Samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as preparation method and application thereof

An SCR catalyst and low temperature technology, applied in the field of catalysts, can solve the problems of complex preparation process and narrow catalytic reaction temperature window, and achieve the effects of simple process, wide reaction temperature window and good catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 0.05Sm-MnO x The preparation of catalyst, concrete steps are as follows:

[0037] 10.1636g (0.0400mol) Mn(CHCOO) 2 4H 2 O and 0.6727g (0.0020mol) Sm(NO 3 ) 3 ·6H 2 Dissolve O in deionized water respectively, mix, stir constantly and add 0.2mol / L sodium carbonate drop by drop, adjust the pH to 9.0, then continue to stir with a magnetic stirrer at room temperature for 24h, then filter, collect the precipitate, and store in an oven Dry at 120°C for 12 hours, grind in a mortar, and sieve 40-60 mesh powder to obtain 0.05Sm-MnO x Low temperature SCR catalyst.

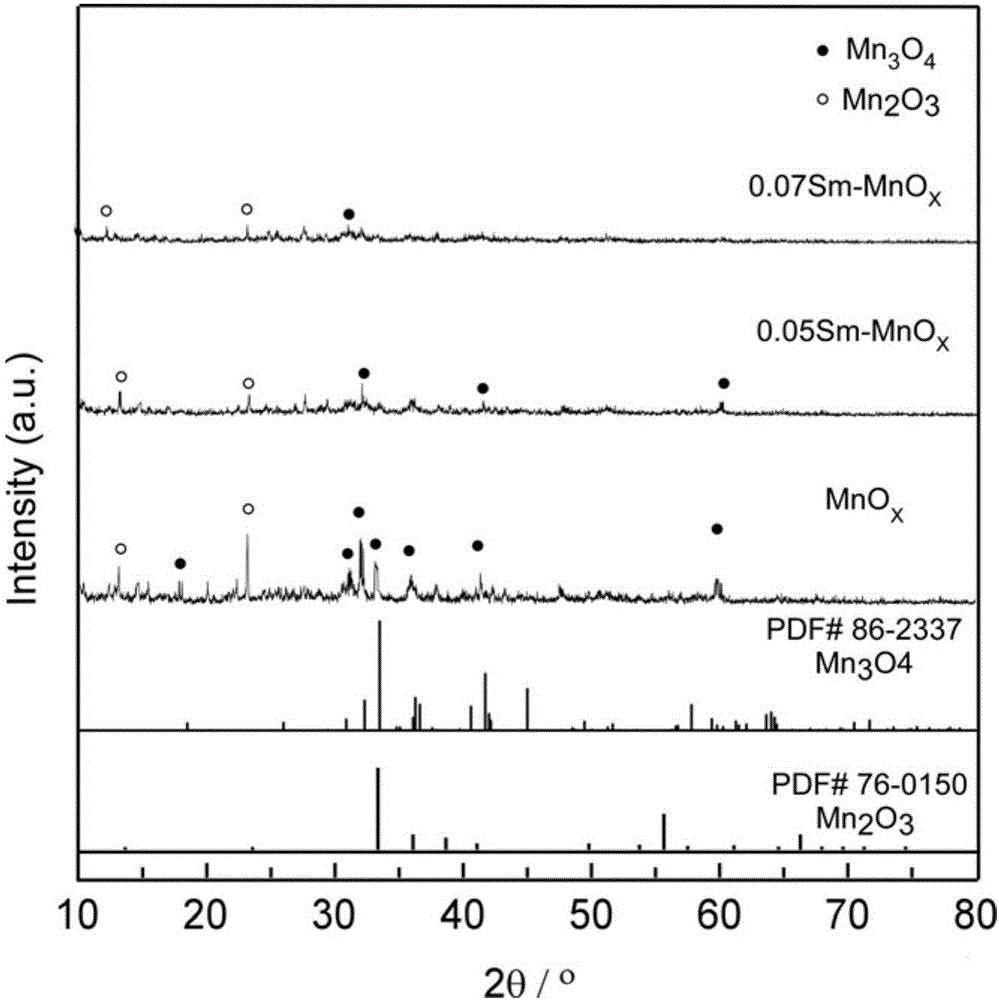

[0038] The 0.05Sm-MnO prepared in this embodiment x XRD pattern of low temperature SCR catalystfigure 1 As shown, it can be seen that 0.05Sm-MnO x The crystallinity of the catalyst is poor, with weak Mn 2 o 3 and Mn 3 o 4 Most of the phases exist in an amorphous state. It shows that samarium interacts with manganese oxides, and the doping of samarium affects the nucleation process of manganese oxides, inhi...

Embodiment 2

[0045] 0.07Sm-MnO x The preparation of catalyst, concrete steps are as follows:

[0046] 10.1636g (0.040mol) Mn(CHCOO) 2 4H 2 O and 0.9431g (0.0028mol) Sm(NO 3 ) 3 ·6H 2 Dissolve O in deionized water respectively, mix, stir constantly and add 0.2mol / L sodium carbonate drop by drop, adjust the pH to 9.0, then continue to stir with a magnetic stirrer at room temperature for 24h, then filter, collect the precipitate, and store in an oven Dry at 120°C for 12 hours, grind in a mortar, and sieve 40-60 mesh powder to obtain 0.07Sm-MnO x Low temperature SCR catalyst.

[0047] The 0.07Sm-MnO prepared in this embodiment x XRD pattern of low temperature SCR catalyst figure 1 As shown, it can be seen that 0.07Sm-MnO x The diffraction peaks of the catalyst basically disappeared, and it can be seen that the crystallinity is very poor, and most of them exist in an amorphous state. It shows that there is a strong interaction between samarium and manganese oxides, and the doping of s...

Embodiment 3

[0051] 0.10Sm-MnO x The preparation of catalyst, concrete steps are as follows:

[0052] 10.1636g (0.04mol) Mn(CH 3 COO) 2 4H 2 O and 1.3454g (0.004mol) Sm(NO 3 ) 3 ·6H 2 Dissolve O in deionized water, mix, stir constantly and add 0.2mol / L sodium carbonate drop by drop, adjust the pH to 9.0, then continue to stir with a magnetic stirrer at room temperature for 24h, then filter, collect the precipitate, and place in an oven Dry at 120°C for 12 hours, grind in a mortar, and sieve 40-60 mesh powder to obtain 0.10Sm-MnO x Low temperature SCR catalyst.

[0053] Compared with Example 1, this example changes the molar ratio of the samarium-manganese precursor, and the molar ratio of samarium-manganese is 0.10:1.

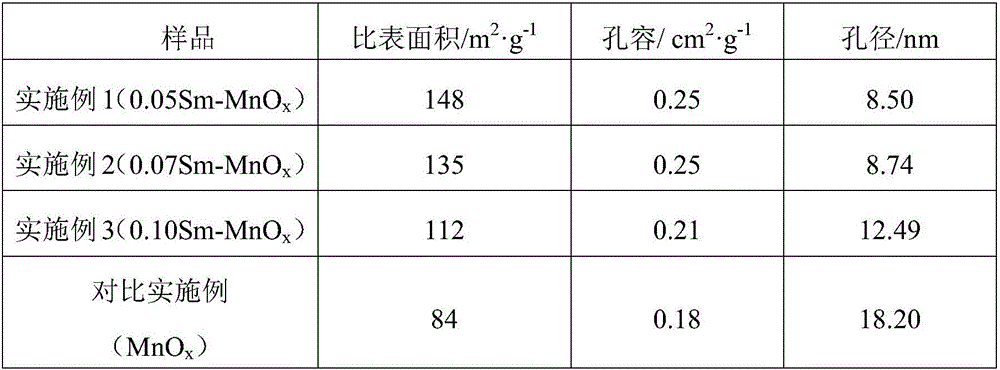

[0054] BET analysis (Table 1) showed that 0.10Sm-MnO x The catalyst has a small specific surface area of 112m 2 g -1 , the pore volume is also smaller, while the pore diameter is larger.

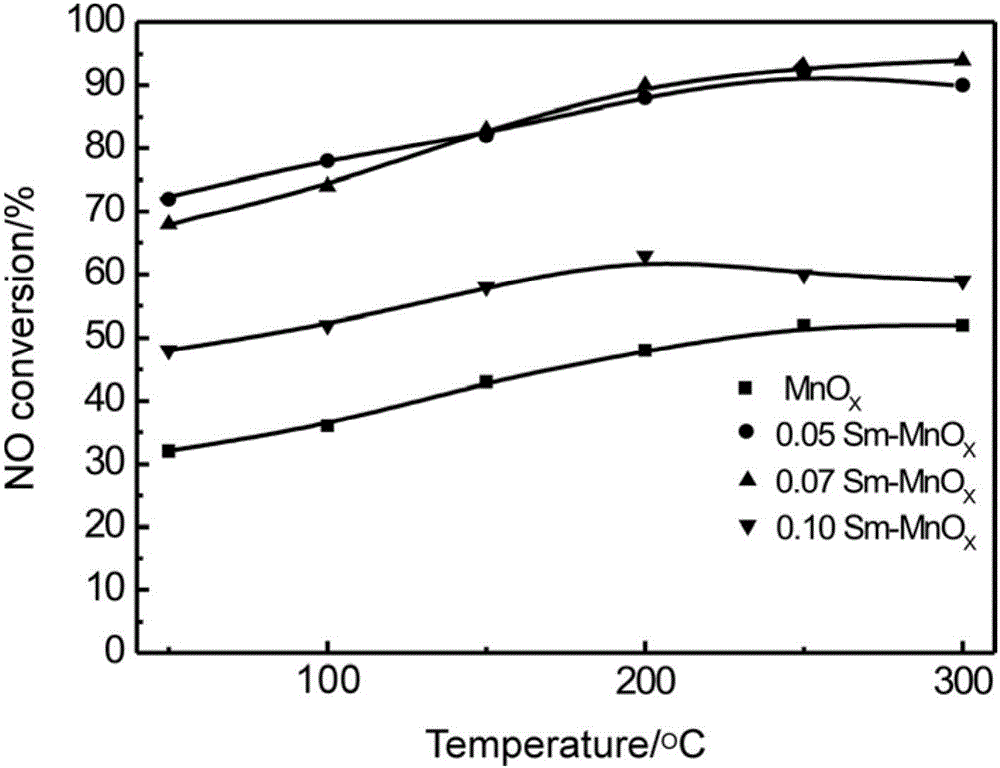

[0055] For the 0.10Sm-MnO prepared in this embodiment x The low-temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com