A kind of concrete inner surface hydrophobic treatment agent and preparation method thereof

A technology for hydrophobic treatment and concrete interior, which is applied in the field of concrete inner surface hydrophobic treatment agent and its preparation, which can solve the problems of high cost and insufficient durability, and achieve the effects of high production cost, high labor intensity and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Use isoprenol polyoxyethylene ether (TPEG) with a molecular weight of 2400, according to TPEG: hydroxyethyl acrylate: hydrogen peroxide (concentration 27.5%): vitamin C: thioglycolic acid: water = 350: 80: 3: 0.3: 0.4 : 425 mass ratio to synthesize coating liquid;

[0052] The synthesis steps are:

[0053] First, add 350 parts of prenol polyoxyethylene ether and 300 parts of deionized water into the three-necked flask, and stir at room temperature for 20 minutes to ensure that the prenol polyoxyethylene ether is completely dissolved;

[0054] Add 3 parts of hydrogen peroxide (concentration 27.5%) and stir for 5 minutes;

[0055] Prepare solution A and solution B. Among them, liquid A: 0.4 part of thioglycolic acid, 0.3 part of vitamin C, 85 parts of deionized water. Liquid B: 80 parts of hydroxyethyl acrylate, 40 parts of deionized water;

[0056] Both liquid A and liquid B were added dropwise into the three-necked flask, wherein A was added dropwise for 3 hours,...

Embodiment 2

[0078] 1) Using isoprenol polyoxyethylene ether (TPEG) with a molecular weight of 3000, according to TPEG: hydroxybutyl acrylate: ammonium persulfate: ferrous sulfate heptahydrate: mercaptopropionic acid: water = 330: 100: 2: 0.2: 0.3:435 mass ratio to synthesize the coating liquid;

[0079] The synthesis steps are,

[0080] First, add 330 parts of prenol polyoxyethylene ether and 310 parts of deionized water into the three-necked flask, and stir at room temperature for 20 minutes to ensure that the prenol polyoxyethylene ether is completely dissolved; add 2 parts of ammonium persulfate, stir for 5 minute;

[0081] Prepare solution A and solution B. Among them, liquid A: 0.3 parts of thioglycolic acid, 0.2 parts of ferrous sulfate, 85 parts of deionized water. Liquid B: 100 parts of hydroxybutyl acrylate, 40 parts of deionized water;

[0082] Both liquid A and liquid B were added dropwise into the three-necked flask, wherein A was added dropwise for 3 hours, and B was adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

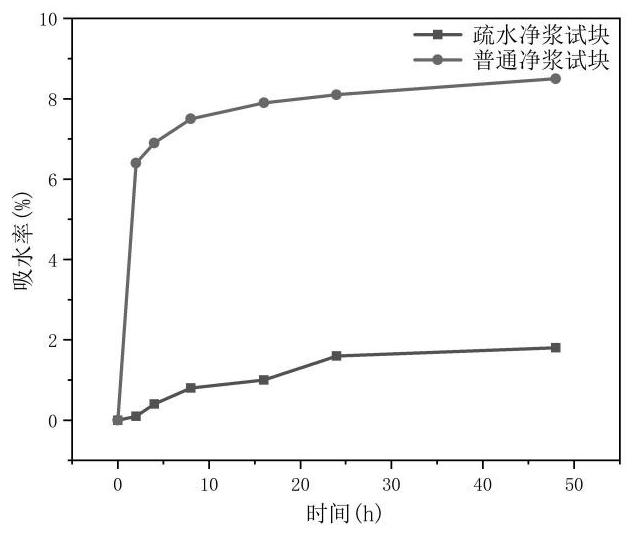

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com