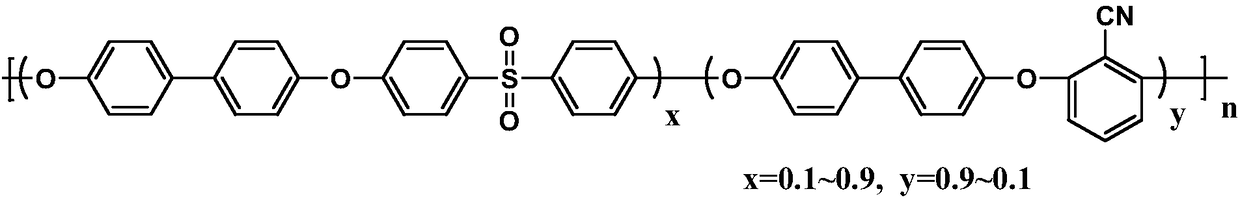

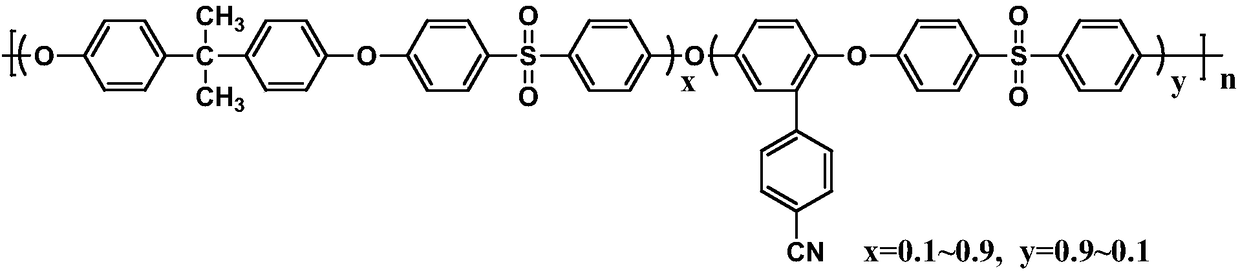

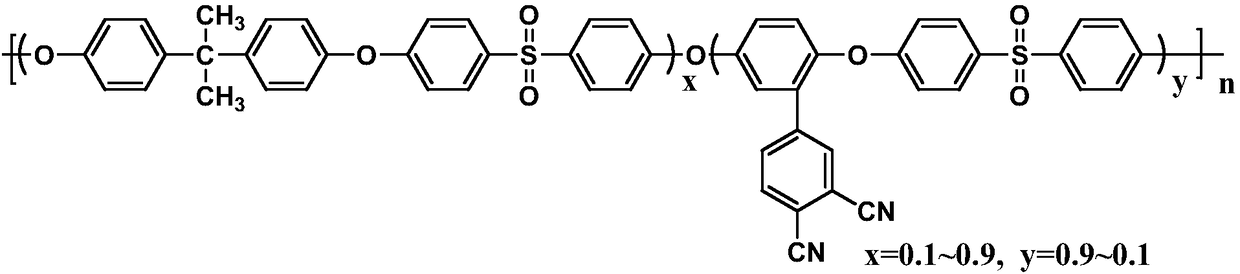

Cyano-containing polyarylethersulfone/polyethersulfone coating composition as well as preparation method and coating technology thereof

A technology of polyarylethersulfone and composition, which is applied in the field of polyarylethersulfone/polyethersulfone coating composition and its preparation, can solve the problems of poor adhesion, phase separation and insufficient dispersion of polyethersulfone coating, and achieve The effect of dense coating, improved adhesion and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The ratio of each component in the coating composition is as follows:

[0052]

[0053] According to the above ratio, under the stirring speed of 3800r / min, the polyethersulfone resin with the logarithmic reduced viscosity of 0.34 and the polyarylethersulfone CN3 (x=0.9, y=0.1) containing cyano group were dissolved in the N- Add chromium trioxide, titanium dioxide and organic bentonite to the complex solvent composed of methylpyrrolidone, dimethylacetamide, toluene and methyl ethyl ketone in sequence, and grind for 2 hours in a sand mill to make a coating. Appropriately add a diluent to the ground paint composition to adjust the viscosity, and then use an air spray gun and an air compressor to spray a paint with a suitable viscosity on a metal substrate that has not been sandblasted but has been pretreated, and bake it at 100 ° C. After 30 minutes, the temperature was raised to 375°C and cured for 10 minutes to obtain a coating, and then cooled to room temperature fo...

Embodiment 2

[0057] The ratio of each component in the coating composition is as follows:

[0058]

[0059] According to the above ratio, under the stirring speed of 3600r / min, the polyethersulfone resin with the logarithmic reduced viscosity of 0.33 and the polyarylethersulfone CN1 (x=0.1, y=0.9) containing cyano group were dissolved in the N- Add dichromium trioxide and fumed silicon dioxide in sequence to a complex solvent composed of methylpyrrolidone, dimethylacetamide, toluene and methyl ethyl ketone, and grind in a sand mill for 4 hours to make a coating. Appropriately add a diluent to the ground coating composition to adjust the viscosity, and then use an air spray gun and an air compressor to spray a coating with a suitable viscosity on a metal substrate that has not been sandblasted but has been pretreated, and bake it at 110 ° C. After 10 minutes, the temperature was raised to 385°C and cured for 5 minutes to obtain a coating, and then cooled to room temperature for testing. ...

Embodiment 3

[0064] The ratio of each component in the coating composition is as follows:

[0065]

[0066] According to the above ratio, under the stirring speed of 3400r / min, the polyethersulfone resin with the logarithmic reduced viscosity of 0.34 and the polyarylethersulfone CN1 (x=0.5, y=0.5) containing cyano group were dissolved in the N- Add graphite, titanium dioxide, and organic bentonite to the complex solvent composed of methylpyrrolidone, dimethylacetamide, toluene, and methyl ethyl ketone in sequence, and grind in a sand mill for 6 hours to make a coating. Appropriately add a diluent to the ground coating composition to adjust the viscosity, and then use an air spray gun and an air compressor to spray a coating with a suitable viscosity on a metal substrate that has not been sandblasted but has been pretreated, and bake it at 120 ° C. After 15 minutes, the temperature was raised to 360°C to cure for 15 minutes to obtain a coating, and then cooled to room temperature for tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com