Method for preparing self-cleaning plastic carpet

A self-cleaning, plastic technology, applied in the direction of biochemical fiber treatment, fiber chemical characteristics, conjugated synthetic polymer rayon, etc. Anti-pollution ability, easy to clean, reduce the effect of adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

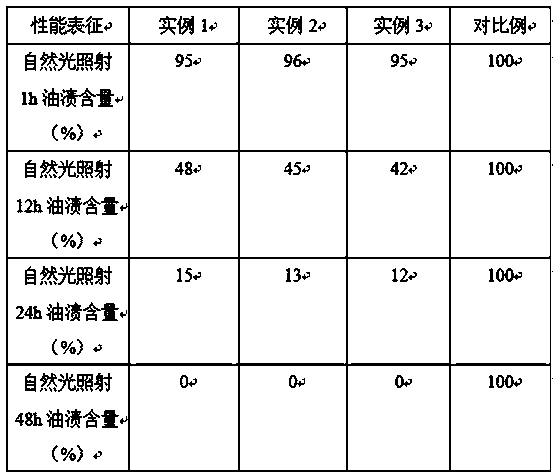

Examples

example 1

[0027] Mix 50g of 0.1mol / L acetic acid solution with 5-10g of nano-titanium dioxide, add 1g of sodium laurate, and sonicate for 1h to obtain a modified nano-titanium dioxide suspension; take 50g of 0.1mol / L acetic acid solution and 10g of chitosan, stir for 30min, Obtain the acetic acid suspension of chitosan; Add 20g glycerin and 15g starch in the acetic acid suspension of chitosan and stir 40min, obtain mixed solution; Add the modified nano-titanium dioxide suspension in the mixed solution, after continuing to stir for 60min, use The high-speed disperser disperses at a speed of 5000r / min for 30 minutes, and uses 0.1mol / L sodium hydroxide solution to adjust the pH value of the composite system to 6 during the reaction process to obtain a composite solution; take 70g of polymethyl methacrylate , 30g of polyacrylonitrile and 120g of N,N-dimethylformamide were stirred evenly, and after standing for about 24 hours for defoaming, the blended fibers were prepared by spinning and dra...

example 2

[0029] Mix 75g of 0.1mol / L acetic acid solution with 7nm titanium dioxide, add 1.5g of sodium laurate, and ultrasonicate for 1.5h to obtain a modified nano-titanium dioxide suspension; take 75g of 0.1mol / L acetic acid solution and 15g of chitosan, stir for 30min, Obtain the acetic acid suspension of chitosan; Add 30g glycerol and 22g starch in the acetic acid suspension of chitosan and stir 40min, obtain mixed solution; Add the modified nano-titanium dioxide suspension in the mixed solution, after continuing to stir for 60min, use The high-speed disperser disperses at a speed of 5000r / min for 30 minutes, and uses 0.1mol / L sodium hydroxide solution to adjust the pH value of the composite system to 6 during the reaction to obtain a composite solution; take 105g of polymethyl methacrylate , 45g of polyacrylonitrile and 180g of N,N-dimethylformamide were stirred evenly, and after standing for about 24 hours for defoaming, the blended fiber was prepared by spinning and drawing using...

example 3

[0031] Mix 100g of 0.1mol / L acetic acid solution with 10g of nano-titanium dioxide, add 2g of sodium laurate, and sonicate for 2 hours to obtain a modified nano-titanium dioxide suspension; take 100g of 0.1mol / L acetic acid solution and 20g of chitosan, and stir for 30 minutes to obtain a shell Acetic acid suspension of polysaccharide; add 40g glycerin and 30g starch to the acetic acid suspension of chitosan and stir for 40 minutes to obtain a mixed solution; add the modified nano-titanium dioxide suspension to the mixed solution, continue stirring for 60 minutes, and disperse with high speed The machine carried out high-speed dispersion at a speed of 5000r / min for 30min, and used 0.1mol / L sodium hydroxide solution to adjust the pH value of the composite system to 6 in the reaction process to obtain a composite solution; take 140g polymethyl methacrylate, 60g Stir polyacrylonitrile and 240g N,N-dimethylformamide evenly, let stand for degassing for about 24 hours, and use wet sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com