A kind of flame-retardant SBS modified asphalt waterproofing membrane and its preparation method

A technology of waterproofing membrane and modified asphalt, applied in the direction of flame retardant fiber, fiber type, physical treatment, etc., can solve the problems such as the inability to guarantee the flame retardant performance and waterproof performance of waterproof membrane, cracking and falling off of flame retardant asphalt, etc. , to achieve the effects of excellent flame retardant and waterproof performance, improved waterproof performance, and appropriate component ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

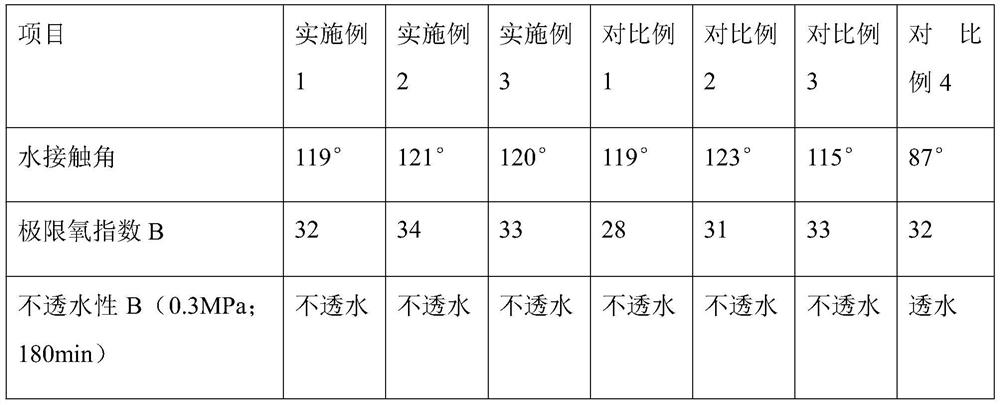

Examples

Embodiment 1

[0033] A flame-retardant SBS modified bitumen waterproofing membrane and a preparation method thereof, comprising the following steps:

[0034] (1) Take the carbon fiber, extract and clean it with acetone, the reflux temperature is 353K, the reflux time is 20h, and the vacuum is dried at 373K for 20h. After drying, the carbon fiber is placed in a mixed solution of dilute sulfuric acid and potassium permanganate, and bromine is added to make it It was placed in a reaction kettle, heated to 593K in a salt bath after sealing, oxidized for 20 minutes, the reaction kettle was cooled, and then the carbon fibers were taken out, washed with absolute ethanol and deionized water in turn, dried, and then extracted with acetone for 1 hour, and dried to obtain carbon oxide fibers. . The amount of potassium permanganate is 0.5g, the amount of bromine is 2mL, and the amount of dilute sulfuric acid is 48mL;

[0035]Take polyester, heat it to 280°C to melt, add glass fiber, stir evenly, sprea...

Embodiment 2

[0043] A flame-retardant SBS modified bitumen waterproofing membrane and a preparation method thereof, comprising the following steps:

[0044] (1) Take the carbon fiber, extract and clean it with acetone, the reflux temperature is 353K, the reflux time is 22h, vacuum-drying at 373K for 22h, after drying, the carbon fiber is placed in a mixed solution of dilute sulfuric acid and potassium permanganate, and bromine is added to make it It was placed in a reaction kettle, heated to 593K in a salt bath after sealing, and oxidized for 24 minutes. After the reaction kettle was cooled, the carbon fibers were taken out, washed with absolute ethanol and deionized water in turn, dried, and then extracted and washed with acetone for 1.5 hours, and dried to obtain oxidation carbon fiber. The amount of potassium permanganate is 0.5g, the amount of bromine is 2mL, and the amount of dilute sulfuric acid is 48mL;

[0045] Take polyester, heat it to melt at 290°C, add glass fiber, stir evenly...

Embodiment 3

[0053] A flame-retardant SBS modified bitumen waterproofing membrane and a preparation method thereof, comprising the following steps:

[0054] (1) Take the carbon fiber, extract and clean it with acetone, the reflux temperature is 353K, the reflux time is 24h, and vacuum-drying at 373K for 24h. After drying, the carbon fiber is placed in a mixed solution of dilute sulfuric acid and potassium permanganate, and bromine is added. It was placed in a reaction kettle, heated to 593K in a salt bath after sealing, and oxidized for 25 minutes. After the reaction kettle was cooled, the carbon fibers were taken out, washed with absolute ethanol and deionized water in turn, dried, and then extracted with acetone for 2 hours and dried to obtain carbon oxide fibers. . The amount of potassium permanganate is 0.5g, the amount of bromine is 2mL, and the amount of dilute sulfuric acid is 48mL;

[0055] Take polyester, heat it to 300°C to melt, add glass fiber, stir evenly, spread it out, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com