significance when applied to the field of fireproof cables.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +2

Method for preparing self-cleaning plastic carpet

InactiveCN109183421AHydrophobicAchieve hydrophobicityStain/soil resistant fibresCarbon fibresFiberCarbon fibers

The invention relates to a method for preparing a self-cleaning plastic carpet, which belongs to the technical field of a novel material. The method combines two materials of nano titanium dioxide andchitosan which can synergistically achieve the double-effect sterilization effect; after treatment with an acid solution and a surface modifier, nano-titanium dioxide has hydrophobicity and improvedanti-pollution ability, and at the same time, titanium dioxide has strong photocatalytic ability and can play a certain self-cleaning effect; the method adopts half carbon fiber to replace the original fiber to prepare the carpet, improves the strength of the carpet, utilizes the conductivity of the carbon fiber to diffuse and release the static electricity on the surface of the carpet, reduces the adsorption force on the dust and hair, and facilitates the cleaning. The self-cleaning plastic carpet prepared by the invention has strong self-cleaning ability, can inhibit bacteria and kill bacteria, has no electrostatic adsorption for dust, stains and animal hair, and is hydrophobic and convenient to use.

Owner:吕莉

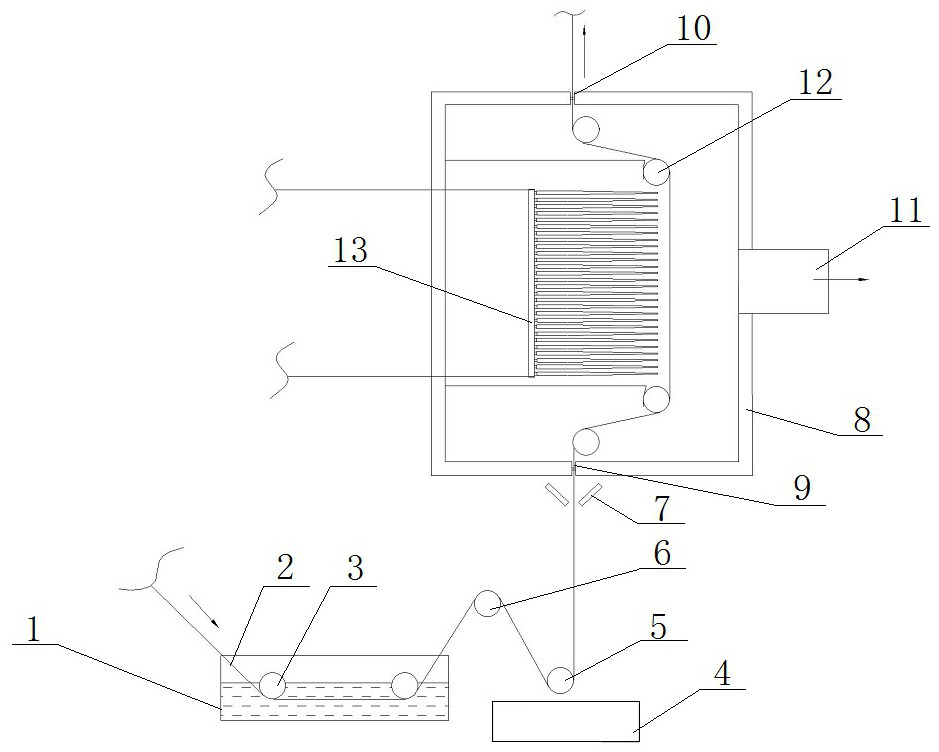

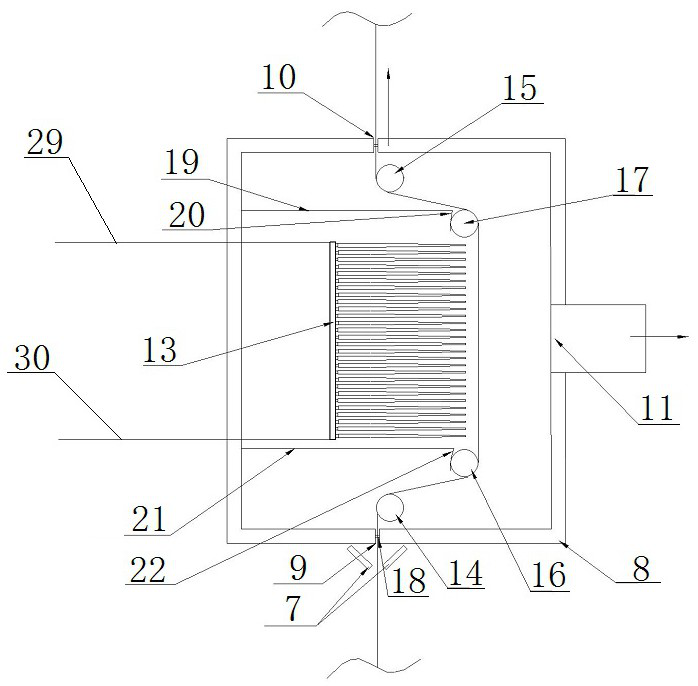

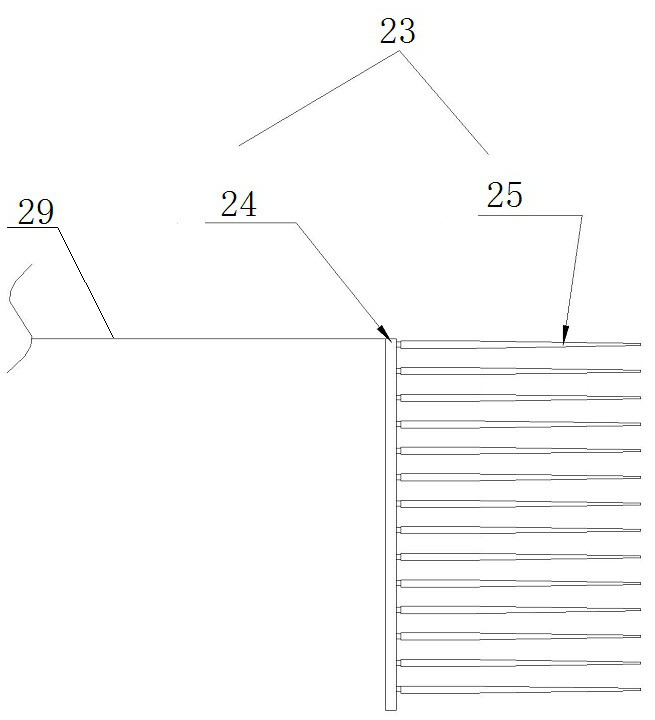

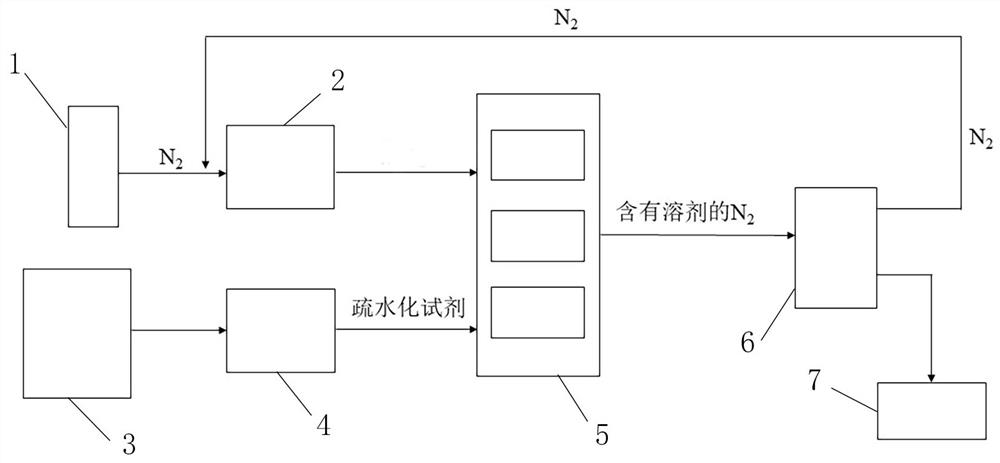

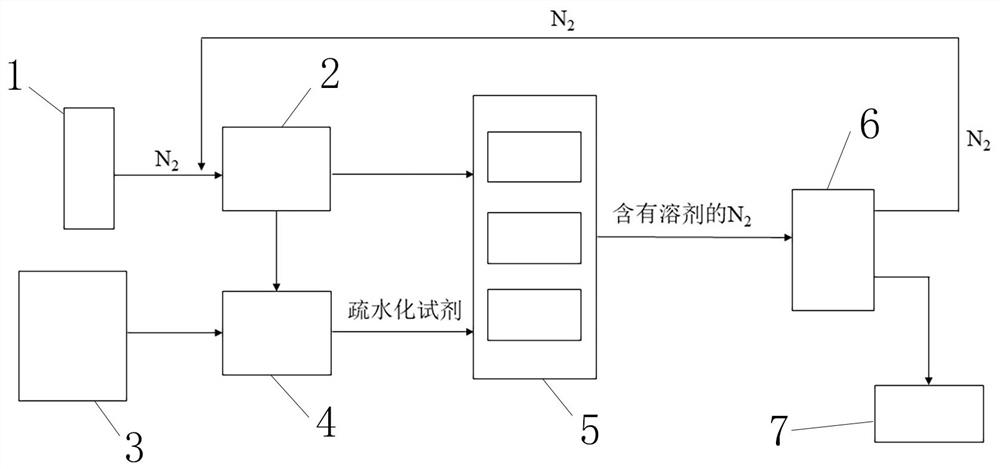

Device and method for preparing silicon dioxide aerogel felt and silicon dioxide aerogel felt

ActiveCN114653529AAchieve hydrophobicityAchieving processing powerPretreated surfacesCoatingsHydrophobic silicaSilicon oxide

The invention relates to a device and method for preparing a silicon dioxide aerogel felt and the silicon dioxide aerogel felt. The device comprises a gum dipping tank, and the gum dipping tank is provided with a compression roller; the liquid collecting tank is arranged on one side of the gum dipping tank, and the winding roller group is arranged above the liquid collecting tank; the drainage drying box is arranged above the liquid collecting tank, a felt inlet and a felt outlet are formed in the drainage drying box, and a tensioning mechanism and a drying assembly are arranged in the drainage drying box; the tensioning mechanism comprises a tensioning roller set, and the tensioning roller set is used for tensioning the gel felt located between the felt inlet and the felt outlet; the drying assembly comprises an air injection assembly communicated with the air inlet pipe, the air injection assembly comprises an air distribution row and a plurality of hot air knives communicated with the air distribution row, air outlets of the hot air knives are aligned with the tensioning gel felt, and the air injection assembly is used for injecting preheated nitrogen and a gas-phase hydrophobization reagent to the fiber felt body; an exhaust hole for exhausting gas is reserved in the hydrophobic drying box; therefore, hydrophobic and drying treatment of the silicon dioxide wet gel felt is achieved, and it is guaranteed that the formed hydrophobic silicon dioxide aerogel felt has high quality.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Method for preparing hydrophobic silicon dioxide aerogel felt under normal pressure

According to the method for preparing the hydrophobic silicon dioxide aerogel felt under the normal pressure, a liquid-phase hydrophobization reagent is promoted to be converted into a gas-phase hydrophobization reagent through preheated nitrogen, and the circulated preheated nitrogen and the gas-phase hydrophobization reagent can bring out an organic solvent in wet gel during hydrophobization treatment; and dewatering and drying treatment on the wet gel felt is realized. According to the preparation method, the preparation period of conventional hydrophobic aerogel can be obviously shortened, the production cost can be reduced, meanwhile, replacement of a large amount of solvent after a traditional hydrophobization reaction is completed can be avoided, the whole preparation process is simple in technology, the aerogel drying process and aerogel hydrophobization treatment are carried out at the same time, operation is easy, and economical and environment-friendly effects are achieved.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

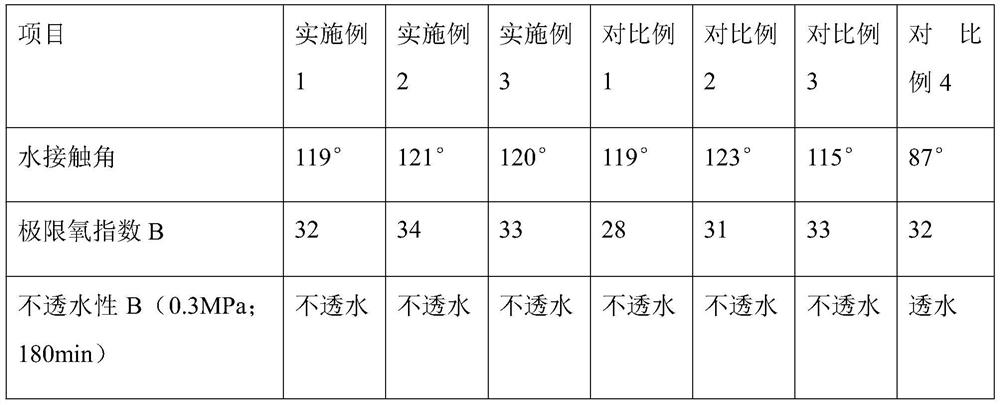

A kind of flame-retardant SBS modified asphalt waterproofing membrane and its preparation method

ActiveCN114086398BImprove flame retardant performanceImprove waterproof performancePhysical treatmentCarbon fibresPolyesterPolymer science

The invention discloses a flame-retardant SBS modified asphalt waterproofing membrane and a preparation method thereof. During preparation, polyester felt is used as the base, flame-retardant asphalt is coated on both sides, and the waterproofing membrane is obtained after the film is applied and dried; In this plan, in order to improve the flame retardant performance of the waterproof membrane, this application introduces decabromodiphenyl ethane and antimony oxide with a mass ratio of 1:1 during the preparation of flame retardant asphalt. Antimony works synergistically to improve the flame retardant properties of waterproof membranes. The waterproofing membrane prepared by this application not only has excellent waterproofing performance, but also has excellent flame retardant properties; and when the waterproofing membrane is actually used, when the outer layer of asphalt material falls off and breaks due to external force, the waterproofing membrane still has relatively excellent properties. Excellent flame retardant and waterproof performance, long service life and high practicality.

Owner:常州畅韵工程材料有限公司

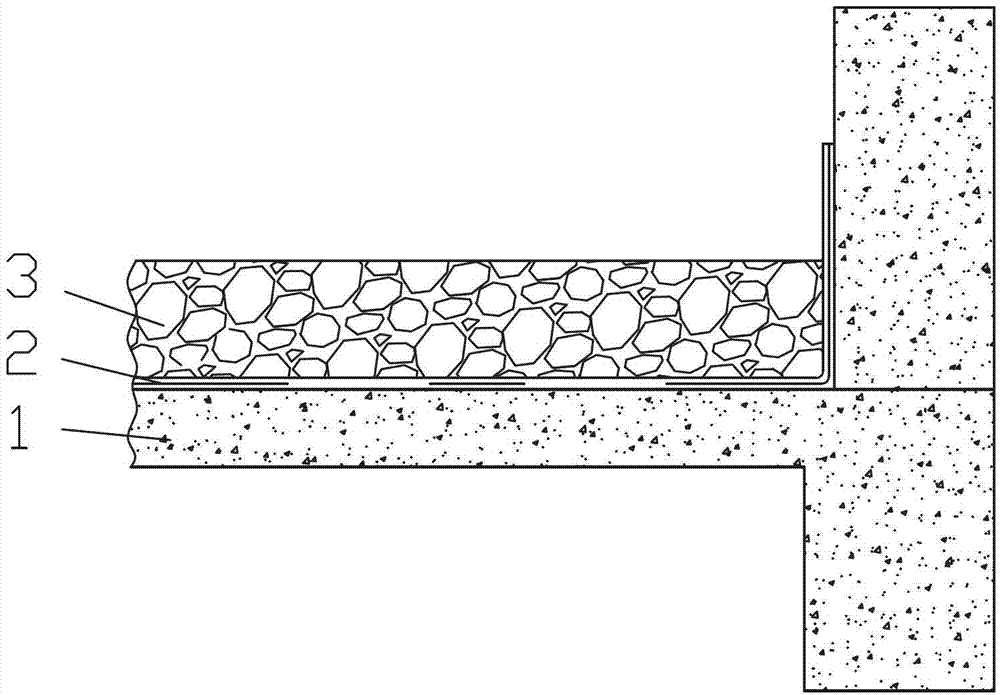

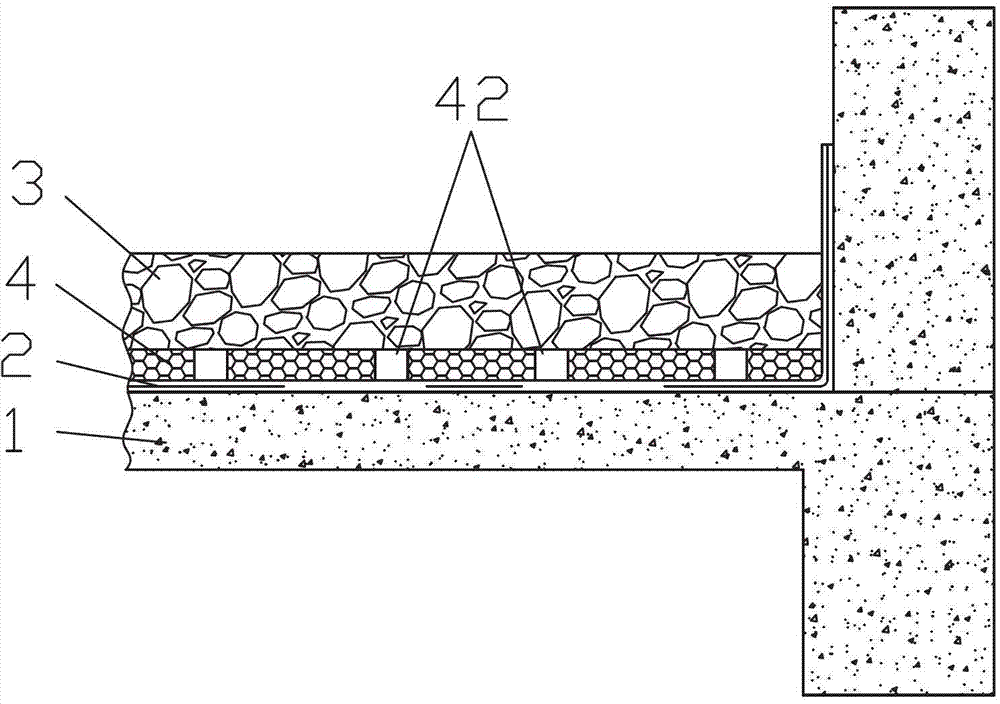

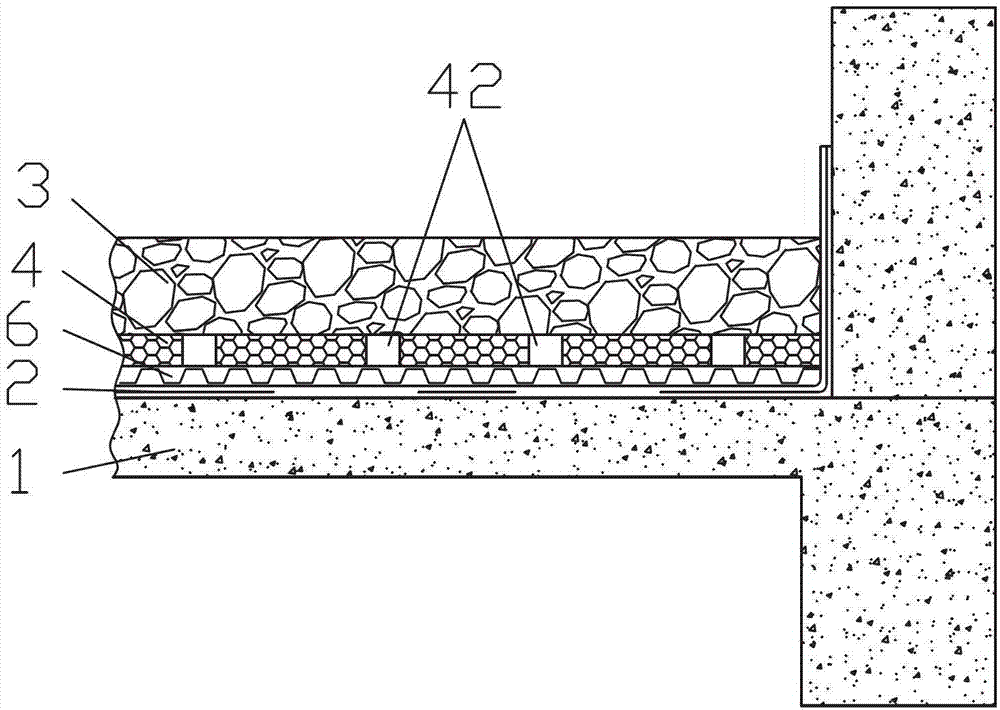

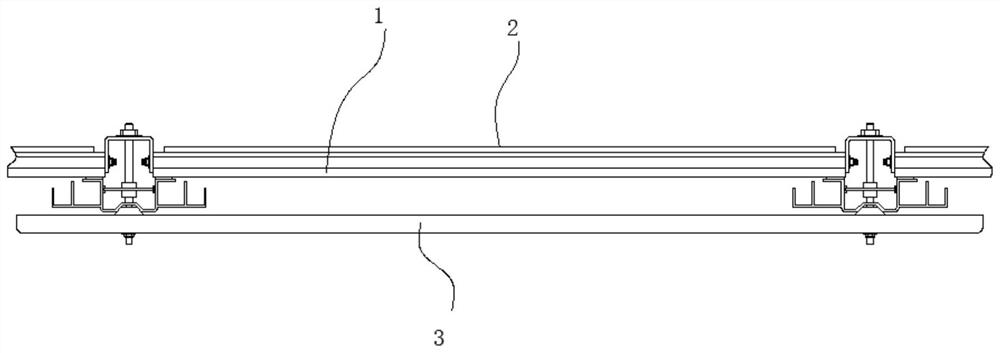

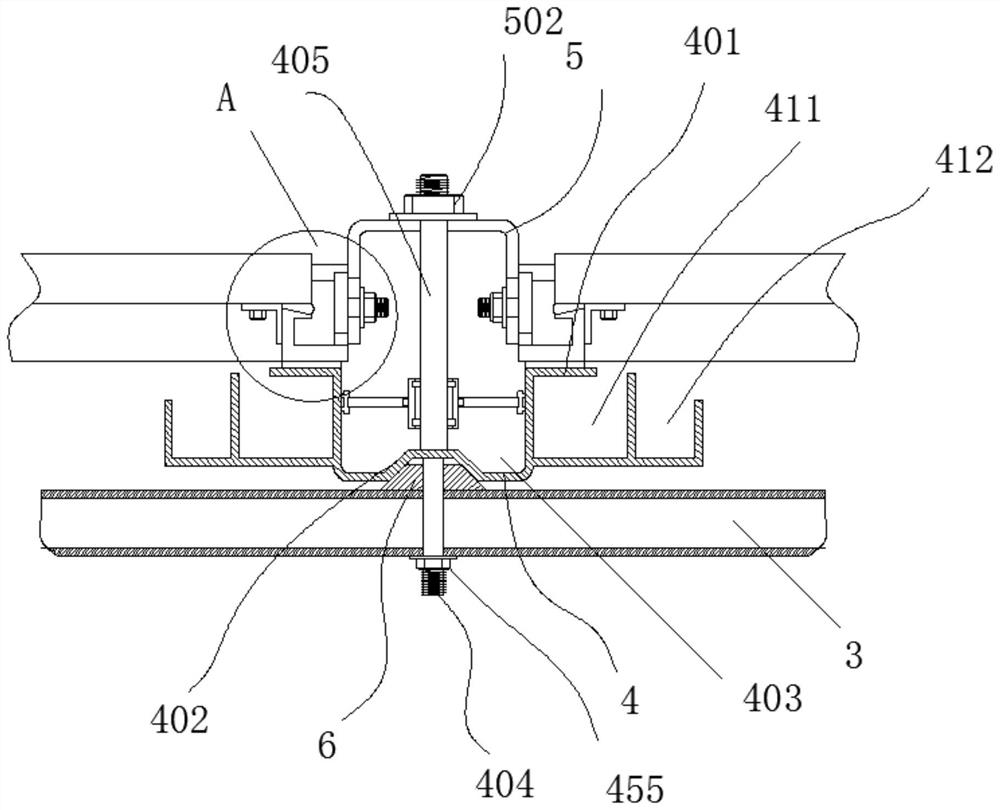

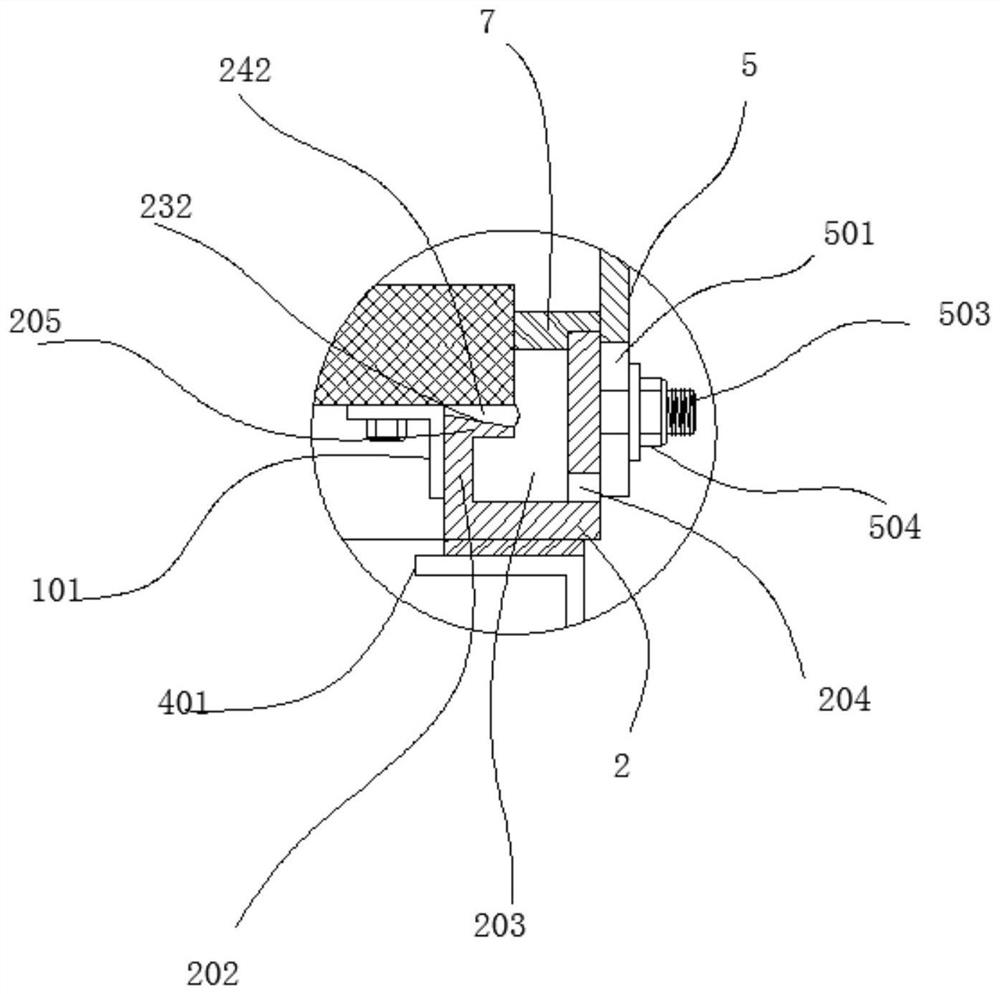

Construction method, system and special components of a ventilating roof system

ActiveCN102900204BExtended service lifeMaintain moisture absorption and release propertiesBuild-up roofsRoof drainageArchitectural engineeringStructural engineering

Owner:DONGGUAN CAILI BUILDING MAINTAIN TECH

A kind of preparation process of decorative board containing polyurethane insulation layer

ActiveCN111677218BHigh strengthSolve the problem of low strength affecting service lifeCovering/liningsEpoxyPolymer science

Owner:山东斯蒙特新材料有限公司

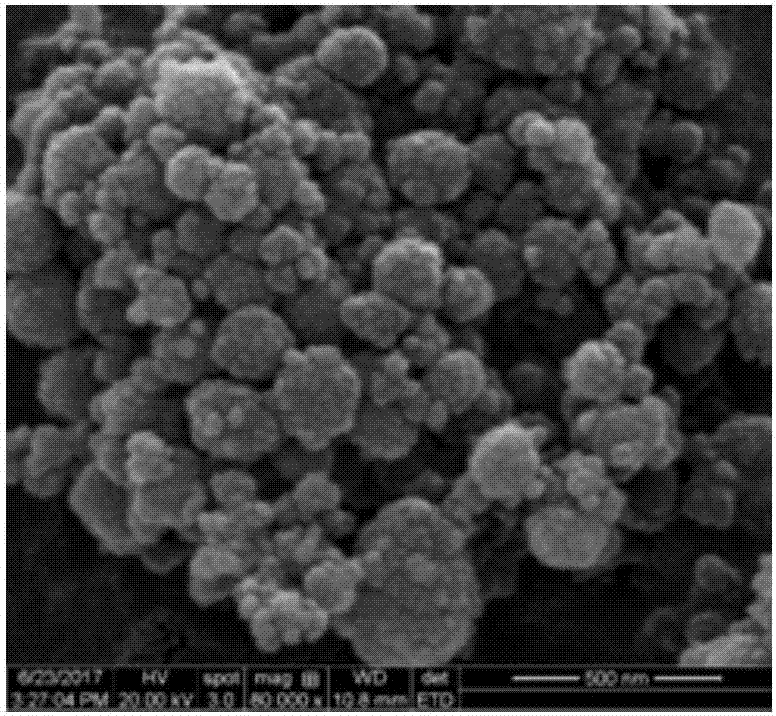

Hydrophobic high-nickel ternary positive electrode material and preparation method thereof

ActiveCN112436110AAchieve hydrophobicityImprove homogenizationSecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention discloses a hydrophobic high-nickel ternary material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a fluorosilane solution; S2, preparing the hydrophobic high-nickel ternary positive electrode material; and S3, performing sintering heat treatment to obtain the high-nickel ternary positive electrode material with the hydrophobiclayer with the stable surface structure. Fluorosilane is hydrolyzed in an acidic environment, a hydrophobic layer is formed on the surface of the high-nickel ternary positive electrode material, and the surface structure of the high-nickel ternary positive electrode material is more stable through sintering heat treatment, so that the hydrophobicity of the high-nickel ternary material is realized,the homogenate and coating processability of the high-nickel ternary positive electrode material is improved, a pole piece is prevented from storing and absorbing water, the side reaction of moistureand electrolyte is reduced, the electrical property of the lithium ion battery is obviously improved, meanwhile, the preparation process is simple, the cost is low, and industrialization is easy to realize.

Owner:东莞格林德能源有限公司

A kind of hydrophobic high-nickel ternary positive electrode material and preparation method thereof

ActiveCN112436110BAchieve hydrophobicityEasy to processSecondary cellsPositive electrodesElectrolytic agentElectrical performance

The invention discloses a hydrophobic high-nickel ternary material and a preparation method thereof. The preparation method comprises the following steps: S1: preparing a fluorosilane solution; S2: preparing a hydrophobic and high-nickel ternary positive electrode material; S3: sintering heat treatment to obtain surface stability A high-nickel ternary cathode material with a structured hydrophobic layer. The invention uses fluorosilane to hydrolyze in an acidic environment to form a layer of hydrophobic layer on the surface of the high-nickel ternary positive electrode material, and through sintering heat treatment to make the surface structure more stable, so as to realize the hydrophobicity of the high-nickel ternary material and improve the high-nickel ternary material Homogenization and coating processing performance of ternary positive electrode materials, prevent pole pieces from absorbing water during storage, reduce side reactions between water and electrolyte, and significantly improve electrical properties of lithium-ion batteries. At the same time, the preparation process is simple, and the cost is low, and it is easy to realize industrial change.

Owner:东莞格林德能源有限公司

Cyanogroup-containing polyarylethersulfone/polyethersulfone coating composition and its preparation method and coating process

ActiveCN108314962BImprove adhesionExtended service lifeFireproof paintsPretreated surfacesPolymer scienceButanone

The invention provides a cyano-containing polyarylethersulfone / polyethersulfone coating composition and a preparation method thereof and belongs to the technical field of coating. The cyano-containingpolyarylethersulfone / polyethersulfone coating composition takes a mixture of polyethersulfone resin and cyano-containing polyarylethersulfone resin as film-forming resin; a preparation technology comprises the following steps: dissolving the polyethersulfone resin and the cyano-containing polyarylethersulfone resin into a compound solvent composed of N-methylpyrrolidone, dimethylacetylamide, toluene, butanone and the like at a stirring peed of 3200 to 3800r / min; then adding components including pigment and filler and the like in sequence and grinding in a sand grinder for 2 to 6h. The preparation and coating technologies of the coating, provided by the invention, are simple to operate, production equipment is easy to realize and an applicable range is relatively wide; a prepared coating layer has good impact resistance, corrosion resistance and the like; meanwhile, the cyano-containing polyarylethersulfone is added, so that the attachment force of the coating layer is further improvedwhen being compared with that of a pure polyethersulfone coating layer.

Owner:JILIN UNIV

Preparation method of copper-based superhydrophobic surface structure

InactiveCN103406248BShort preparation cycleEasy to operatePretreated surfacesCoatingsMicro nanoScale structure

A manufacturing method for a copper-based super-hydrophobic surface structure mainly includes that step 1, a metal copper base is pre-processed; step 2, a layer of photoresist is coated on the surface of the processed copper base in a rotation mode, and the photoresist layer attached to the surface of the copper base forms a well-aligned porous array template through photoetching processing; step 3, the copper base with the well-aligned porous array template obtained in the step 2 is used as an anode and soaked in a CuSO4 solution to form a primary battery to conduct a reaction for 4-8 min; step 4, the copper base of the primary battery obtained in the step 3 after reaction is finished is soaked into an AgNO3 solution to conduct in-situ reduction for 30-70s; step 5, the copper base subjected to the reaction in the step 4 is subjected to silanization processing, and the copper-based super-hydrophobic surface structure is manufactured. By means of the method, two simple redox processes are utilized to obtain a layer of micro-nano dual-scale structure similar to the lotus leaf surface on the surface of copper metal, hydrophobe is achieved, the performance of the manufactured super-hydrophobic surface is stable, a contact angle between the super-hydrophobic surface and a water solution with a pH value ranging from 1 to 14 can be larger than 155 degrees, and the minimum rolling angle can be smaller than 1.5 degrees.

Owner:WUHAN UNIV OF TECH

A kind of concrete inner surface hydrophobic treatment agent and preparation method thereof

The invention relates to a hydrophobic treatment agent for the inner surface of concrete and a preparation method thereof, in particular to a technology for coating hydrophobic shell-based powder with a water-soluble polymer substance. The coated hydrophobic shell-based powder is added to the concrete, and then mixed evenly. The method of the invention can form a hydrophobic surface inside the concrete to prevent the intrusion of external erosive ions, thereby improving the durability of the concrete, and the final commercialized form of the invention is a powder, which is convenient for storage, transportation and use.

Owner:YANTAI UNIV

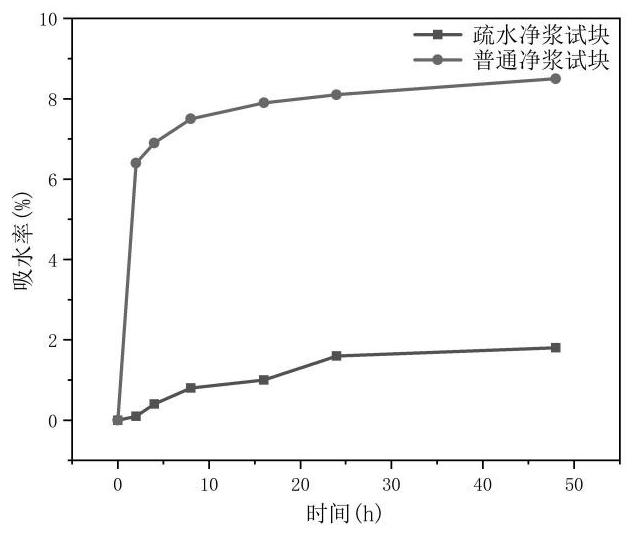

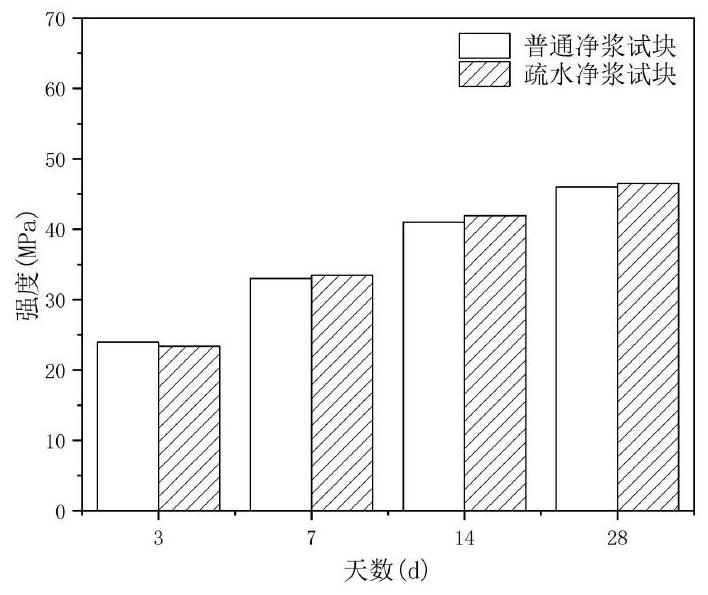

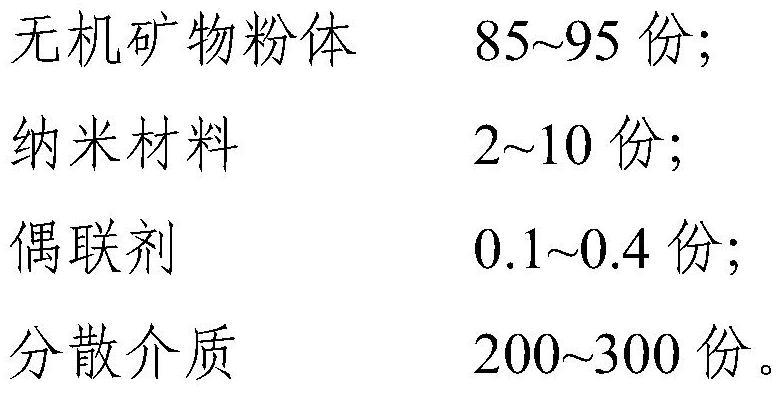

Nano modified inorganic mineral waterproof agent as well as preparation method and application thereof

ActiveCN114163159AReduce dosageAchieve hydrophobicitySolid waste managementPhysical chemistryStearic acid

The invention relates to the field of concrete structure protection and waterproof mortar, in particular to a nano-modified inorganic mineral waterproof agent as well as a preparation method and application thereof. The nano modified inorganic mineral waterproof agent is prepared from the following raw materials: 80-95 parts of inorganic mineral powder; 2-10 parts of a nano material; 0 to 0.5 part of a coupling agent; the nano material is selected from one or more of nano graphene, nano stearate, nano calcium carbonate and nano titanium oxide. The nano-modified inorganic mineral waterproof agent provided by the invention is low in mixing amount when being used for preparing waterproof concrete or waterproof mortar, has better comprehensive performance while realizing an overall waterproof protection function, and meets the requirements of low cost and high performance of engineering.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Novel energy-saving building structure

InactiveCN113279526AReduce dosageEasy constructionPhotovoltaic supportsRoof covering using slabs/sheetsArchitectural engineeringStructural engineering

Owner:东莞市盈通环保科技有限公司

Preparation process of decorative plate containing polyurethane thermal insulation layer

ActiveCN111677218AHigh strengthSolve the problem of low strength affecting service lifeCovering/liningsEpoxyPolymer science

The invention discloses a preparation process of a decorative plate containing a polyurethane thermal insulation layer. The preparation process comprises the following specific steps that a support isolation layer is soaked in an ethylenediamine solution, then the support isolation layer is fished out to wipe off redundant ethylenediamine on the surface, then the wiped support isolation layer is fixed below a mold, and a polyurethane material to be foamed is injected into the mold to obtain a thermal insulation support plate; and the thermal insulation support plate is soaked in 3-(2, 3-epoxypropoxy) propyltrimethoxysilane and then fished out to be dried, the bottom face of the decorative layer is coated with a layer of epoxy resin adhesive, then the decorative layer is bonded to the surface of the support isolation layer of the hydrophobic thermal insulation support plate through the epoxy resin adhesive, and the decorative plate is obtained. According to the preparation process, thehigh-strength support isolation layer is arranged between the thermal insulation layer and the soft porcelain decoration layer, the strength of the decorative plate can be improved, the decoration layer can be directly torn down after being used for a period of time, a new decoration layer is pasted again, no decoration layer remains on the surface of the torn-down supporting isolation layer, andsecondary pasting is not affected.

Owner:山东斯蒙特新材料有限公司

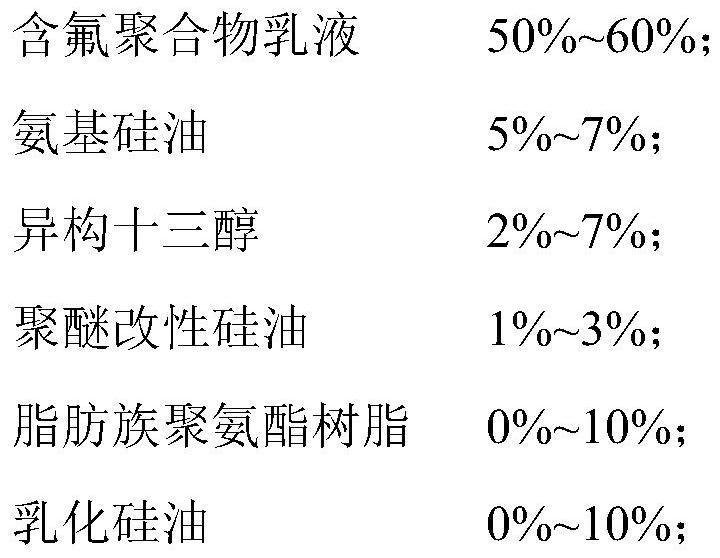

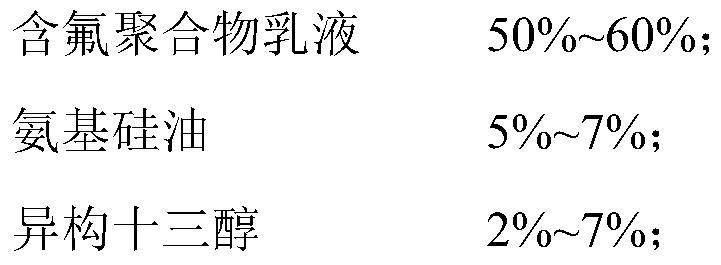

A kind of dermis care waterproof film-forming agent and preparation method thereof

ActiveCN109182622BAchieve hydrophobicityDoes not affect breathabilityLeather surface finishingLeather impregnationPolymer scienceFluoropolymer

The invention discloses a leather-care waterproof film-forming agent and a preparation method thereof. The leather-care waterproof film-forming agent contains the following raw materials in percentageby mass: 50%-60% of a fluorine-containing polymer emulsion, 5%-7% of amino silicon oil, 2%-7% of iso-tridecanol, 1%-3% of polyether modified silicone oil, 0-10% of aliphatic polyurethane resin, 0-10%of emulsified silicone oil, 0-15% of isopropanol and the balance of water. The invention simultaneously discloses a preparation method and a use method of the leather-care waterproof film-forming agent. A layer of waterproof and dirt-proof protecting film can be formed on the surface of all leather by the leather-care waterproof film-forming agent, so that the leather is protected, and meanwhile,a hydrophobic effect is achieved.

Owner:GUANGZHOU DIFU KALE IMPORT & EXPORT TRADE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com