Patents

Literature

63results about How to "Pore structure is suitable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

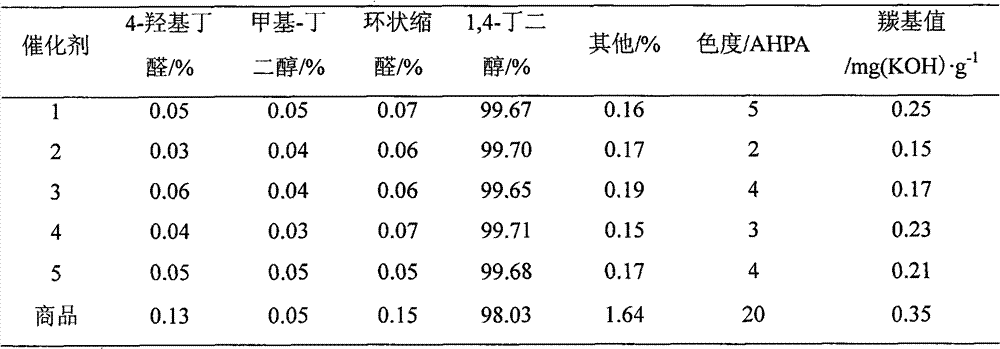

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

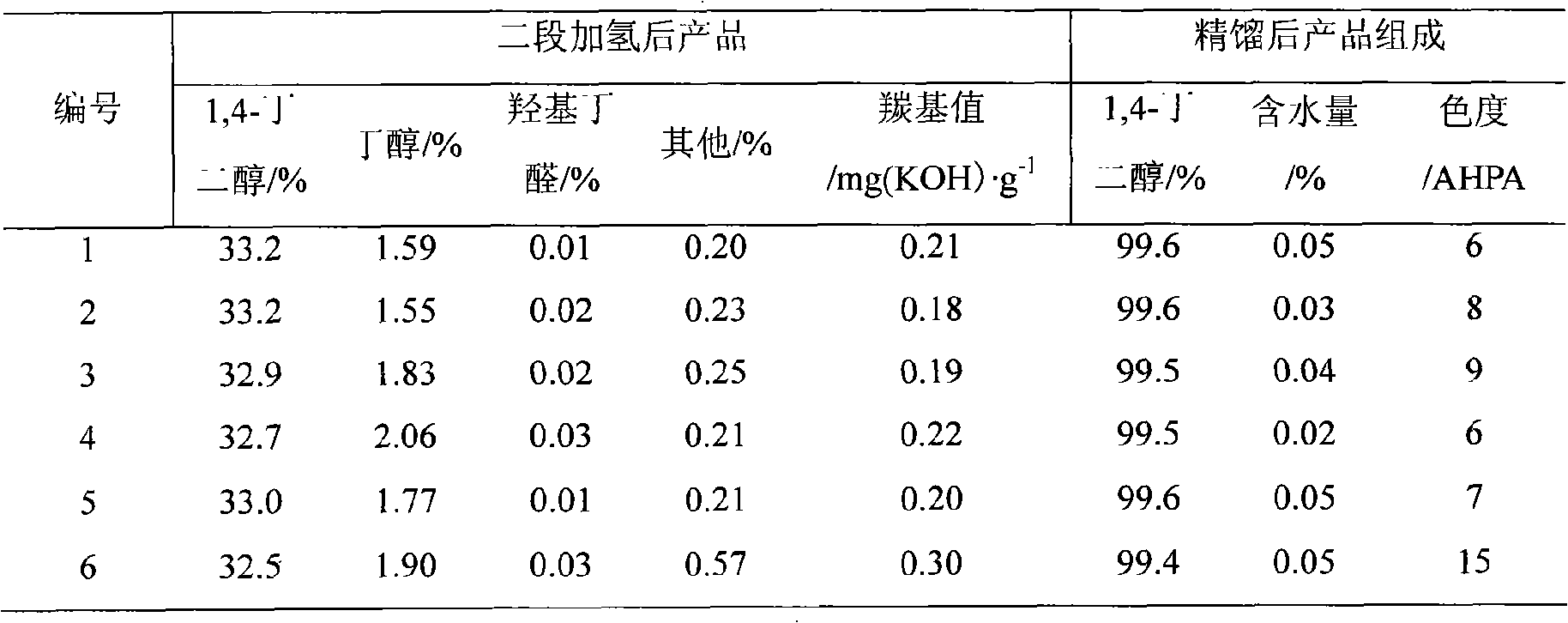

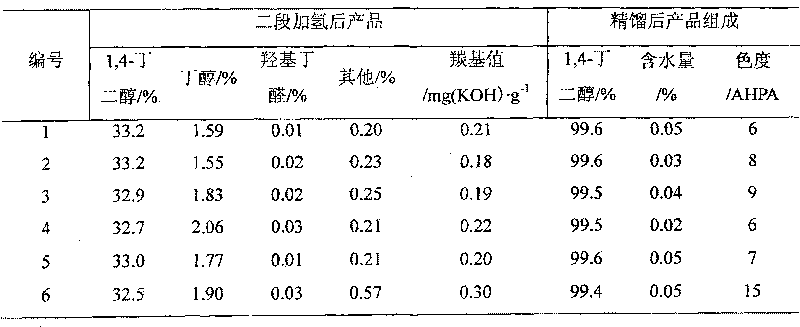

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

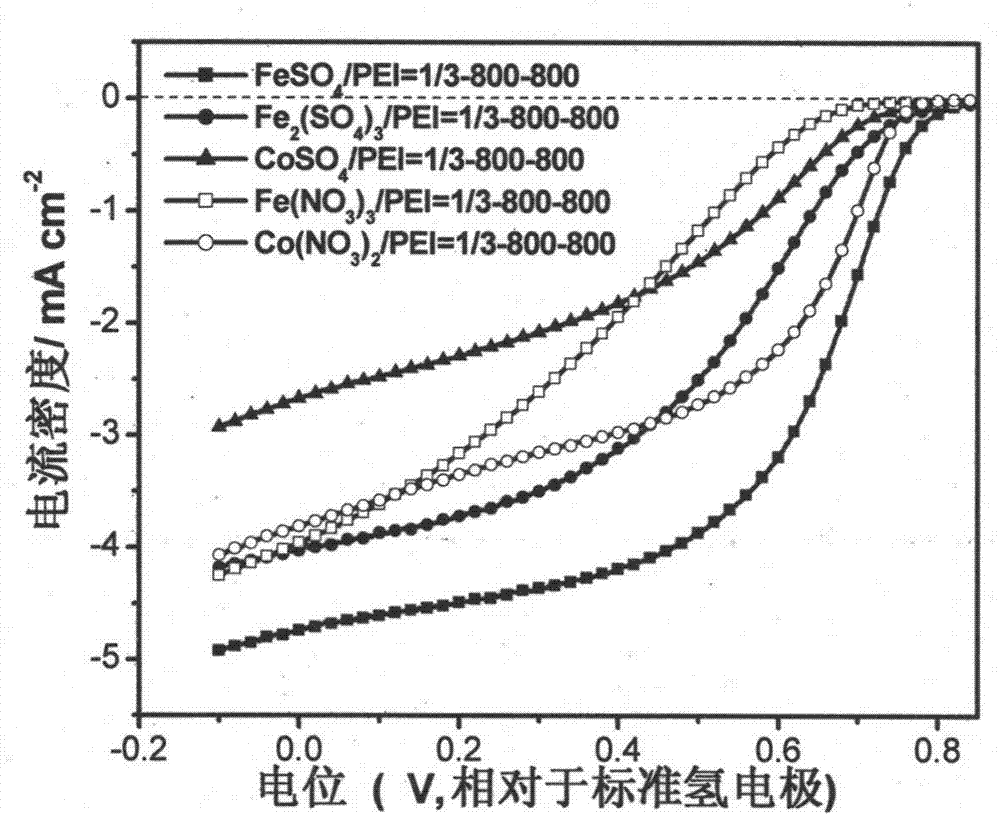

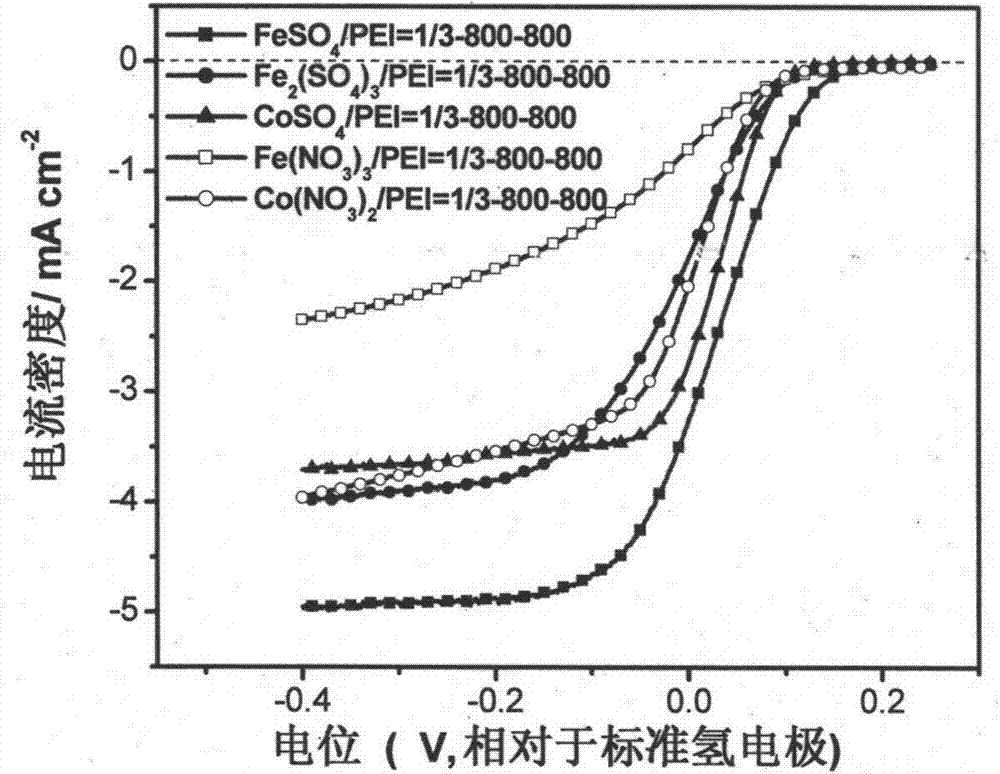

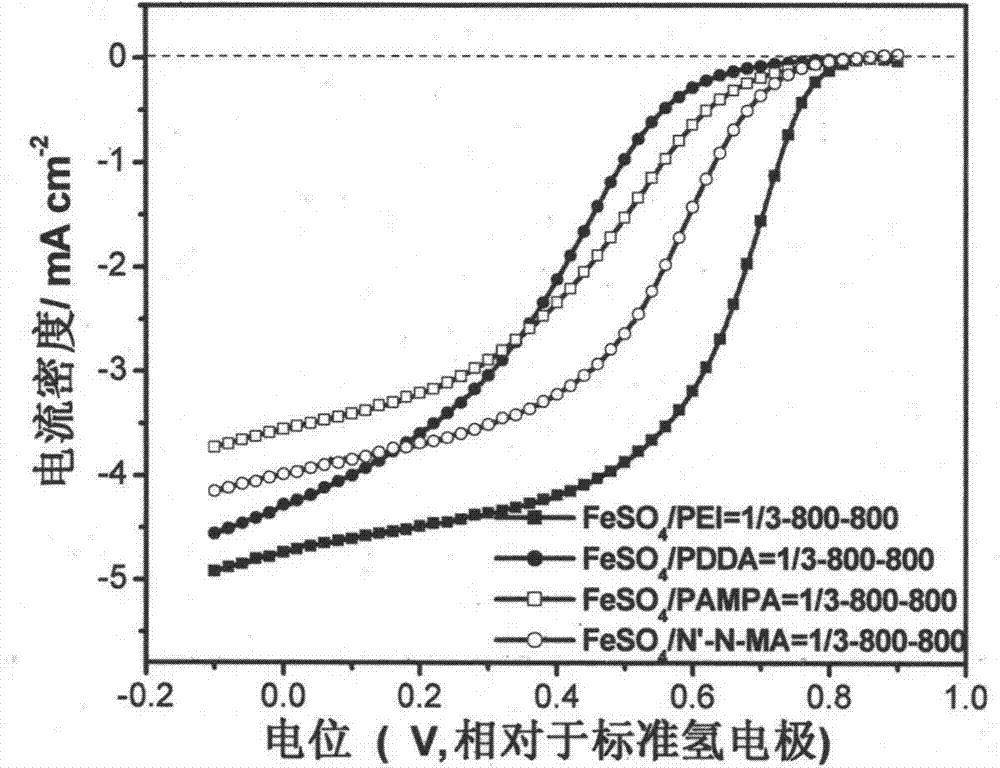

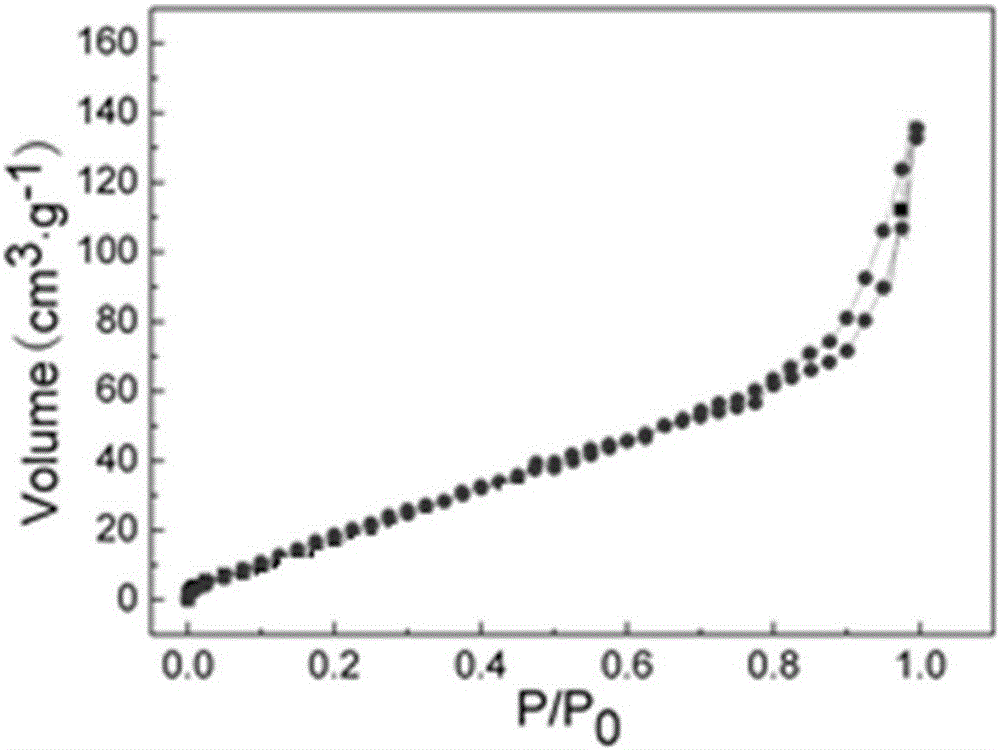

Metal-free nitrogen-doped functionalized mesoporous carbon catalyst and preparation method and applications thereof

InactiveCN103566961AHigh catalytic activityAvoid defects such as deactivation (corrosion)Physical/chemical process catalystsCell electrodesStrong acidsAcid washing

The invention relates to a metal-free nitrogen-doped functionalized mesoporous carbon catalyst and preparation method and applications thereof. A precursor of the metal-free nitrogen-doped functionalized mesoporous carbon catalyst comprises the following components in percentage by mass: 20-85% of template agent, 10-75% of nitrogen compound, and 5-50% of transition metal salt. The nitrogen compound is carbonized at high temperature under the existence condition of transition metal, to form a high-nitrogen-content pyridine and graphite nitrogen (Nx-C) composite structure, and the catalytic activity of oxygen can be remarkably enhanced; the transition metal in the nitrogen-doped mesoporous carbon catalyst can be removed through acid pickling, so that the inactivation (corrosion) of the catalyst containing the transition metal under the conditions of strong acid and strong alkali can be avoided, the characteristics of being high in stability, not easy to poison and the like can be achieved, and the metal-free nitrogen-doped functionalized mesoporous carbon catalyst has excellent application prospects in the fields of treating waste water of fuel batteries, metal-air batteries, supercapacitors, energy-storage batteries, microbial fuel cells, and the like.

Owner:DONGHUA UNIV

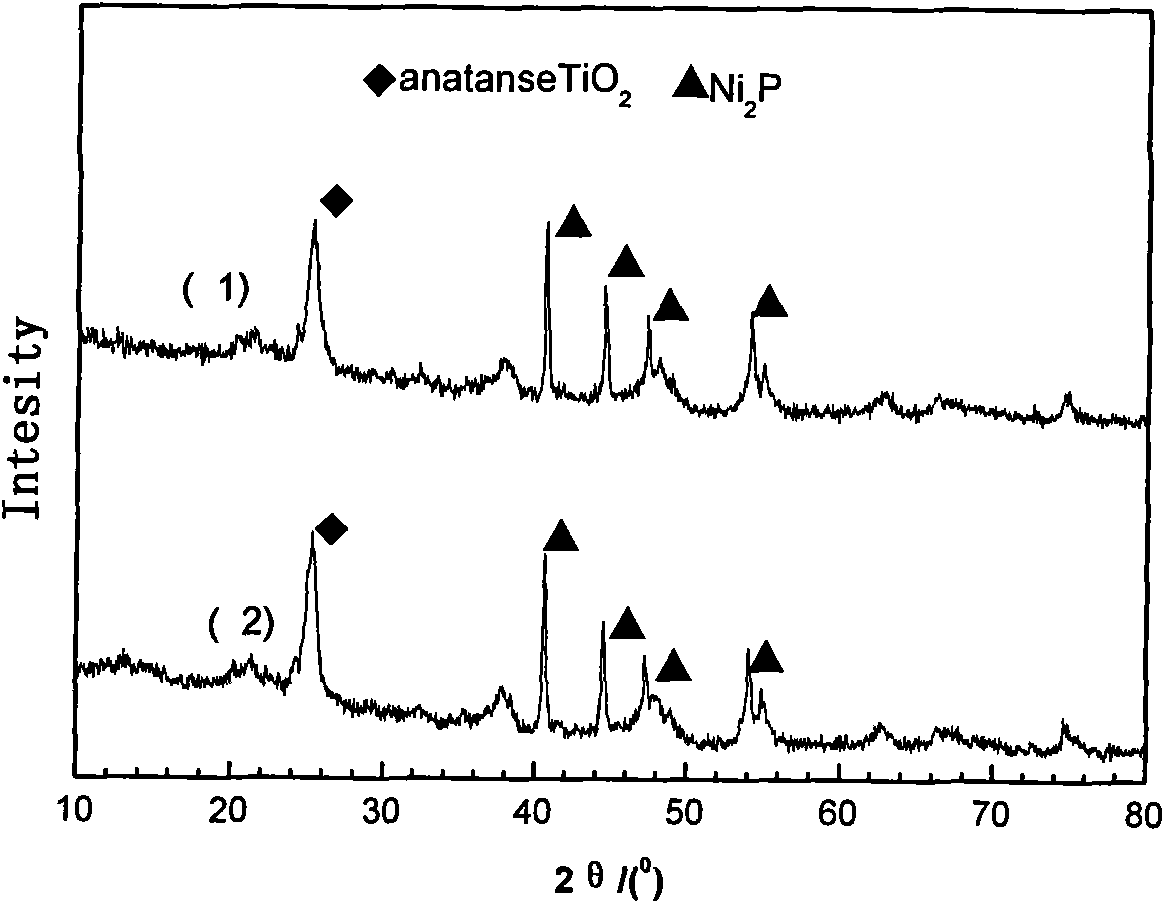

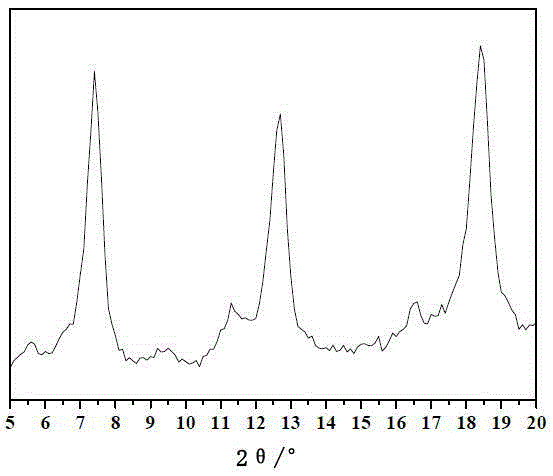

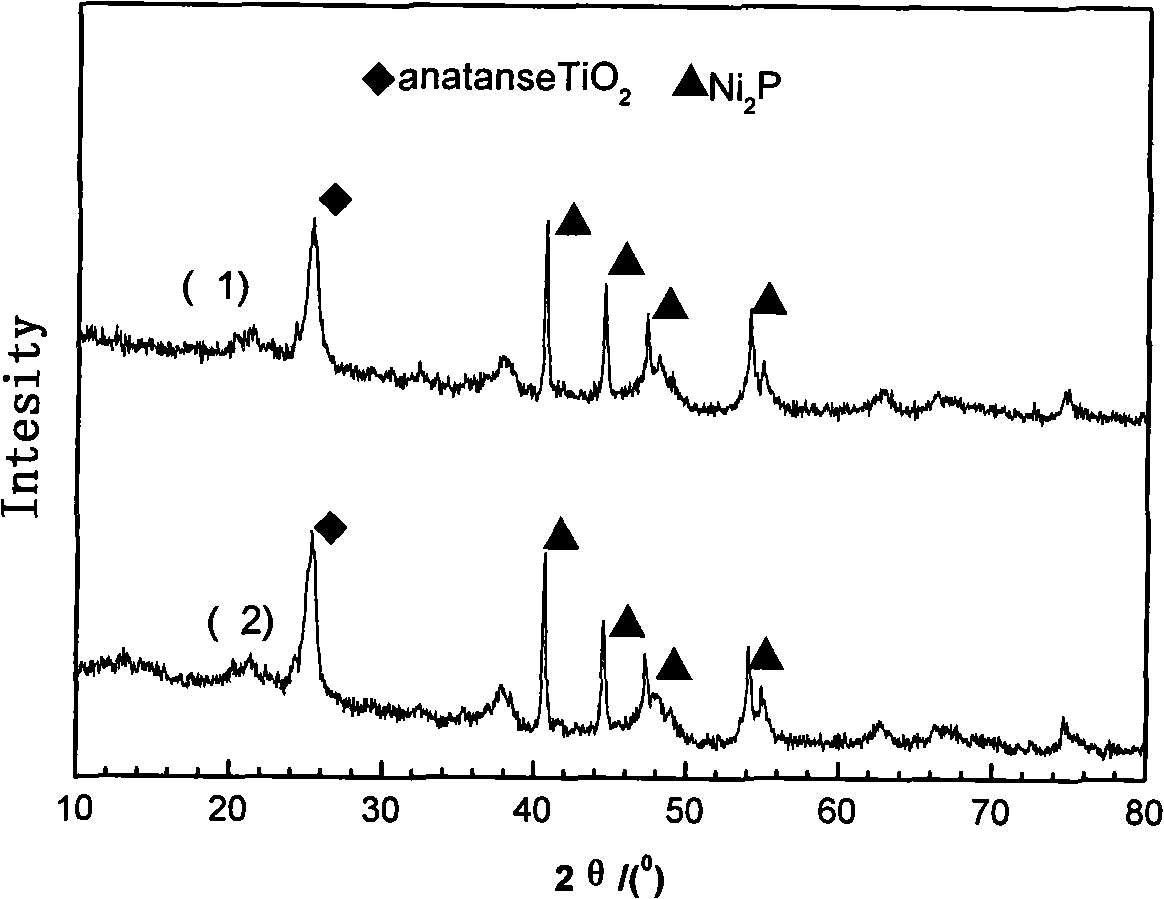

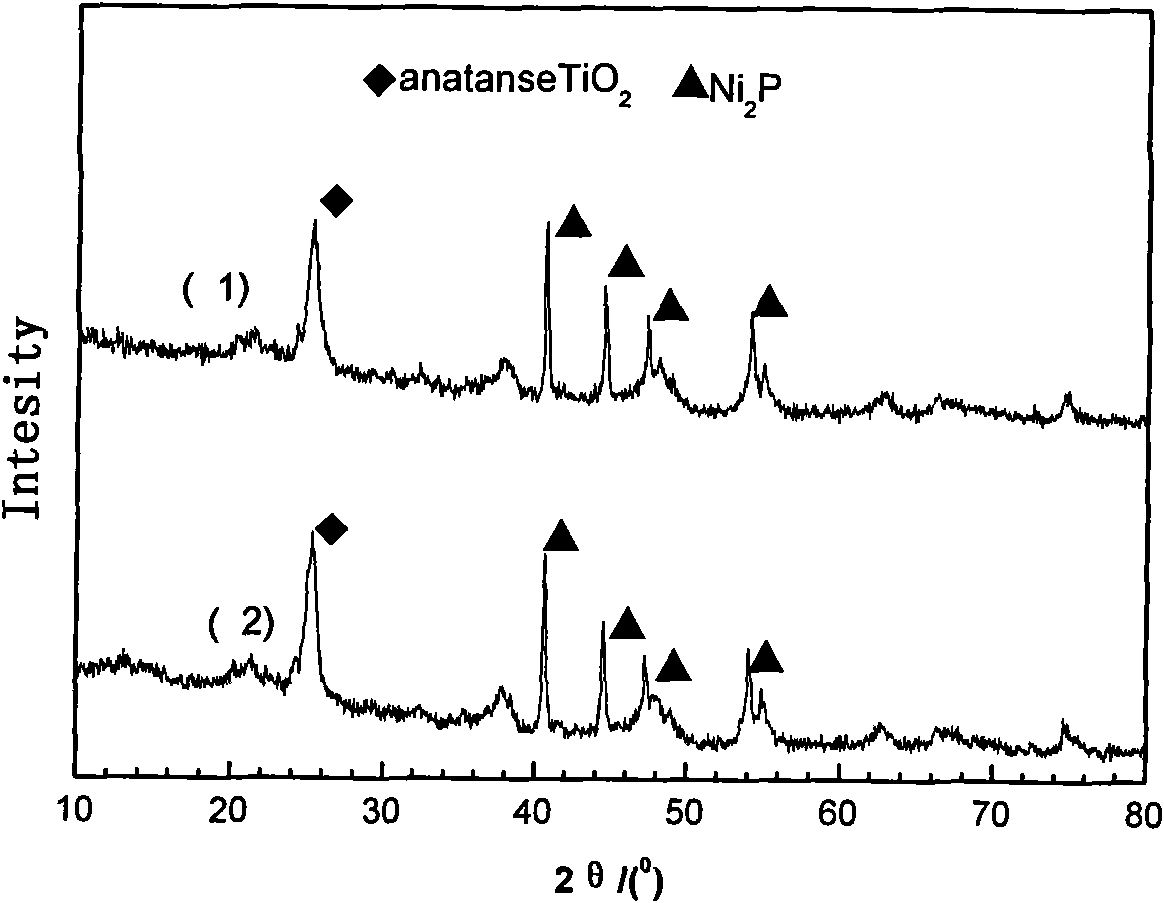

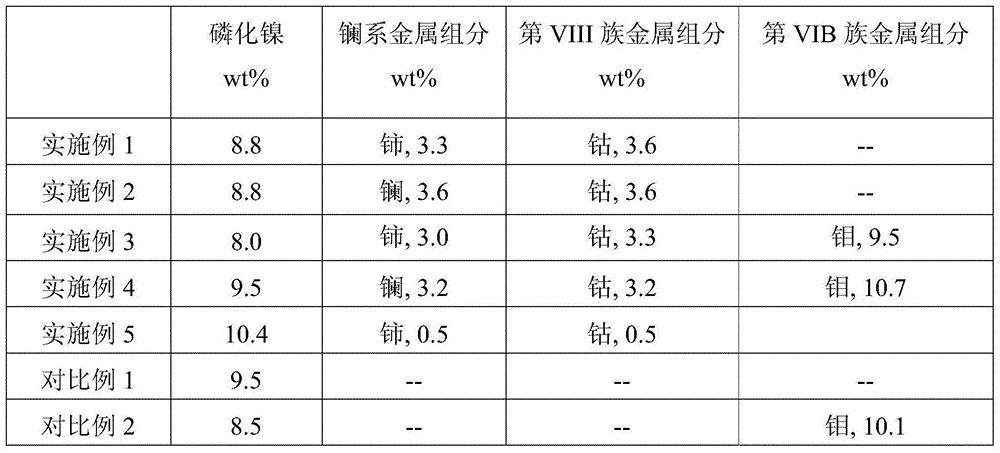

Preparation method of nickel phosphide catalyst carried by composite carrier

InactiveCN101612584ALittle loss of activityHigh activityCatalyst activation/preparationRefining to eliminate hetero atomsNickel saltPhosphate

The invention relates to a preparation method of a nickel phosphide catalyst carried by a composite carrier. The method is characterized by comprising the following steps: firstly, using activated alumina and relative enzymes and alcohols as raw materials to prepare a composite carrier of TiO2-Al2O3 by adopting an improved sol-gel method; further, selecting suitable nickel salt and phosphate and carrying out ultrasound dipping and drying in microwaves to obtain a catalyst precursor; and finally, increasing a temperature by a program and reducing to obtain the composite support. The composite carrier of TiO2-Al2O3 prepared by the invention not only can effectively overcome the defect that nickel phosphide is apt to react with gamma-Al2O3 to generate AlP4 to lose the activity, but also overcomes the defect that a specific surface area of single TiO2 is relatively small, effectively exerts the strong metal-support interaction (SMSI) of the TiO2, thereby obtaining a hydrodesulfurization catalyst with remarkable activity efficacy.

Owner:XI AN JIAOTONG UNIV

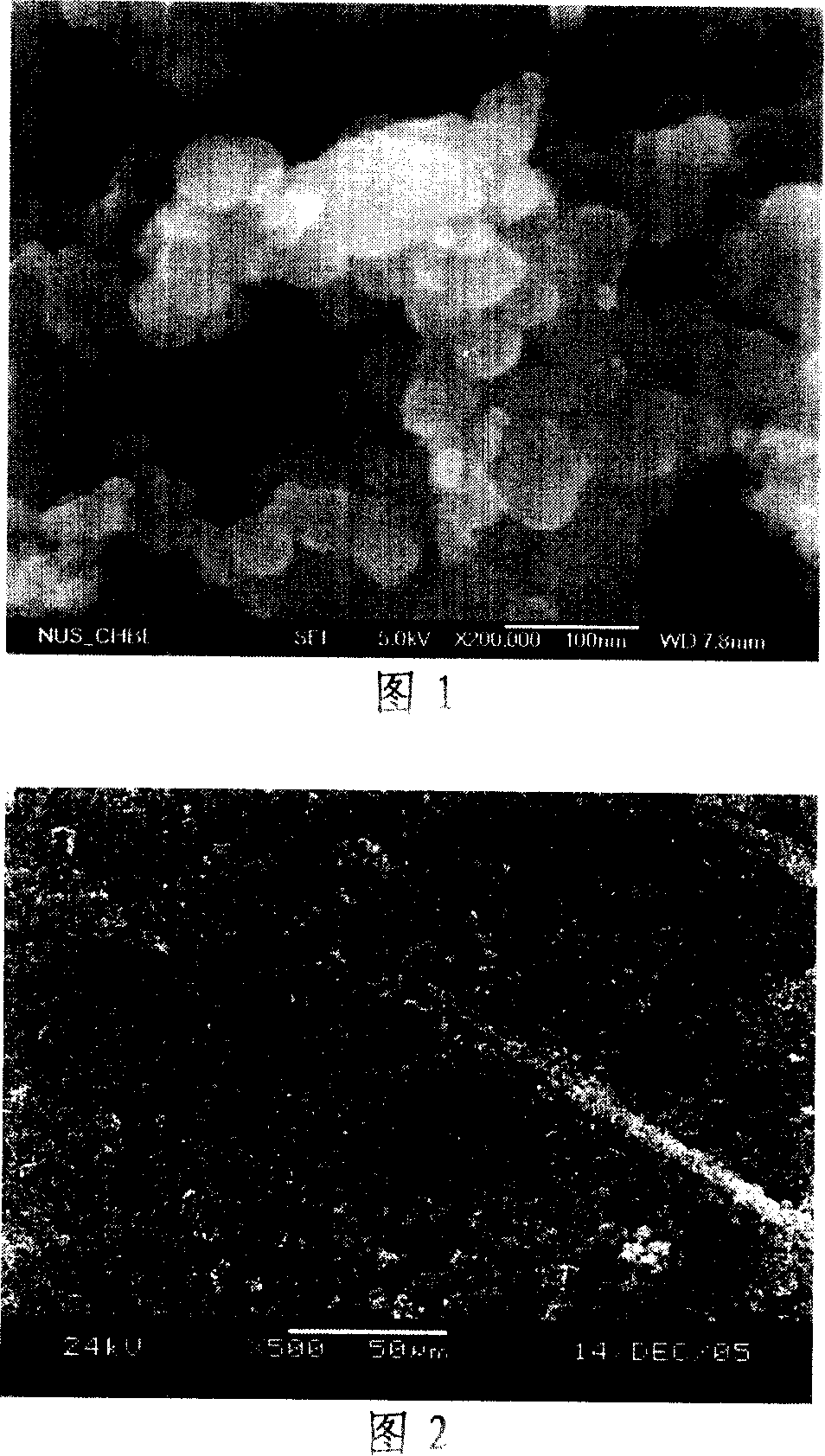

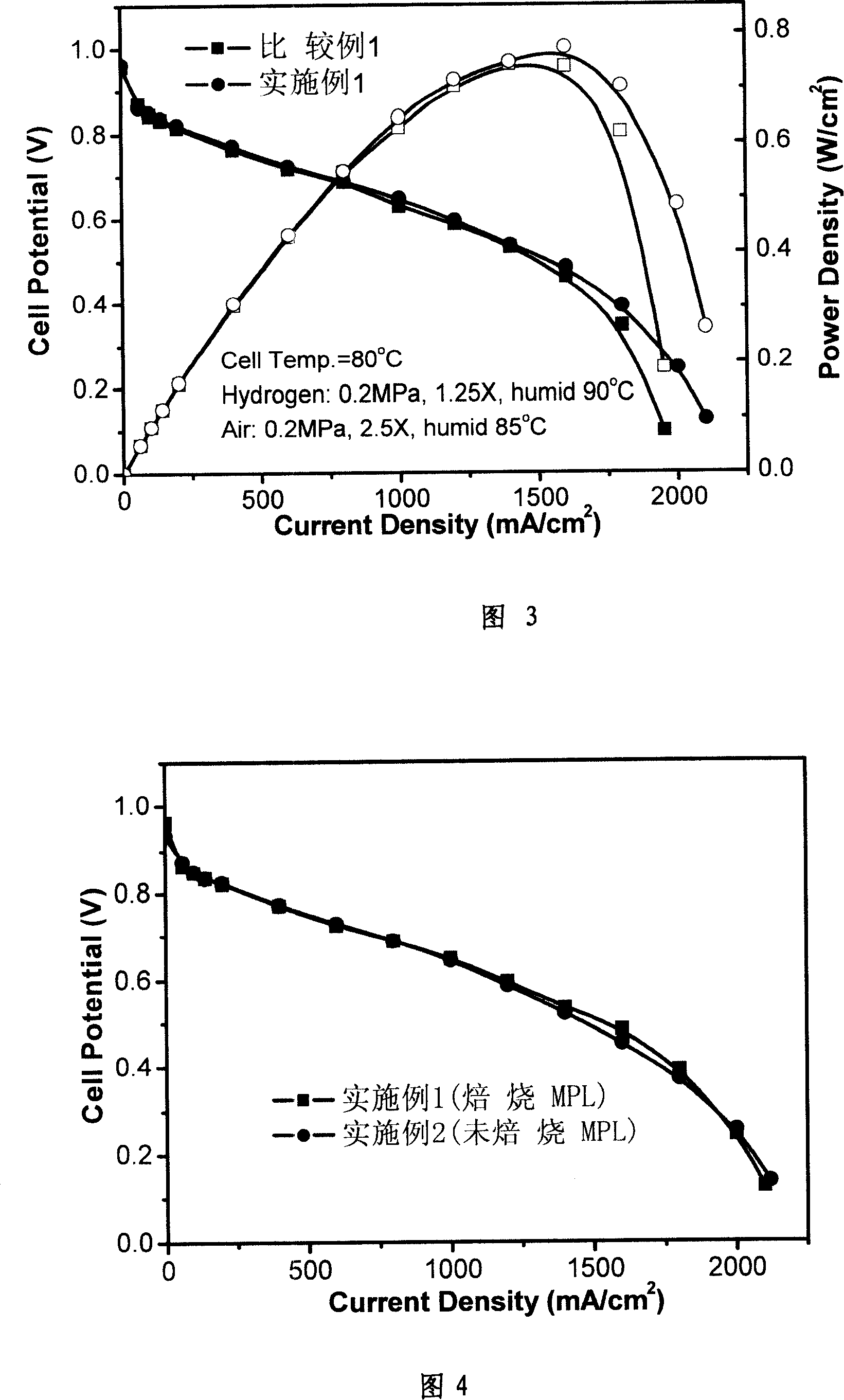

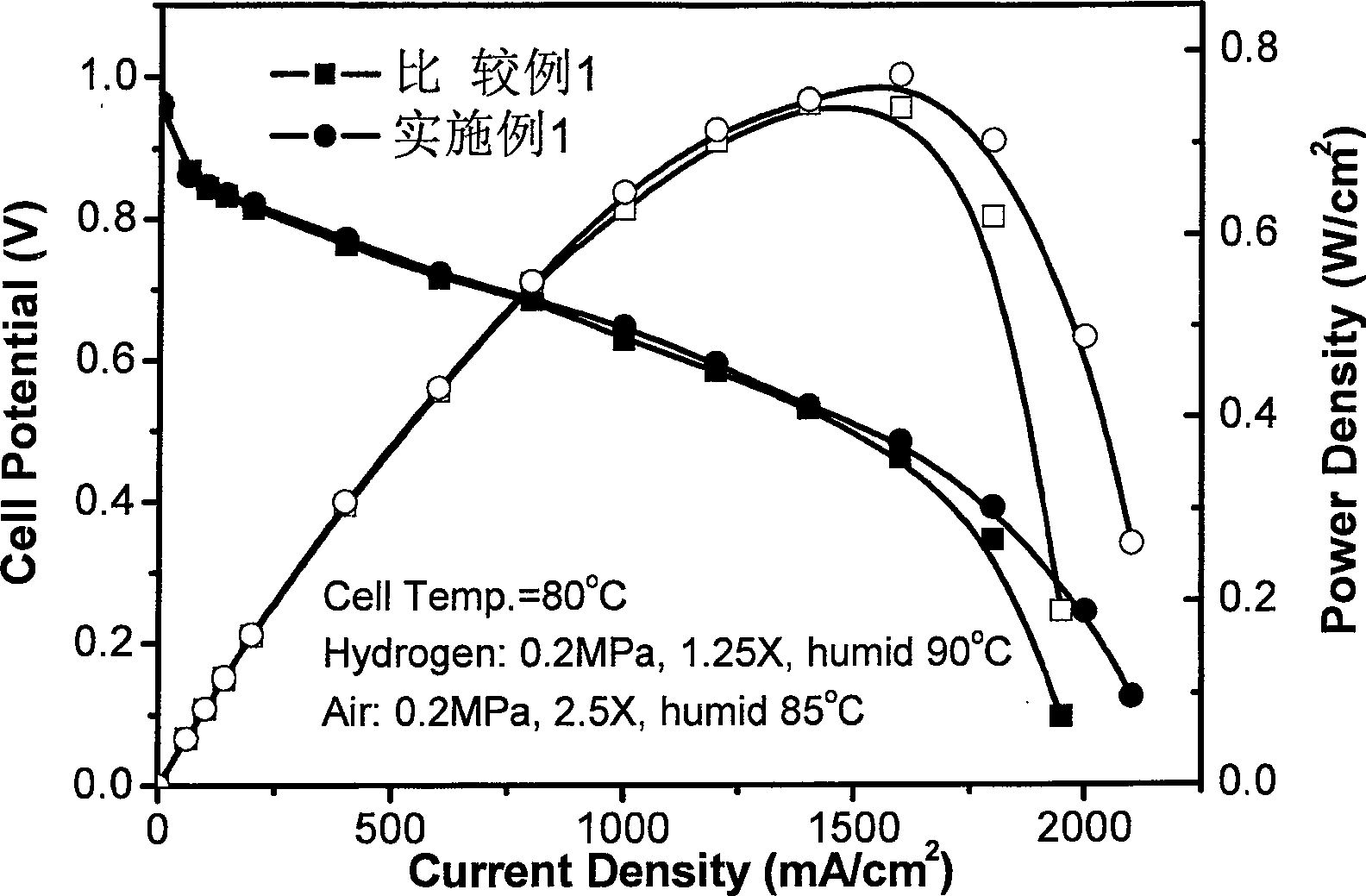

Gas diffusion layer for fuel cell and its production

InactiveCN101154733AGuaranteed hydrophobicityAchieve hydrophobicityCell electrodesFinal product manufactureFuel cellsElectrical battery

The invention relates to a fuel battery, in particular to a gas diffusing layer and the preparation for the fuel battery; the gas diffusing layer consists of basic bottom layer and a micro-hole layer, which is made by fabricating the micro-hole constructed by a water repellent agent / a composite powder body of electric conduction copper material at one side or two sides of a porous electric conduction basic bottom processed by a hydrophobic water; the water repellent agent / the composite powder body of electric conduction copper material is made by a microwave dielectric heating technology; because of the favorable water repellent performance and the grain diameter structure therefore, the gas diffusing layer to be fabricated has a strong and even water repellent performance and a suitable hole structure, so that the favorable mass transfer capability of the gas diffusing layer can be assured. The fuel battery assembled by the invention can show a better battery output performance, and is particularly suitable to be used in the fuel battery where the air is used as oxidizer with a strong practicality value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

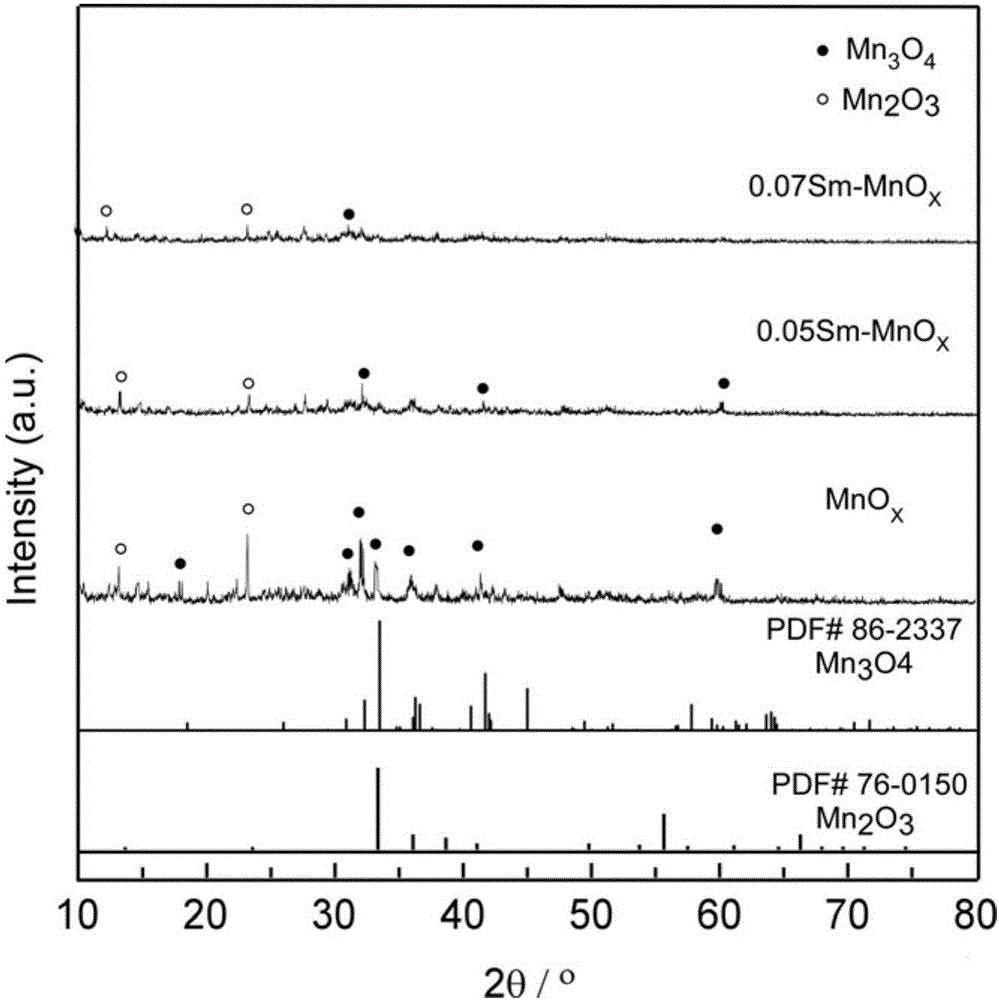

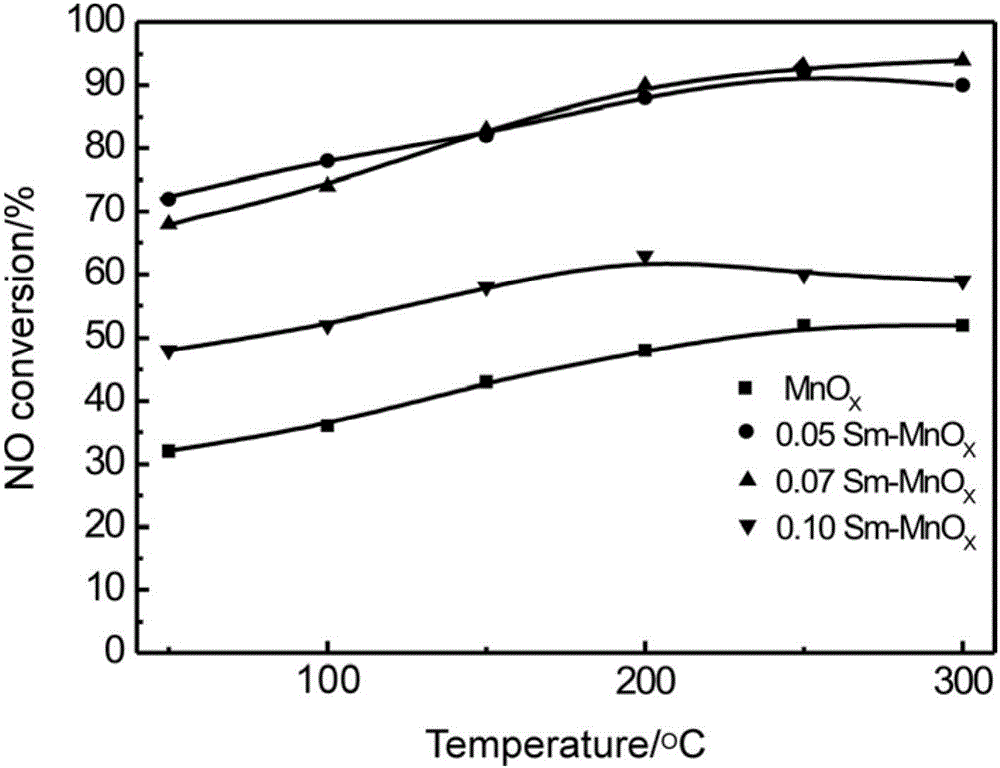

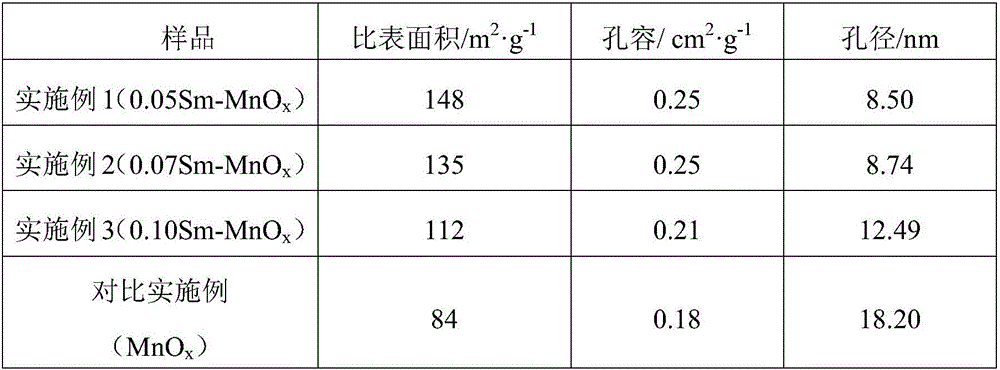

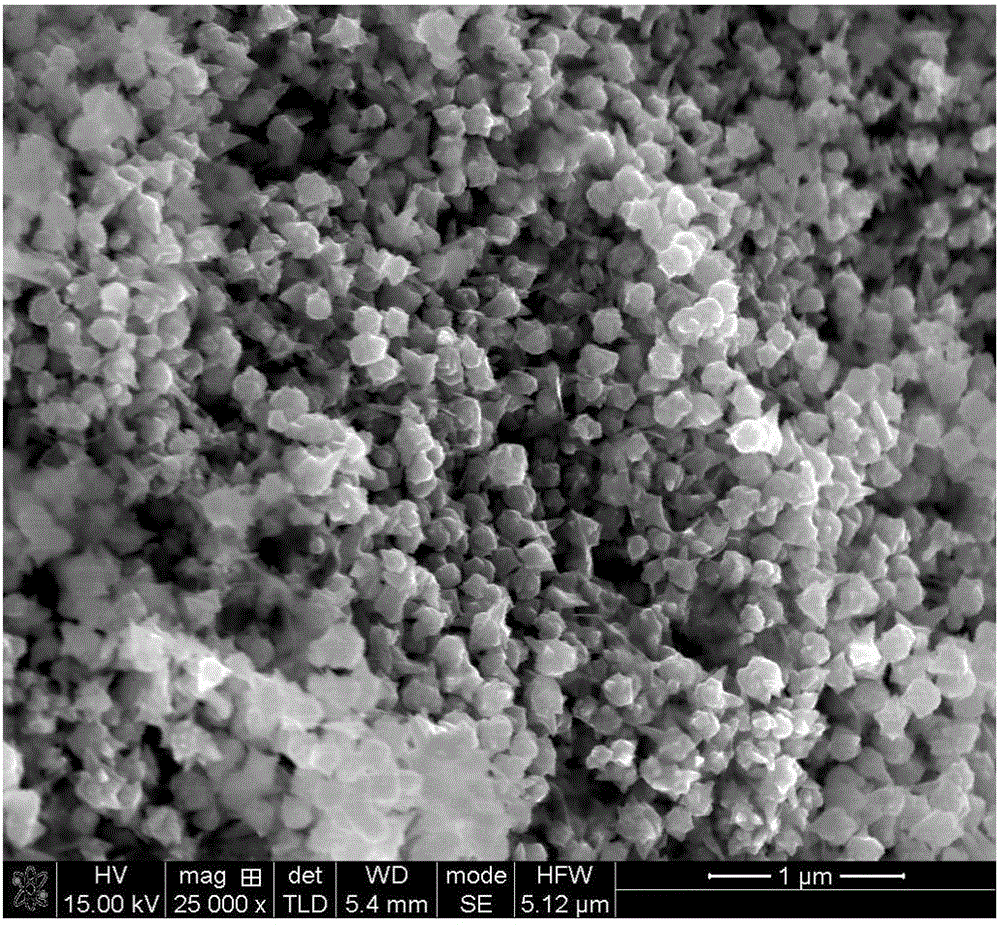

Samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as preparation method and application thereof

InactiveCN106268787ALarge specific surface areaSmall particle sizeHeterogenous catalyst chemical elementsDispersed particle separationDispersityMischmetal

The invention relates to a samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as a preparation method and application thereof. A proper amount of rare-earth metal samarium is doped into a manganese-based catalyst to obtain the samarium-doped MnOx low-temperature SCR catalyst; compared with a single manganese-based catalyst, the specific surface area of the catalyst is enlarged and the grain diameter of MnOx is reduced; the dispersity of manganese oxide in the catalyst is improved, and reaction activity of the MnOx at low temperature is effectively facilitated; an SCR denitration activity temperature window is expanded, and a modification effect on an MnOx catalyst is very good; the samarium-doped MnOx low-temperature SCR catalyst has relatively high catalytic activity at the low temperature.

Owner:WUHAN UNIV OF TECH

Metal aerogel with high specific surface area and preparation method thereof

InactiveCN105970193AHigh specific surface areaLow densityLiquid/solution decomposition chemical coatingAerogel preparationSolventChemical plating

The invention discloses metal aerogel with a high specific surface area and a preparation method thereof. The method comprises the steps that (1) cellulose aerogel is placed in a sensitizing solution to be soaked and then is washed with water; (2) the treated cellulose aerogel is soaked in a metal chemical plating solution for chemical plating, and metal / cellulose composite aerogel is obtained; (3) the metal / cellulose composite aerogel is placed in a LiOH / urea solution, the process of removing a cellulose aerogel template is conducted at a low temperature, and a nanometer porous metal solution is obtained; and (4) the prepared nanometer porous metal solution is washed with water, then is subjected to solvent exchange with acetone and is dried, and the metal aerogel with the high specific surface area is obtained. The method adopting the cellulose aerogel as the template for preparing the metal aerogel with the high specific surface area is provided for the first time. The cellulose aerogel has a high specific surface area and is of a pore structure suitable for chemical plating. Meanwhile, the template is easy to remove after the chemical plating, and reference is provided for preparation of metal aerogel with other templates.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

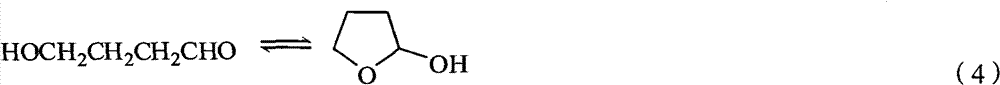

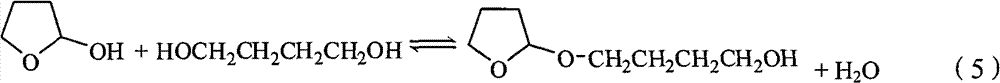

Preparation method of Ni-SiO2/Al2O3 catalyst

ActiveCN102145286BIncrease profitGood dispersionOrganic compound preparationHydroxy compound preparationNickel saltHydrolysis

The invention provides a preparation method of Ni-SiO2 / Al2O3 catalyst, which comprises the steps of: introducing auxiliaries into an alumina carrier; heating the carrier; preparing nickel salt containing urea; impregnating the solution onto the heated carrier in a manner of isometric impregnation; placing the impregnated sample in a sealed container for in-situ reaction at the temperature higher than 90 DEG C; and carrying out drying, roasting, reducing and passivating to obtain the catalyst product which contains 5 to 25% of nickel by mass fraction and 0.5 to 7% of silicon auxiliary by mass fraction and which includes the double functions of hydrolysis and hydrogenation. The catalyst is used for the secondary hydrogenation process for the preparation of 1, 4-butanediol from hydrogenated 1,4-butynediol by a two-step method, thereby accomplishing the hydrolyzed and hydrogenated conversion of chromophore cyclic acetal, reducing the chromaticity of 1,4-butanediol products and improving the product quality.

Owner:SHANXI UNIV

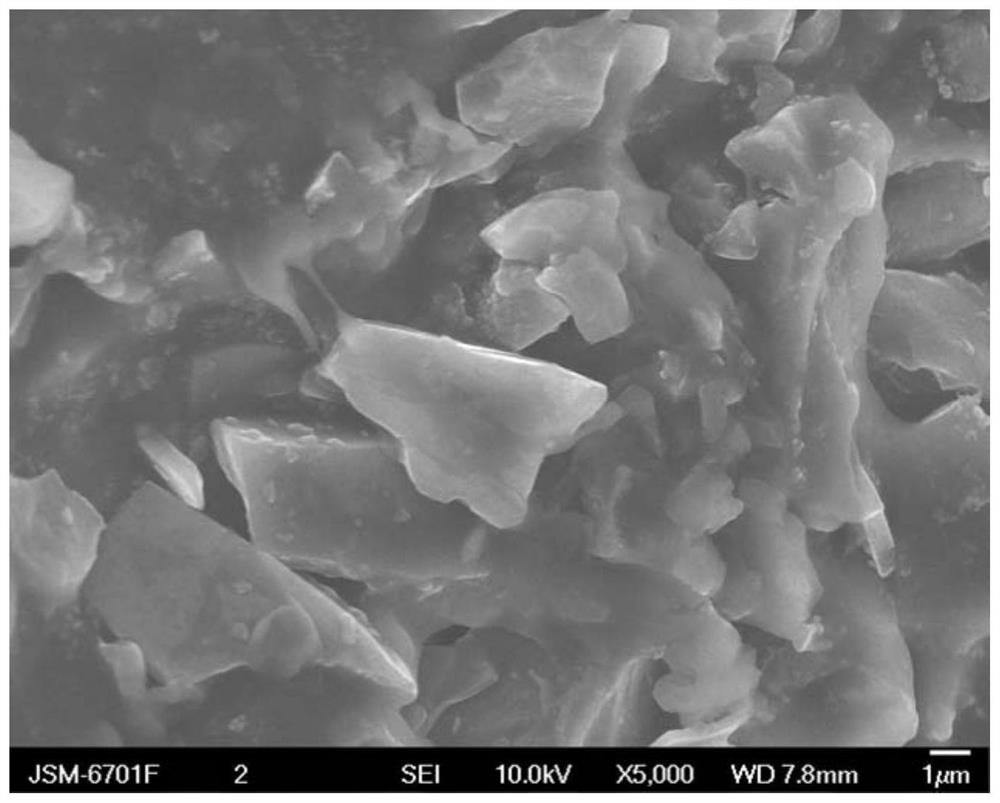

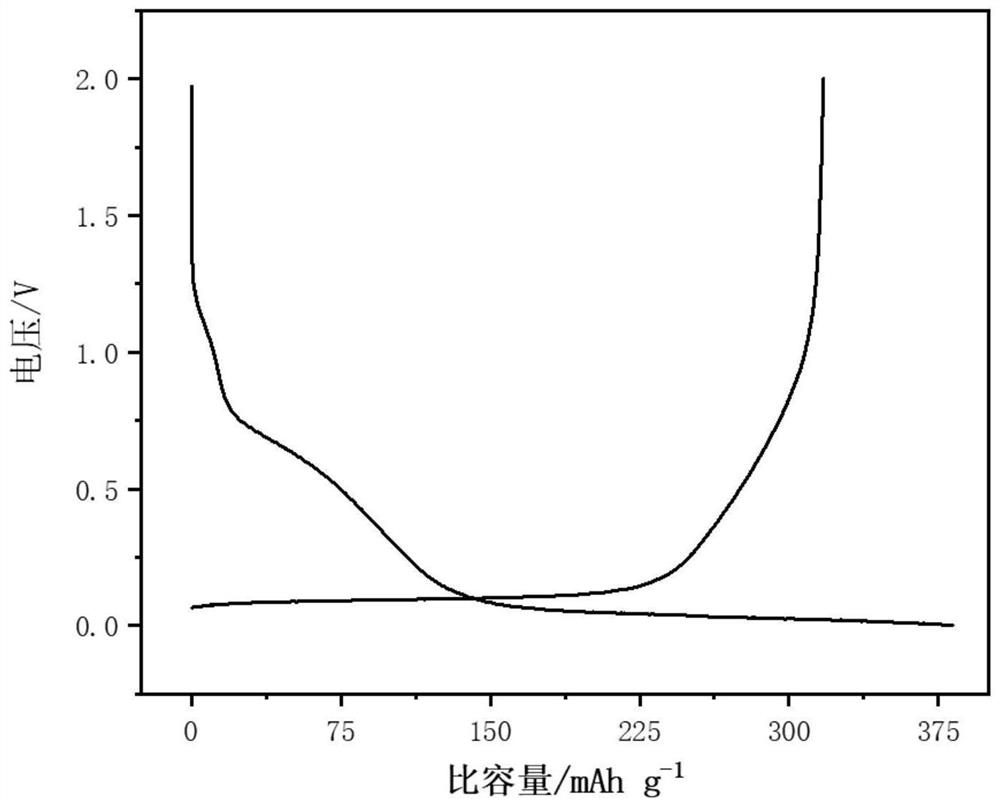

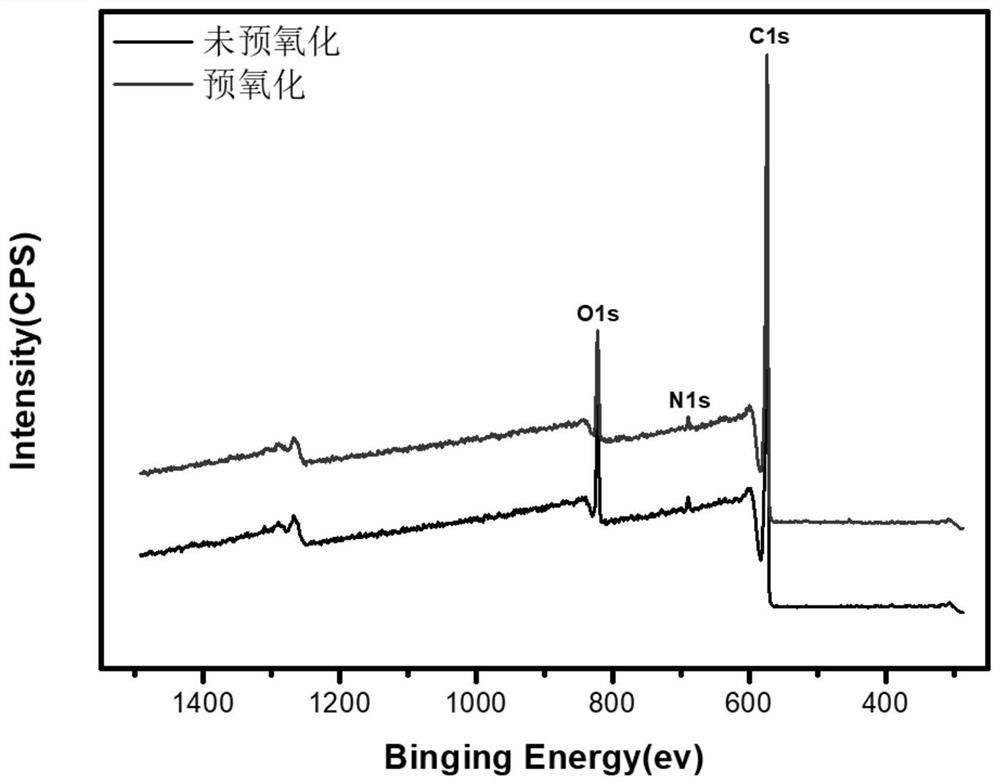

Hard carbon material and preparation method and application thereof

ActiveCN112225194AReduces the formation of crystals and impuritiesImprove charge and discharge capacityCell electrodesSecondary cellsCyclic stabilityMaterials science

The invention relates to a hard carbon material as well as a preparation method and application thereof. A conductive additive is introduced into the hard carbon material precursor to improve the conductivity of an obtained material, and a large number of oxygen-containing functional groups are introduced in combination with variable-speed heating pre-oxidation, so that the crosslinking degree ofa material skeleton is increased, the strength of the material is improved, and the sodium storage specific capacity, the first-circle coulombic efficiency and the rate capability are remarkably improved. The hard carbon material has the advantages of high reversible capacity, high first-circle coulombic efficiency, good cycling stability and the like when being used for the sodium ion battery. The material has the characteristics of simple preparation method and cheap and easily available raw materials, and provides more choices for the negative electrode of the sodium-ion battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

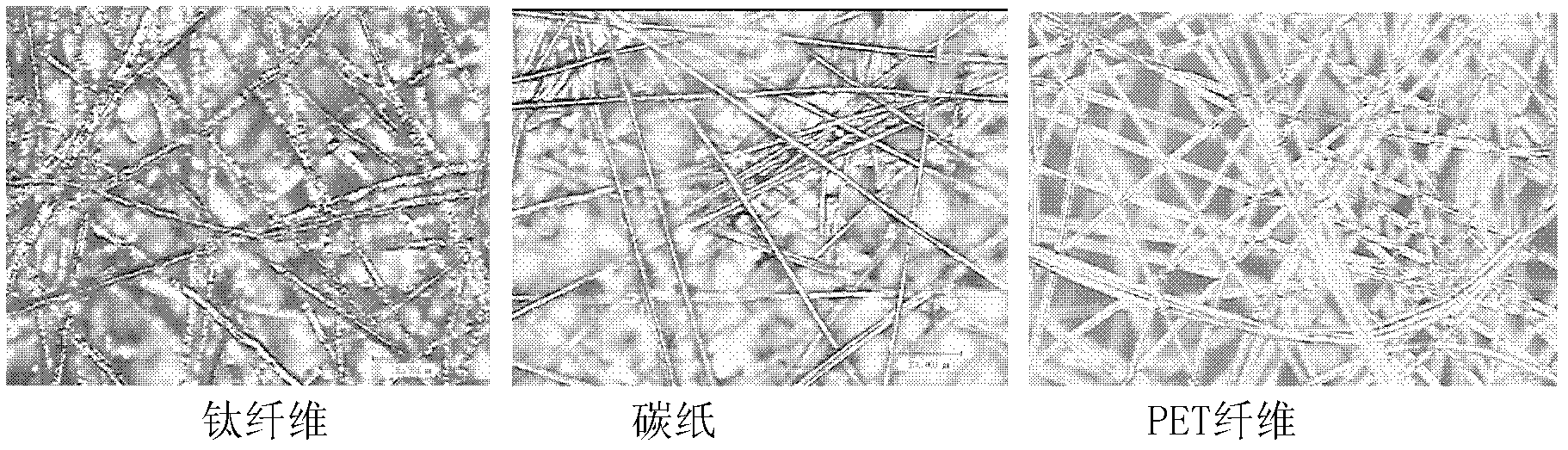

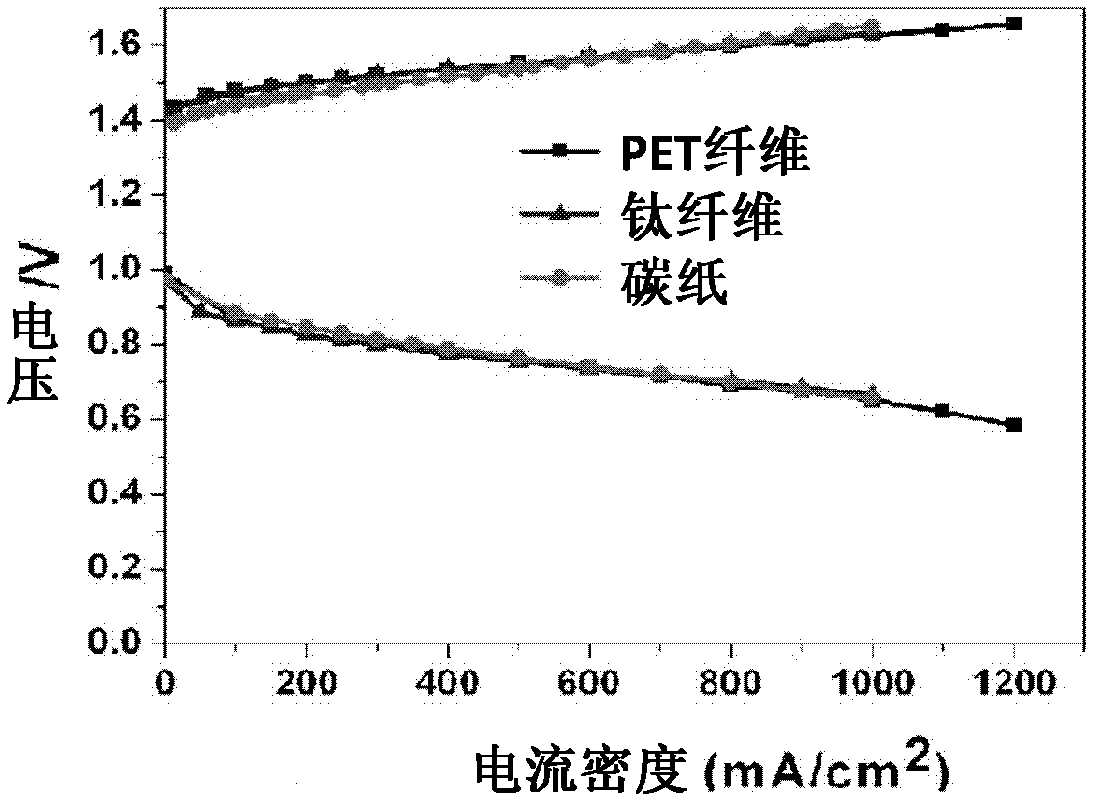

Gas diffusion layer for unitized regenerative fuel cell, and its preparation method

InactiveCN102856567ASolving High Potential Corrosion ProblemsSuitable hydrophilic and hydrophobic propertiesFuel cell detailsUnitized regenerative fuel cellHydrophilic hydrophobic

The invention provides a gas diffusion layer for unitized regenerative fuel cell, and its preparation method. The gas diffusion layer comprises nonconductive organic synthetic fiber cloth as a support body, and conductive corrosion-resistance metal / metal oxide network formed on the support body and filled in the pores of the organic fibers. The gas diffusion layer further comprises a hydrophobic agent and a binder for achieving proper hydrophilic-hydrophobic property and good pore structure, so as to ensure mass transfer balance of the URFC in different work modes. The invention solves the corrosion problem of existing URFC support body, increases gravimetric specific power, and lowers electrode cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Residual oil hydrotreating catalyst and preparation method thereof

ActiveCN103055932ALarge specific surface areaLarge apertureMolecular sieve catalystsHydrocarbon oils refiningChemistryLarge pore size

The invention discloses a residual oil hydrotreating catalyst and a preparation method thereof. In the catalyst, the active metal constituents are Group VIII metals and Group VIB metals; and the supporter is composed of aluminum oxide and mesoporous molecular sieve, wherein the mesoporous molecular sieve accounts for 4.5-9.5 wt% of the supporter. In the catalyst supporter preparation process, a proper amount of alkaline nitrogen-containing compound is added into the raw materials quasi-boehmite, aluminum oxide powder and mesoporous molecular sieve; and due to the actions of blending and sintering, the prepared catalyst has large specific area, large pore size and proper pore structure, reduces the diffusion restriction of the reactants, is suitable for catalyzing macromolecule-participated reactions, has proper acid value and improved wear resistance, and maintains the desulfurization activity on the premise of enhancing the hydrogenation demetallization and deasphaltenizing activities.

Owner:CHINA PETROLEUM & CHEM CORP +1

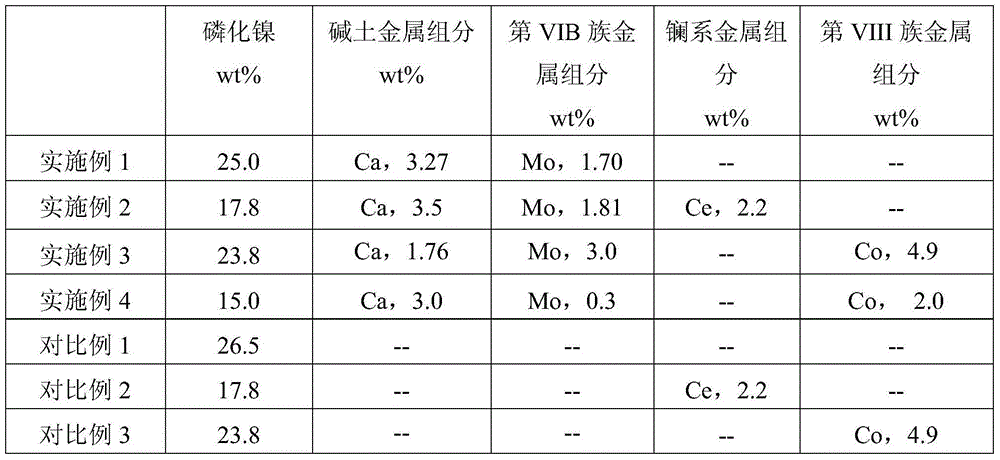

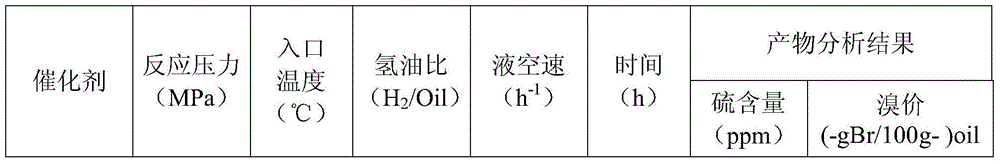

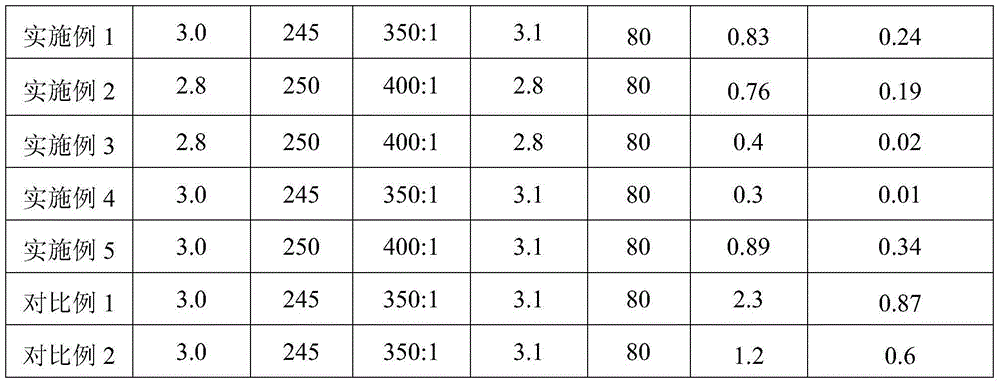

Hydrodesulfurization catalyst, preparation method and applications thereof

ActiveCN104437578AImprove hydrogenation activityImprove hydrodesulfurization performancePhysical/chemical process catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The present invention provides a hydrodesulfurization catalyst, which comprises a modified titania-alumina composite carrier and nickel phosphide loaded on the carrier, wherein the modified titania-alumina composite carrier comprises an alkaline earth metal component and a group VIB metal component. The catalyst of the present invention has low temperature hydrogenation activity and good stability when the catalyst is used for the C5-C9 distillate oil hydrodesulfurization process. The present invention further provides a preparation method of the catalyst and a C5-C9 distillate oil hydrodesulfurization method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hybridized organic framework material and preparation method and application thereof

ActiveCN106622143AStrong thermal stabilityImprove removal efficiencyOther chemical processesHydrocarbon oils refiningSolventFuel oil

The invention discloses a hybridized organic framework material preparation method. The method comprises the following steps: 1) adding 1,4,5,8-naphthalene tetracarboxylic acid and a copper source in a solvent, uniformly mixing the materials, performing first ultrasonic treatment, when a precipitate is generated, adding a starch slouble aqueous solution, continuously performing secondary ultrasonic processing; and 2) filtering a mixture through secondary ultrasonic processing, placing a filtered solid in an acetone aqueous solution containing ammonium salt and stirring the materials, then filtering the material, washing the material with water and drying the material to obtain the hybridized organic framework material. The invention also provides the hybridized organic framework material prepared by the method and an application thereof. The hybridized organic framework material has strong thermostability and appropriate pore structure, has more active sites and good space symmetry, and is suitable for an adsorption desulphurization process for fuel oil such as gasoline and diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

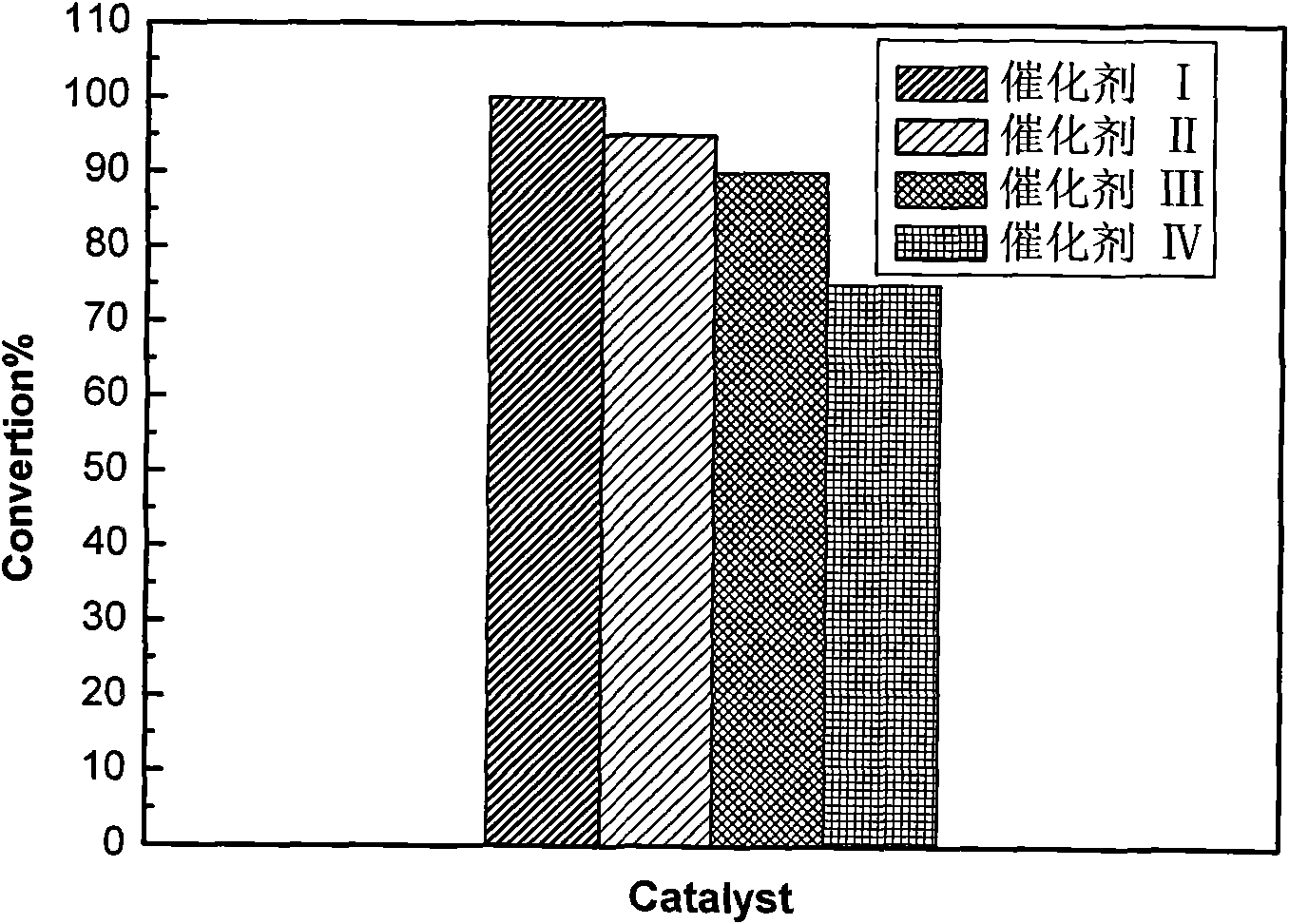

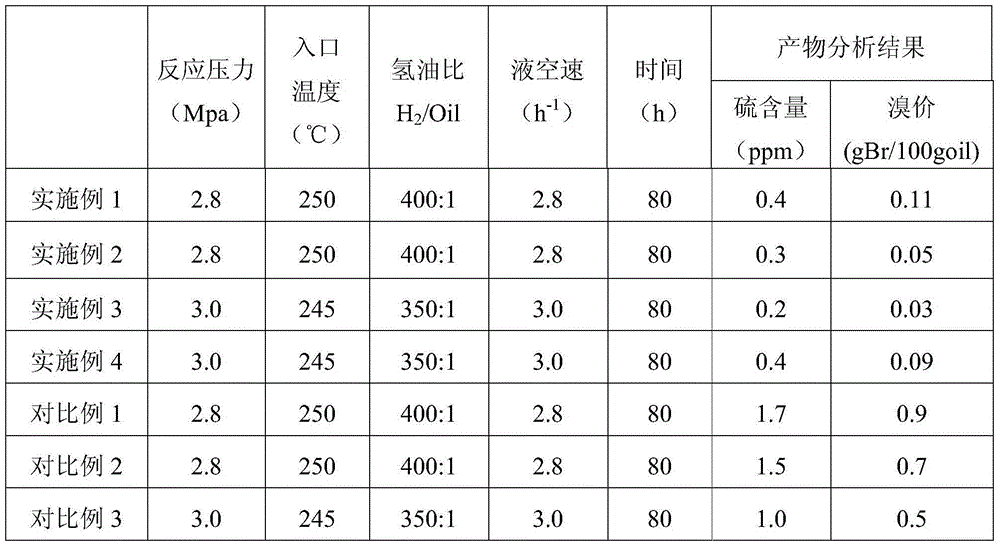

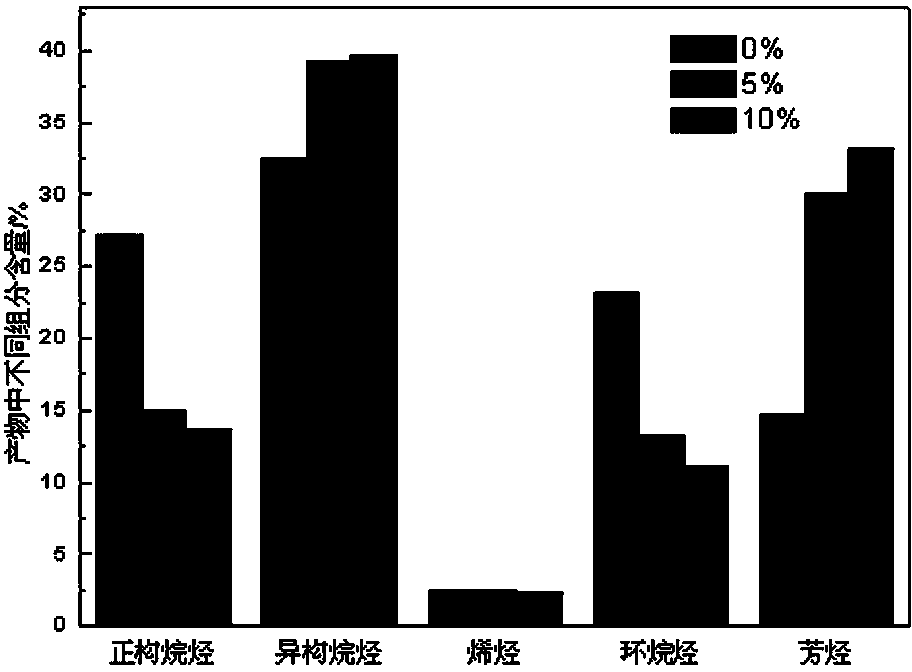

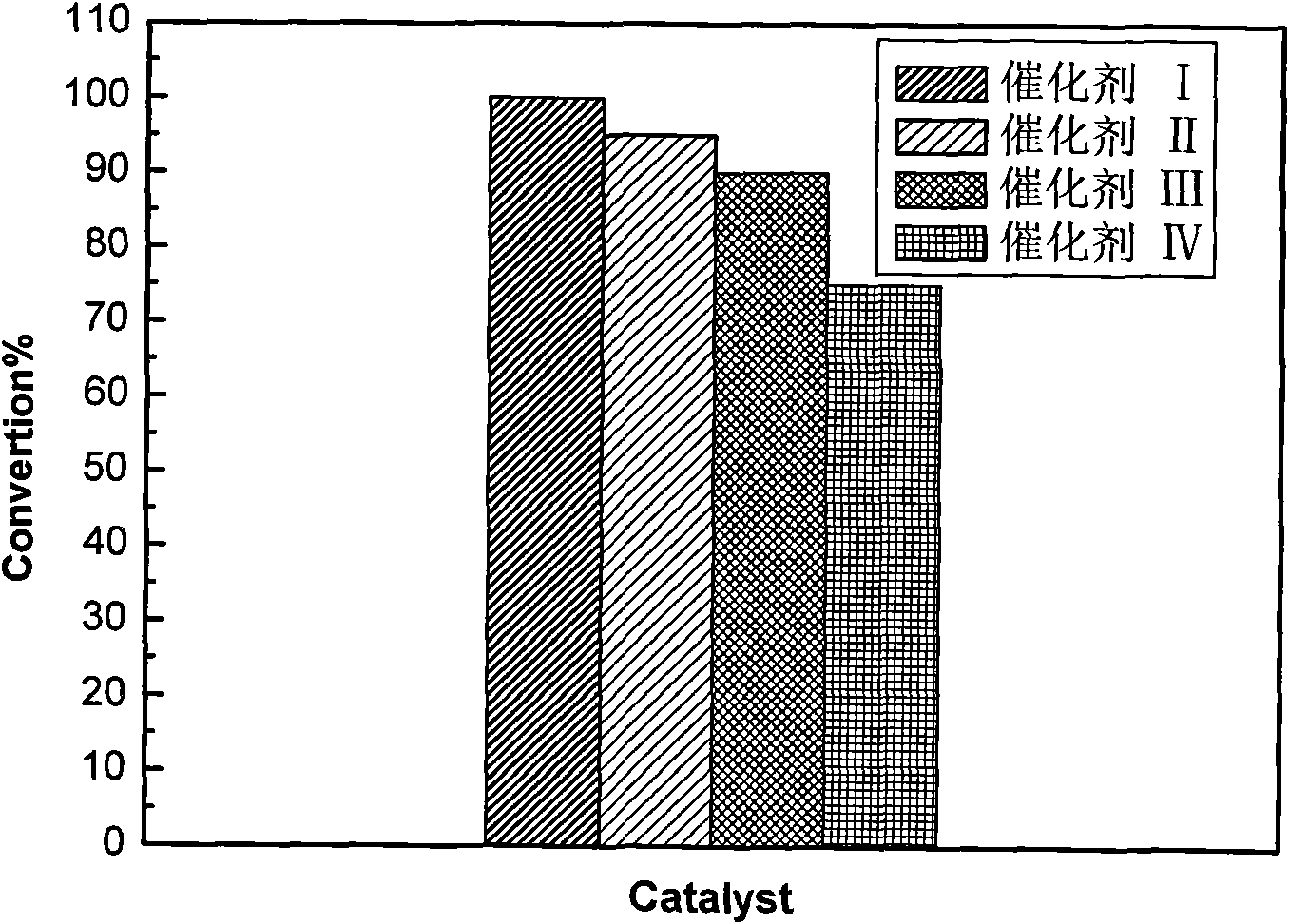

Preparation method and application method of non-noble metal reforming catalyst

ActiveCN103638968AGood reforming reaction performancePlay an acidic functionMolecular sieve catalystsNaphtha reformingPtru catalystAluminium hydroxide

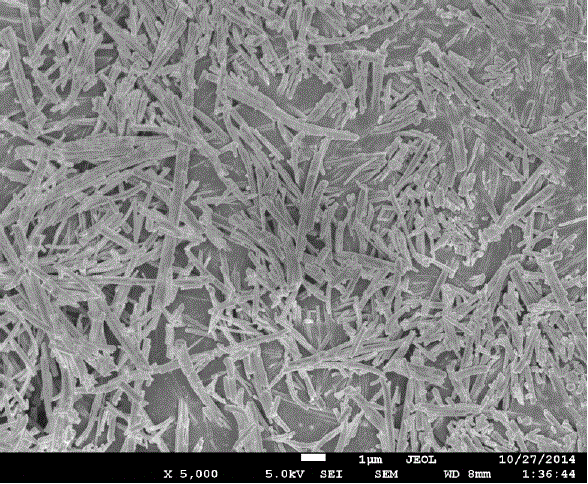

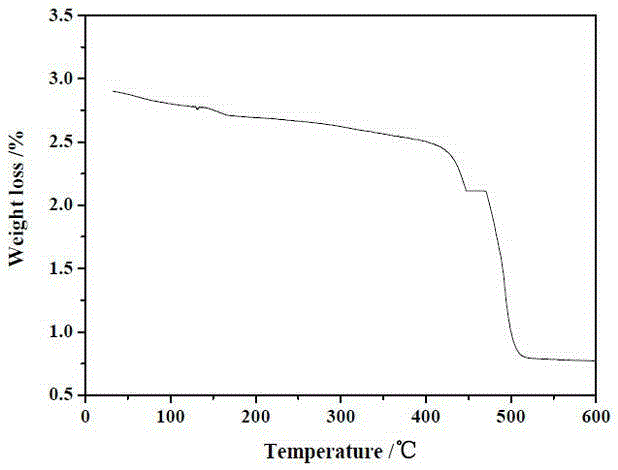

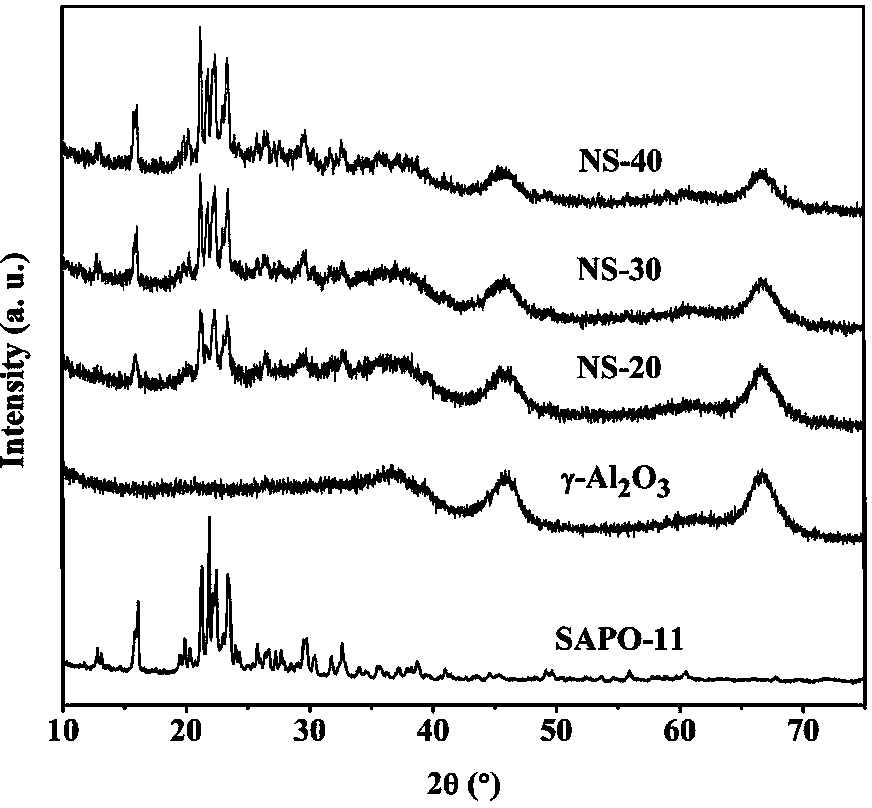

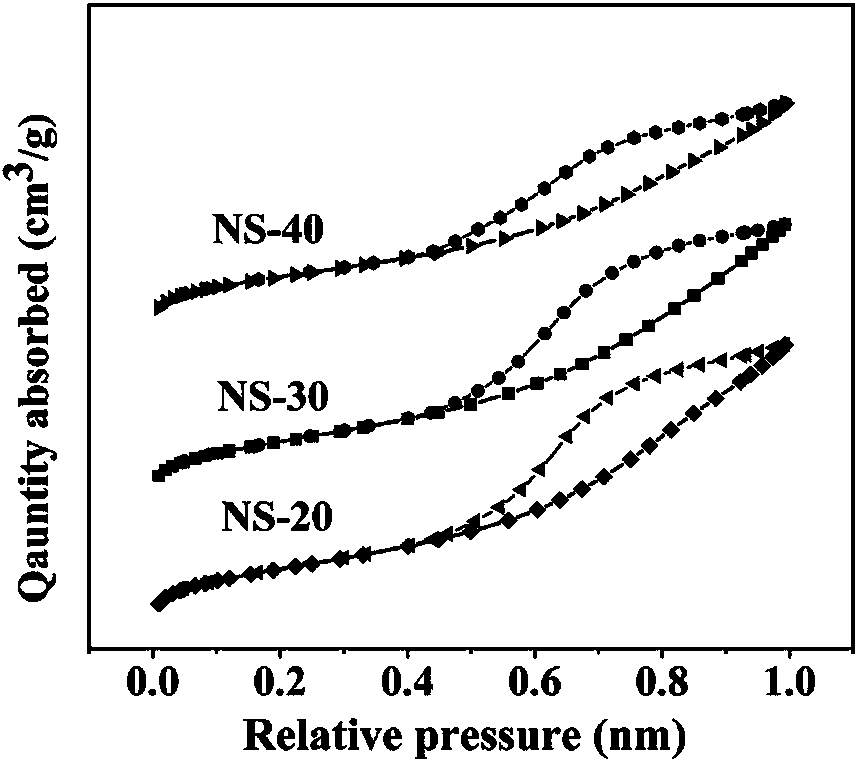

A preparation method and an application method of a non-noble metal reforming catalyst. The catalyst comprises a Ni2P active component and a composite carrier. The composite carrier comprises gama-Al2O3 and SAPO-11. The preparation method comprises the following steps: firstly, adding sesbania powder into raw materials of aluminium hydroxide dry gel powder, pseudo-boehmite and SAPO-11, then adding nitric acid aqueous solution, performing kneading, strip extrusion, air drying, drying and roasting to prepare a composite carrier of gama-Al2O3-SAPO-11; secondly, preparing a nickel hypophosphite impregnation liquid at 60-80 DEG C, controlling the molar ratio of phosphorus to nickel, impregnating the composite carrier by constant temperature supersaturation impregnation, performing air drying and vacuum drying to obtain a catalyst precursor; finally, putting the catalyst precursor in a tubular furnace, and roasting in N2 to prepare the Ni2P / gama-Al2O3-SAPO-11 catalyst. Compared with the prior art, the preparation method is simple in process, low in preparation temperature, and mild in reaction conditions; the prepared catalyst is high in dispersity, can be used in naphtha reforming reaction, has high aromatic hydrocarbon yield and activity stability, and is low in price.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

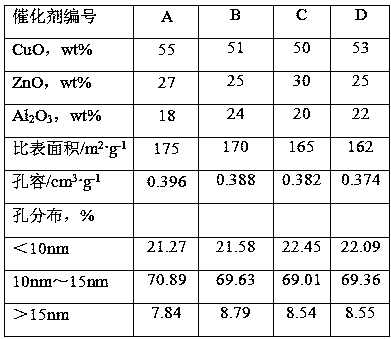

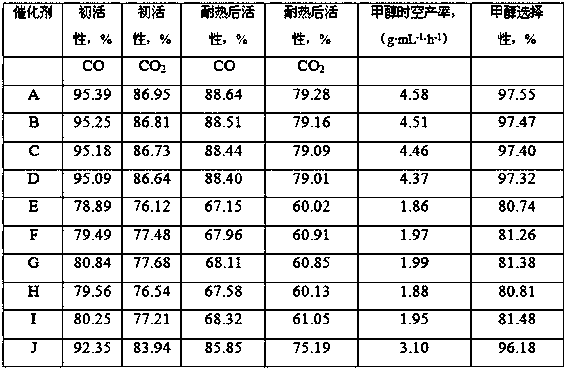

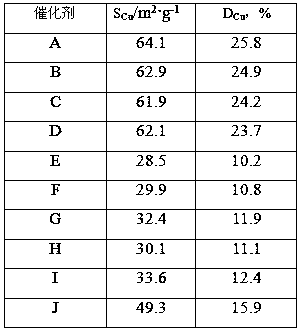

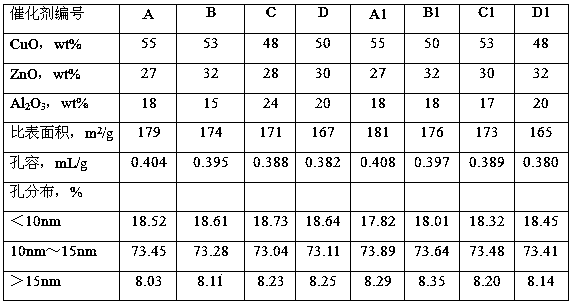

Preparation method of copper-containing catalyst

ActiveCN111686739AEvenly dispersedGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-containing catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallel flow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein a quaternary ammonium salt compound is added before the gelling reaction in the step (1), wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst has characteristics of uniform active metal copper distribution, good synergistic effect, large active metal active center number, catalyst activity improving, catalyst selectivity improving, catalyst thermal stability improving, and good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

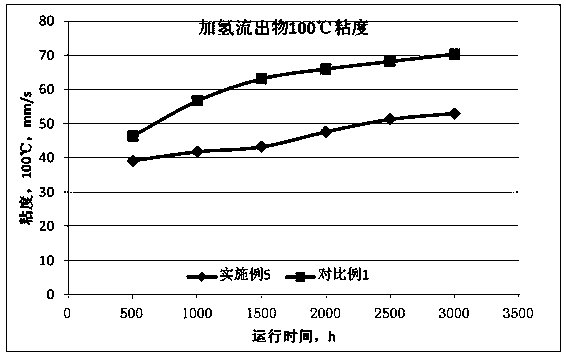

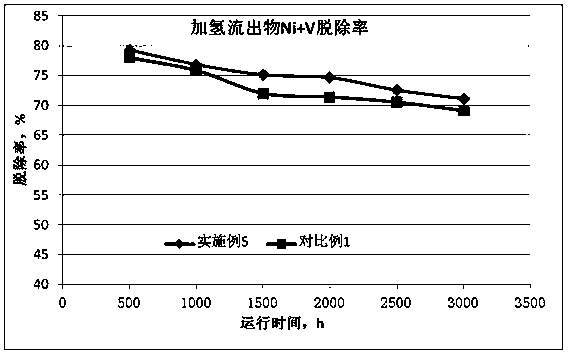

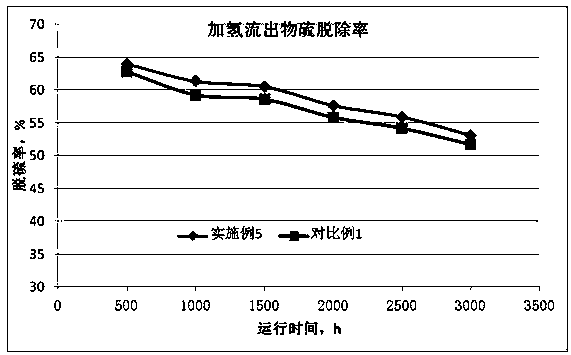

Method for removing metal impurities in residual oil through hydrogenation

ActiveCN111378471ARapid responseImprove responseTreatment with hydrotreatment processesRefining to eliminate hetero atomsPtru catalystMetal impurities

The invention discloses a method for removing metal impurities in residual oil through hydrogenation. According to the method, fed materials comprise a residual oil raw material, hydrogen and a material viscosity adjusting auxiliary agent, the material viscosity adjusting auxiliary agent comprises ethylene tar, and the fed materials are subjected to a hydrotreatment reaction in a hydrodemetallization reaction zone to obtain a hydrogenation effluent; the hydrodemetallization reaction zone is at least filled with a first hydrodemetallization catalyst, wherein the first hydrodemetallization catalyst comprises a carrier component and a hydrogenation active metal component, and the carrier component comprises carbon and alumina. According to the method disclosed by the invention, the ethylene tar is added into the residual oil raw material as a material viscosity adjusting aid, so that the system viscosity under the reaction condition can be effectively reduced, the hydrodemetallization ofthe residual oil is promoted, and the improvement of the reaction performances such as subsequent desulfurization, carbon residue removal and the like is facilitated through the synergistic effect ofall the components under the hydrodemetallization reaction condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

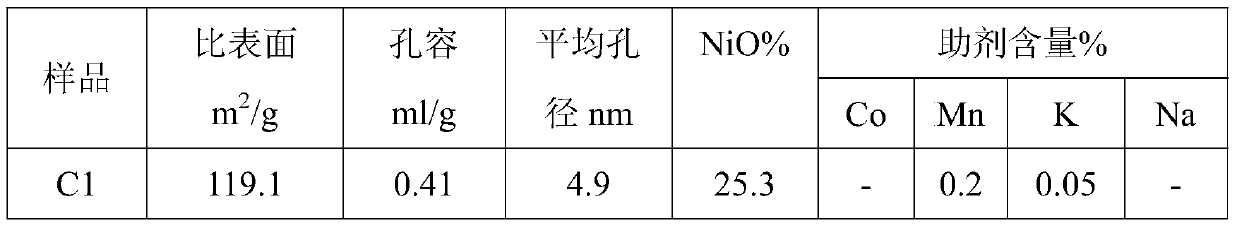

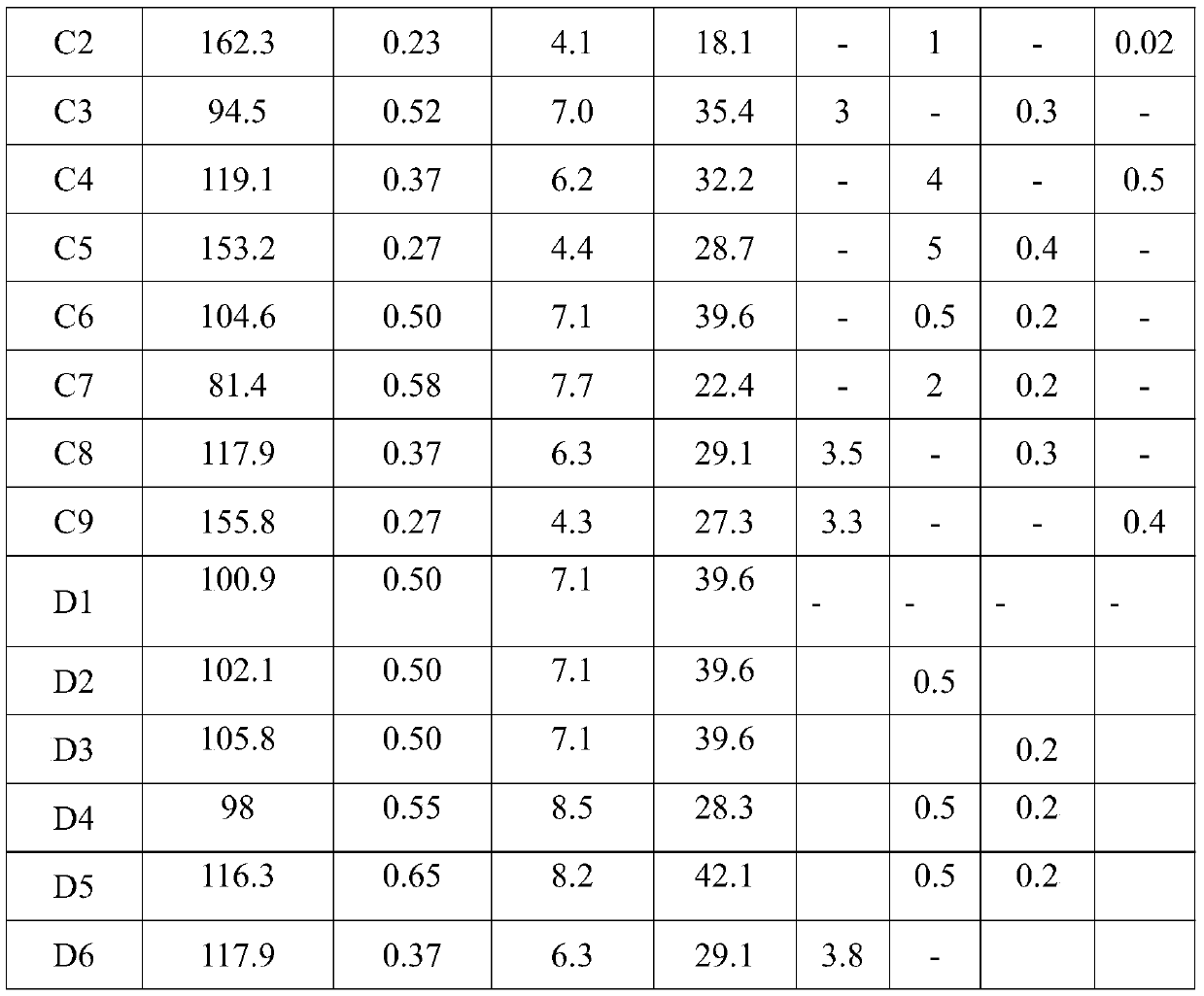

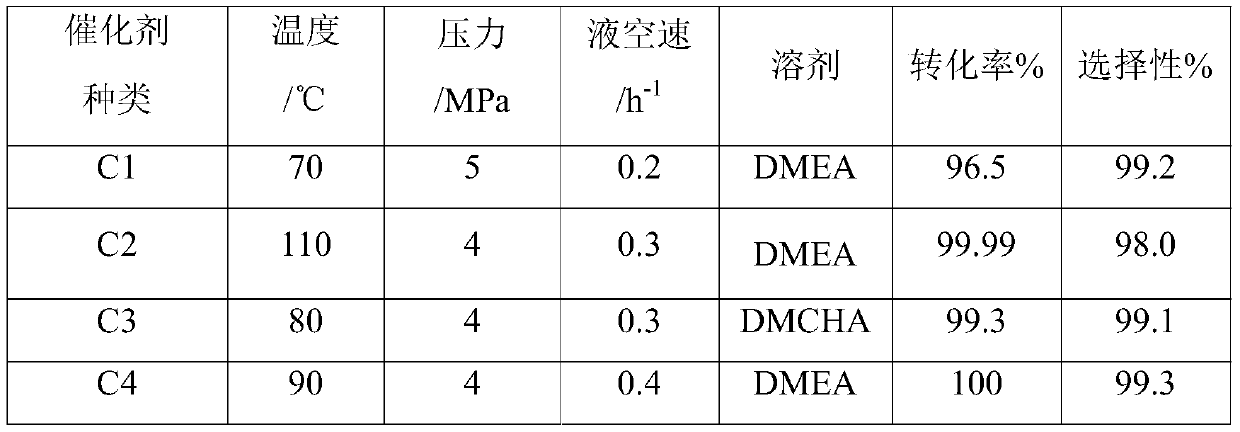

Catalyst for preparing meta-xylylenediamine and application of catalyst

ActiveCN110152642AControl acid-base centerHigh selectivityOrganic compound preparationCatalyst activation/preparationActive componentBiological activation

The invention discloses a catalyst for preparing meta-xylylenediamine and application of the catalyst, and belongs to the field of hydrogenation catalysts. Alumina or a mixture of magnesium and aluminum is adopted as a carrier, the active element is Ni, and the auxiliary agent 1 is one of Co and Mn; and the auxiliary agent 2 is one of Na and K, and preparation of the catalyst comprises the steps of preparation of the catalyst carrier, impregnation of the active component, impregnation of the auxiliary agents and activation of the catalyst. A preparation method has a simple process and low cost, and is suitable for industrial production, and the catalyst has suitable pores; through addition of the suitable additives, the reaction process conditions are optimized, and the catalyst has the characteristics of high activity, no easy clogging of the pores, a long service life and the like; and when the catalyst is applied to preparation of meta-xylylenediamine through hydrogenation of isophthalonitrile, the conversion rate of isophthalonitrile is 100%, and the selectivity to meta-xylylenediamine is 99% or above.

Owner:CHANGZHOU UNIV

Preparation method of nickel phosphide catalyst carried by composite carrier

InactiveCN101612584BLittle loss of activityHigh activityCatalyst activation/preparationRefining to eliminate hetero atomsNickel saltPhosphate

The invention relates to a preparation method of a nickel phosphide catalyst carried by a composite carrier. The method is characterized by comprising the following steps: firstly, using activated alumina and relative enzymes and alcohols as raw materials to prepare a composite carrier of TiO2-Al2O3 by adopting an improved sol-gel method; further, selecting suitable nickel salt and phosphate and carrying out ultrasound dipping and drying in microwaves to obtain a catalyst precursor; and finally, increasing a temperature by a program and reducing to obtain the composite support. The composite carrier of TiO2-Al2O3 prepared by the invention not only can effectively overcome the defect that nickel phosphide is apt to react with gamma-Al2O3 to generate AlP4 to lose the activity, but also overcomes the defect that a specific surface area of single TiO2 is relatively small, effectively exerts the strong metal-support interaction (SMSI) of the TiO2, thereby obtaining a hydrodesulfurization catalyst with remarkable activity efficacy.

Owner:XI AN JIAOTONG UNIV

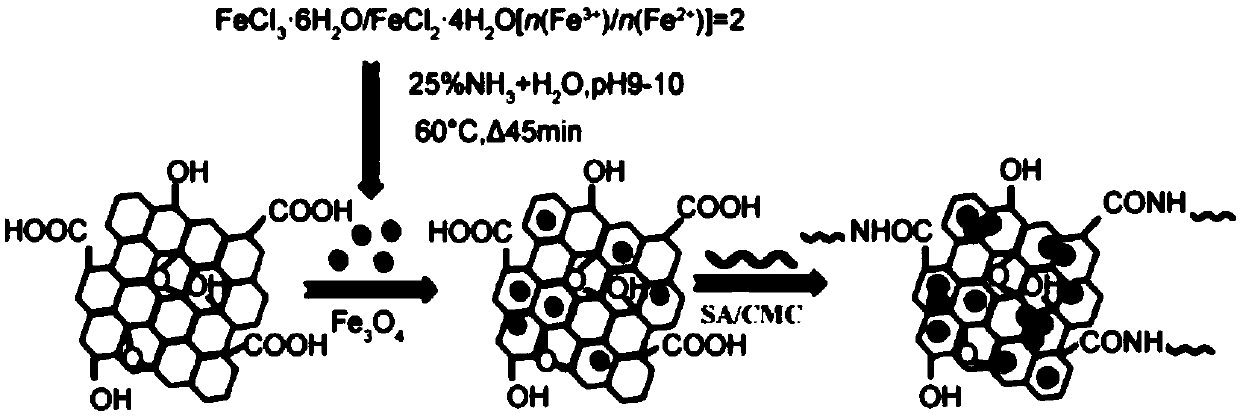

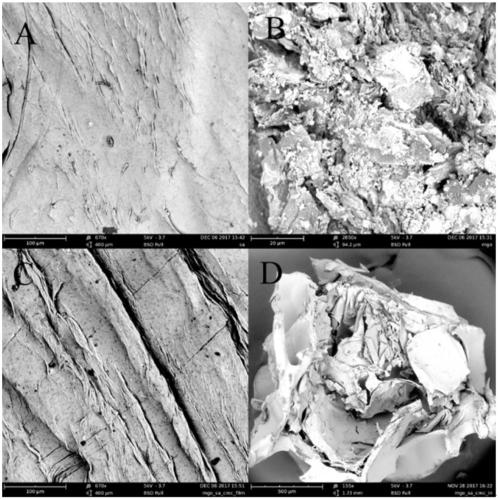

Magnetic graphene oxide/sodium alginate/sodium carboxymethyl cellulose composite material and preparation method thereof

InactiveCN111036176ALarge specific surface areaPore structure is suitableOther chemical processesWater contaminantsCarboxymethyl celluloseIon exchange

The invention discloses a magnetic graphene oxide / sodium alginate / carboxymethyl cellulose composite material and a preparation method thereof. The method comprises the following steps: preparing magnetic graphene oxide by adopting a chemical coprecipitation method, and preparing the magnetic graphene oxide / sodium carboxymethyl cellulose / sodium alginate composite material from the magnetic grapheneoxide, sodium carboxymethyl cellulose and sodium alginate by adopting an ion exchange method. The composite material provided by the invention contains rich active functional groups, can generate a relatively strong coordination effect with heavy metal ions, improves the adsorption performance of the composite material on the heavy metal ions, has the maximum adsorption capacity of 92.6 mg / g, andis suitable for heavy metal ion adsorption treatment.

Owner:NANJING UNIV OF SCI & TECH

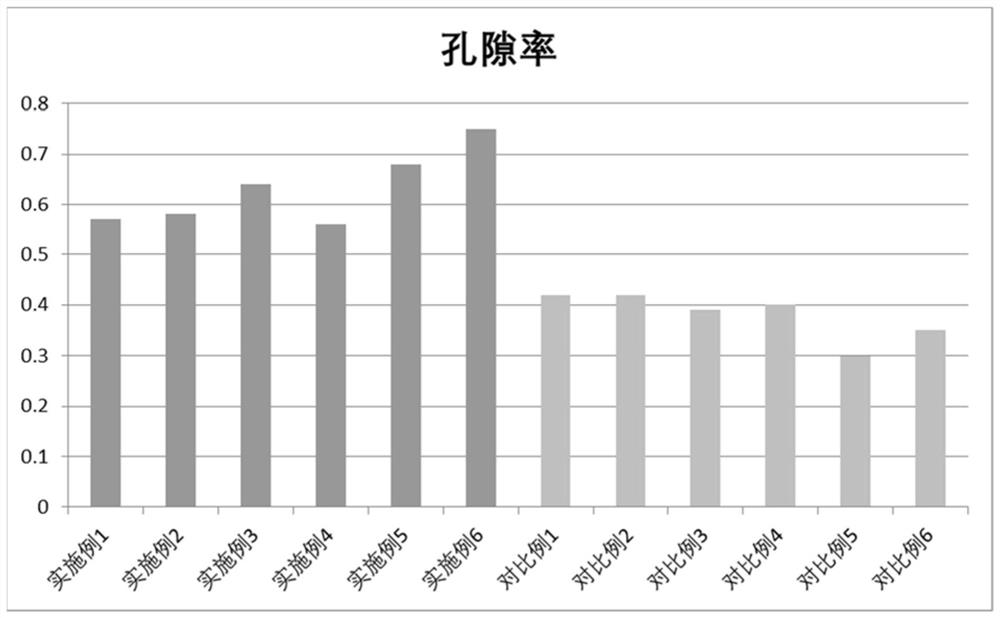

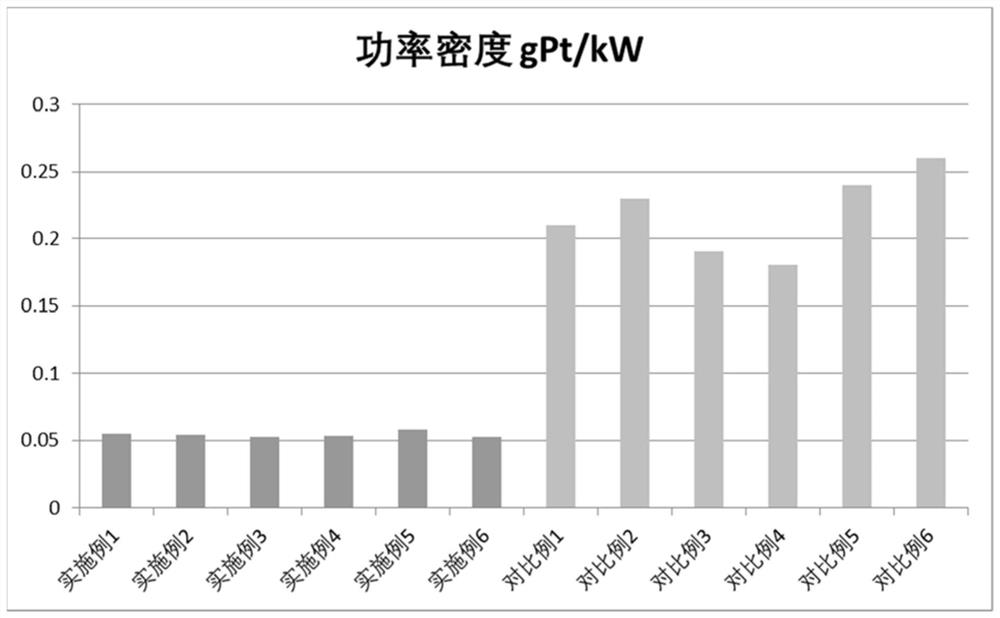

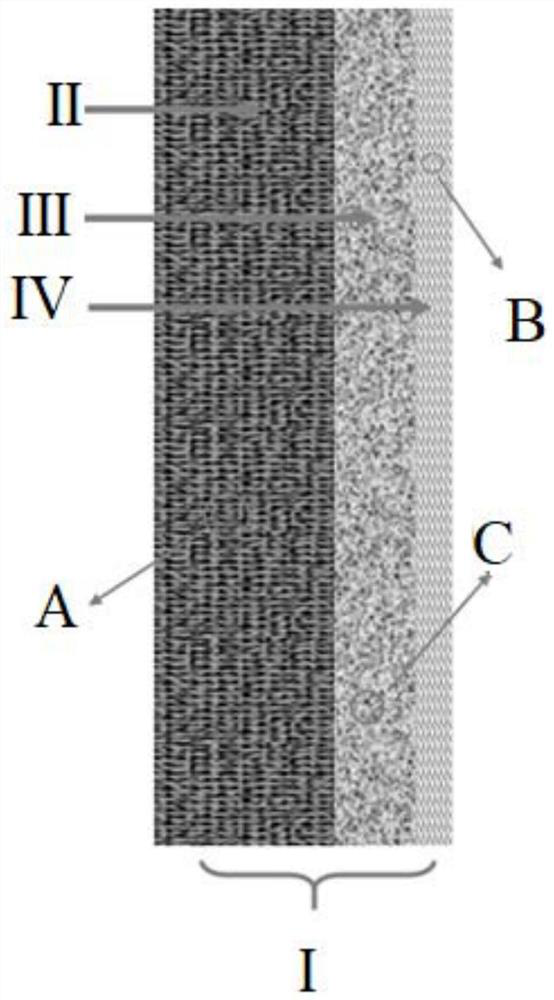

Membrane electrode for proton exchange membrane fuel cell and preparation method of membrane electrode

ActiveCN113270593AIncrease profitEnhanced mass transferCell electrodesFinal product manufacturePtru catalystPhysical chemistry

The invention relates to a membrane electrode for a proton exchange membrane fuel cell and a preparation method of the membrane electrode. The preparation method comprises the following steps: A, spinning catalyst slurry onto a microporous layer on the surface of hydrophobic carbon paper by adopting a variable-voltage electrostatic spinning process to obtain a gas diffusion catalyst layer integrated electrode; B, assembling according to the assembly sequence of the gas diffusion catalyst layer integrated electrode, the proton exchange membrane and the gas diffusion catalyst layer integrated electrode, and after assembly, preparing the membrane electrode for the proton exchange membrane fuel cell through a hot pressing or cold pressing process. The catalyst layer is directly spun on the gas diffusion layer by means of an electrostatic spinning technology, the thickness of the catalyst layer and the loading capacity of a catalyst are reduced, the dispersity of the catalyst is improved, and a fibrous structure obtained through spinning is good in uniformity and rich and moderate in pore structure; water transmission and air mass transfer in a high-current density area of the fuel cell are improved, and the cell performance is improved.

Owner:上海唐锋能源科技有限公司

Hydrodesulfurization catalyst, preparation method and application thereof

ActiveCN104437571AReduce load requirementsLow costPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrodesulfurizationLanthanide

The invention provides a hydrodesulfurization catalyst, which contains a modified titanium oxide-alumina carrier and nickel phosphide loaded on the carrier, the modified titanium oxide-alumina carrier comprises a lanthanide metal component and a VIII metal component, and the catalyst has low temperature hydrogenation activity and good stability for being used in the hydrodesulfurization technology for cracking gasoline C5-C10 distillate oil. The invention also provides a preparation method of the catalyst and the hydrodesulfurization method for the C5-C10 distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for synthesizing isopropyl trifluoroacetate by esterification and preparation method thereof

ActiveCN103611569AHigh specific surface areaImprove adsorption performanceOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonHydrogen fluoride

The invention provides a catalyst for synthesizing isopropyl trifluoroacetate by esterification. The preparation method comprises the following steps: carrying out high-temperature roasting on a support resin-base spherical activated carbon with high specific area and micropore structure, activating with hydrogen fluoride to obtain a support with high specific area and mesopore structure, loading neodymium trifluoroacetate on the support by a liquid-phase sedimentation process, and meanwhile, modifying with a complexing agent. The catalyst has the advantages of very high specific area and proper pore structure, thus, has excellent adsorbability, and finally has favorable property for catalyzing the synthesis of isopropyl trifluoroacetate. The invention also provides a preparation method of the catalyst.

Owner:NANTONG FINC PHARMA CHEM

Method for preparing hydrofining catalyst

ActiveCN110038584APore structure is suitableOptimized areaHeterogenous catalyst chemical elementsCatalyst activation/preparationOrganic acidNitrogen

The invention discloses a method for preparing a hydrofining catalyst. According to the hydrofining catalyst, firstly, a mixed solution A containing Ni and W and a sodium metaaluminate alkaline solution react in a parallel flow manner, obtained slurry is aged, then, a mixed solution B containing W, Mo and Al components and ammonia water are added to the aged slurry in a parallel flow manner, agingis performed, then, first drying, forming and second drying are performed, treatment is performed with a mixed aqueous solution of aluminum salt and organic acid, washing, third drying, calcination and other steps are performed, and the hydrofining catalyst is prepared. The catalyst can be applied to super deep hydrodesulfurization and hydrodenitrification reactions of diesel fractions, has higher hydrodesulfurization and hydrodenitrification reaction activity and is particularly applied to tretament of diesel materials with high nitrogen and sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing basalt fiber reinforced foam glass

The invention relates to a method for preparing basalt fiber reinforced foam glass. The method includes the following steps that firstly, glass powder and fly ash pass a 200-mesh screen for use; secondly, 70-80 parts by mass of glass powder obtained in the first step, 20-30 parts by mass of fly ash obtained in the first step, 0.151-0.757 part by mass of basalt fiber, 2-6 parts by mass of sodium carbonate, 2 parts by mass of trisodium phosphate, 2 parts by mass of borax and 30-35 parts by mass of water are weighed and evenly mixed to prepare a mixed material; thirdly, the mixed material obtained in the second step is placed in a high-temperature-resistant mould and then vibrated for 5-10 min on a vibrating table; fourthly, the vibrated mould is placed in an oven and dried for 0.5-2 h at 100 DEG C to obtain a blank; fifthly, the blank obtained in the fourth step is fired at 840-850 DEG C, and the basalt fiber reinforced foam glass is obtained.

Owner:SHIHEZI UNIVERSITY

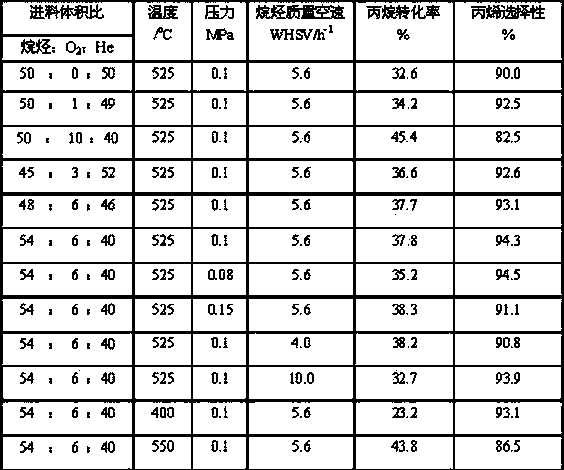

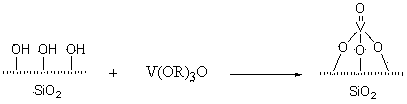

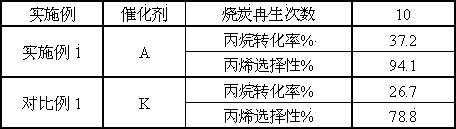

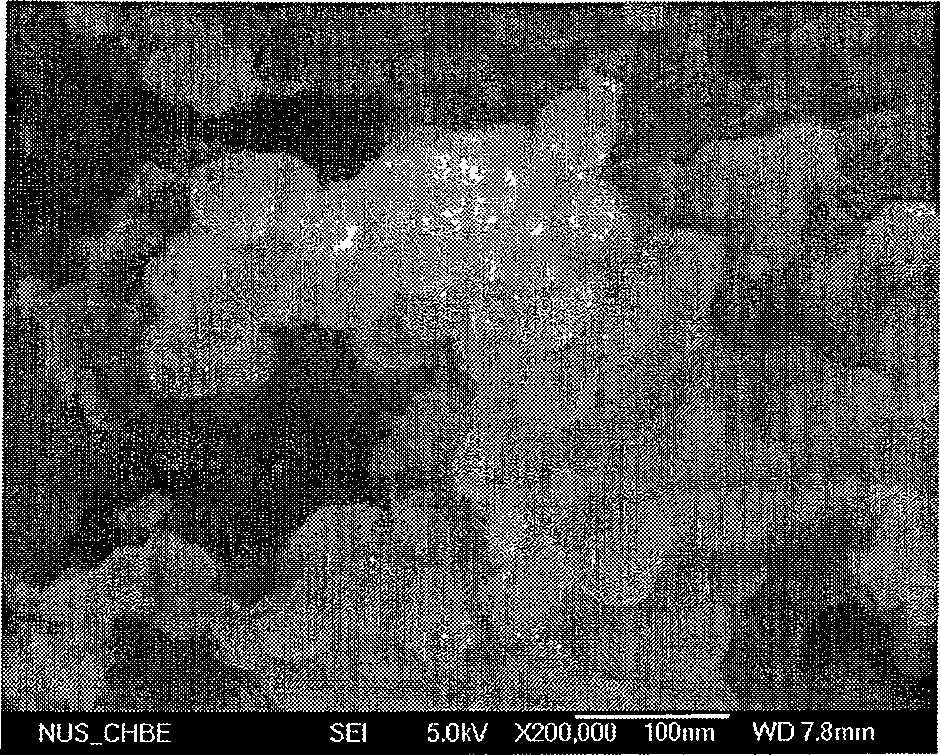

Vanadium-based catalyst for light alkane dehydrogenation to produce alkene and preparation method and process thereof

ActiveCN104230624AImprove carrying capacityReduce usageMolecular sieve catalystsHydrocarbonsAlkaneActive component

The invention relates to a method for preparing alkene from light alkane dehydrogenation, and mainly solves the problems of low dispersion, easy aggregation crystallization of active components, low selectivity under high temperature and poor one-way stability in the existing vanadium-based catalyst under high loading. The invention provides a vanadium-based catalyst for light alkane dehydrogenation to produce alkene and a preparation method thereof. The catalyst uses a silicon-based material as a carrier, vanadium or its oxide as the active component, and uses a synthetic method for preparation. Under the condition of low O2 concentration, a combined oxidative dehydrogenation and direct dehydrogenation method s used for catalysis of alkane preparation from alkane dehydrogenation; and finally the catalyst is subjected to charking for regeneration. The technical scheme well solves the above problems, and can be used for in the industrial production of alkene preparation from light alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas diffusion layer for fuel cell and its production

InactiveCN100521328CGuaranteed hydrophobicityAchieve hydrophobicityCell electrodesFinal product manufactureElectricityFuel cells

The invention relates to a fuel battery, in particular to a gas diffusing layer and the preparation for the fuel battery; the gas diffusing layer consists of basic bottom layer and a micro-hole layer, which is made by fabricating the micro-hole constructed by a water repellent agent / a composite powder body of electric conduction copper material at one side or two sides of a porous electric conduction basic bottom processed by a hydrophobic water; the water repellent agent / the composite powder body of electric conduction copper material is made by a microwave dielectric heating technology; because of the favorable water repellent performance and the grain diameter structure therefore, the gas diffusing layer to be fabricated has a strong and even water repellent performance and a suitable hole structure, so that the favorable mass transfer capability of the gas diffusing layer can be assured. The fuel battery assembled by the invention can show a better battery output performance, and is particularly suitable to be used in the fuel battery where the air is used as oxidizer with a strong practicality value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

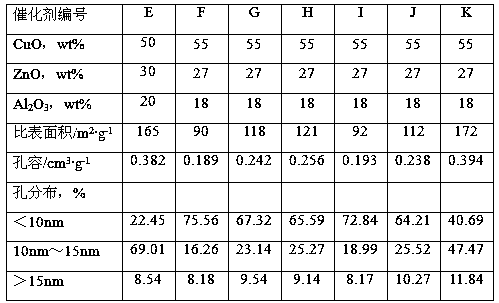

Preparation method of methanol synthesis catalyst

ActiveCN110935456AGood dispersionOptimized areaOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a methanol synthesis catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt and a soluble zinc salt, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper and auxiliary agent zinc, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368BUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltAccelerant

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity morethan or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

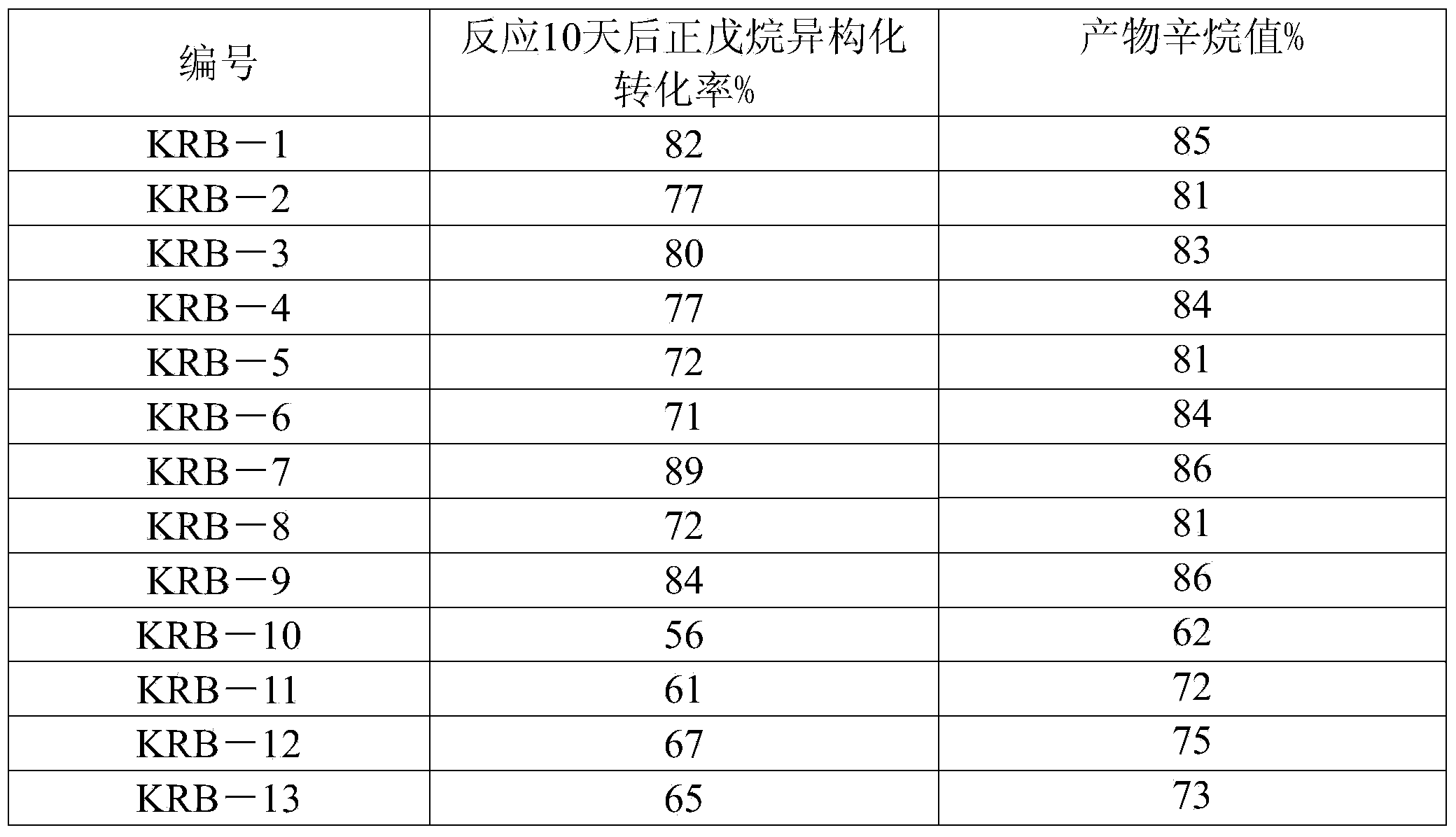

Light-hydrocarbon isomerization catalyst and method for preparing same

InactiveCN103464210AExcellent isomerization performanceLarge specific surface areaHydrocarbon by isomerisationCatalyst carriersHydrogen fluoridePolymer science

The invention discloses light-hydrocarbon isomerization catalyst and a method for preparing the light-hydrocarbon isomerization catalyst. Resin ribbon ball-shaped active carbon having high specific surface area and a micro-hole structure serves as the carrier, is roasted under high temperature and is activated through hydrogen fluoride to obtain a carrier with high specific surface area and a mesoporous structure, palladium loading is then carried out according to a liquid phase deposition method, and modifying is carried out through fluorine-containing chlorides at the same time to obtain the light-hydrocarbon isomerization catalyst. The light-hydrocarbon isomerization catalyst has extremely large specific surface area and a proper hole structure, and has good isomerization performance after modifying is carried out through the fluorine-containing chlorides. High activity of the light-hydrocarbon isomerization catalyst can still be kept after long-period operation and the light-hydrocarbon isomerization catalyst is long in service life.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Preparation method of copper-zinc catalyst

ActiveCN110935457AHigh activityGood synergyOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-zinc catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

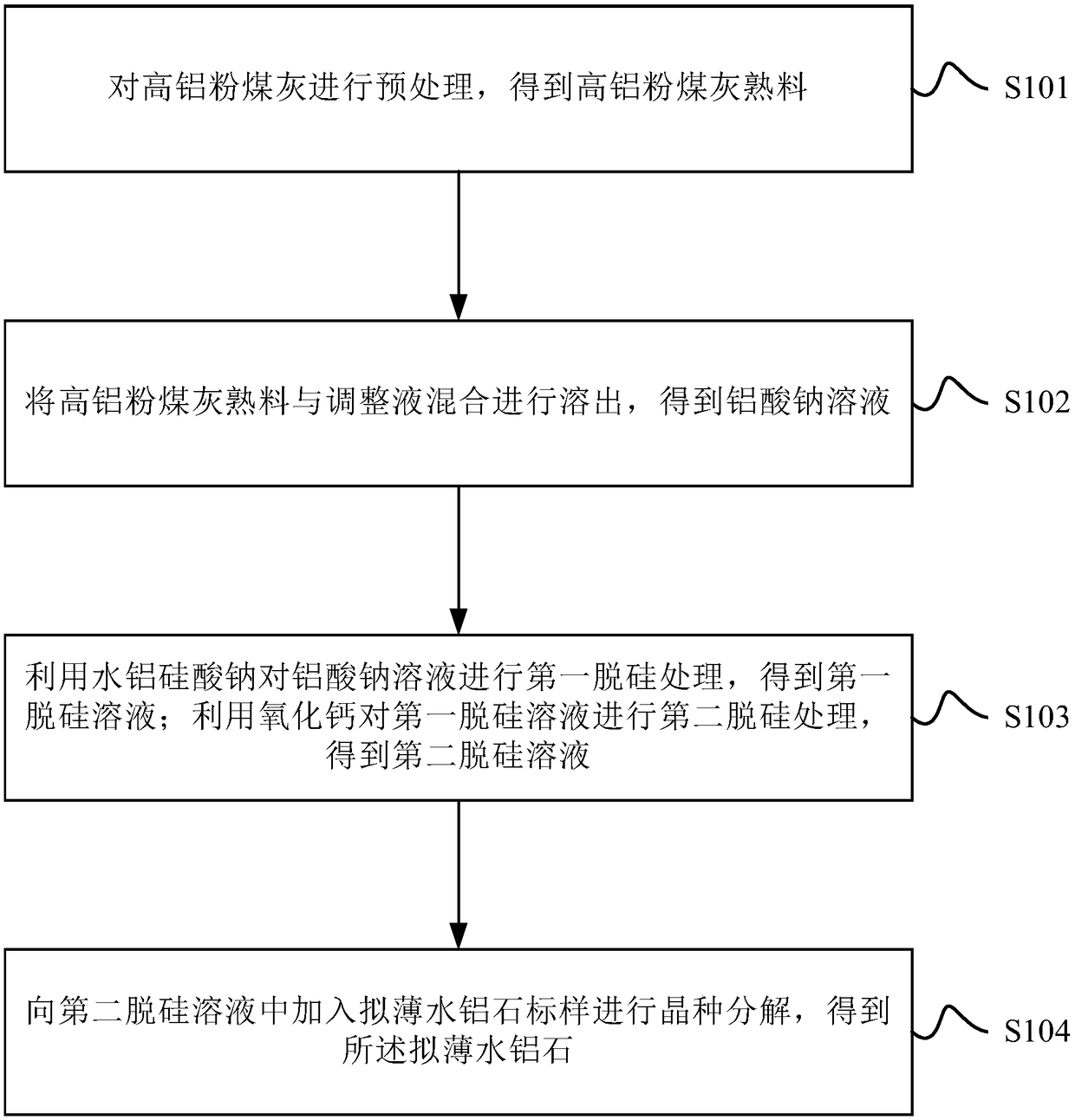

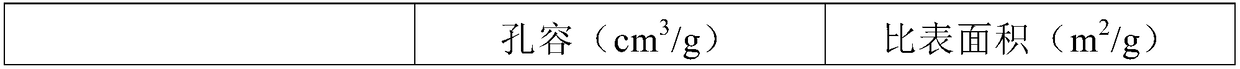

Method for preparing pseudo-boehmite by using high-alumina fly ash

InactiveCN108793212AReduce pollutionImprove economyAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateAdditional values

The invention provides a method for preparing pseudo-boehmite by using high-alumina fly ash. The method comprises the following steps: 1) pretreating the high-alumina fly ash to obtain a high-aluminafly ash clinker; 2) mixing the high-alumina fly ash clinker and a correction liquor, dissolving out to obtain a sodium aluminate solution; 3) using hydro-sodium aluminosilicate to desilicicate the sodium aluminate solution for the first time, obtaining a first desilicication solution; using calcium oxide to desilicicate the first desilicication solution for the second time, obtaining a second desilicication solution; 4) adding a pseudo-boehmite standard sample into the second desilicication solution to precipitate a seed crystal, and obtaining the pseudo-boehmite. The invention provides a novel technical method for preparing the pseudo-boehmite with high additional value by using the high-alumina fly ash, and the environment pollution pressure brought about by the fly ash is alleviated while the utilization level of the fly ash is improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com