Preparation method of nickel phosphide catalyst carried by composite carrier

A composite carrier, nickel phosphide technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the active anatase type is not stable enough, difficult to be widely used, mechanical strength To achieve the effect of good mechanical strength and thermal stability, suitable pore structure, and improved dispersion effect

Inactive Publication Date: 2010-11-10

XI AN JIAOTONG UNIV

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, TiO2 also has some weaknesses as a catalyst carrier. For example, its specific surface area is relatively small, generally not more than 100m2 g-1. Weak acidity makes it difficult to be widely used in industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

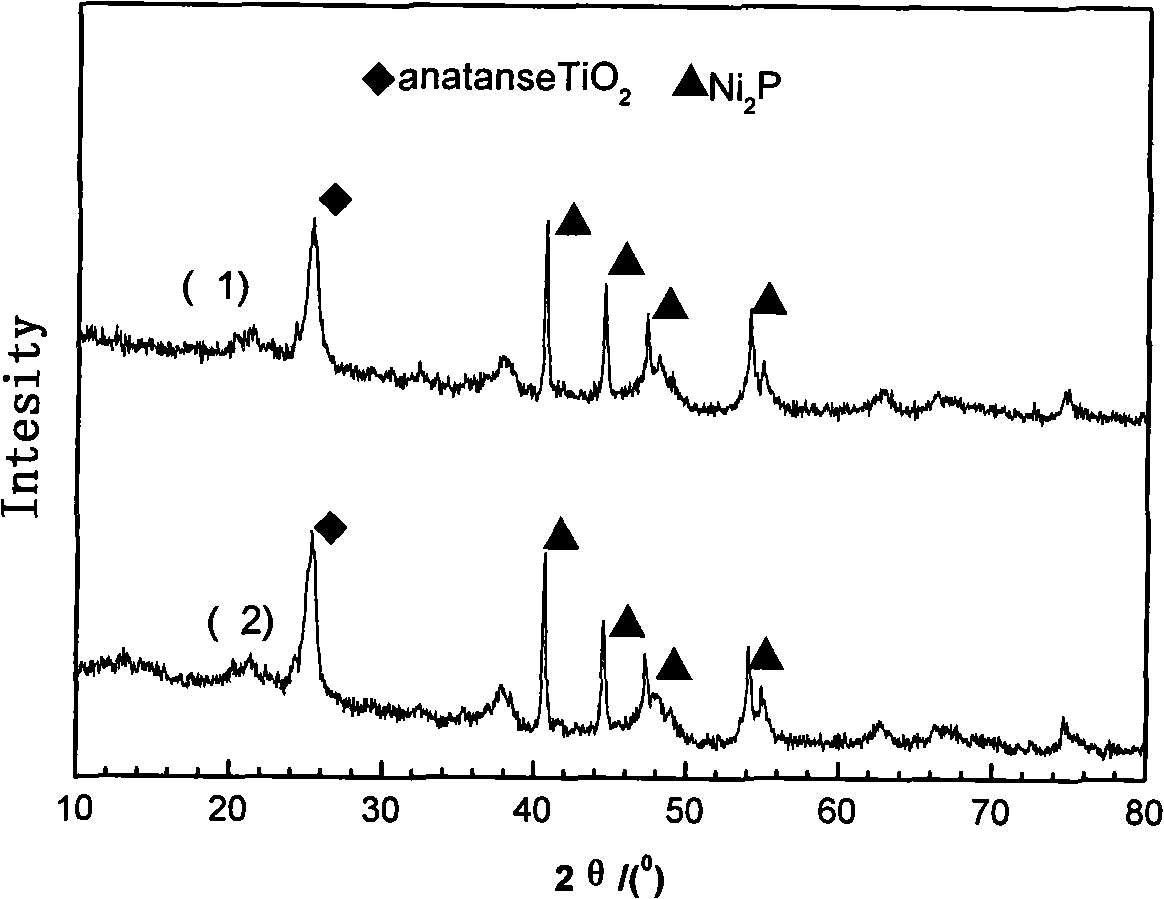

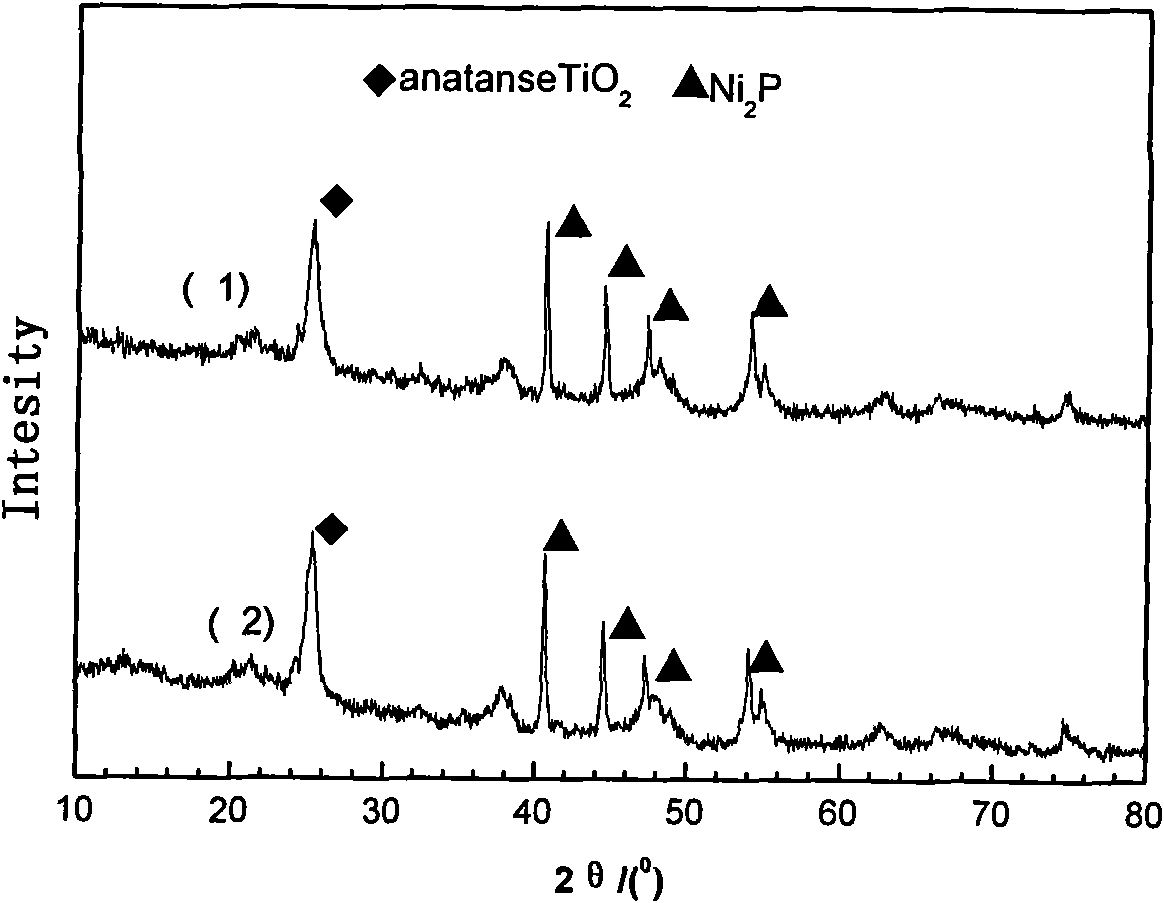

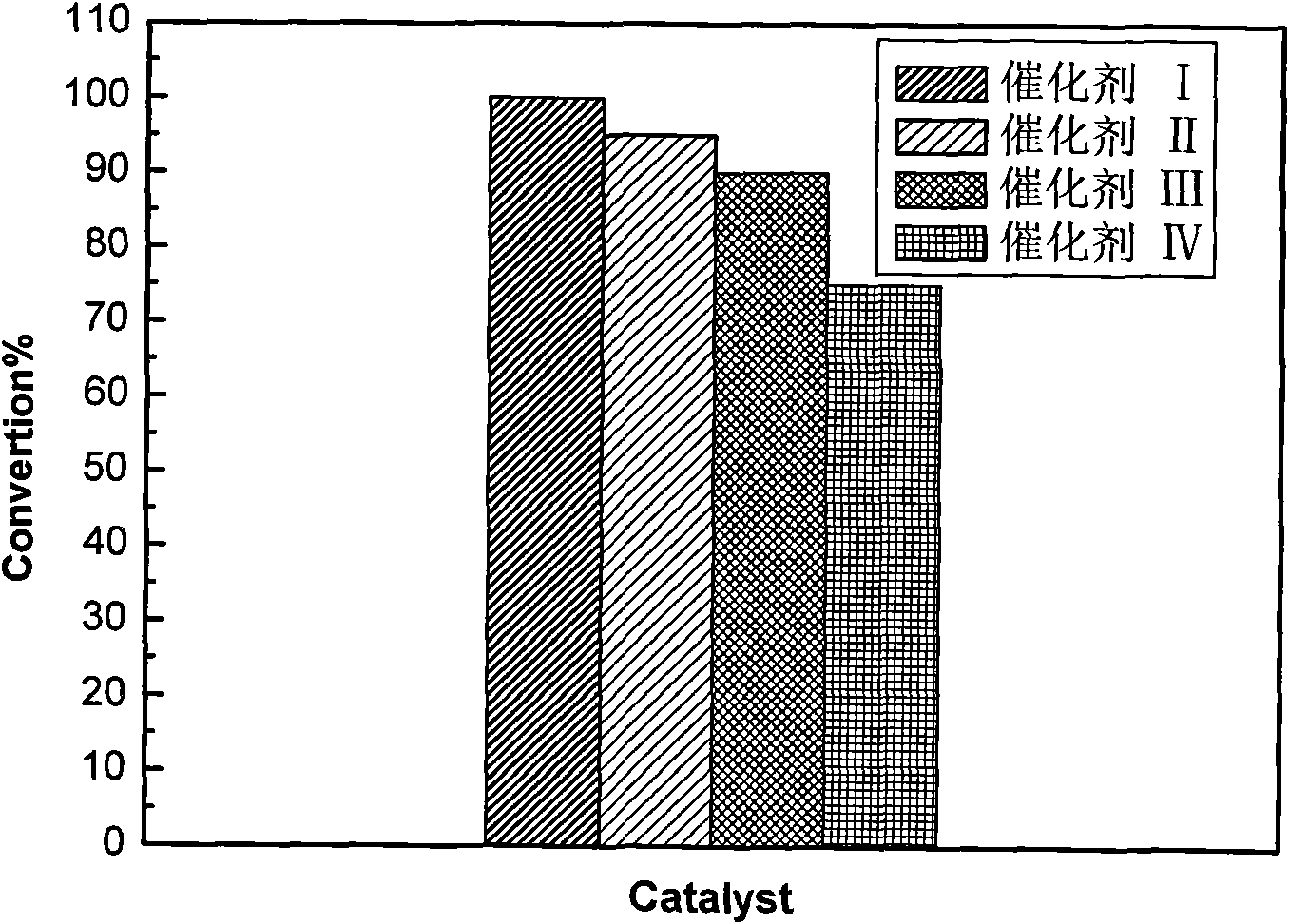

The invention relates to a preparation method of a nickel phosphide catalyst carried by a composite carrier. The method is characterized by comprising the following steps: firstly, using activated alumina and relative enzymes and alcohols as raw materials to prepare a composite carrier of TiO2-Al2O3 by adopting an improved sol-gel method; further, selecting suitable nickel salt and phosphate and carrying out ultrasound dipping and drying in microwaves to obtain a catalyst precursor; and finally, increasing a temperature by a program and reducing to obtain the composite support. The composite carrier of TiO2-Al2O3 prepared by the invention not only can effectively overcome the defect that nickel phosphide is apt to react with gamma-Al2O3 to generate AlP4 to lose the activity, but also overcomes the defect that a specific surface area of single TiO2 is relatively small, effectively exerts the strong metal-support interaction (SMSI) of the TiO2, thereby obtaining a hydrodesulfurization catalyst with remarkable activity efficacy.

Description

A kind of preparation method of nickel phosphide catalyst supported by composite carrier technical field The present invention relates to the preparation of an oil hydrodesulfurization catalyst, in particular to a preparation method of a nickel phosphide catalyst that changes the carrier used for carrying the active component Background technique As we all know, catalytic hydrodesulfurization (HDS) technology is still the main way to reduce the sulfur content of gasoline and diesel. The activity of traditional hydrodesulfurization catalysts has not reached the new low-sulfur content standard, so it is urgent to find efficient hydrogenation desulfurization catalyst. Studies have shown that transition metal phosphide catalysts, especially nickel phosphide, have attracted much attention due to their excellent hydrodesulfurization activity, but the specific surface area of unsupported Ni2P catalysts is very small (less than 1 m2g-1), in order to improve their activity Surf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J27/185B01J37/34B01J37/02B01J37/16C10G45/06

Inventor 杨伯伦王凯乐

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com