Light-hydrocarbon isomerization catalyst and method for preparing same

A technology for isomerization and catalyst, applied in the field of light hydrocarbon isomerization catalyst and its preparation, can solve the problems of short service life, long process flow, short service life of catalyst, etc., and achieve improved isomerization performance and high isomerization activity , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

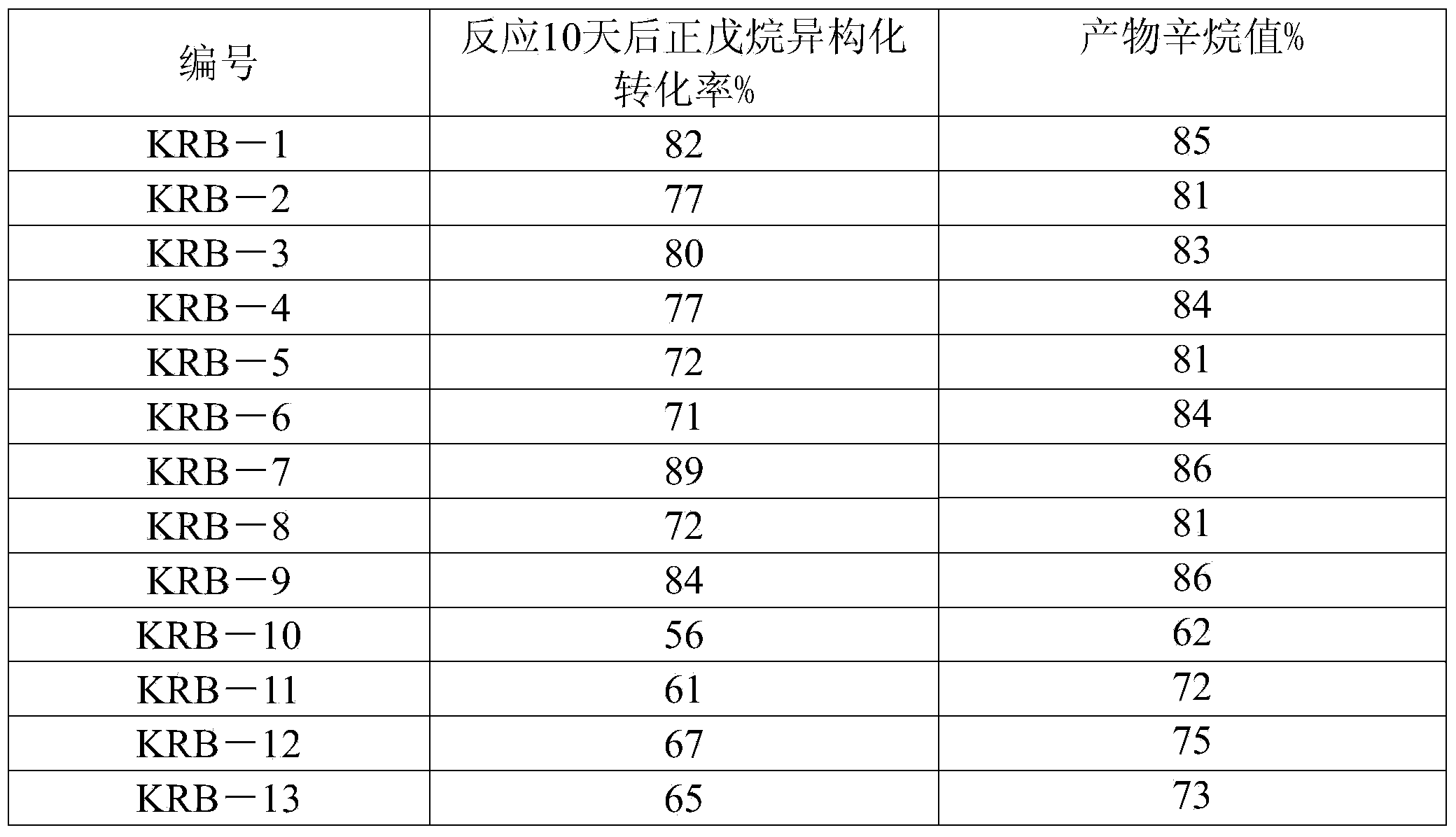

Examples

Embodiment 1

[0022] Resin-based spherical activated carbon, produced by Shanxi Cuihong Technology Co., Ltd.

[0023] Ball diameter is 0.3-1.2mm, specific surface area (BET) 950-1200(m 2 / g), the pore volume is 0.6-0.75ml / g.

[0024] 1). Preparation of carrier:

[0025] Move the resin-based spherical activated carbon into a tubular electric furnace with a nitrogen flow for pyrolysis, slowly raise the temperature from room temperature to 800°C, switch nitrogen to hydrogen fluoride at a flow rate of 5L / hour after reaching the temperature, and activate it for 5 hours, and cool the product to room temperature. A catalyst carrier is obtained. In the catalyst carrier, mesopores accounted for 82% and micropores accounted for 18%.

[0026] 2). Load operation

[0027] Soak the catalyst carrier in ethanol solvent for 4 hours, the mass ratio of catalyst carrier to ethanol solvent is 1:3, add palladium nitrate accounting for 3% of the mass percentage of the catalyst carrier, and the loading time is...

Embodiment 2

[0029] Adding in step 2 accounts for the palladium nitrate of 1% by mass percentage of the catalyst carrier, and the others are the same as in Example 1. The resulting product number is KRB-2. In the catalyst carrier, mesopores account for 85% and micropores account for 15%.

Embodiment 3

[0031] Adding in step 2 and accounting for catalyst carrier mass percent is 5% palladium nitrate, other is the same as embodiment 1. The resulting product number was KRB-3. In the catalyst carrier, mesopores accounted for 81%, and micropores accounted for 19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com