Vanadium-based catalyst for light alkane dehydrogenation to produce alkene and preparation method and process thereof

A technology for producing low-carbon alkanes and olefins, which is applied in the direction of hydrocarbons, hydrocarbons, molecular sieve catalysts, etc., can solve the problems of easy aggregation and crystallization of active components, low dispersion of metal vanadium, poor single-pass stability, etc., to avoid precious metals. The use of high specific surface area, the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

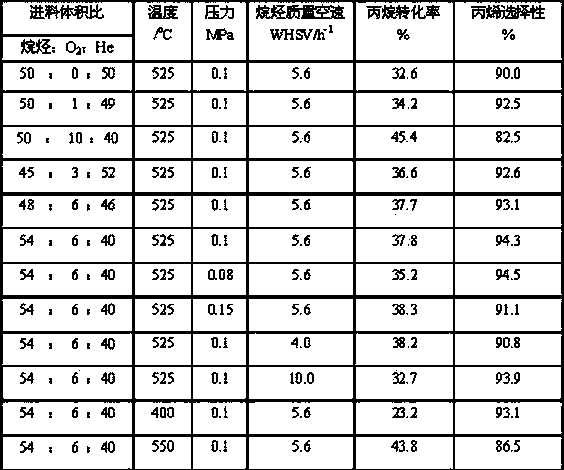

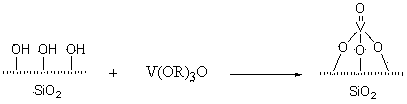

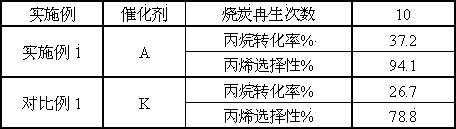

[0031] 40g V 2 o 5 and 400mL of tert-butanol were added to 1.2L of toluene, at 110 o Reaction under C for 24h, the water produced in the reaction process is separated out with a water trap, along with V 2 o 5 Dissolution, the solution turns from light yellow to red, after the reaction is completed, the unreacted V 2 o 5 Remove by filtration, then distill off toluene and tert-butanol under reduced pressure to obtain V(OC(CH 3 ) 3 ) 3 O white crystals, the product was again at 100 o C for 12 hours under vacuum. Under the protection of Ar, 12.45g of the prepared V(OC(CH 3 ) 3 ) 3 O and 95g of pure silicon molecular sieve MCM-41 were added to 300mL of toluene, left to stand at room temperature for 12 hours, then the toluene was distilled off under reduced pressure, and then at 120 o C for 2 hours, and finally at 600 o Calcined at C for 5 hours to obtain the corresponding supported vanadium-based catalyst, the active component VO 4 3- 5% of the weight of the catal...

Embodiment 2

[0034] 40g V 2 o 5 and 400mL tert-butanol were added to 1.2L toluene, at 60 o Reaction under C for 48h, the water produced in the reaction process is separated out with a water trap, along with V 2 o 5 Dissolution, the solution turns from light yellow to red, after the reaction is completed, the unreacted V 2 o 5 Remove by filtration, then distill off toluene and tert-butanol under reduced pressure to obtain V(OC(CH 3 ) 3 ) 3 O white crystals, the product was again at 90 o C for 24 hours under vacuum. in N 2 Under protection, 2.49g of prepared V(OC(CH 3 ) 3 ) 3 O and 99g pure silicon molecular sieve MCM-41 are added in 300mL toluene, at 10 o C under standing for 24 hours, then the toluene was distilled off under reduced pressure, and then at 90 o C for 24 hours, and finally at 500 o Roasting at C for 24 hours, the corresponding supported vanadium-based catalyst, the active component VO 4 3- 1% of the weight of the catalyst. Before the prepared catalyst ca...

Embodiment 3

[0037] 40g V 2 o 5 and 400mL tert-butanol were added to 1.2L benzene, at 80 o C under reaction 10h, the water produced in the reaction process is separated out with a water trap, and the unreacted V 2 o 5 Remove by filtration, then distill off the solvent and tert-butanol under reduced pressure to obtain V(OC(CH 3 ) 3 ) 3 O white crystals, the product was again at 150 o C for 1 hour in vacuo. Under the protection of Ar, 24.90 g of the prepared V(OC(CH 3 ) 3 ) 3 O and 90g pure silicon molecular sieve MCM-41 are added in 300mL benzene, at 60 o C for 1 hour, then distilled benzene under reduced pressure, and then at 150 o C for 1 hour, and finally at 650 o Calcined at C for 1 hour to obtain the corresponding supported vanadium-based catalyst, the active component VO 4 3- 10% of the weight of the catalyst. Before the prepared catalyst catalyzes the dehydrogenation reaction, the catalyst is heated in air at 600 o C for 1 hour to obtain catalyst C.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com