Naphtha reforming catalyst and method for preparing same

A technology for reforming catalysts and naphtha, applied in chemical instruments and methods, physical/chemical process catalysts, catalytic cracking, etc., can solve problems such as difficulties, poor mechanical strength of shaped carriers, and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of catalyst provided by the invention comprises the steps:

[0028] (1) Dissolve aluminum alkoxide in alcohol solvent, add organotitanium compound and dispersant, mix well, add water, stir to obtain a colloidal solution, filter the colloidal solution, wash the filter cake with water until the lotion is neutral, TiO after drying 2 -Al 2 o 3 composite oxide,

[0029] (2) Dry and roast the composite oxide obtained in step (1) to obtain TiO 2 -Al 2 o 3 Composite carrier,

[0030] (3) The catalyst active component is introduced into the composite carrier by impregnation method, then dried and calcined.

[0031] Above-mentioned method (1) step is TiO 2 -Al 2 o 3 The preparation of composite oxides uses aluminum alkoxide and organic titanium compound as raw materials, the aluminum alkoxide is preferably aluminum triisopropoxide, the organic titanium compound is preferably titanium alkoxide, titanium hydroxydilactate , isopropyl triisostearyl t...

example 1

[0050] Preparation of strip-shaped TiO by the method of the present invention 2 -Al 2 o 3 Composite carrier

[0051] Add 100 mL of isopropanol to 100 g (0.49 mol) of aluminum triisopropoxide, heat to 80° C. and reflux for 6 hours to completely dissolve the aluminum triisopropoxide. The solution was cooled to 25°C for 12 hours. Add 5 grams (0.018 mol) of titanium tetraisopropoxide and 5 grams (0.026 mol) of citric acid into the above solution, mix well and stir evenly. Add 150 mL of deionized water to the above solution, and vigorously stir at 25 °C to obtain a colloidal solution. The colloidal solution was filtered to remove water, and the obtained colloidal substance was washed with water until the washing solution was neutral. The jelly obtained after washing with water was dried under reduced pressure at 40°C for 12 hours, and dried at 120°C for 12 hours to obtain TiO 2 -Al 2 o 3 Powder. Will get TiO 2 -Al 2 o 3 The powder is kneaded evenly according to the mass...

example 2

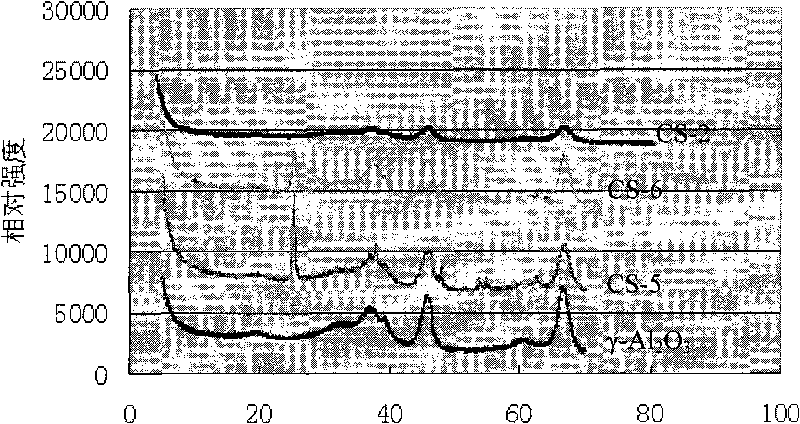

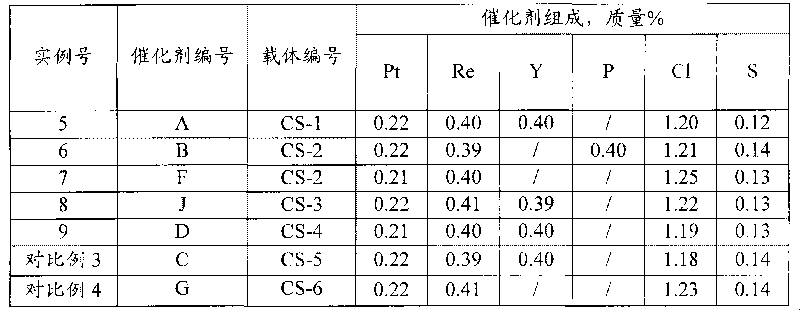

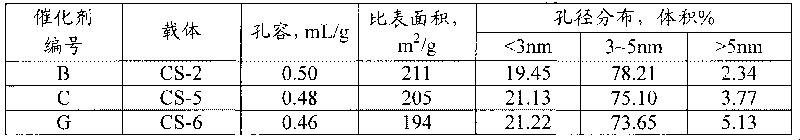

[0053] Add 20 mL of absolute ethanol to 100 g (0.49 mol) of aluminum triisopropoxide, heat to 70° C. and reflux for 6 hours to completely dissolve the aluminum triisopropoxide. The solution was cooled to 25°C for 12 hours. Add 10 grams (0.029 mol) of tetra-n-butoxytitanium, 2 mL (0.035 mol) of acetic acid and 1 gram (0.005 mol) of dodecylamine into the above solution, mix well and stir evenly. Add 50 mL of deionized water to the above solution and stir vigorously at 40 °C to obtain a colloidal solution. This colloidal solution is filtered, washed with water until the washing liquid is neutral, then dried according to the method of Example 1 and extruded into strips, dried and roasted to obtain strip-shaped TiO 2 -Al 2 o 3 Carrier CS-2, its TiO 2 The content is 10% by mass, the physical properties are shown in Table 2, and the XRD spectrum is shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com