Preparation method and application method of non-noble metal reforming catalyst

A reforming catalyst, non-precious metal technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high price and poor adaptability of reforming raw materials, and achieve simple methods, low cracking and disproportionation. Activity, the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

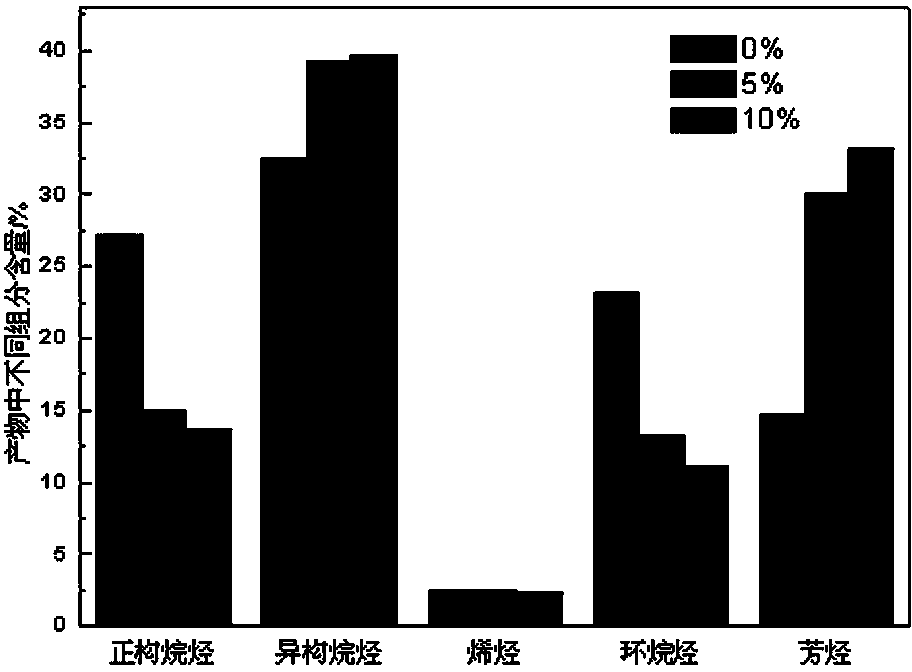

Examples

Embodiment 1

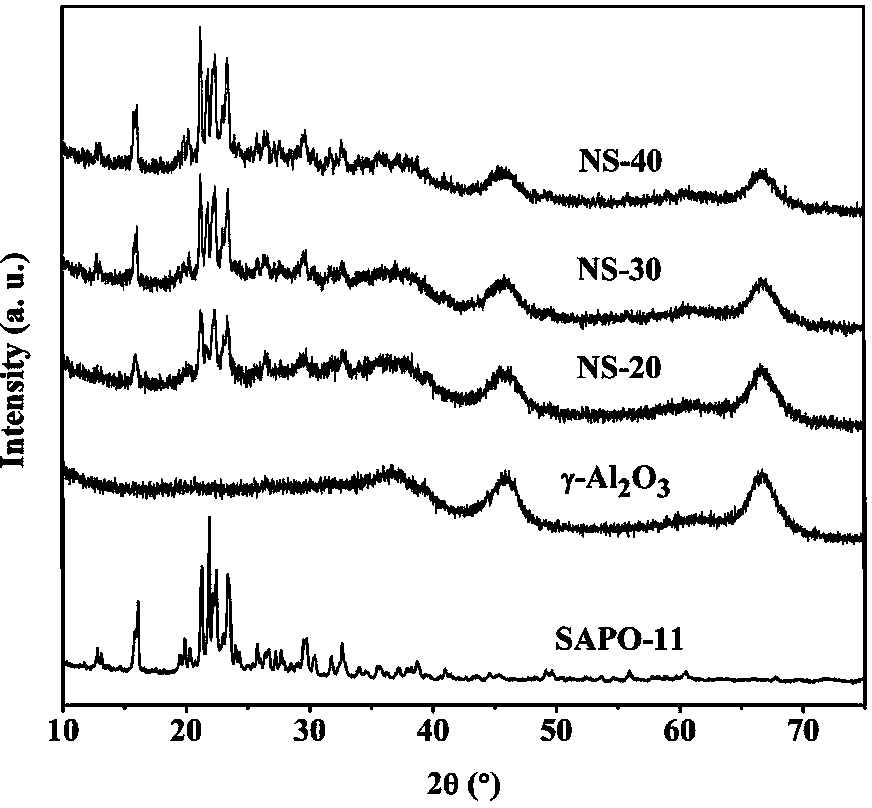

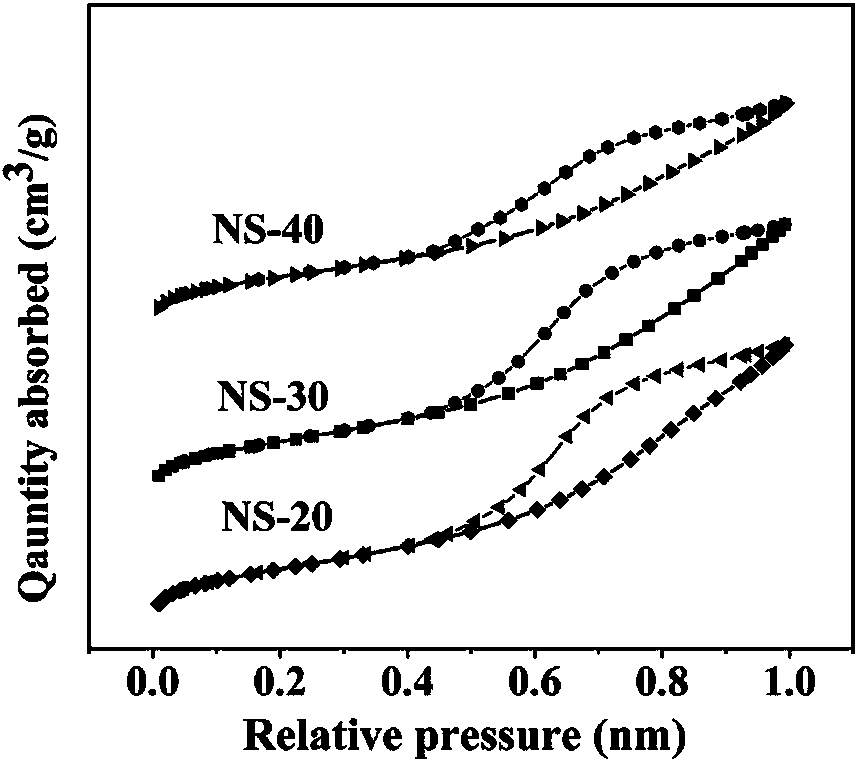

[0028] Ni 2 P / γ-Al 2 o 3 -The preparation method of SAPO-11 catalyst, comprises following process:

[0029] (1) Preparation of composite carrier. Use 49.0g of aluminum hydroxide dry rubber powder, 21.0g of SB powder and 30.0g of SAPO-11, add 2.0g of kale powder and mix evenly, then add 80.5g of deionized water and 4.5g of concentrated nitric acid (65-68m%) After kneading about three times, extrude on the F-26(Ⅲ) twin-screw extruder, the finished product is air-dried, dried at 120°C for 6-12h after molding, and calcined at 550°C for 4h to obtain the composite carrier. (SAPO / γ-Al 2 o 3 =3 / 7, mass ratio), the composite carrier is counted as NS-30.

[0030] (2) Preparation of catalyst precursor. Immerse 22.2g of nickel hypophosphite hexahydrate into 22.5g of deionized water at 60~80°C, carry out constant temperature supersaturated impregnation for 1h, then suction filter, wash with deionized water three times, and dry at 60°C for 24h in vacuum to obtain the catalyst prec...

Embodiment 2

[0033] The preparation process of the catalyst is the same as in Example 1, except that the mass content of the prepared catalyst carrier SAPO-11 molecular sieve is 20%, and the composite carrier is counted as NS-20.

Embodiment 3

[0035] The preparation process of the catalyst is the same as in Example 1, except that the mass content of the prepared catalyst carrier SAPO-11 molecular sieve is 40%, and the composite carrier is NS-40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com