Ultrasonic pickling regeneration method for waste flue gas denitration catalyst

A denitrification catalyst, ultrasonic acid technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst deactivation, reduce cleaning steps, etc., to reduce cleaning steps and reduce activity Loss and effect of reducing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

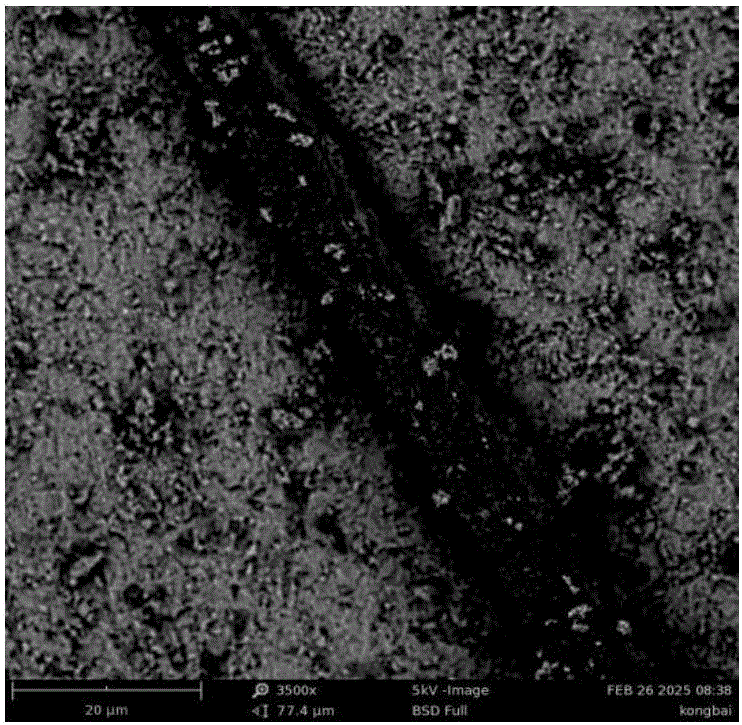

[0021] refer to figure 1 , Take the deactivated catalyst sample without pickling, conduct scanning electron microscope test, magnify 3500 times, observe the surface morphology of deactivated catalyst sample.

Embodiment 2

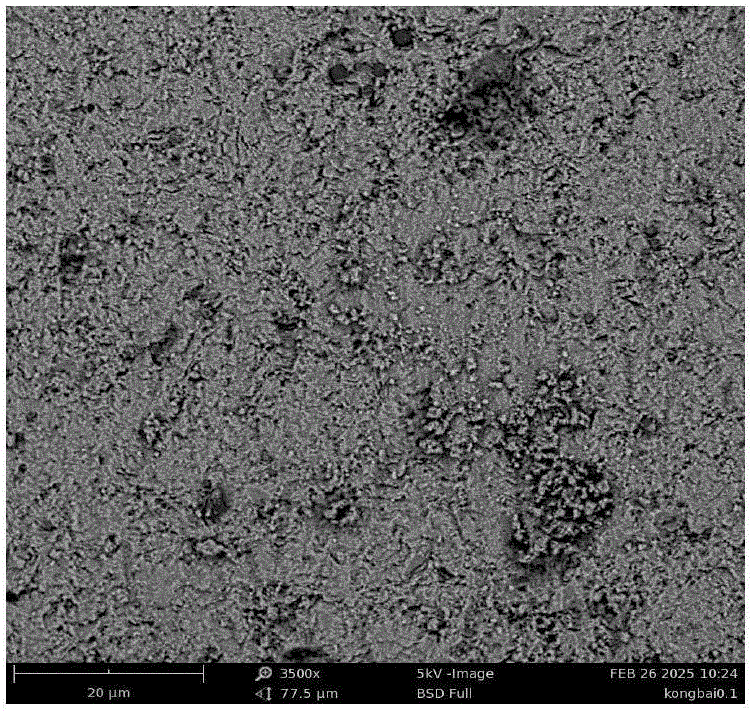

[0023] refer to figure 2 , take the deactivated catalyst, randomly cut into 20g small samples, blow soot and remove dust, and remove dust and impurities on the surface of the sample;

[0024] Place the sample in 500mL deionized water solution, put it in an ultrasonic generator with a power of 3kw, and wash it ultrasonically for 20 minutes;

[0025] Prepare 500 mL of mixed acid solution, wherein the mass fraction of fatty alcohol polyoxyethylene ether is 0.03 wt%, the mass fraction of polyethylene glycol fatty acid ester is 0.03 wt%, and the concentration of sulfuric acid is 0.1 mol / L;

[0026] Submerge the water-washed catalyst sample in the mixed acid solution for ultrasonic pickling for 25 minutes, and the power of the ultrasonic generator is 2kw;

[0027] The acid-washed catalyst was dried in a vacuum oven at 120°C for 3 hours to obtain a regenerated catalyst;

[0028] The samples were taken for scanning electron microscope test to observe the surface morphology of the c...

Embodiment 3

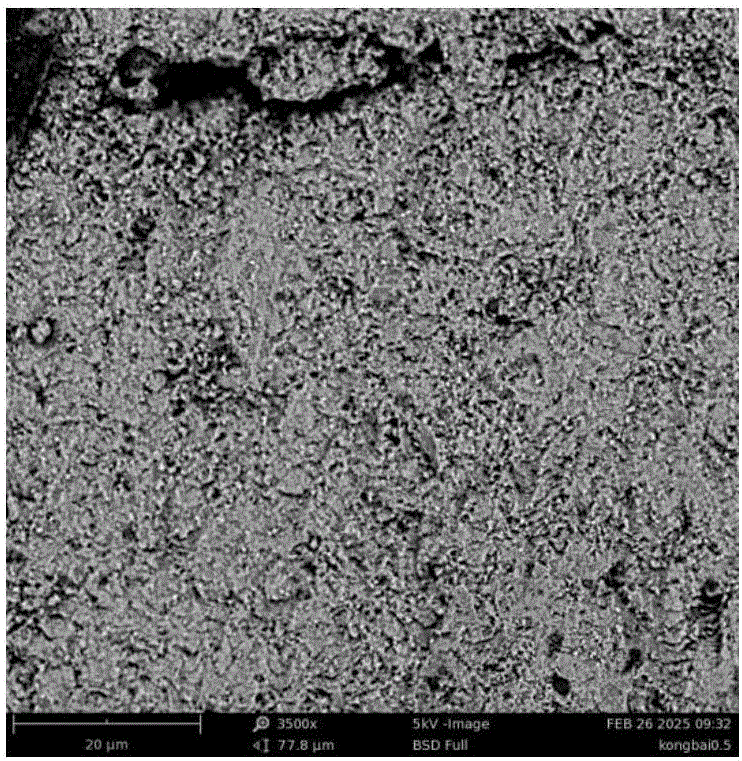

[0030] refer to image 3 , take the deactivated catalyst, randomly cut into 25g small samples, blow soot and remove dust, and remove dust and impurities on the surface of the sample;

[0031] Place the sample in 500mL deionized water solution, put it in an ultrasonic generator with a power of 1kw, and wash it ultrasonically for 40 minutes;

[0032] Prepare 500 mL of mixed acid solution, wherein the mass fraction of fatty alcohol polyoxyethylene ether is 0.01 wt%, the mass fraction of polyethylene glycol fatty acid ester is 0.05 wt%, and the concentration of sulfuric acid is 0.5 mol / L;

[0033] Submerge the water-washed catalyst sample in the mixed acid solution for ultrasonic pickling for 20 minutes, and the power of the ultrasonic generator is 5kw;

[0034] The acid-washed catalyst was dried in a vacuum oven at 100°C for 8 hours to obtain a regenerated catalyst;

[0035] The samples were taken for scanning electron microscope test to observe the surface morphology of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com