Patents

Literature

167 results about "Palladium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Palladium(II) nitrate is the inorganic compound with the formula Pd(NO3)2. It is a red-brown deliquescent solid. As a solution in nitric acid, it catalyzes the conversion of alkenes to dinitrate esters.

Method for preparing noble metal modified one-dimensional titanium dioxide Hg-removing catalyst

ActiveCN101961651ASimple processEasy to masterOther chemical processesDispersed particle separationCatalytic oxidationRutile

The invention discloses a method for preparing a noble metal modified one-dimensional titanium dioxide Hg-removing catalyst. The method comprises the following steps of: by taking a titanium dioxide nanotube as an active main body and a noble metal salt or a nonmetal modifier as a modifier, heating in water, roasting, optically reducing, drying and grinding to prepare the noble metal elementary substance modified titanium dioxide nanotube photocatalyst. The nano titanium dioxide is in a rutile type, an anatase type or a mixed type of rutile and anatase; the noble metal salt is one or mixture of a plurality of silver nitrate, palladium chloride, palladium nitrate, chloroplatinic acid or chloroauric acid; and a photo-reduction sacrifice agent is one or mixture of a plurality of methanol, ethanol, ethylene glycol, propanol, isopropanol or propylene glycol. The invention is simple in process, easy to master and not easy to inactivate; and the prepared titanium dioxide nanotube and the noble metal elementary substance modified titanium dioxide nanotube photocatalyst can efficiently catalyze and oxidize Hg elementary substances in flue gas.

Owner:ZHEJIANG UNIV

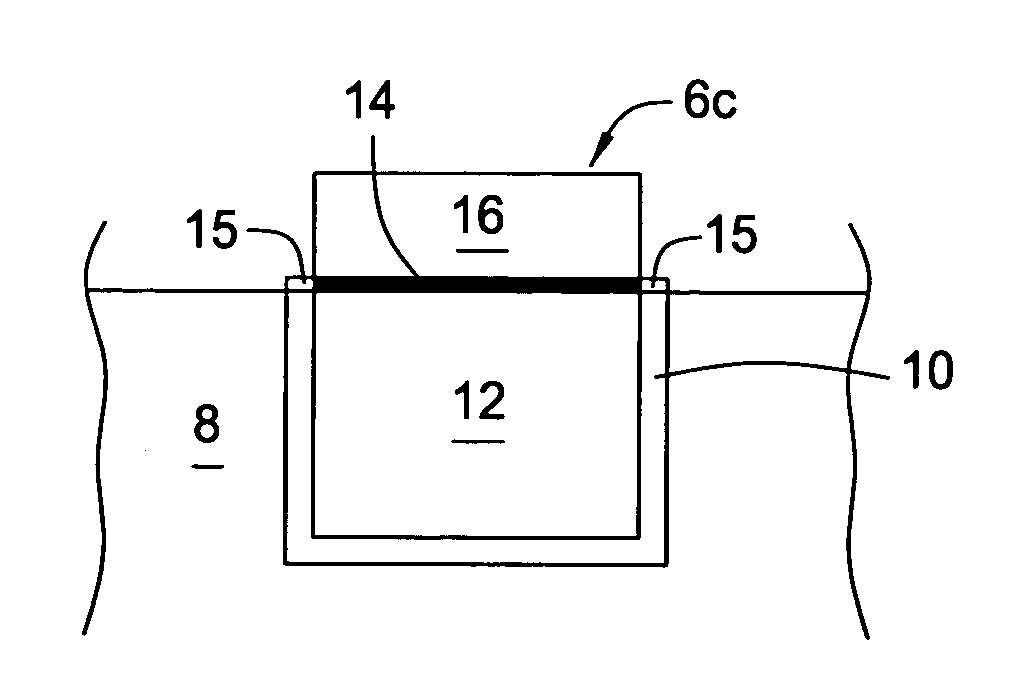

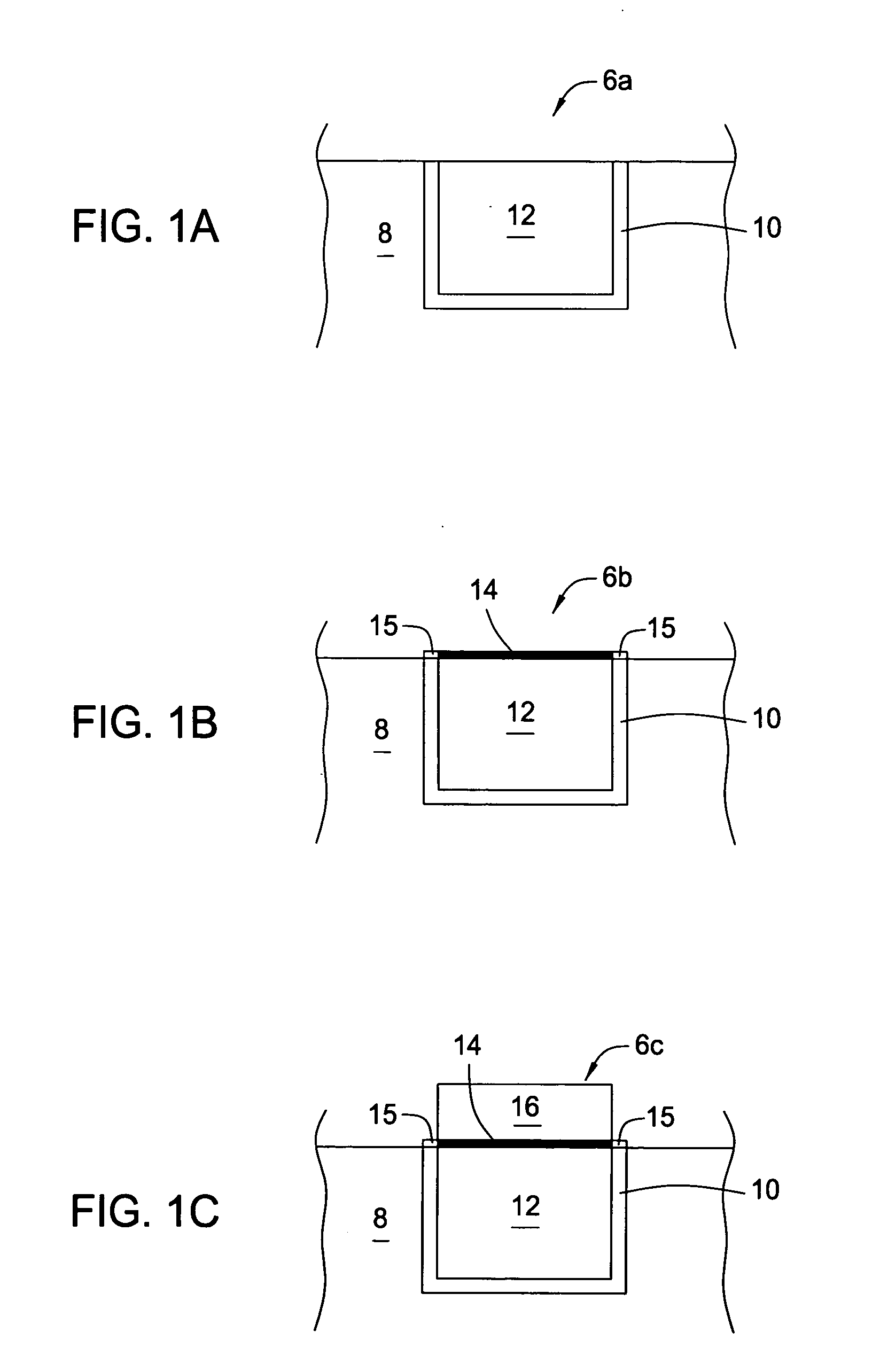

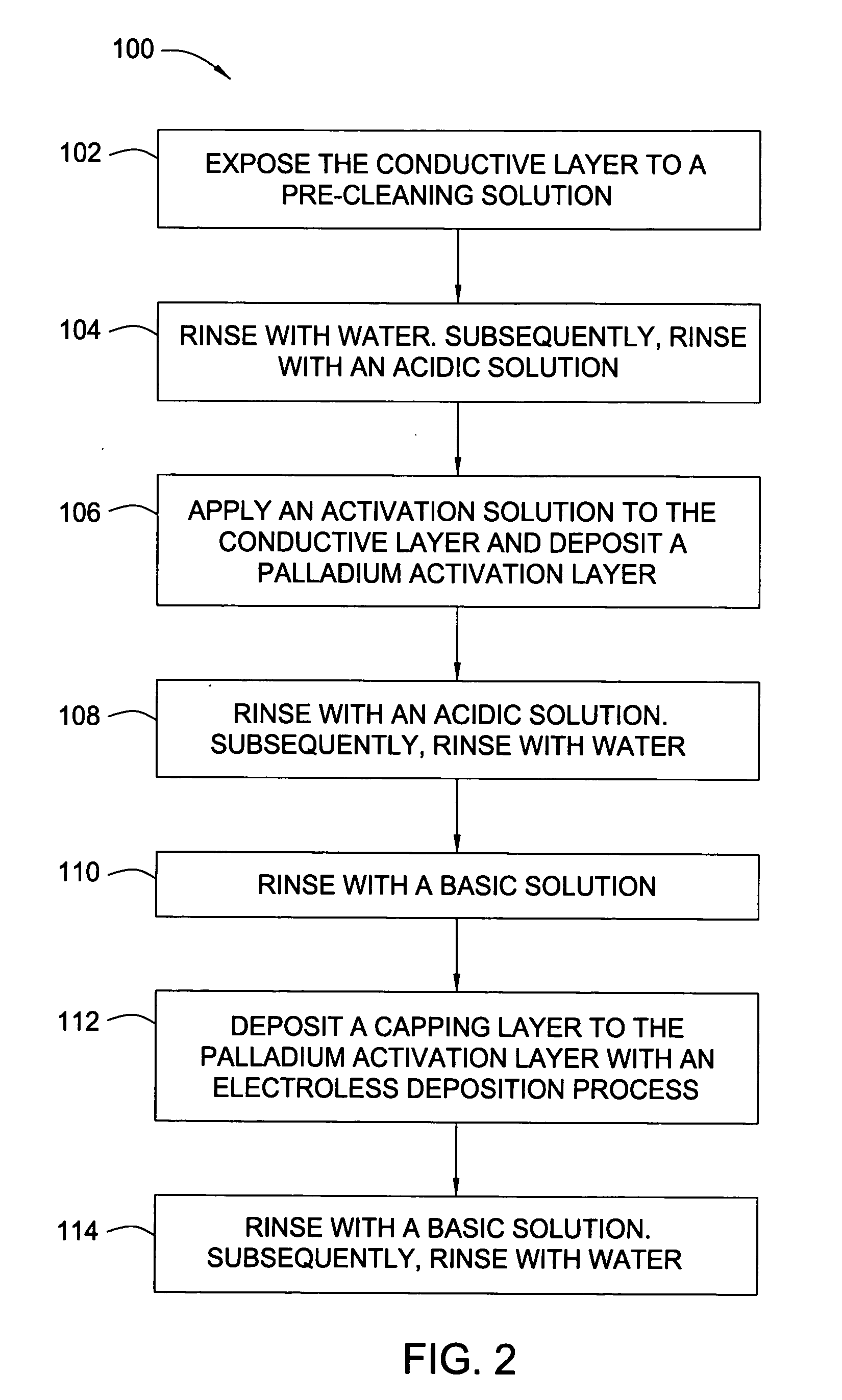

Electroless palladium nitrate activation prior to cobalt-alloy deposition

InactiveUS20050170650A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBiological activationMethanesulfinic acid

In one embodiment, a method for activating a metal layer prior to depositing a cobalt-containing capping layer is provided which includes exposing the metal layer to an electroless activation solution to deposit a palladium layer on the metal layer and depositing the cobalt-containing capping layer on the palladium layer. The electroless activation solution contains palladium nitrate at a concentration in a range from about 0.01 mM to about 1.0 mM, nitric acid at a concentration in a range from about 0.01 mM to about 3.0 mM and water. In another embodiment, the electroless activation solution contains palladium nitrate at a concentration in a range from about 0.01 mM to about 1.0 mM, methanesulfonic acid at a concentration in a range from about 0.01 mM to about 3.0 mM and water.

Owner:APPLIED MATERIALS INC

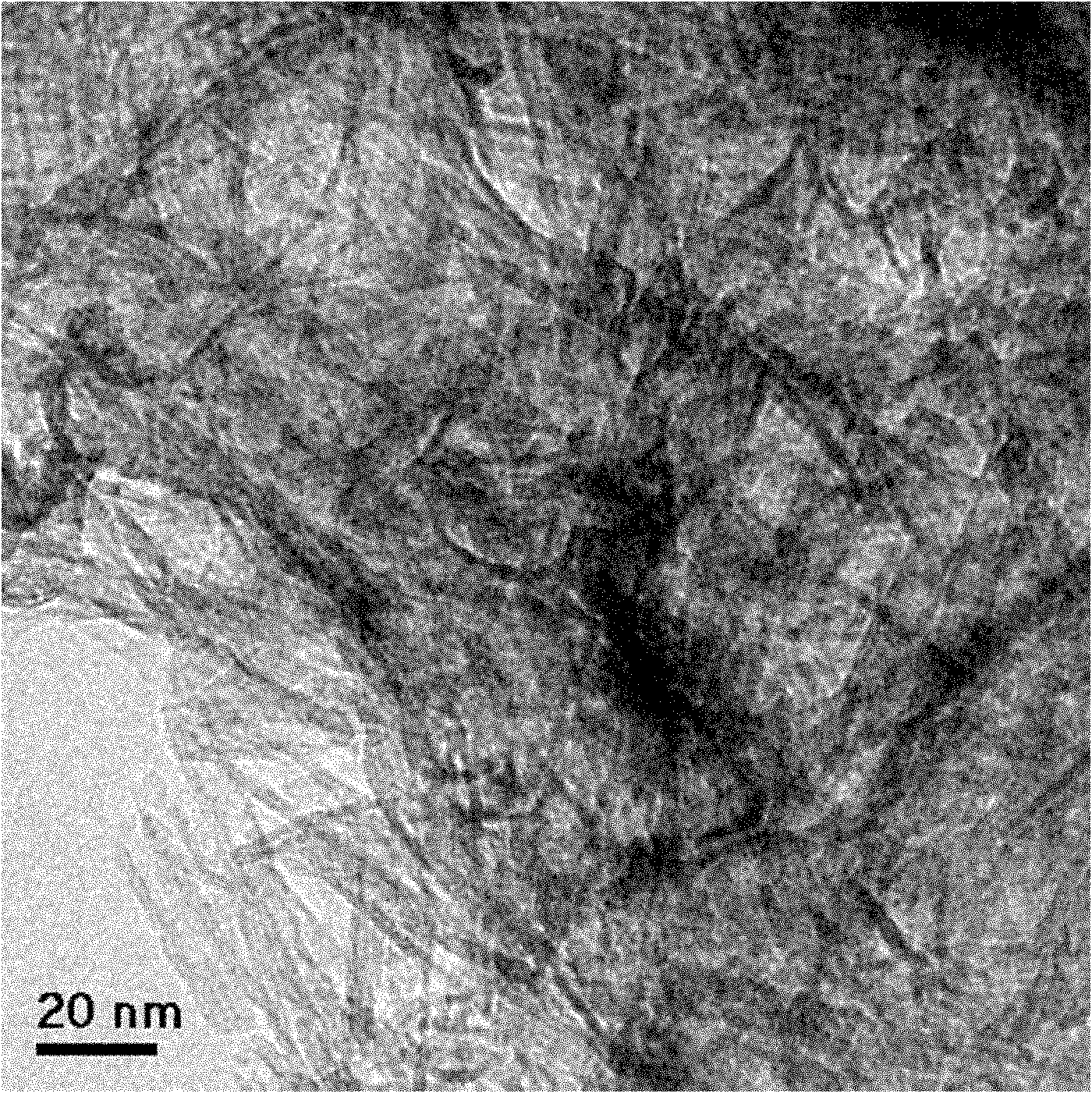

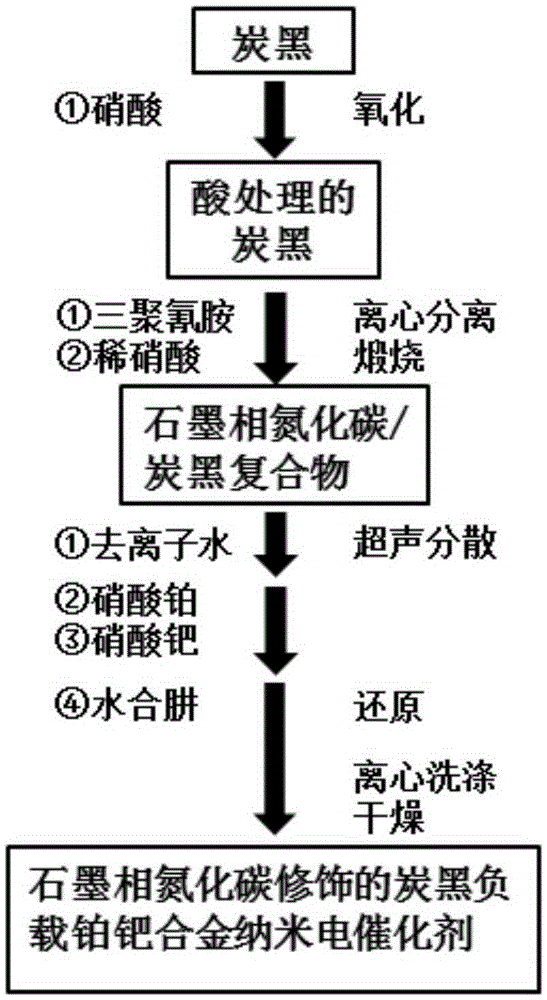

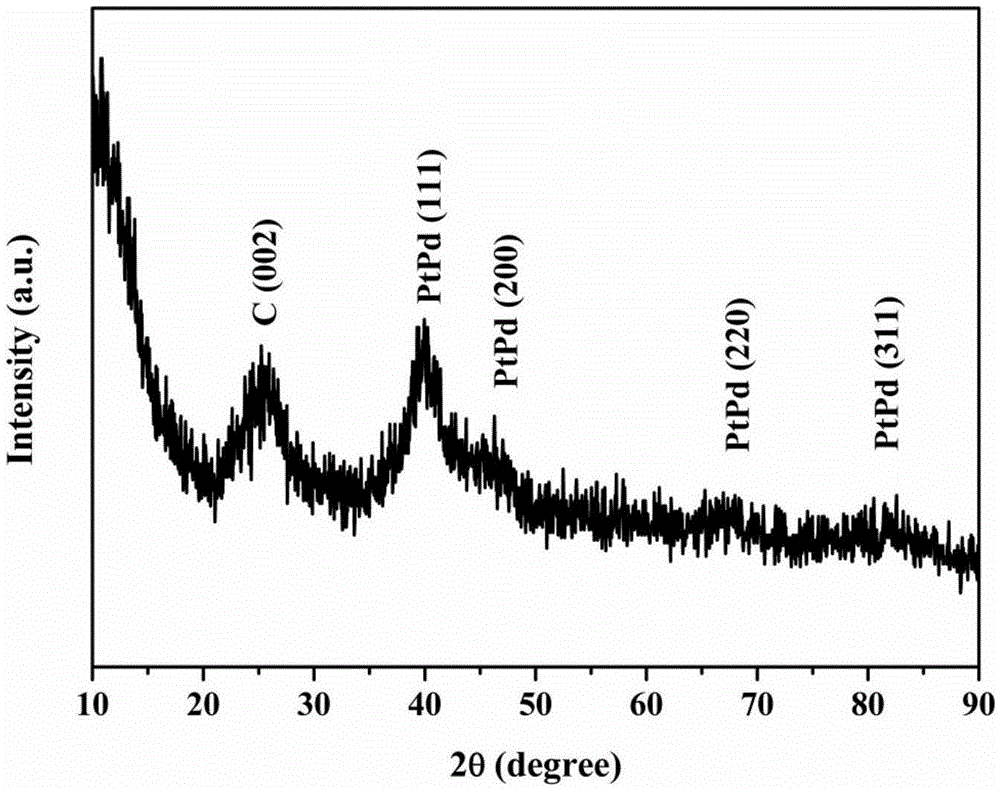

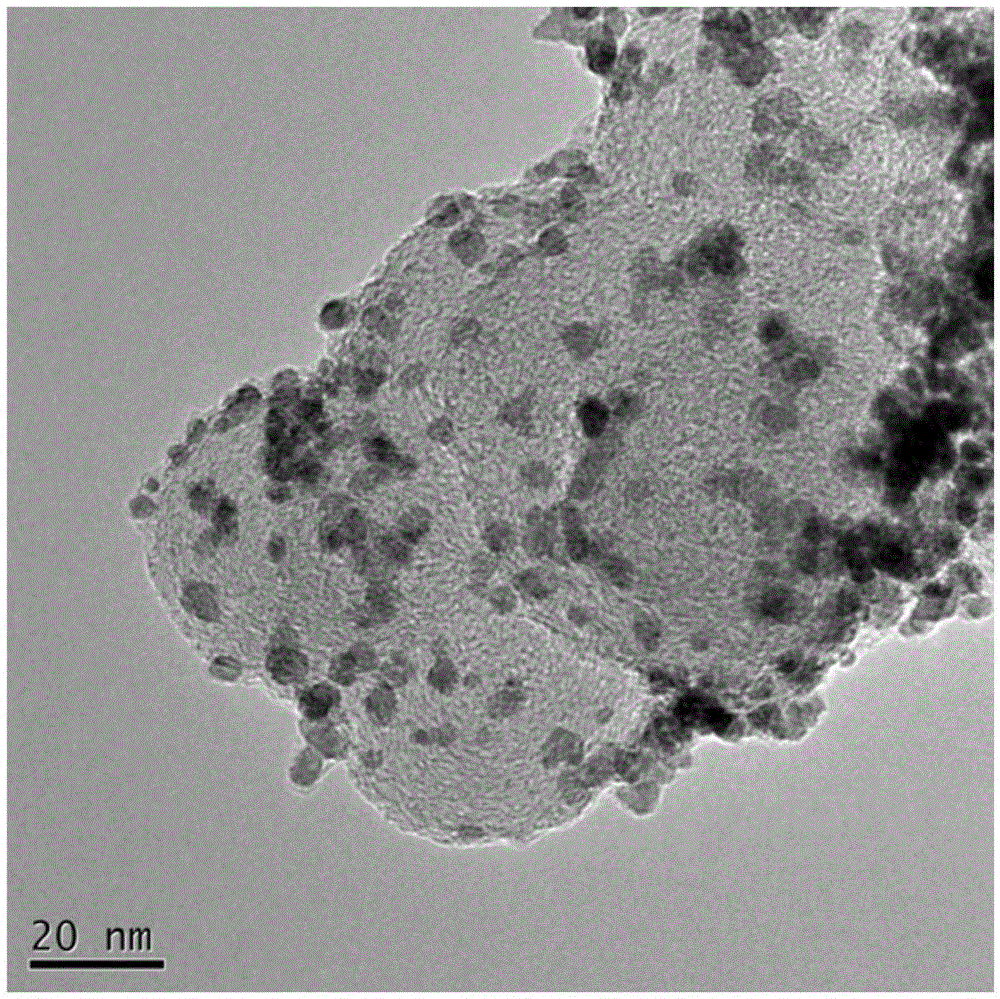

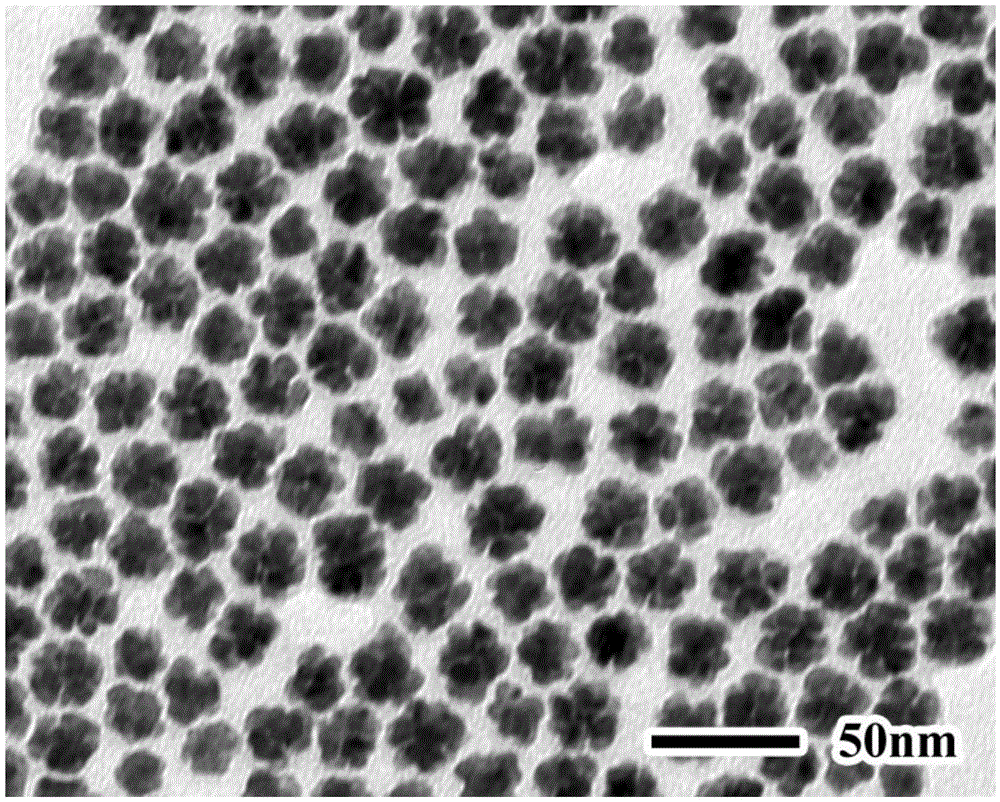

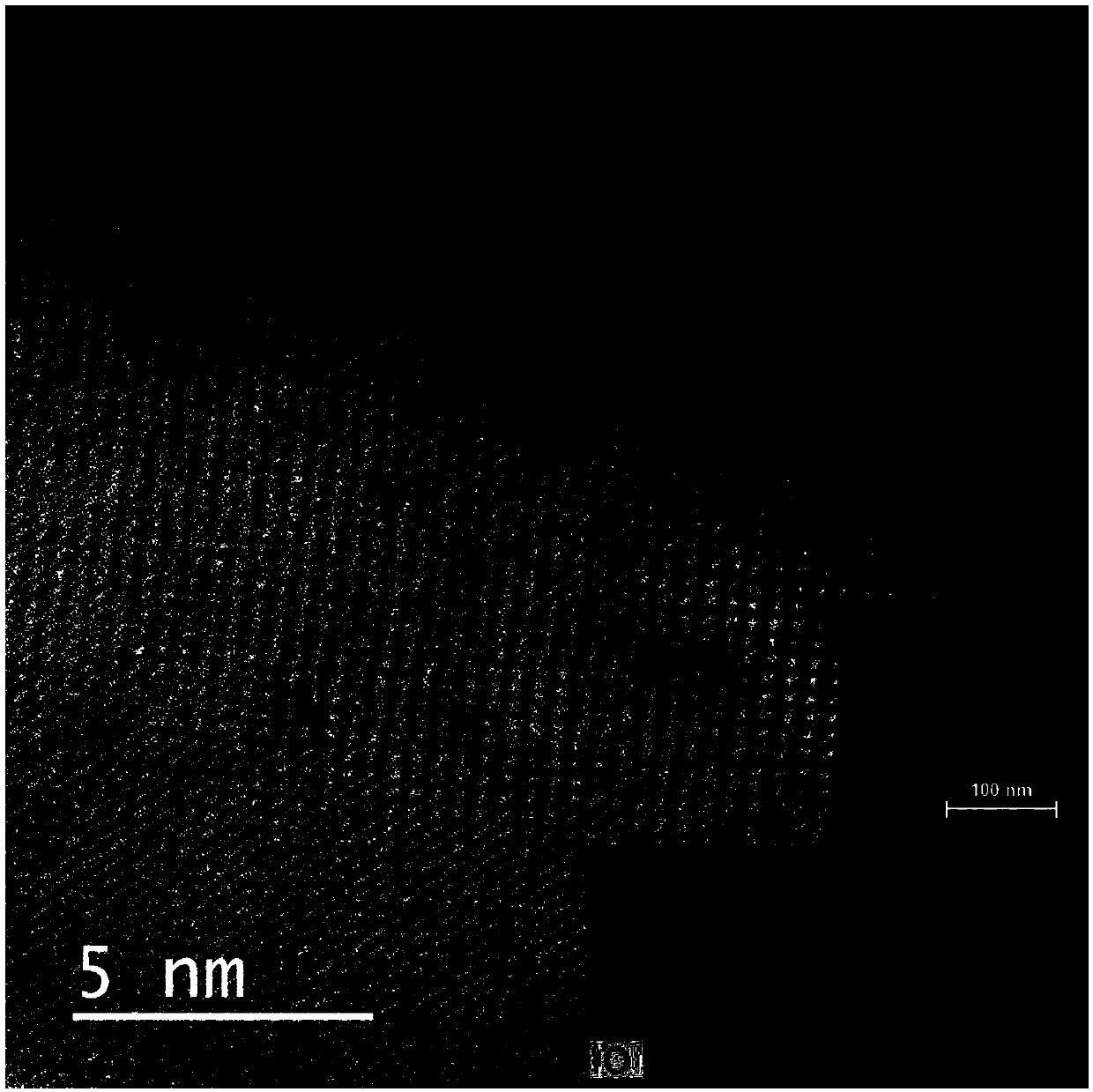

Graphite-phase carbon nitride-modified carbon black-loaded platinum-palladium alloy nano electrocatalyst and preparation method

InactiveCN105244513AReduce energy consumptionSimple production processMaterial nanotechnologyCell electrodesCarbon blackPalladium nitrate

The invention discloses a graphite-phase carbon nitride-modified carbon black-loaded platinum-palladium alloy nano electrocatalyst and a preparation method. The method comprises the steps as follows: melamine is adopted as a precursor for the first time; graphite-phase carbon nitride grows on a carbon black surface, so that the electrochemical corrosion resistance of the carbon black in an acidic electrolyte is improved; and with platinum nitrate and palladium nitrate as the precursors and hydrazine hydrate as a reducing agent, platinum-palladium alloy nanoparticles of which the average particle size is 5nm are evenly deposited on the graphite-phase carbon nitride-modified carbon black surface, so as to obtain the graphite-phase carbon nitride-modified carbon black-loaded platinum-palladium alloy nano electrocatalyst. Reaction conditions are mild; a surfactant does not need to be used; and the graphite-phase carbon nitride-modified carbon black-loaded platinum-palladium alloy nano electrocatalyst has relatively high electrochemical catalytic activity, stability and electrochemical corrosion resistance, and has relatively good application prospect and economic benefits in the aspects of direct alcohol fuel cells.

Owner:NANJING UNIV OF SCI & TECH

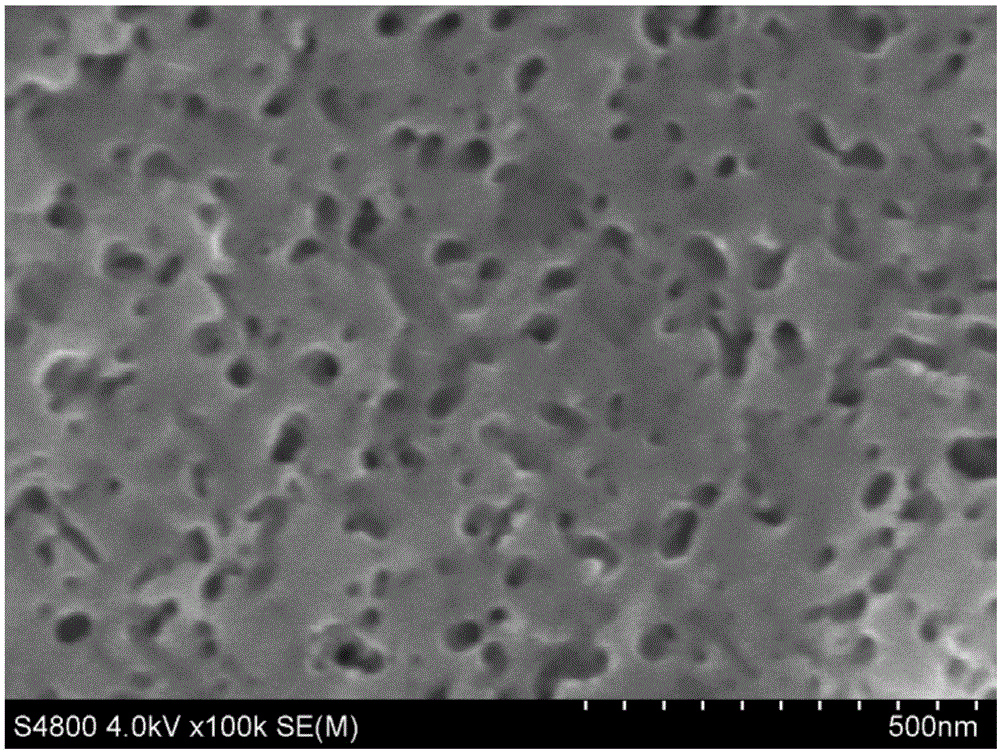

Polycrystalline black silicon texturization treatment fluid, polysilicon chip texturization method applying treatment fluid, and polycrystalline black silicon texturization product

InactiveCN105154982AUniform suedeImprove trapping effectPolycrystalline material growthAfter-treatment detailsPlatanic acidPalladium nitrate

The invention provides a polycrystalline black silicon texturization treatment fluid. The polycrystalline black silicon texturization treatment fluid comprises a hydrofluoric acid solution, a hydrogen peroxide solution and a metal salt, wherein a volume ratio of the hydrofluoric acid solution to the hydrogen peroxide solution is 1-25:5-40, the mass fraction of hydrofluoric acid in the hydrofluoric acid solution is 40-50%, the mass fraction of hydrogen peroxide in the hydrogen peroxide solution is 20-55%, the metal salt is at least one of copper nitrate, silver nitrate, palladium nitrate, copper chloride, auric chloride acid, chloroplatinic acid, potassium chromate and nickel sulfate, and the mole concentration of the metal salt is 1-10<5>[mu]mol / L. The invention also provides a polysilicon chip texturization method applying the polycrystalline black silicon texturization treatment fluid, and a polycrystalline black silicon texturization product.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

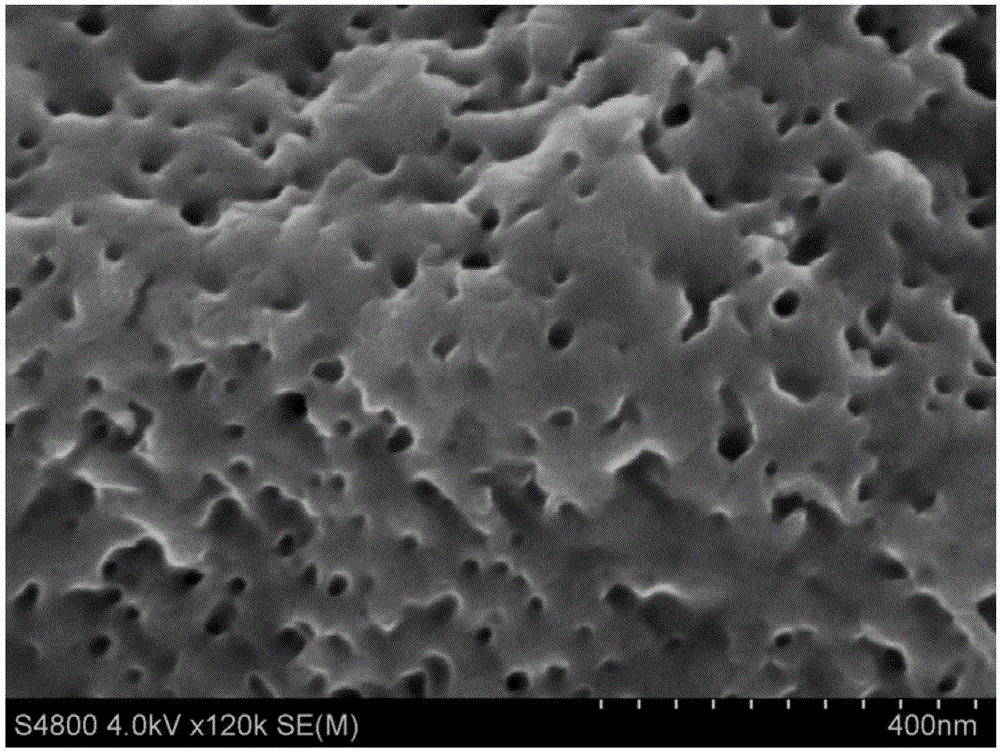

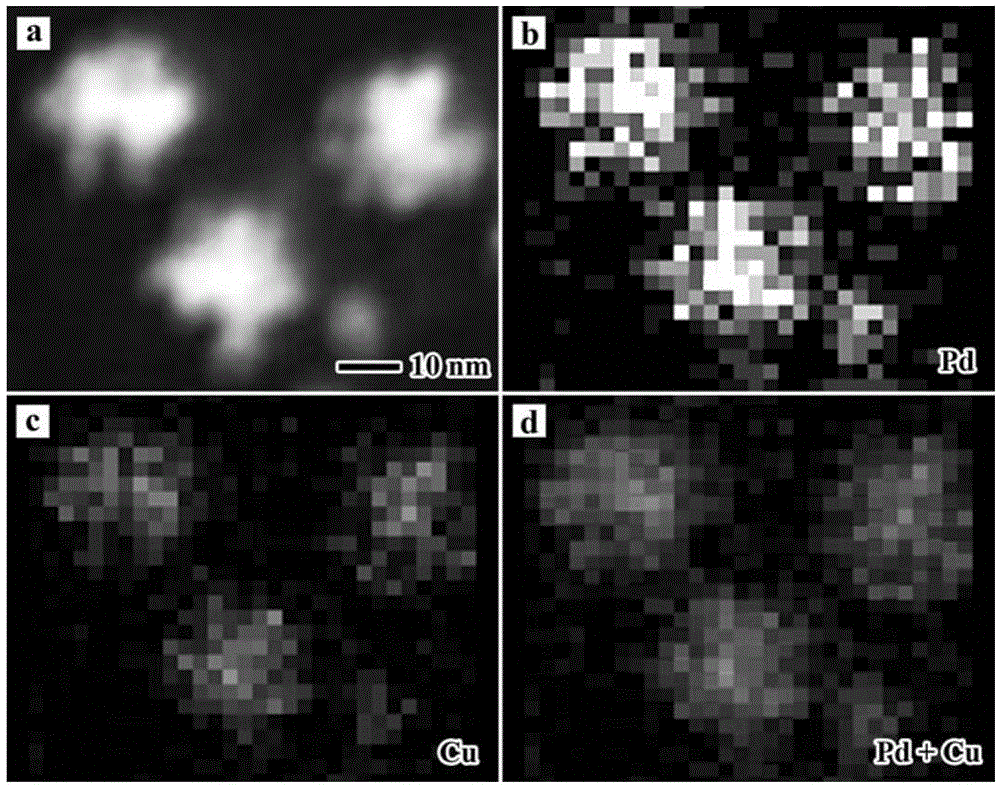

Preparation method for dendritic copper-palladium nanocrystalline alloy and product of preparation method

InactiveCN105618784AEasy to operateMild reaction conditionsTransportation and packagingMetal-working apparatusCopper chlorideCopper nitrate

The invention relates to a preparation method for a dendritic copper-palladium nanocrystalline alloy, which comprises the following steps: dissolving a palladium precursor, a copper precursor and a dispersant into a solvent, then adding a reducing agent, performing a reaction at 120-160 DEG C for 1-2 h, and performing centrifugal separation to obtain a dendritic copper-palladium nanocrystalline alloy, wherein the palladium precursor is palladium acetylacetonate, palladium acetate or palladium nitrate; and the copper precursor is copper acetylacetonate, copper chloride, copper nitrate or copper sulfate. The invention further relates to the dendritic copper-palladium nanocrystalline alloy. Dendritic nanocrystals with adjustable sizes and good dispersibility can be prepared according to the preparation method, and the preparation method is simple, has high repeatability and is low in cost.

Owner:ZHEJIANG UNIV

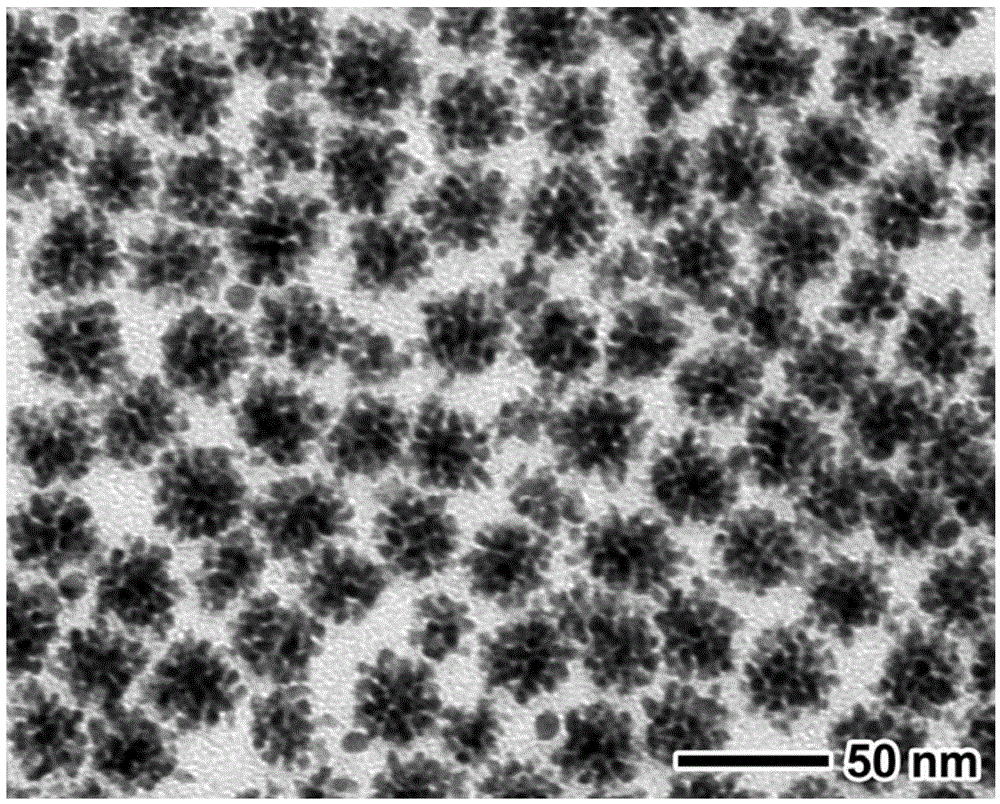

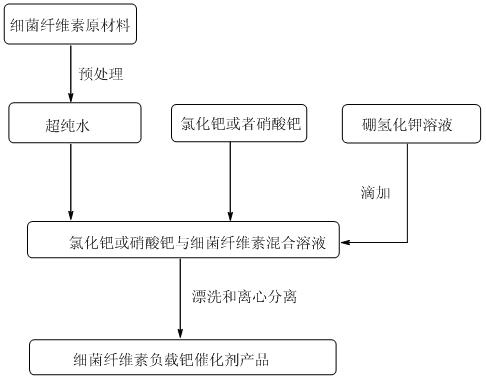

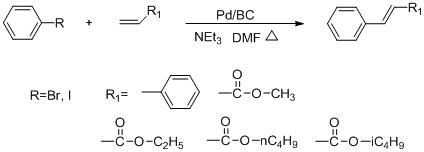

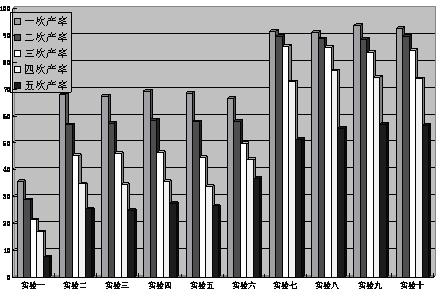

A kind of preparation method of bacterial cellulose supported nanometer palladium catalyst

ActiveCN102274753AEasy to makeImprove thermal stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPotassium borohydridePtru catalyst

The invention discloses a method for preparing a bacterial cellulose loaded nanometer palladium catalyst. The method comprises the following steps of: pretreating bacterial cellulose, stirring the pretreated bacterial cellulose in ultrapure water, and dispersing; adding palladium chloride or palladium nitrate, dispersing fully, removing oxygen, and heating; adding potassium borohydride solution; and after reaction is finished, blanching and centrifugal separation repeatedly to obtain the bacterial cellulose loaded nanometer palladium catalyst. In the method, divalent potassium ions are reduced by using the potassium borohydride solution under the hydrothermal condition to form the zero-valent palladium catalyst with small grain diameters and uniform distribution; and the preparation process is simple, the prepared catalyst is high in catalytic efficiency, and the method can be applied in the fields of organic synthesis and the like.

Owner:NANJING UNIV OF SCI & TECH

Synthesis method for increasing Pd content of metal organic framework based on Zr(IV) ions

InactiveCN105669779AEasy to operateLow costCarboxylic acid nitrile preparationOrganic compound preparationSalicylaldehydeSynthesis methods

The invention discloses a synthesis method for increasing the Pd content of a metal organic framework based on Zr(IV) ions. The method comprises the following steps: performing a coordination polymerization reaction between an organic ligand (I) and ZrCl4, and performing post-synthesis modification of the product, wherein the post-synthesis modification comprises the following specific steps: enabling a coordination polymerization reaction product, 2-pyridylaldehyde or salicylaldehyde and a catalyst formic acid in a molar ratio of 1:(1-4):(0.1-0.3) to react in an organic solvent; performing centrifugal washing of the product and dispersing in an organic solvent; adding palladium nitrate in a molar ratio of 1:(0.8-1.2); after the reactions, centrifuging and drying to obtain powder; dispersing the obtained powder into water; adding sodium borohydride in a molar ratio of 1:(0.5-1.5); and after the reactions, centrifuging, washing and drying to obtain the product. In the invention, the synthesized compound is an organic-inorganic composite supermolecular material and has a metal organic framework which is easy to operate and low in cost and has nanoscale particle size; and the compound has very high efficiency when being used as a catalytic material for benzyl alcohol oxidation and benzaldehyde condensation.

Owner:SHANDONG NORMAL UNIV

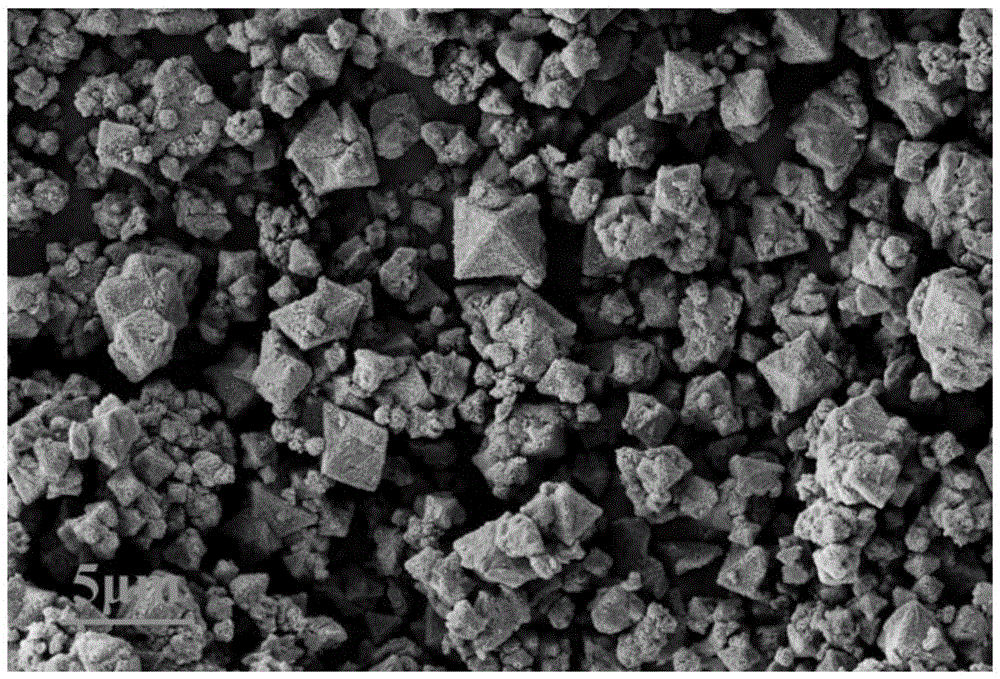

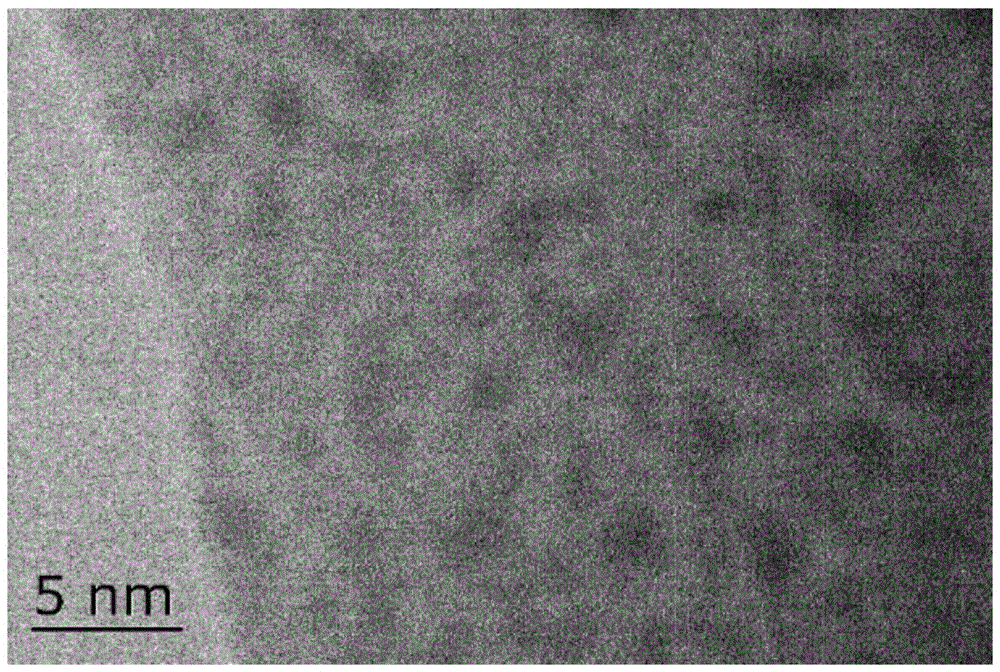

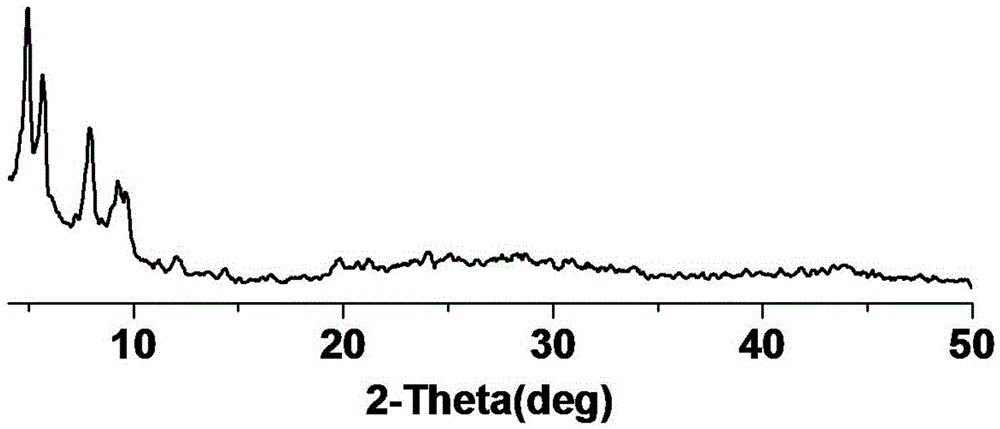

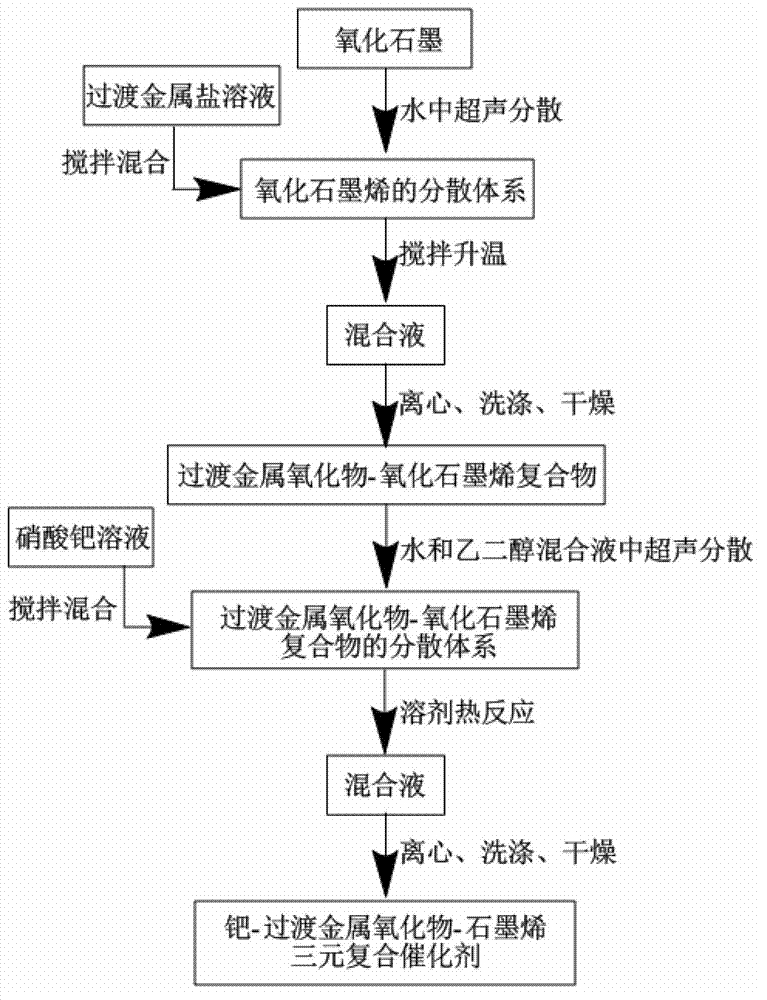

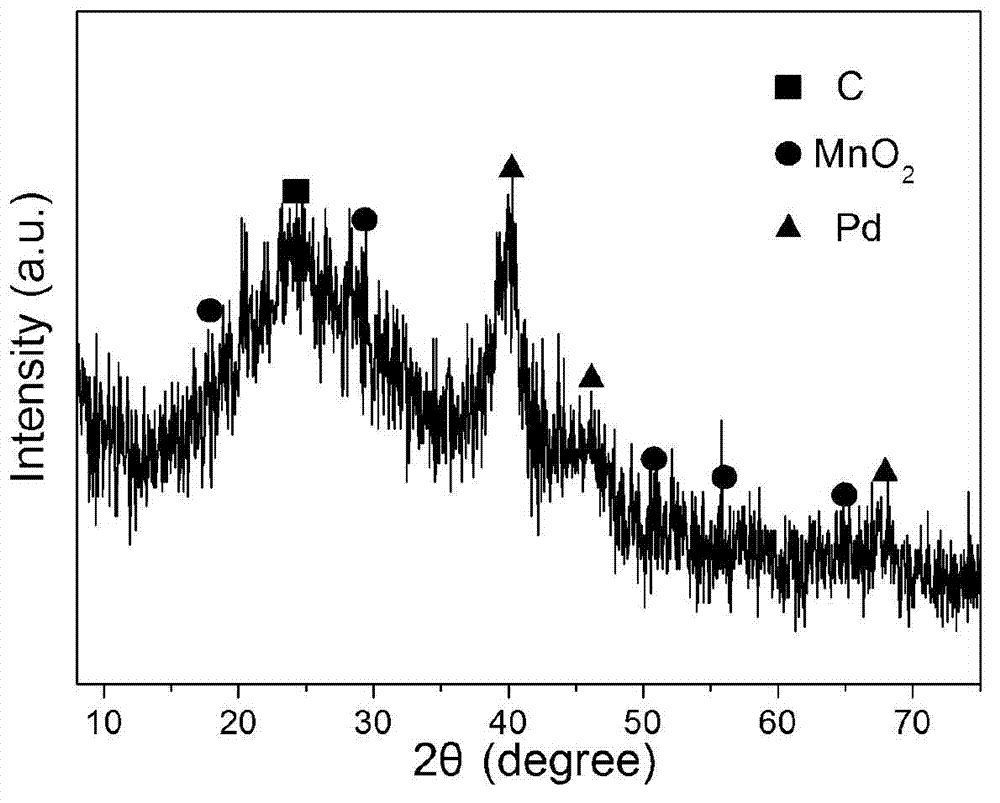

Palladium-transition metal oxide-graphene ternary composite catalyst and preparation method thereof

InactiveCN102814178AHigh catalytic activityImprove anti-poisoning performanceOrganic compound preparationCatalyst activation/preparationOrganic reactionUltrasonic dispersion

The invention relates to a palladium-transition metal oxide-graphene ternary composite catalyst and a preparation method thereof. The method comprises the following steps of: putting graphite oxide in water and performing ultrasonic dispersion; adding saline solution of transition metal to the water and continuously stirring to enable the system to be fully and evenly mixed; then, heating a certain temperature for reaction; performing centrifugal separation after the reaction is ended to obtain a solid product; putting in a mixed solution of the water and ethylene glycol for the ultrasonic dispersion; adding palladium nitrate solution to the mixed solution and evenly mixing; and then, transferring the mixed system to a hydrothermal kettle for reaction to obtain the palladium-transition metal oxide-graphene ternary composite catalyst. The catalyst is better in application prospect and economic benefit in the field of catalytic organic reaction and fuel cells.

Owner:NANJING UNIV OF SCI & TECH +2

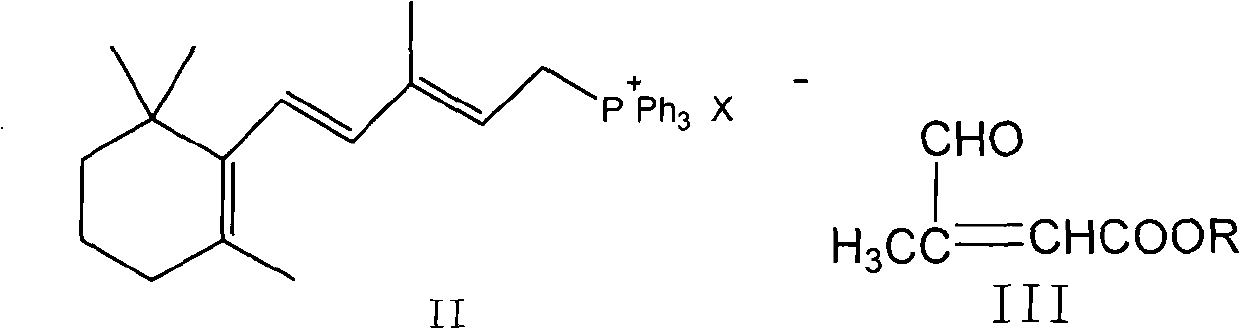

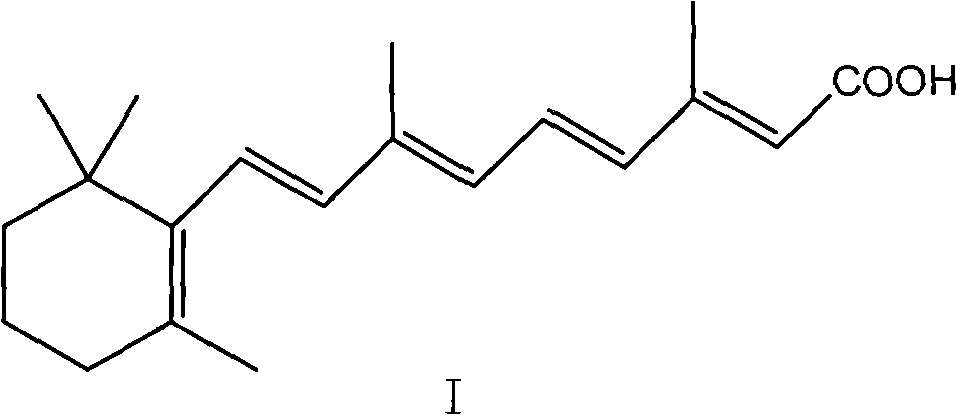

Method for preparing all-trans tretinoin

ActiveCN101774954AEasy to separateThorough responseOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsWittig reactionTretinoin

The invention provides a method for transforming 11-cis-tretinoin into all-trans tretinoin, which is characterized by using a palladium nitrate composite catalyst. The invention also provides a method for synthesizing the all-trans tretinoin, which comprises the following steps of: using compounds (II) and (III) as raw materials to perform WITTIG reaction under the action of alkali so as to obtain a mixture of all-trans retinoic acid ester and 11-cis-retinoic acid ester; performing hydrolysis and acidification to obtain a mixture of the all-trans tretinoin and an isomer 11-cis-tretinoin; and transforming the isomer to obtain the target product namely the all-trans tretinoin. The method can be finished by two steps and has the advantages of complete reaction, high yield, less isomer content in the finished product and low cost, and is suitable for industrial production.

Owner:CHONGQING HUABANGSHENGKAI PHARM

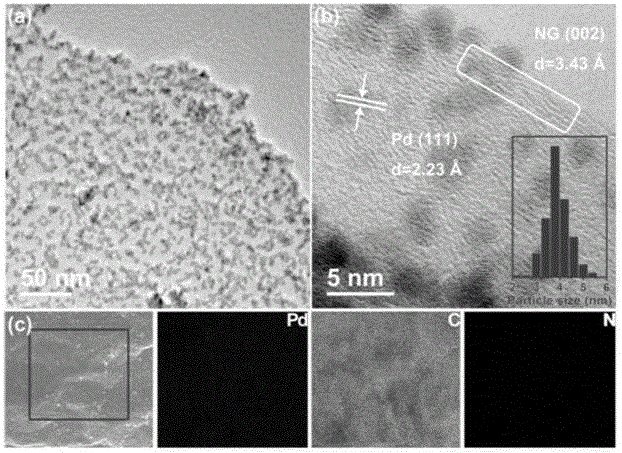

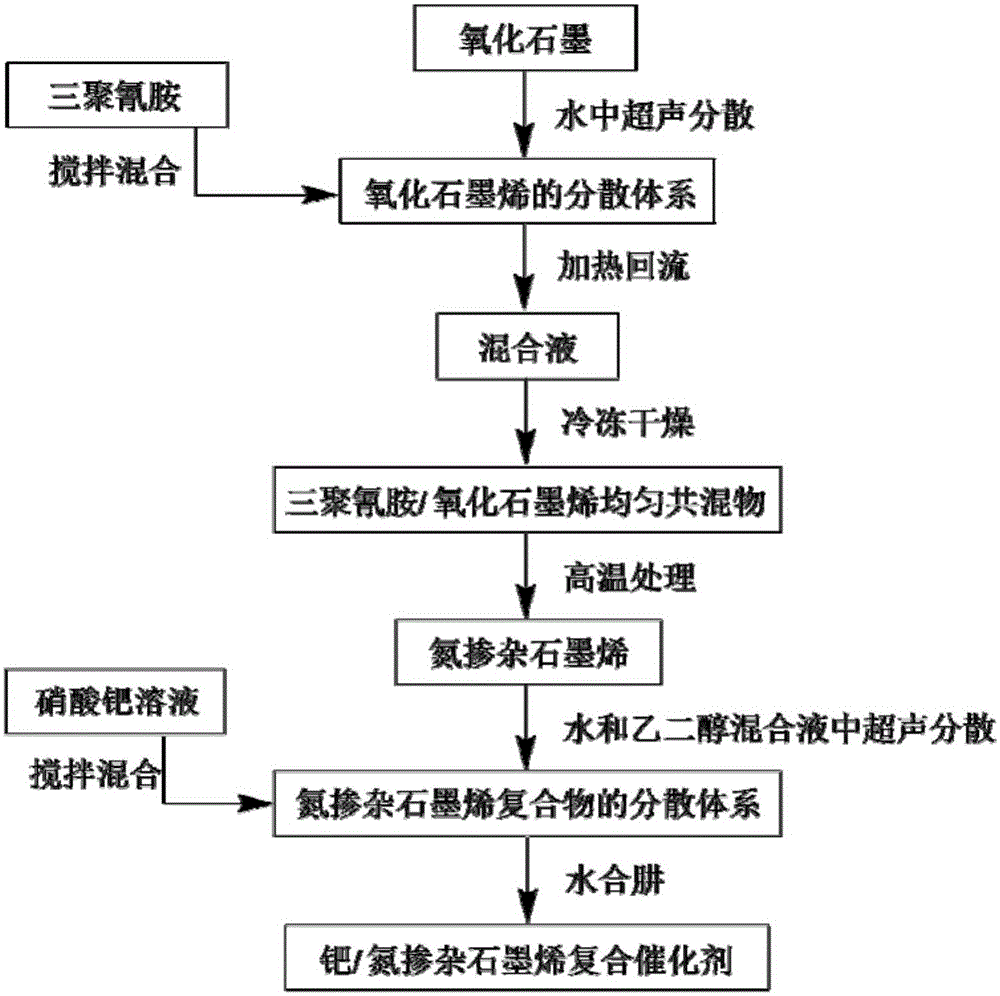

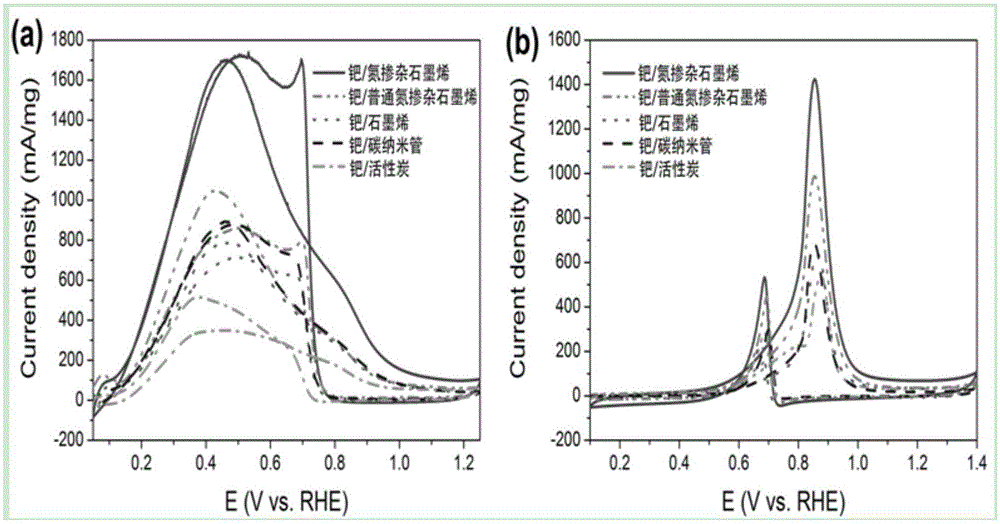

Palladium/nitrogen-doped graphene composite electrode catalyst and preparation method thereof

InactiveCN105024086AImprove electrochemical performanceGood repeatabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNitrogen doped grapheneHigh pressure

The invention discloses a palladium / nitrogen-doped graphene composite electrode catalyst and a preparation method thereof. The preparation method comprises the following steps: carrying out ultrasonic dispersion on oxidized graphene in water, adding tripolycyanamide, heating and stirring the mixture, freezing and drying the mixed system and carrying out high-temperature heat treatment, so as to obtain nitrogen-doped graphene; carrying out ultrasonic dispersion again on the nitrogen-doped graphene in an ethylene glycol solution, adding a palladium nitrate solution to the ethylene glycol solution and mixing the mixture evenly; reducing palladium nitrate by virtue of a mild reduction method, and depositing palladium nanoparticles in-situ on the surface of the nitrogen-doped graphene; and after reaction is ended, carrying out centrifugal separation to obtain a solid product, and washing and drying the product to obtain the catalyst. By virtue of the mild reduction method, the palladium nanoparticles are deposited in-situ on the surface of the nitrogen-doped graphene; and high temperature or high pressure is not needed, so that the preparation method is simple and controllable, and the repeatability is relatively good. The prepared palladium / nitrogen-doped graphene composite electrode catalyst has excellent electrochemical properties as a direct methanol / formic acid fuel cell cathode material.

Owner:NANJING UNIV OF SCI & TECH +1

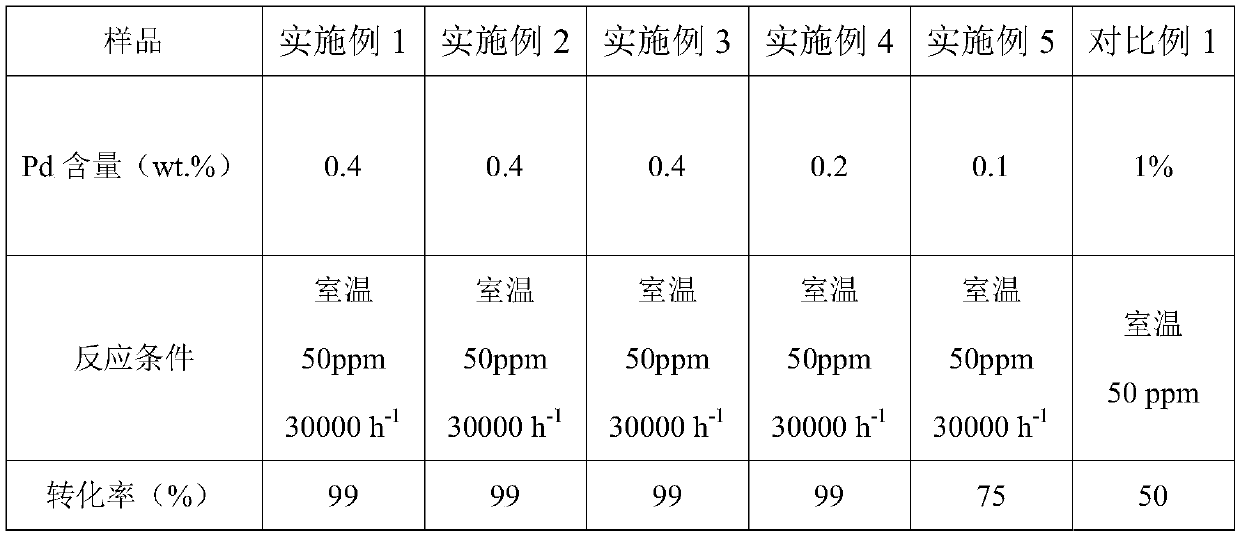

Carbon monoxide room-temperature catalytic oxidation catalyst and preparation method thereof

InactiveCN101422730ACarbon compoundsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitrate

The invention discloses a carbon monoxide oxidizing catalyst at normal temperature and a preparation method of the catalyst in the technical field of catalysts. The carbon monoxide oxidizing catalyst comprises active components, an addition agent and a catalyst carrier. The preparation method of the carbon monoxide oxidizing catalyst comprises following steps: palladium nitrate and heavy metallic nitrate are prepared to be a steeping fluid, the steeping fluid is poured into the catalyst carrier at preserved temperature so as to produce a catalyst precursor, and finally the catalyst precursor is dried and baked to obtain the catalyst. Compared with the prior art, the carbon monoxide oxidizing catalyst has better catalytic activity and stability, low preparation cost, and simple, convenient and popular preparation technique.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

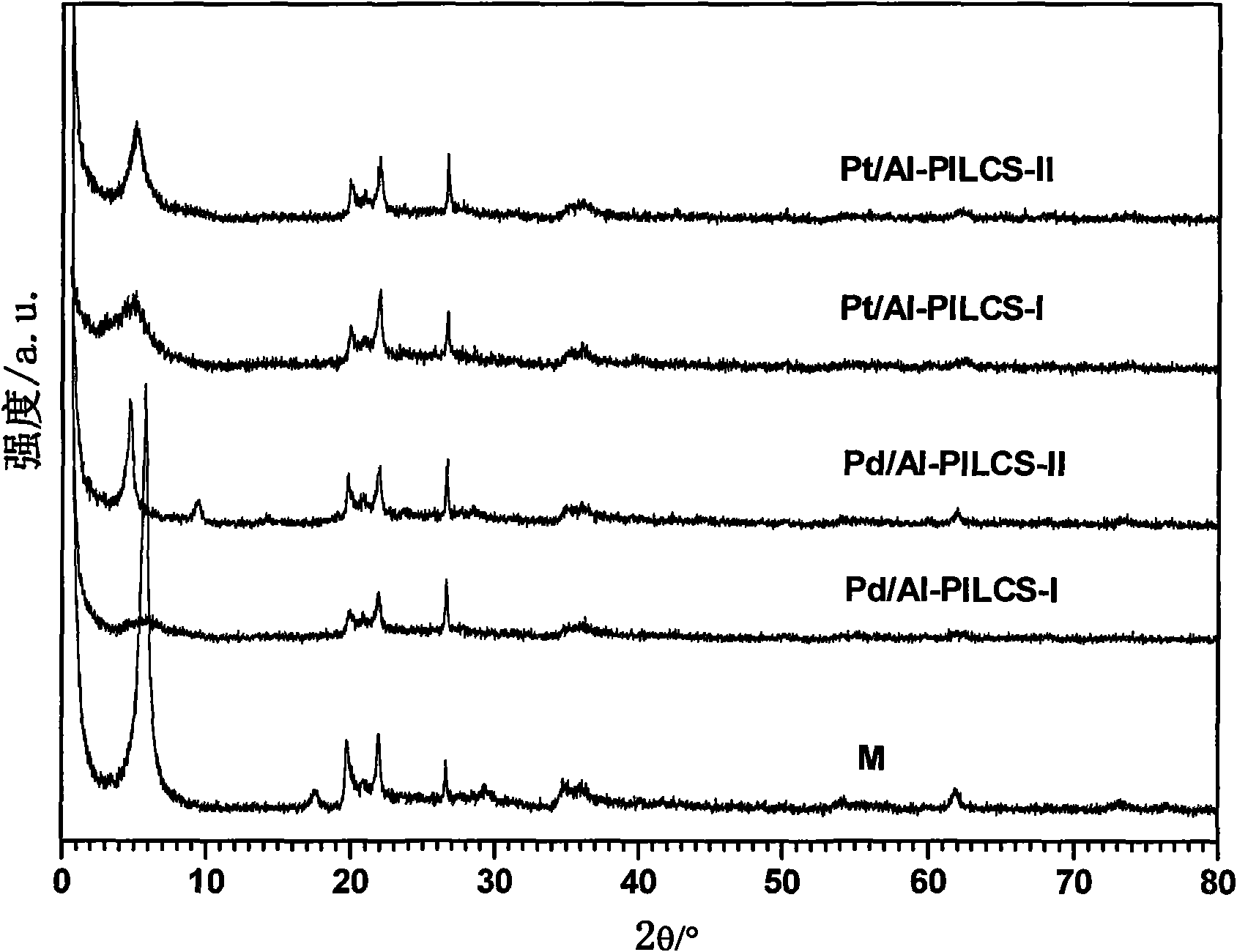

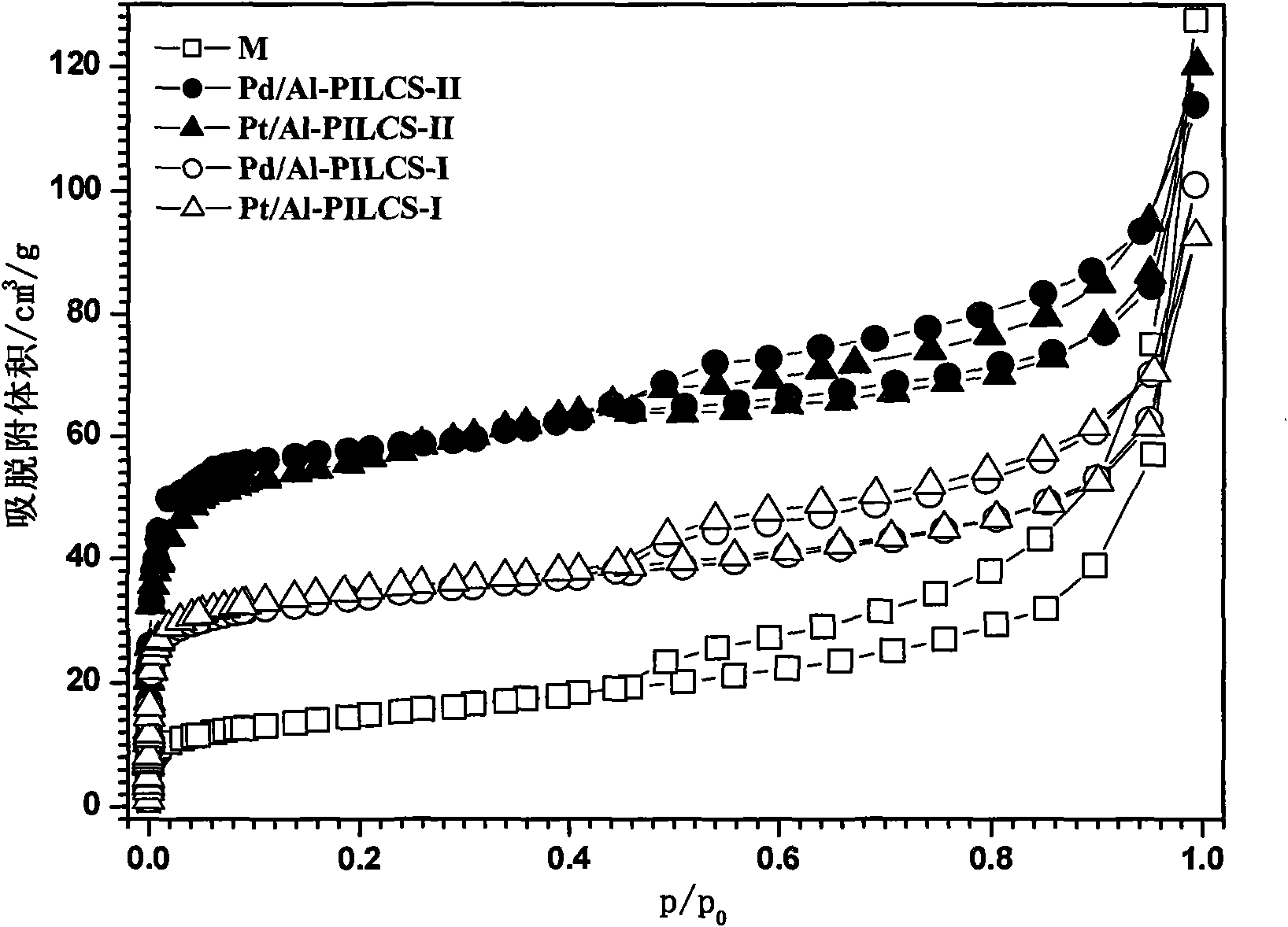

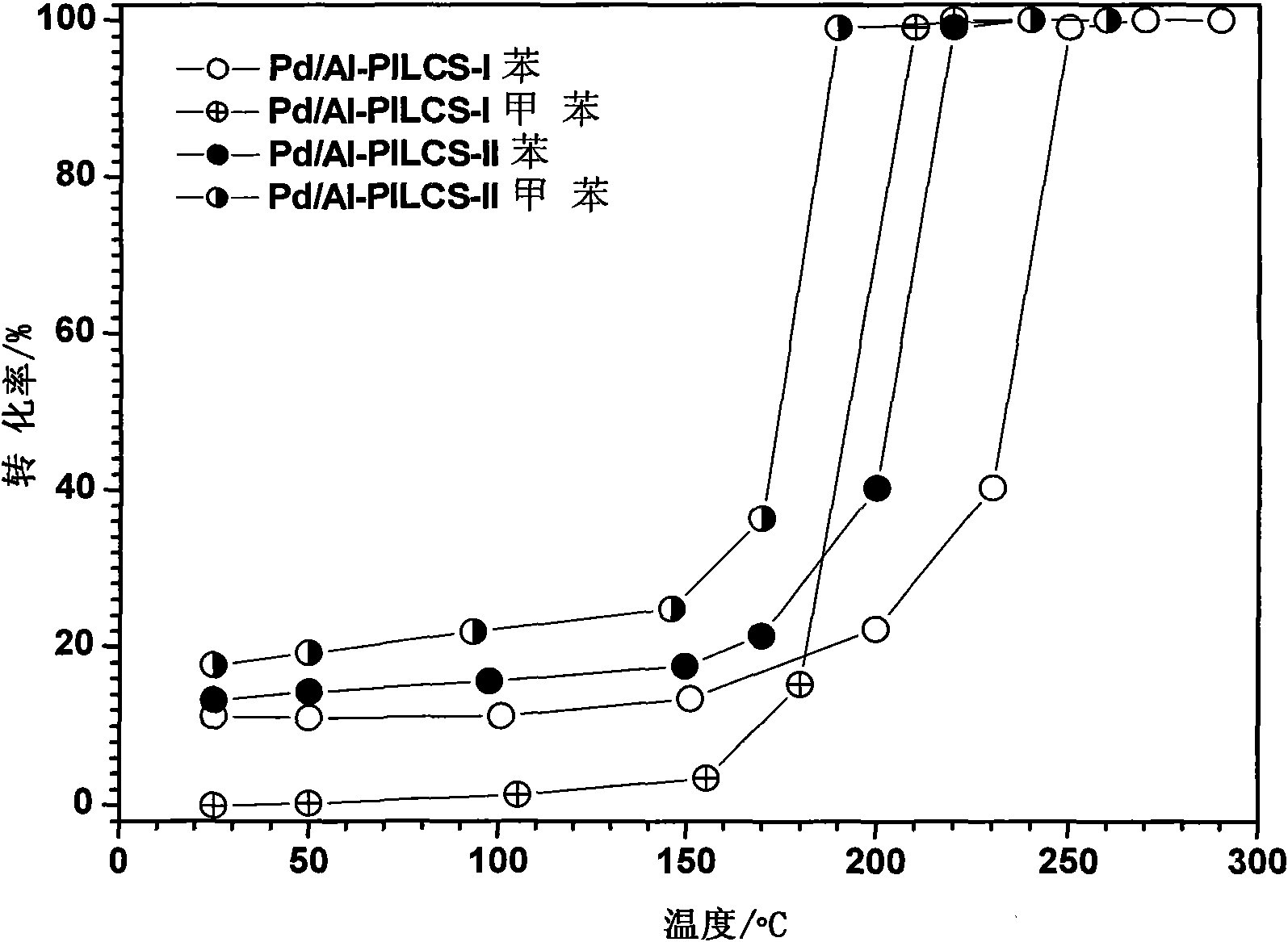

Aluminum-manganese-pillared montmorillonite load catalyst for eliminating benzene series at low temperature as well as preparation and application thereof

InactiveCN101927162AHigh and low temperature catalytic combustion to eliminate activityEasy to makeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAluminum IonLow load

The invention discloses an aluminum-manganese-pillared montmorillonite load catalyst for eliminating benzene series at low temperature as well as preparation and application thereof, belonging to the technical field of catalytic combustion. The catalyst is prepared by loading Pt or Pd on an aluminum-manganese-pillared montmorillonite carrier; the aluminum-manganese-pillared montmorillonite carrier is a composite material which is prepared by inserting hydroxyl manganese and aluminum ions into sodium-treated montmorillonite interlayer and treating; and the aluminum-manganese-pillared montmorillonite load catalyst is prepared by adding palladium nitrate or a chloroplatinic acid solution in an aluminum-manganese-pillared montmorillonite slurry, adjusting the pH value to be 8-1, adding an NaBH4 solution, stirring and washing with water to be neutral and drying. The catalyst has large specific surface area, ordered aluminum-manganese-pillared structure and low load amount of noble metals of Pd and Pt, is used for catalyzing and combusting at low temperature to eliminate the benzene series and has higher efficiency and stability, cheap raw material for preparation and simple preparation process.

Owner:BEIJING UNIV OF TECH

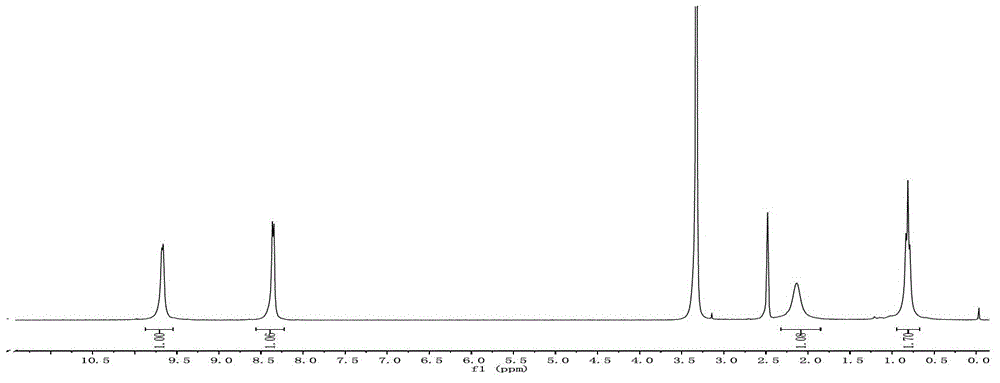

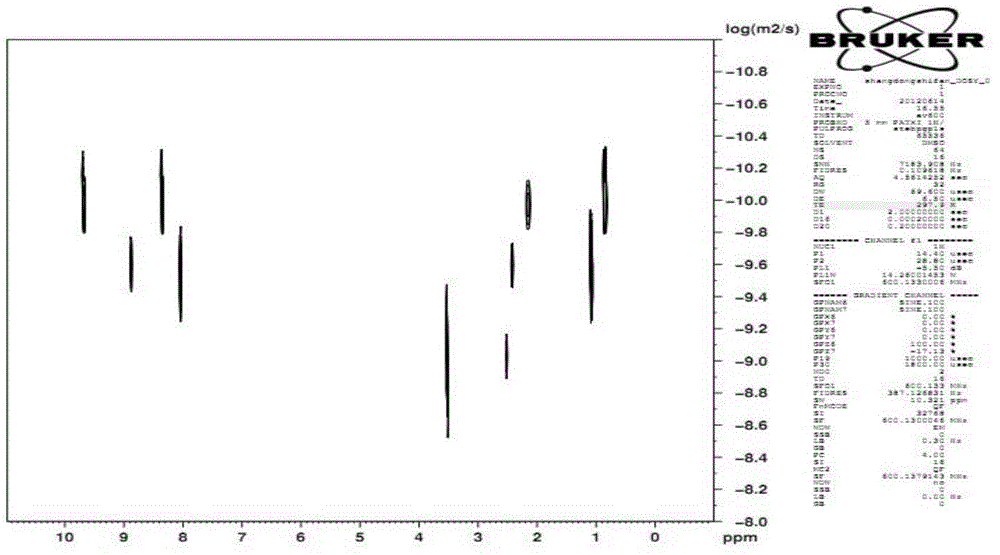

Palladium catalyst for catalyzing Suzuki coupling reaction, synthesis method, application and ligand

InactiveCN102744106AHigh activityReduce dosageCarboxylic acid nitrile preparationOrganic compound preparationSynthesis methodsReaction temperature

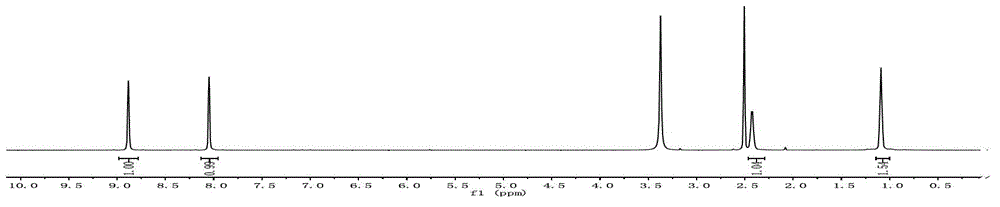

The invention discloses a palladium catalyst for catalyzing a Suzuki coupling reaction, a synthesis method, application and a ligand. The chemical structural formula of the palladium catalyst is Pd6(L11)8(NO3)12. The synthesis method comprises the following steps: (A) heating 2,4,6-triethyl-1,3,5-trimesic acid and SOCl2 of a refluxing volume to carry out a refluxing reaction until the system is clear; (B) adding 5-(4-pyridyl) tetrazole to the reaction system, keeping the refluxing reaction for 2-3 hours in anhydrous pyridine, separating and purifying to obtain the ligand L; and (C) heating the ligand L and palladium nitrate in DMSO (dimethylsulfoxide) at the temperature of 60-70 DEG C for carrying out the refluxing reaction for 2-3 hours, separating and purifying to obtain the catalyst Pd6L8(NO3)12. The invention further provides the application of the palladium catalyst in catalyzing the Suzuki coupling reaction and the ligand. An oxygen-free operation is not needed for the novel palladium catalyst provided by the invention, reagents with larger toxicity, such as toluene, are avoided, the reaction temperature and the reaction time are greatly reduced and shortened, and the activity of the catalyst is higher. The invention is hopefully widely applied on the aspects of medicinal molecules requiring a Suzuki coupling technology and the cleaner production of the ligand.

Owner:SHANDONG NORMAL UNIV

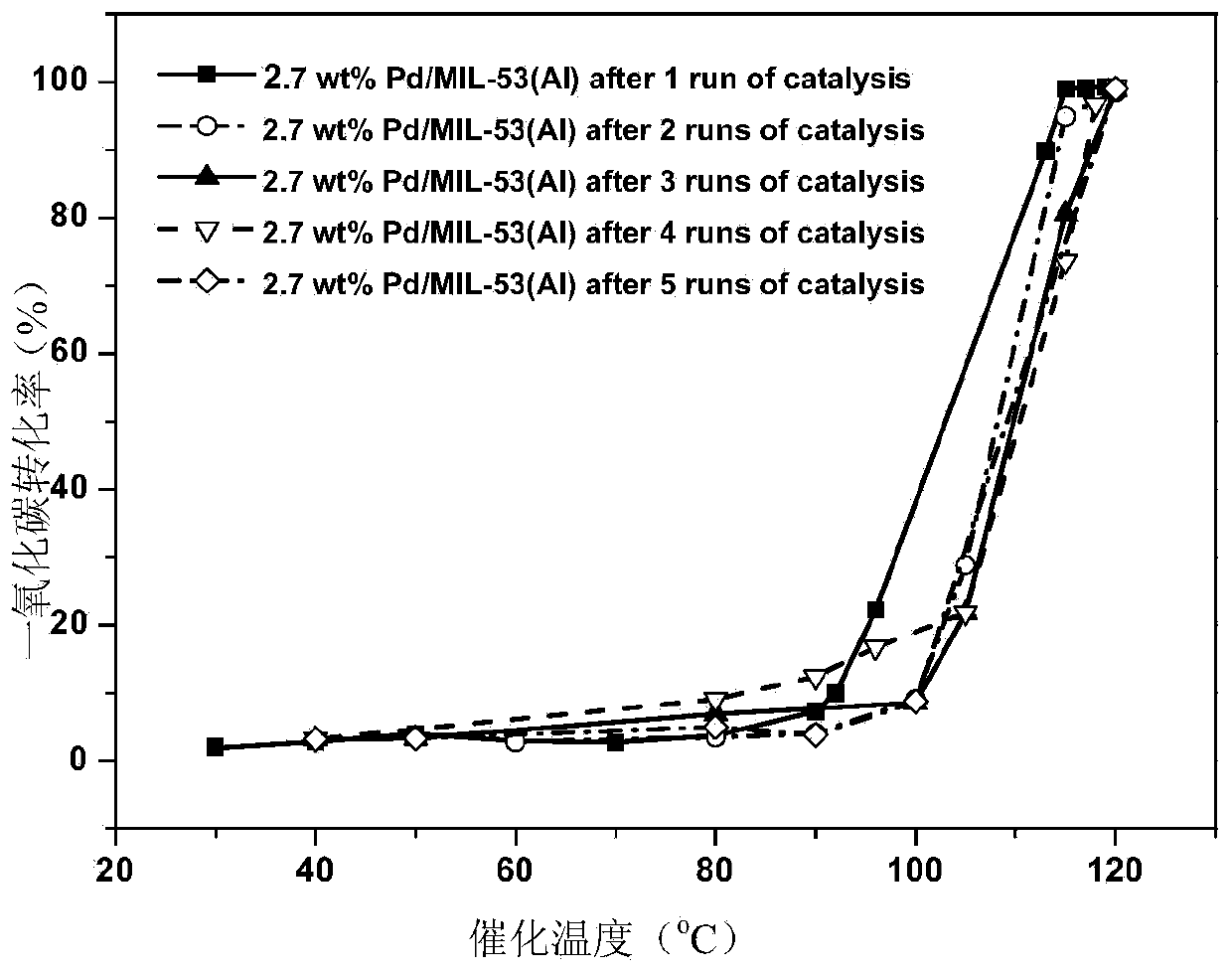

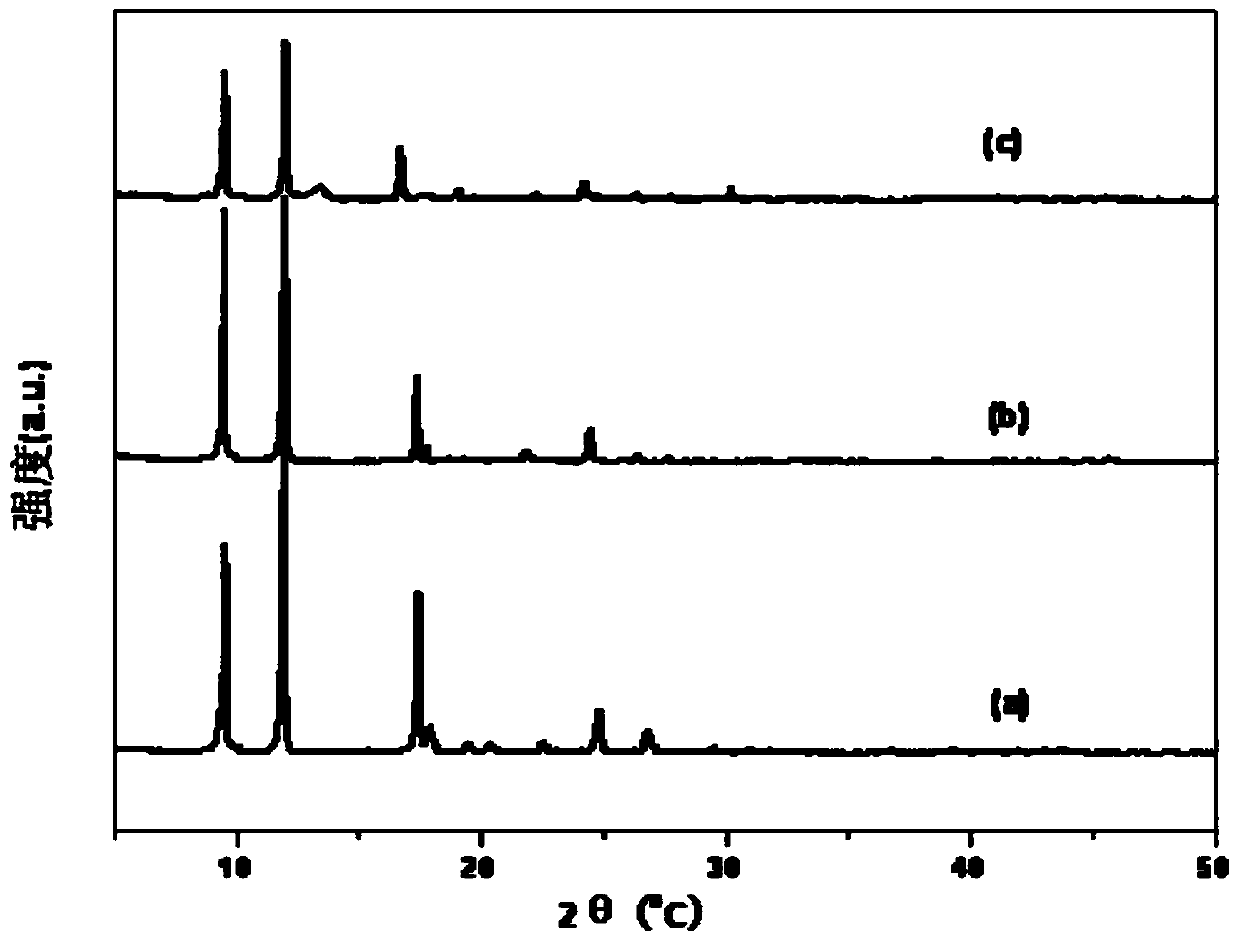

Pd/MIL-53(Al) catalyst, preparation and application thereof

InactiveCN104437640AUniform structureGood chemical stabilityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationStructural formulaBiological activation

The invention relates to a Pd / MIL-53(Al) catalyst, preparation and application thereof. The preparation method includes: letting terephthalic acid, aluminum nitrate and deionized water in a mass ratio of 1:5:20-30 react, conducting natural cooling to room temperature, and carrying out filtering and drying to obtain MIL-53(Al); and performing roasting to obtain a high specific surface area carrier, adding palladium nitrate, and conducting equivalent-volume impregnation to obtain a mixed solution, carrying out drying, and introducing Ar / H2 (0.1-0.2L / min) to conduct reduction activation so as to obtain the Pd / MIL-53(Al) catalyst. The loading capacity of palladium is 1-8wt%; the structural formula of MIL-53(Al) is [Al(OH)(O2C-C6H4-CO2)]. The catalyst is suitable for catalytic elimination of CO in catalytic cracking catalyst regeneration device discharged flue gas and motor vehicle exhaust, and has the advantages of large specific surface area, uniform distribution of active components, high catalytic activity, high thermal stability, easy synthesis, reduction of CO catalytic conversion temperature, and low consumption of precious metals.

Owner:PETROCHINA CO LTD

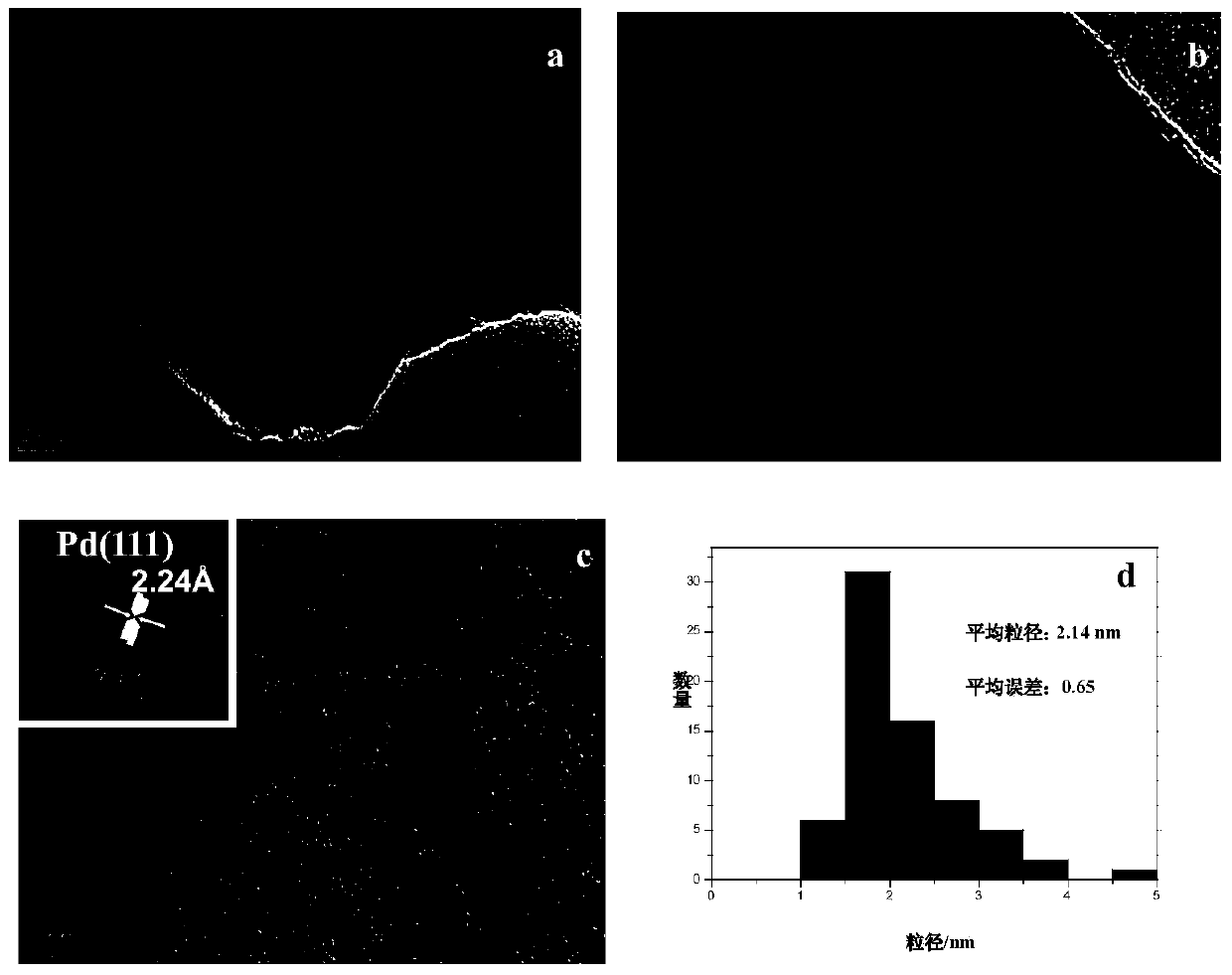

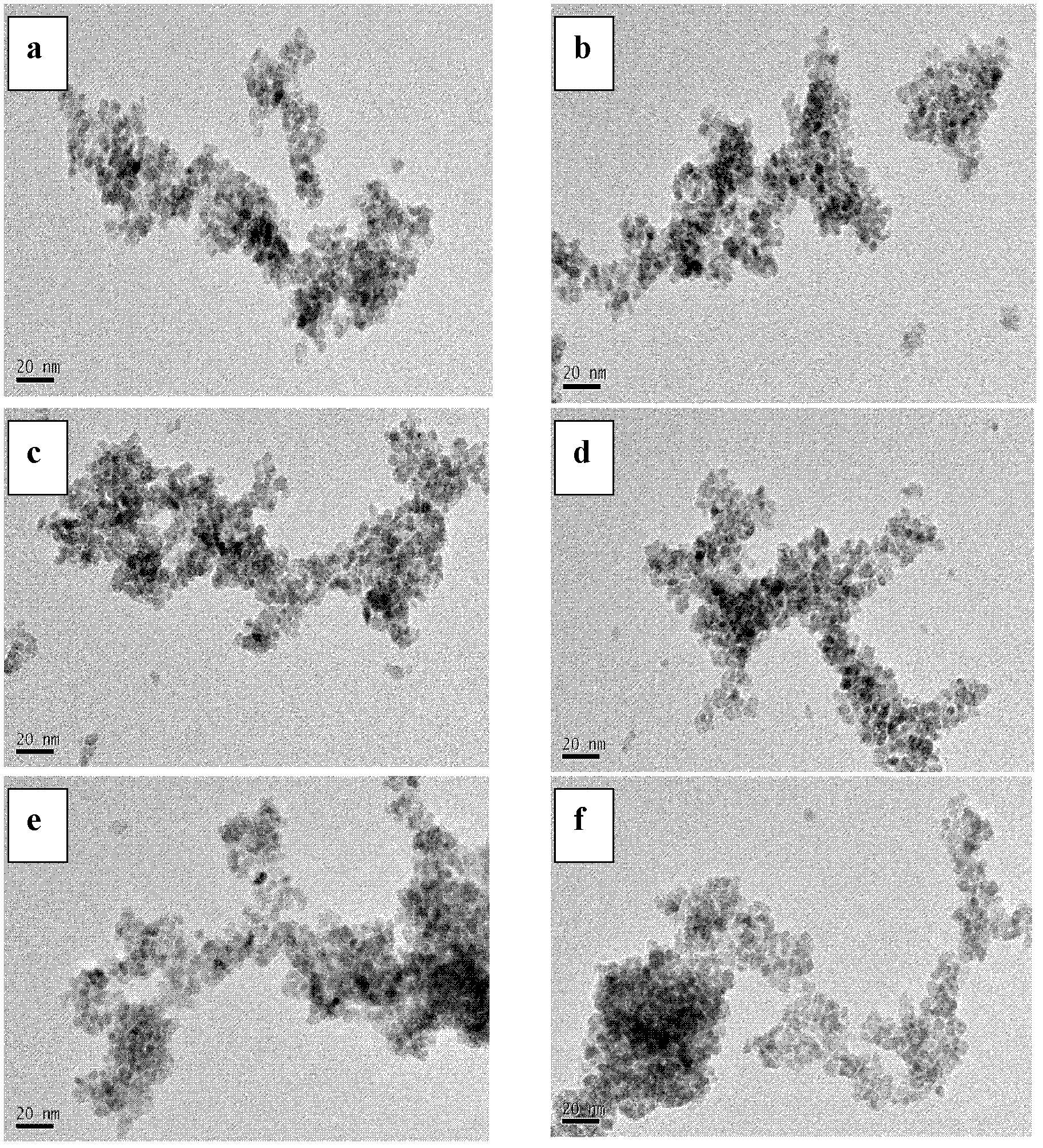

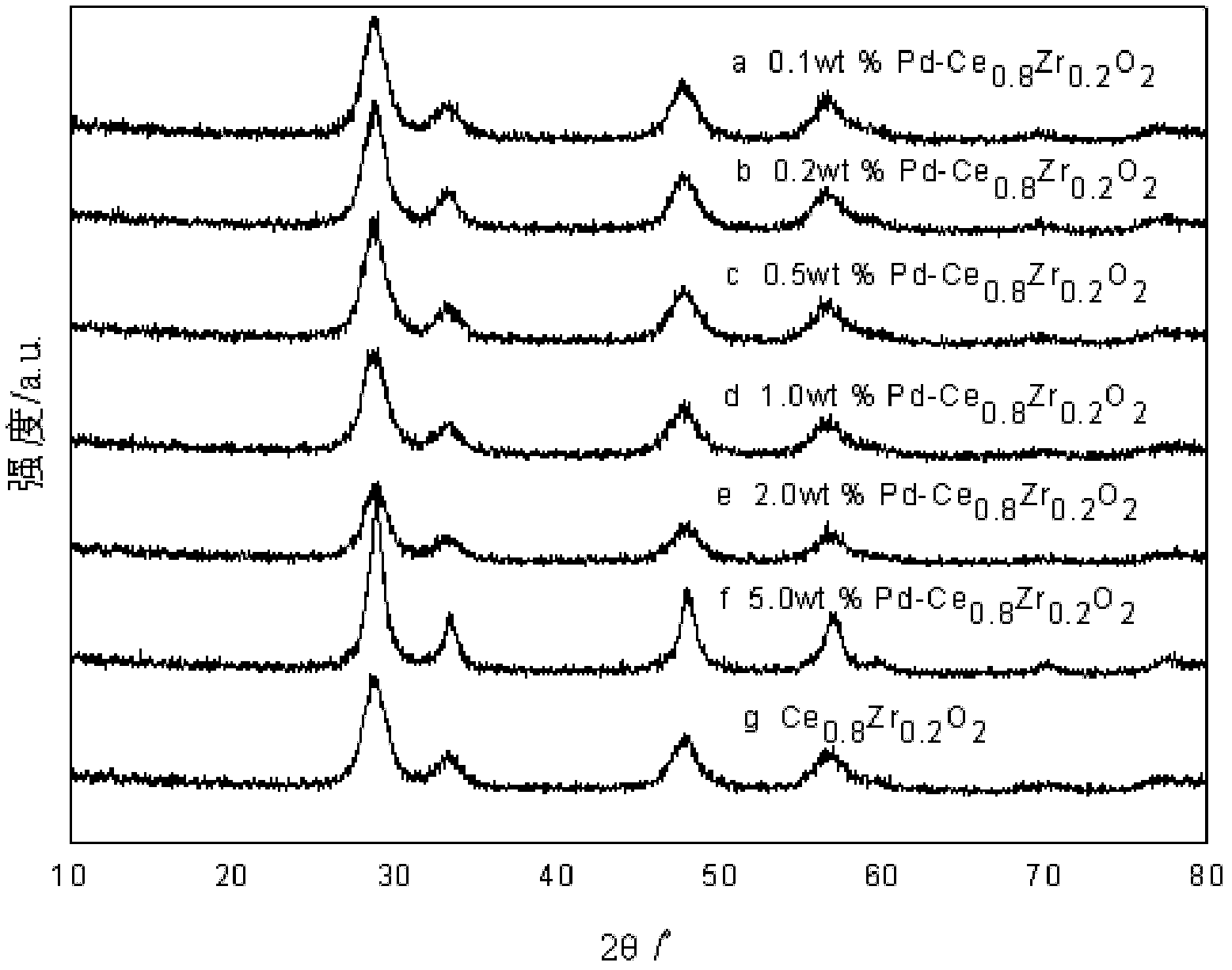

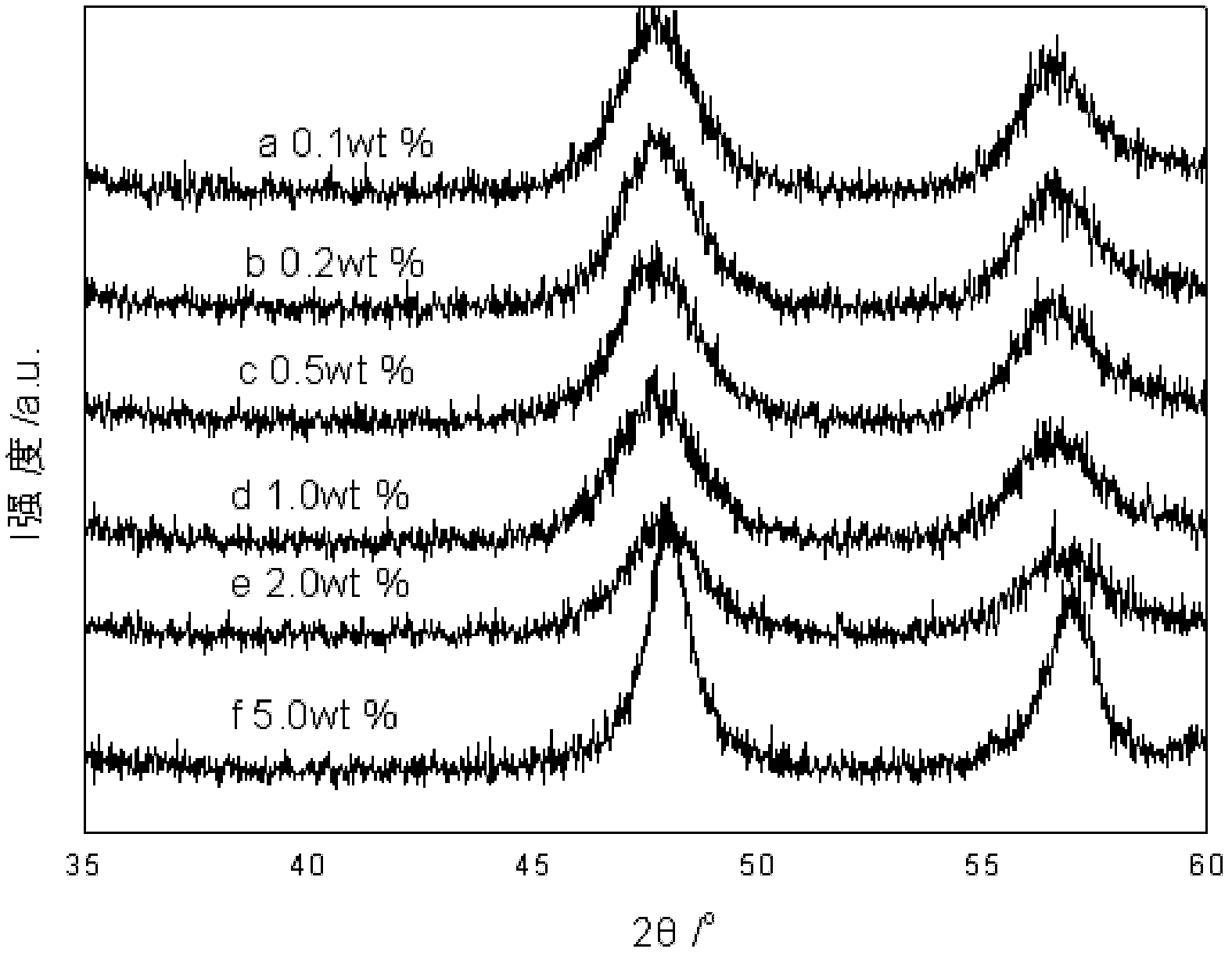

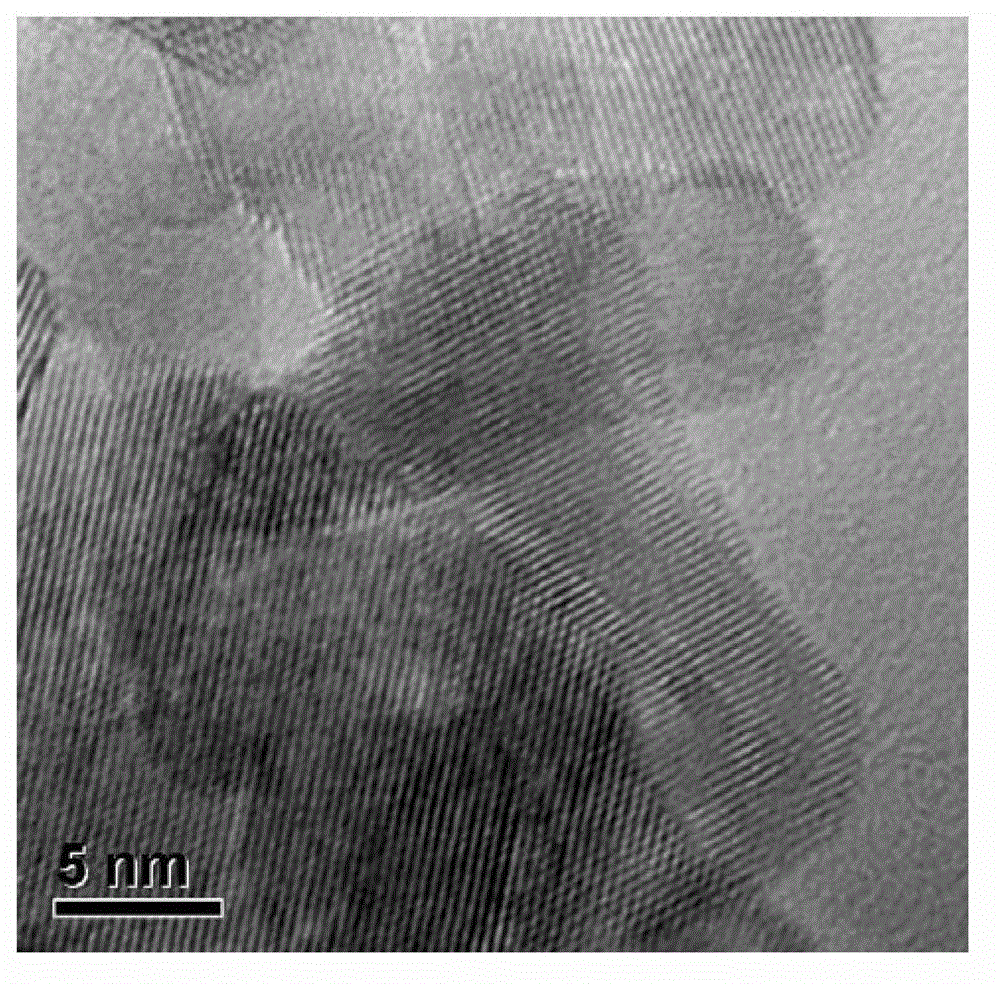

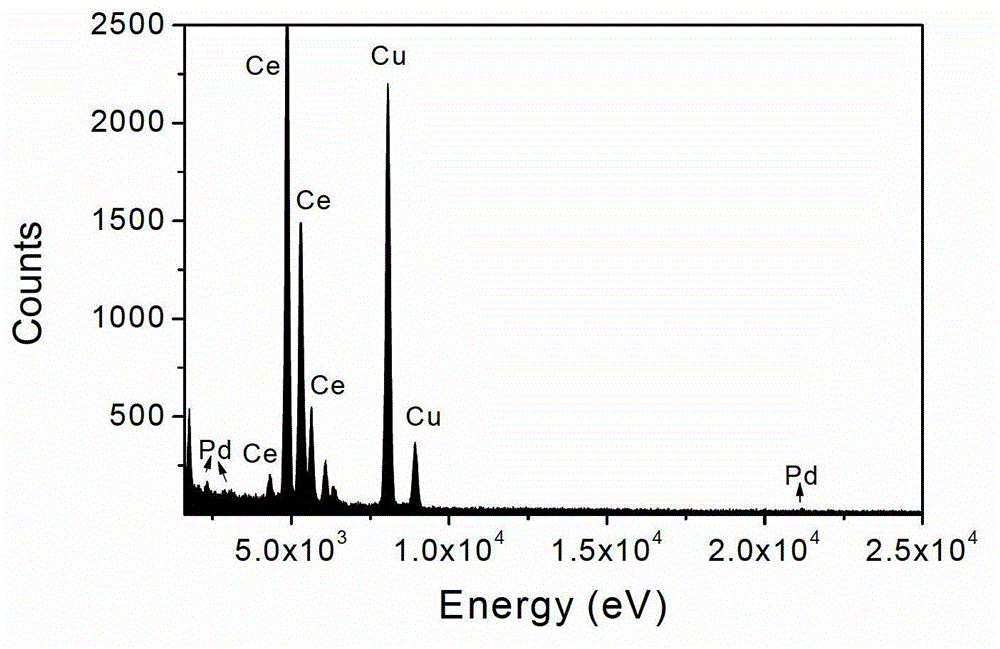

Cerium-zirconium-palladium nanopowder catalyst and preparation and application thereof

ActiveCN102658137AUniform structureGood chemical stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsCerium

The invention relates to a preparation method for a cerium-zirconium-palladium nanopowder catalyst. The preparation method comprises the following steps: dissolving a cerium source and a zirconium source in absolute ethanol, and adding P123 template agent to obtain sol; adding palladium nitrate; keeping constant temperature of 35DEG C and constant relative humidity of 40 percent, and performing evaporation induction to form gel; drying at the temperature of 100DEG C; calcining at the temperature of 400DEG C for 4 hours at the temperature rise rate of 1DEG C per minute; and ensuring that the atomic mole ration of cerium to zirconium is 8:2, the palladium loading quantity is 0.1 to 5 weight percent, and a ratio of the cerium source and the zirconium source to the absolute ethanol to the P123 is 10mmol:20ml:1g. The catalyst is suitable for catalytic elimination of CO in flue gas discharged by a catalytic cracking catalyst regeneration device and Co in tail gas of motor vehicles and has the advantages of large specific surface area, uniform distribution of noble metal active ingredients, high catalytic activity and thermal stability, and simple synthesis method; the temperature for complete catalytic conversion of CO can be greatly reduced; the consumption of noble metals is reduced; and the cost of the catalyst is reduced.

Owner:PETROCHINA CO LTD

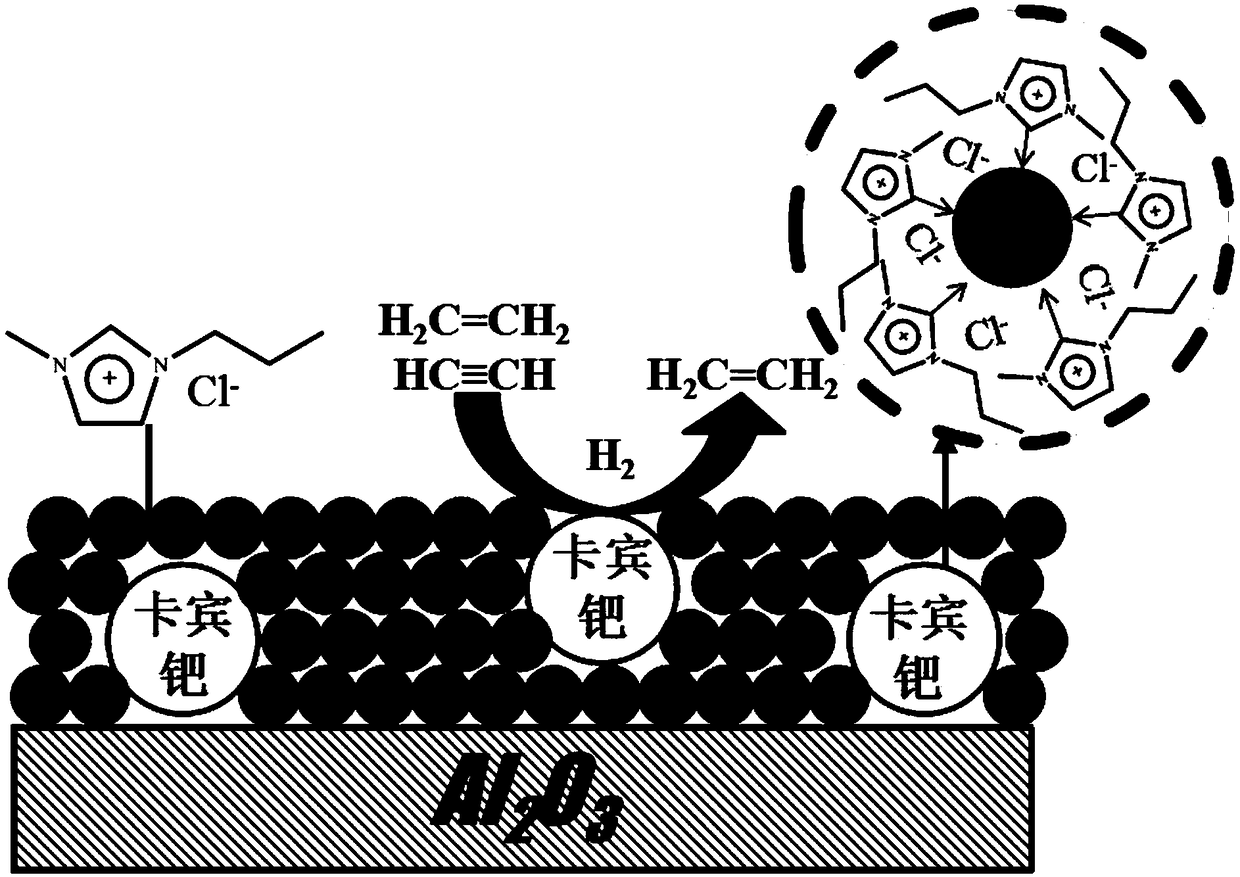

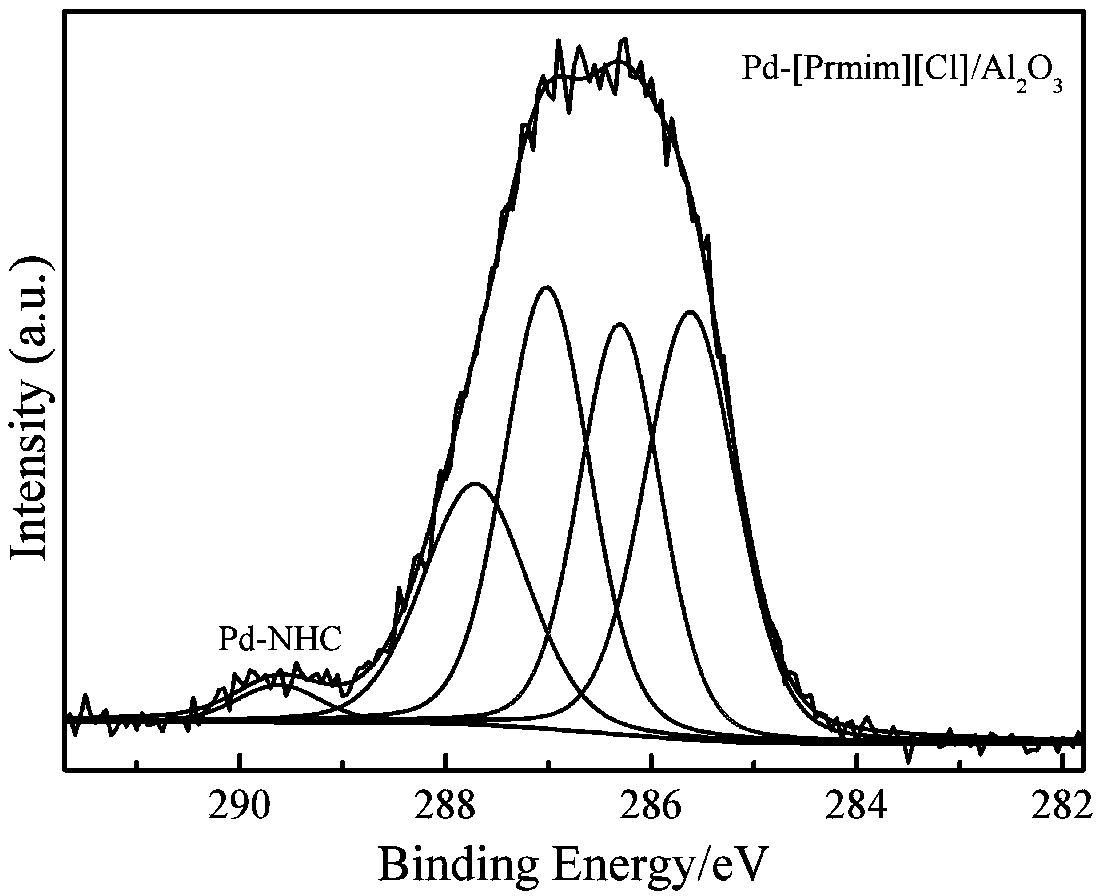

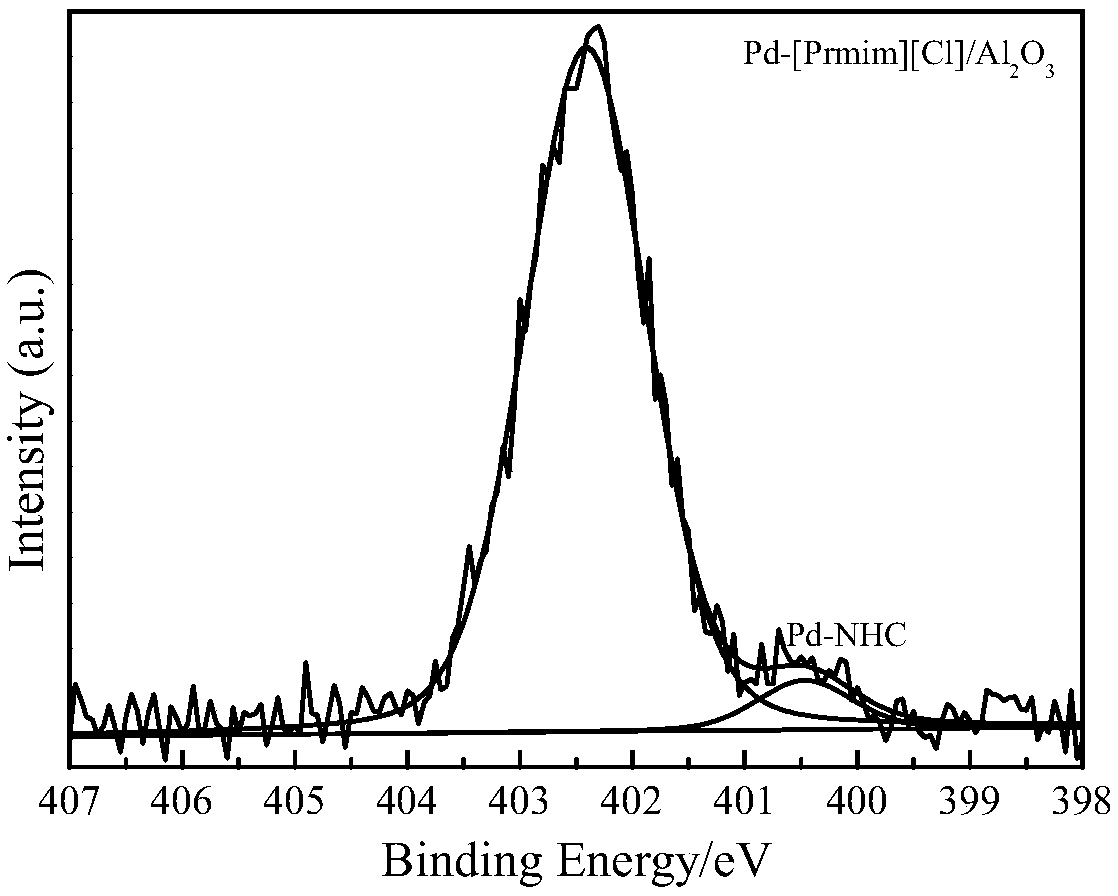

Aluminum oxide-loaded ionic liquid-palladium catalyst, preparation thereof and application thereof in hydrogenation reaction of acetylene

ActiveCN109174177AFacilitate desorptionImprove conversion rateHydrocarbon by hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsPalladium catalystCarbon chain

The invention discloses an aluminum oxide-loaded ionic liquid-palladium catalyst, preparation thereof and application thereof in the hydrogenation reaction of acetylene. The catalyst contains an aluminum oxide carrier, ionic liquid and a palladium compound, wherein the surface of the aluminum oxide carrier is loaded with the ionic liquid and the palladium compound; the palladium compound is selected from one of chloropalladic acid, palladium nitrate, palladium acetate, palladium acetylacetonate, palladium dichloride, ammonium tetrachloropalladate, sodium chloropalladate, tetraammine palladiumnitrate; cations of the ionic liquid are imidazole cations with different carbon chain lengths, and anions are chloride ions, bromide ions, hexafluorophosphate, tetrafluorophosphate or tetrafluoroborate; a layer of liquid film is formed on the surface of the carrier by the ionic liquid, and a carbene structure is further formed by the ionic liquid and the palladium compound; and the loading capacity of palladium in the catalyst is 0.03wt%-1wt%, and the loading capacity of the ionic liquid is 8wt%-40wt%. The catalyst is applied to the selective hydrogenation of acetylene so as to desorb acetylene, so that the selectivity of acetylene in the reaction is greatly improved.

Owner:ZHEJIANG UNIV OF TECH

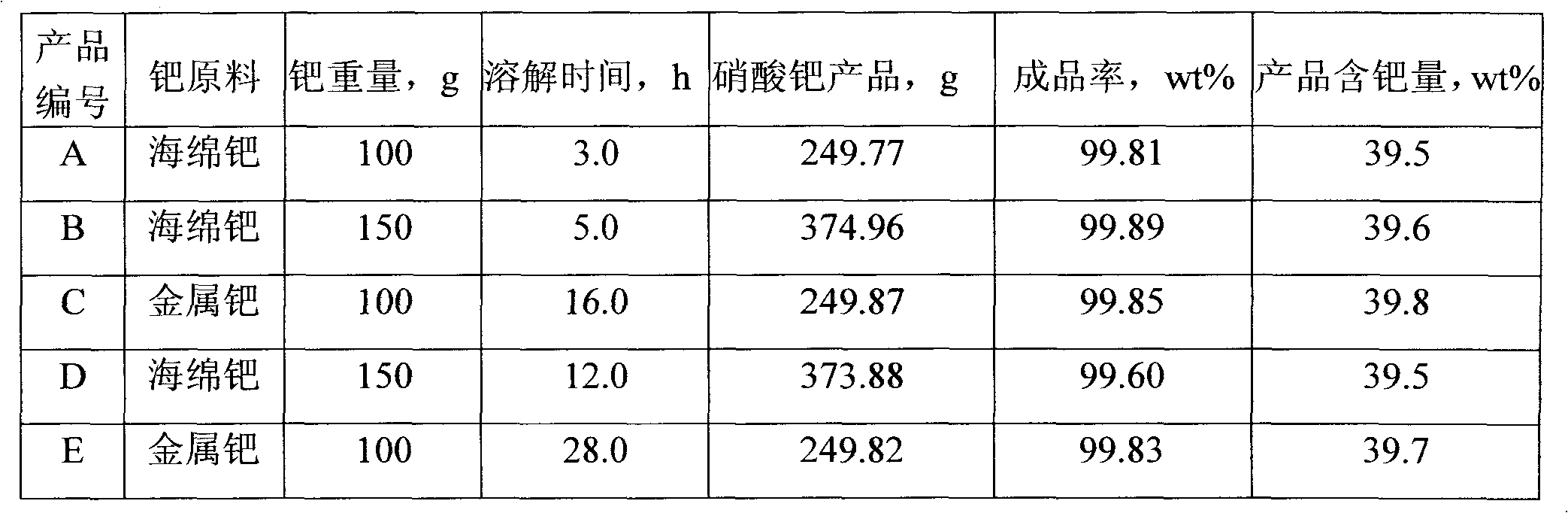

Method for preparing palladium nitrate

InactiveCN102311147AImprove solubilityFast dissolutionRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsState of artDissolution

The invention discloses a method for preparing palladium nitrate, which comprises the following steps of: putting high-purity metal palladium or sponge palladium into a container, slowly adding concentrated nitric acid and hydrogen peroxide by batches, and heating for dissolution; cooling and filtering the solution, heating for evaporating and concentrating until solid-state crystal grains appear on liquid surface, and cooling for crystallization; and washing the obtained crystals with cold water, performing vacuum drying, and grinding into powder to obtain the palladium nitrate product. Compared with the prior art, the method has the advantages that: the concentrated nitric acid and the hydrogen peroxide are added slowly by batches in the dissolving process, the palladium dissolving capacity is improved, the reaction speed is improved, the using amount of the concentrated nitric acid is reduced, steps are simple, the efficiency is high, the production cost is low, and the palladium nitrate contains crystal water, has homogenous property and the purity close to 100 percent, and is a high-quality palladium nitrate product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of Pd-Fe/SiO2 hydrogenation catalyst

InactiveCN105797748AInhibit growthImprove catalytic stabilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsNitrateHydrogenation reaction

The invention provides a preparation method of a Pd-Fe / SiO2 hydrogenation catalyst. The method comprises the following steps that 1, tetraethyl orthosilicate, ferric nitrate and one of P123 or tetrapropyl ammonium hydroxide (TPAOH) are mixed, the mixture is dissolved with a HNO3 solution under magnetic stirring at room temperature, and then a hydrothermal reaction is conducted; 2, obtained precipitates are adjusted to be certain pH with the HNO3 solution and aged at room temperature, centrifugal washing, drying and roasting are sequentially conducted, and a carrier is obtained; 3, the carrier is subjected to equivalent-volume impregnation with a palladium nitrate solution, excessive impregnation is conducted with a NaOH solution, washing, drying and roasting are sequentially conducted, and the efficient loaded-type palladium catalyst is obtained. The preparation method of the Pd-Fe / SiO2 hydrogenation catalyst has the advantages that the preparation conditions are mild, and the Fe-additive is introduced in one step in the process of preparing the carrier precursor through a hydrothermal method; the prepared catalyst has good activity, selectivity and stability to an anthraquinone hydrogenation reaction, and the highest catalytic activity of the catalyst is increased by 143% compared with an industrial catalyst.

Owner:WUHAN UNIV OF TECH

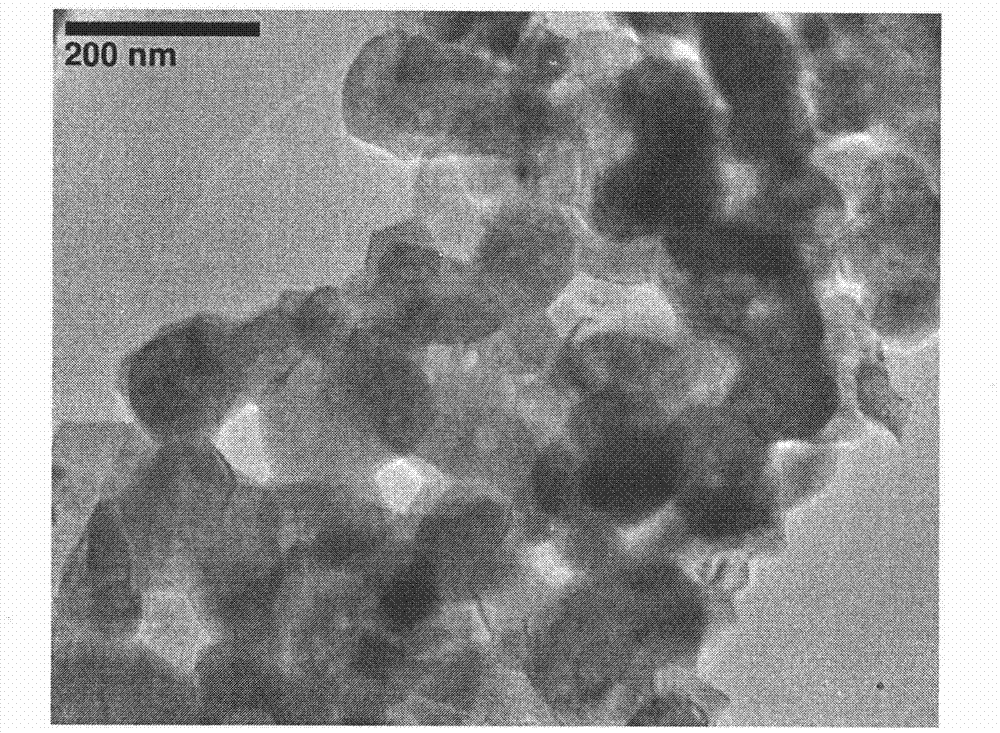

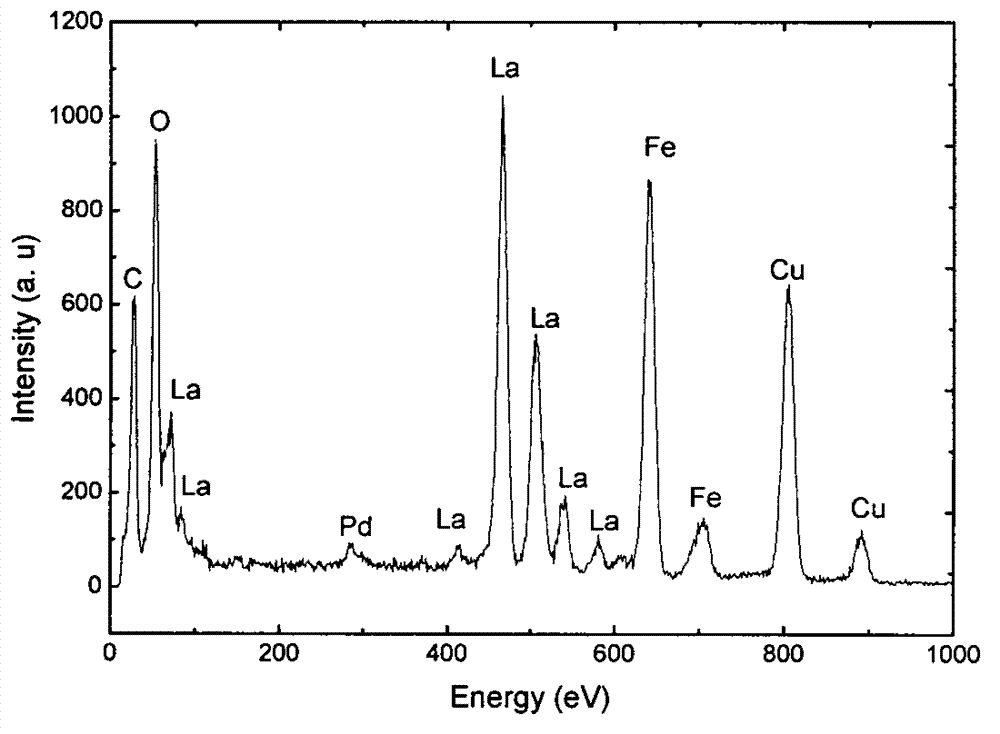

Palladium-doped lanthanum ferrite powder preparation method

InactiveCN103922415ALow priceGuaranteed chemical uniformityIron compoundsMetal/metal-oxides/metal-hydroxide catalystsNitratePolyethylene glycol

The present invention discloses a palladium-doped lanthanum ferrite powder preparation method, which comprises: selecting raw materials such as lanthanum nitrate, iron nitrate, palladium nitrate, citric acid and polyethylene glycol; and respectively weighing lanthanum nitrate, iron nitrate and palladium nitrate according to a ratio of mol(La)<3+> to mol(Fe)<3+> to mol(Pd)<2+> of 1:(1-x):x, adopting deionized water to respectively dissolve, mixing the obtained three solutions, adding citric acid and polyethylene glycol, uniformly mixing to obtain a transparent sol, evaporating water from the sol to obtain a wet gel, drying the wet gel to obtain precursor dry gel powder, and calcining the precursor dry gel powder to obtain the palladium-doped lanthanum ferrite powder, wherein x is 0.05-0.1, the molar amount of the added citric acid is 1.0-1.5 times the total molar amount of the lanthanum nitrate, the iron nitrate and the palladium nitrate, and the weight of the added polyethylene glycol is 0-0.3 time the weight of the citric acid. The method has advantages of low cost, market prospects, high product sample purity, good uniformity and the like.

Owner:LANZHOU UNIVERSITY

Preparation method of catalyst for CO gas-phase catalyzed synthesis of dimethyl oxalate

InactiveCN105597743AReduce usagePreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsDispersityGas phase

The invention provides a preparation method of a catalyst for CO gas-phase catalyzed synthesis of dimethyl oxalate. Palladium chloride, palladium nitrate, palladium acetate and other conventional palladium salt are used as precursors, spherical aluminum oxide with the diameter of 1-5 mm is used as a carrier, and a dipping and direct-reduction mode, namely direct reduction and dipping conducted on carrier spheres precious metal components by adopting a mild reducing agent, is adopted to enable an active component palladium to be supported on an alumina carrier in more optimized state so as to prepare the supported Pd-M / Al2O3 catalyst. The catalyst prepared by means of the method has higher active component dispersity and has good catalytic activity on CO based dimethyl oxalate synthesis reaction under the condition of lower precious metal content.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

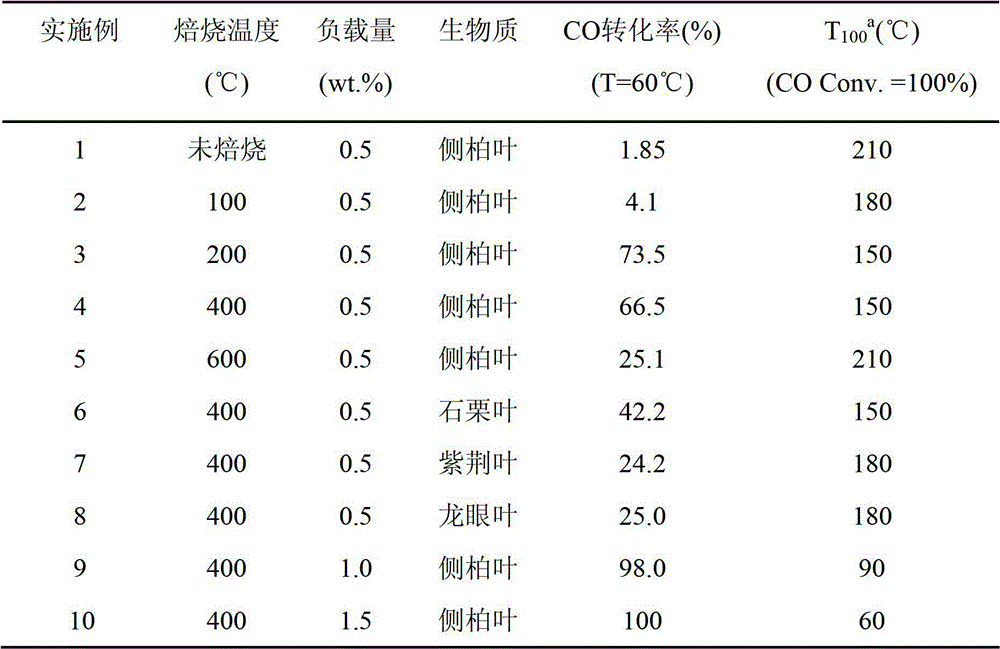

Bio-reduction preparation method of palladium catalyst

InactiveCN102744063AHigh activityMetal/metal-oxides/metal-hydroxide catalystsRoom temperaturePalladium catalyst

The invention provides a bio-reduction preparation method of a palladium catalyst, relating to the palladium catalyst. The bio-reduction room-temperature preparation method of the palladium catalyst without adding any chemical protectant is provided. The preparation method comprises the steps of adding plant biomass dry powder in water, oscillating, and filtering to collect filtrate; calcining cerium nitrate hexahydrate (Ce(NO3)3.6H2O) solid to obtain carrier CeO2; adding the carrier CeO2 into palladium nitrate (Pd(NO3)2) aqueous solution to obtain a mixture; adding the filtrate into the mixture to obtain a mixed solution containing palladium with total content of 0.5 mmol / L, stirring, vacuum-filtering, washing, drying, and calcining to obtain the palladium catalyst.

Owner:XIAMEN UNIV

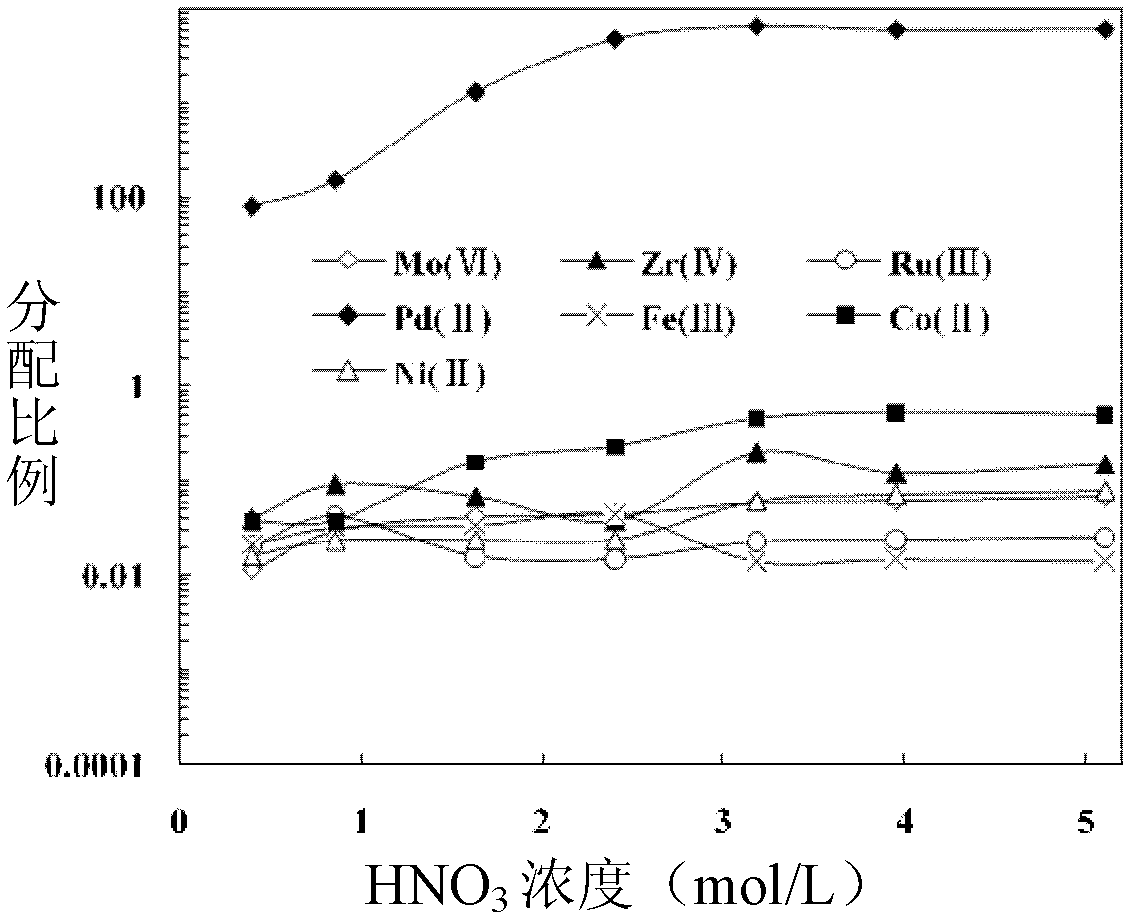

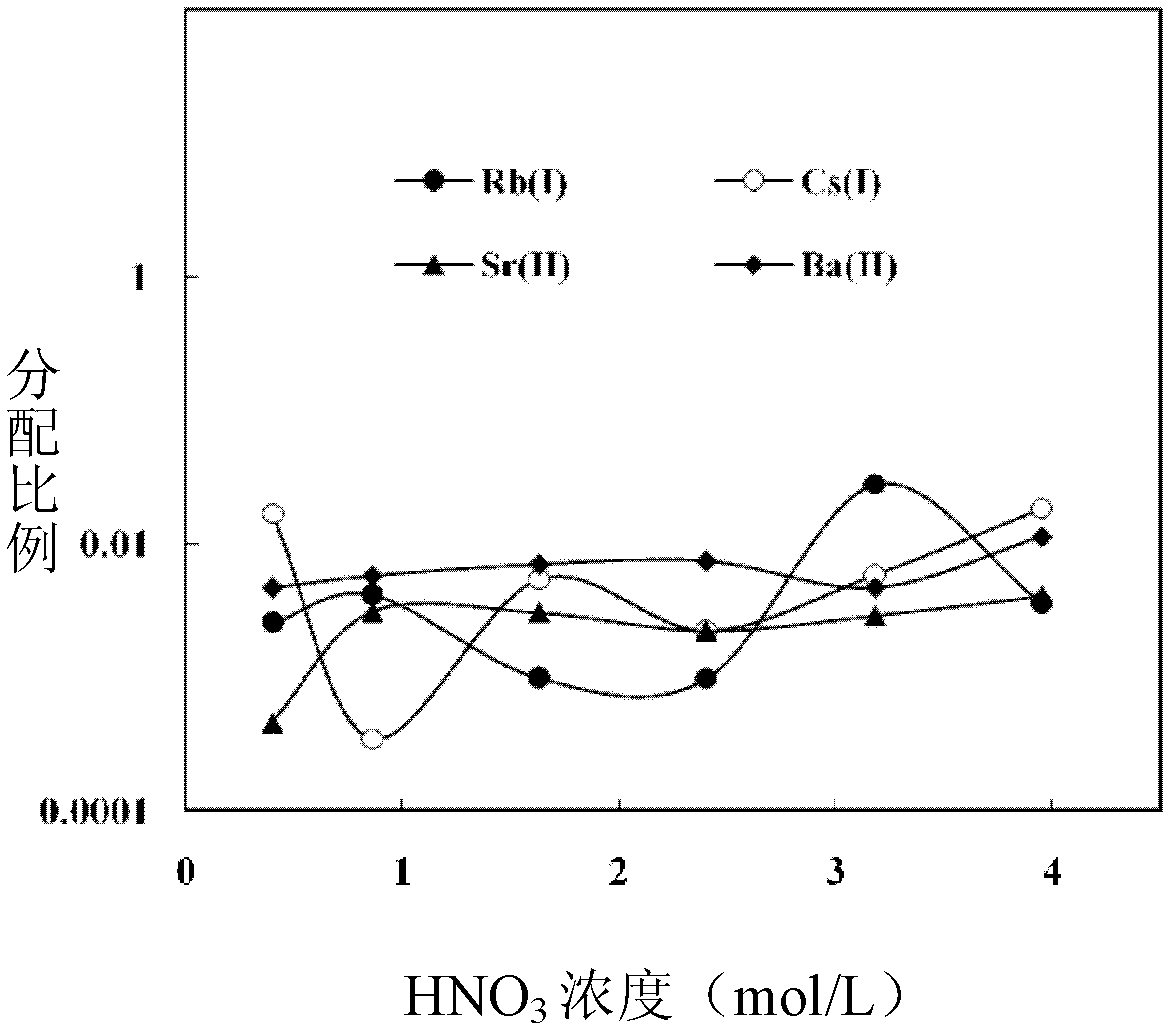

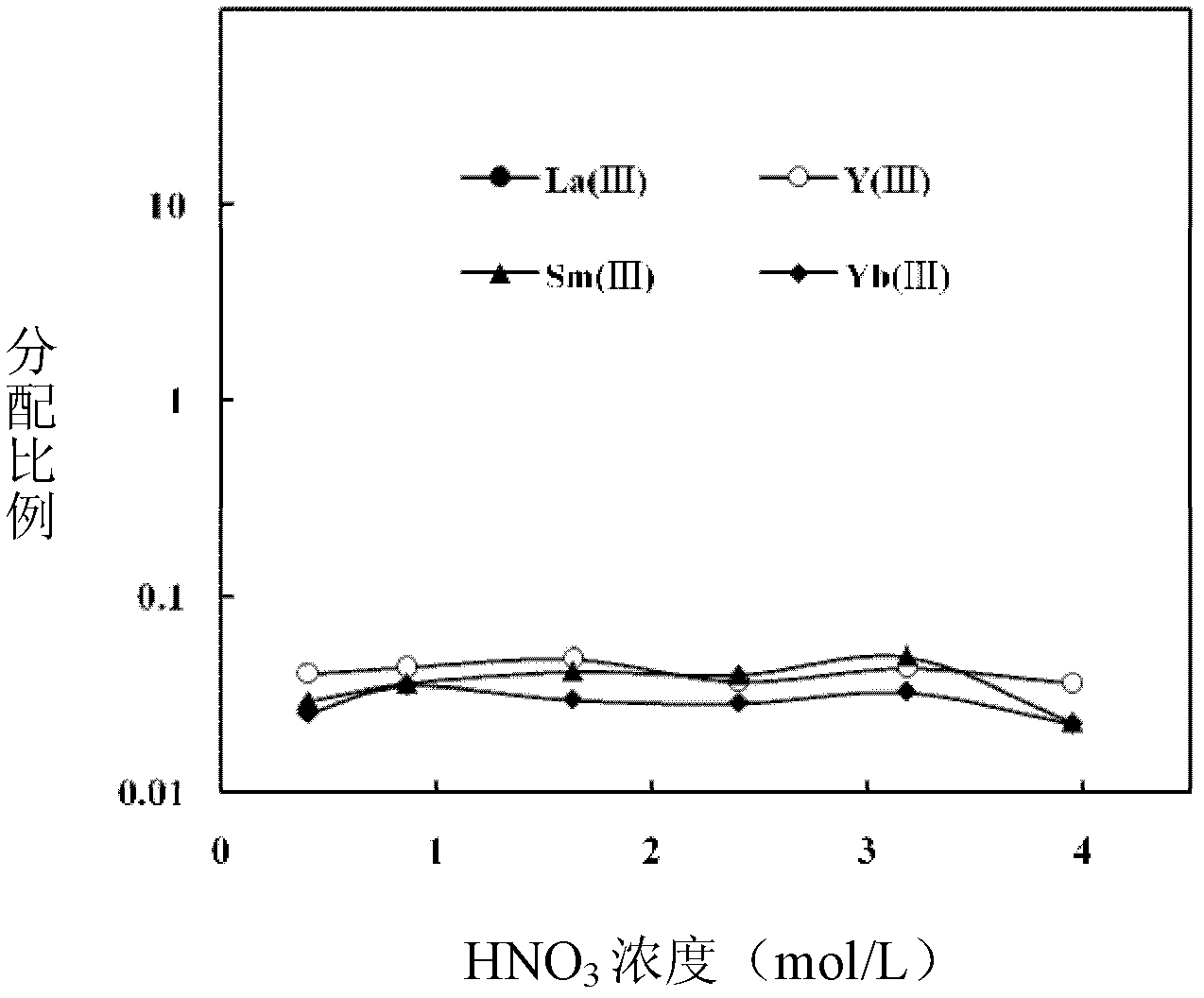

Method for extracting and separating element palladium from high-level waste

InactiveCN102629494AHigh selectivityEasy to separateLiquid solutions solvent extractionRadioactive decontaminationAlkaneOil phase

The invention discloses a method for extracting and separating element palladium from high-level waste. The method comprises the following steps of: adding concentrated nitric acid into nitrate solution of the high-level waste, from which minor actinide elements have been separated, to adjust the concentration of nitric acid to be 0.42-5.11 mol / L to obtain solution A; mixing 2,6-bi (5,6-dinonyl-1,2,4-triazine-3-yl) pyridine, R-OH and alkanes of C6-C12 to obtain solution B, wherein R is alkyl groups of C6-C12, and the volume fraction of R-OH is 30-100 percent in terms of the total volume of the R-OH and alkanes of C6-C12; mixing the solution A and the solution B, oscillating and then demixing to obtain an oil phase and a water phase; separating the oil phase from the water phase to obtain palladium nitrate-containing oil phase and the nitrate solution of the high-level waste from which the element palladium is separated respectively. The method for extracting and separating element palladium from high-level waste provided by the invention has the advantages of high selectivity, high separation capacity and suitability for large-scale industrial application.

Owner:ZHEJIANG UNIV

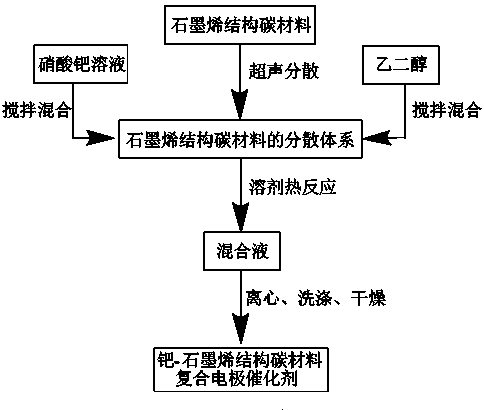

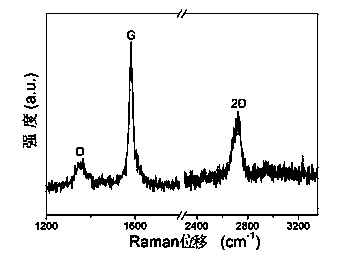

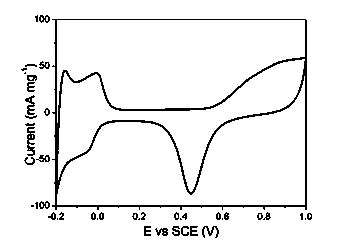

Compounding method for palladium/graphene structural carbon material combined electrode catalyst

InactiveCN103474674AReduce defectsImprove anti-poisoning performanceCell electrodesPtru catalystCarbon nanotube

The invention discloses a compounding method of palladium and a graphene structural carbon material (selected from one of graphene, carbon nanotube or fullerene), and helps to prepare a palladium / graphene structural carbon material combined electrode catalyst. The compounding method comprises the following steps: putting a graphene structural carbon material in 1-methyl-2-pyrrolidone and performing ultrasonic dispersion; respectively adding glycol and a palladium nitrate solution and mixing uniformly, then transferring the mixed system in a hydro-thermal kettle for a reaction, after the reaction is finished, centrifugally separating to obtain a solid product, performing washing and drying to obtain the palladium / graphene structural carbon material combined electrode catalyst. According to the compounding method, the graphene structural carbon material is taken as a substrate; and by employing the hydro-thermal synthetic method, the prepared palladium / graphene structural carbon material combined electrode catalyst has better application prospect and economical benefit in the field of direct methanol fuel cells.

Owner:NANJING UNIV OF SCI & TECH

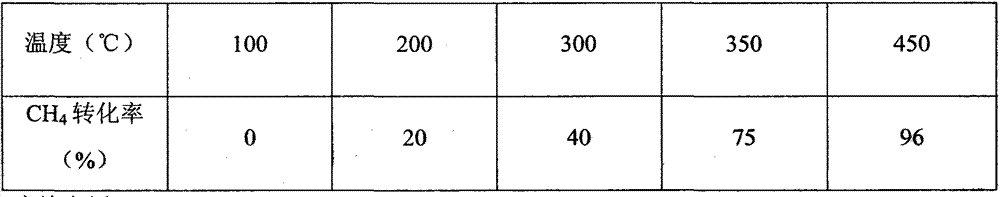

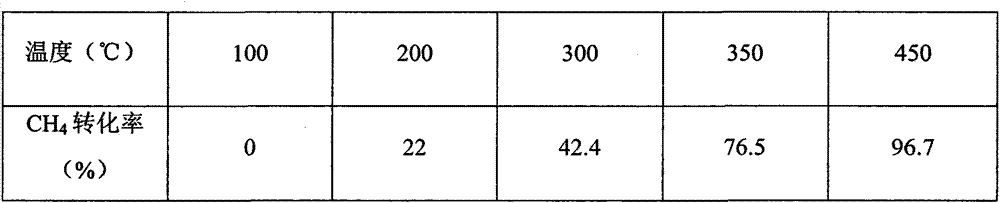

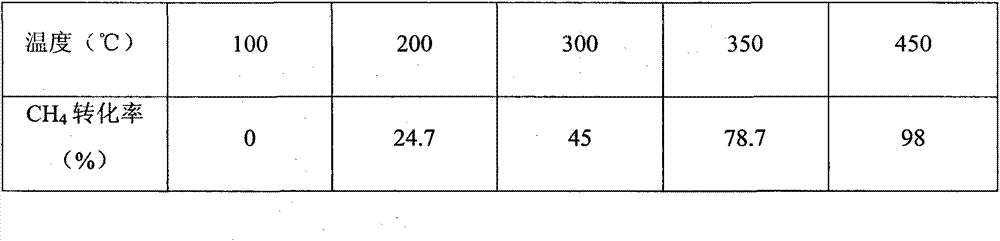

Method for preparing catalyst for catalytic combustion of methane

InactiveCN104707623AShort preparation cycleHigh catalytic activityCatalyst activation/preparationFuel additivesCeriumComposite oxide

The present invention relates to a method for preparing a catalyst for catalytic combustion of methane, and belongs to the field of inorganic material preparation, particularly to a method for co-preparation of a catalyst for catalytic combustion of methane through a hydrothermal method and an impregnating method. The method is characterized in that the catalyst carrier is cerium-iron-cobalt composite oxide, wherein the cerium content is 90-96%, the iron content is 3-7%, the cobalt content is 3-5%, and the active component is palladium and accounts for 0.5-2% of the total catalyst. The catalyst preparation method comprises: (1) preparing a cerium oxide / ferric oxide / cobalt oxide (CeO2 / Fe2O3 / Co2O3) carrier through a hydrothermal method, and (2) preparing a palladium nitrate (Pd(NO3)2) solution, impregnating the catalyst carrier prepared in the step (1) in the palladium nitrate solution, standing, drying, and calcining to prepare the catalyst finished product. The catalyst has advantages of short preparation period, high methane catalysis efficiency, low catalysis temperature, good aging resistance, and the like.

Owner:裴振昭

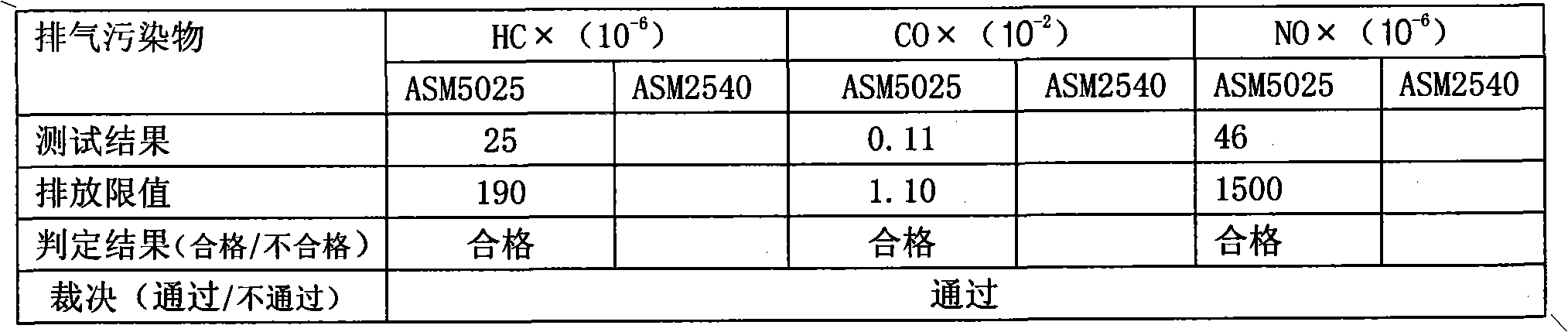

Preparation method of three-way catalyst with high CO purification capability and catalyst of preparation method

ActiveCN109876793AImprove the ability to purify COGuaranteed purification effectCatalyst carriersDispersed particle separationNitrateCerium

The invention discloses a preparation method of a three-way catalyst with a high CO purification capability and the catalyst of the preparation method. The preparation method comprises the following steps: Preparing a cerium zirconium aluminum based composite catalytic material by adopting an improved precipitation method, preparing a first coating and preparing a second coating, wherein the firstcoating is prepared from a cerium zirconium aluminum based material, a cerium zirconium based material, aluminum oxide and metallic palladium and the second coating is prepared from the cerium zirconium aluminum based material, the cerium zirconium based material, an aluminum oxide material, rhodium nitrate and palladium nitrate. According to the preparation method, a cerium zirconium aluminum based component is introduced into the aluminum oxide material to obtain the cerium zirconium aluminum based composite catalytic material; the cerium zirconium aluminum based composite catalytic material is matched with traditional cerium zirconium based material and aluminum oxide material, so that the capability of purifying CO through a traditional three-way catalyst can be improved; meanwhile, HC and NOx purification capabilities can be kept very well and an excellent CO emission reduction effect is realized in WLTC emission of a whole vehicle.

Owner:SINOCAT ENVIRONMENTAL TECH

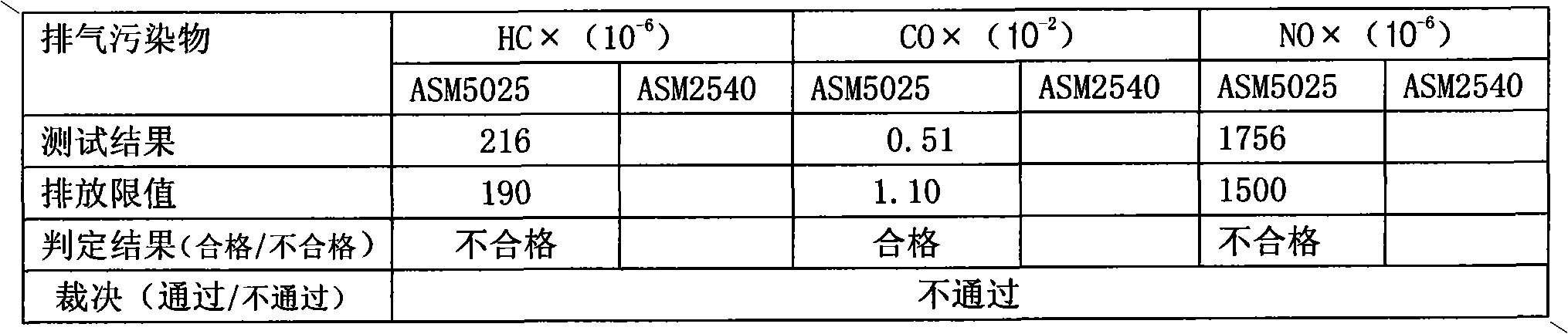

Nano-noble metal catalytic filler for three-way catalytic converter carrier and spraying method thereof

InactiveCN101890359AGuaranteed temperaturePromote repairPhysical/chemical process catalystsInternal combustion piston enginesPt elementMoisture

The invention relates to a nano-noble metal catalytic filler for a three-way catalytic converter carrier and a spraying method thereof. The nano-noble metal catalytic filler is especially suitable for serving as a catalytic filler for an automobile three-way catalytic converter carrier. The filler is prepared from the following raw materials in percentage by weight: 3-8% of palladium nitrate, 1-6% of platinum nitrate, 0.5-2% of rhodium nitrate, 20-40% of nano-titanium dioxide and the balance water, wherein the total percentage is 100%. The spraying method comprises the following steps: (1) disassembling the failed three-way purifier, and cleaning the pollutants in the carrier; (2) blow-drying the moisture in the carrier by using a stainless steel electric blower; (3) repeatedly spraying the nano-noble metal catalytic filler for the three-way catalytic converter carrier on the carrier by adopting a spraying gun; (4) baking the carrier sprayed with the nano-noble metal catalytic filler by using a hot baking gun, and curing; (5) installing the three-way purifier sprayed and cured with the nano-noble metal catalytic filler on the original vehicle; and (6) starting the vehicle after the three-way purifier is installed on the vehicle, and then, detecting.

Owner:SUZHOU LIANCHI ENVIRONMENTAL SCI & TECH DEV CO LTD

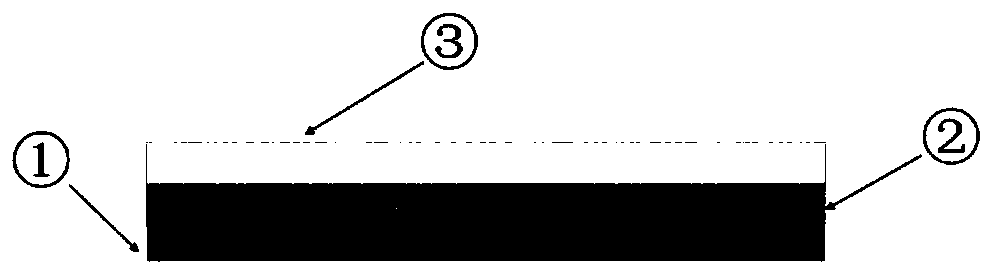

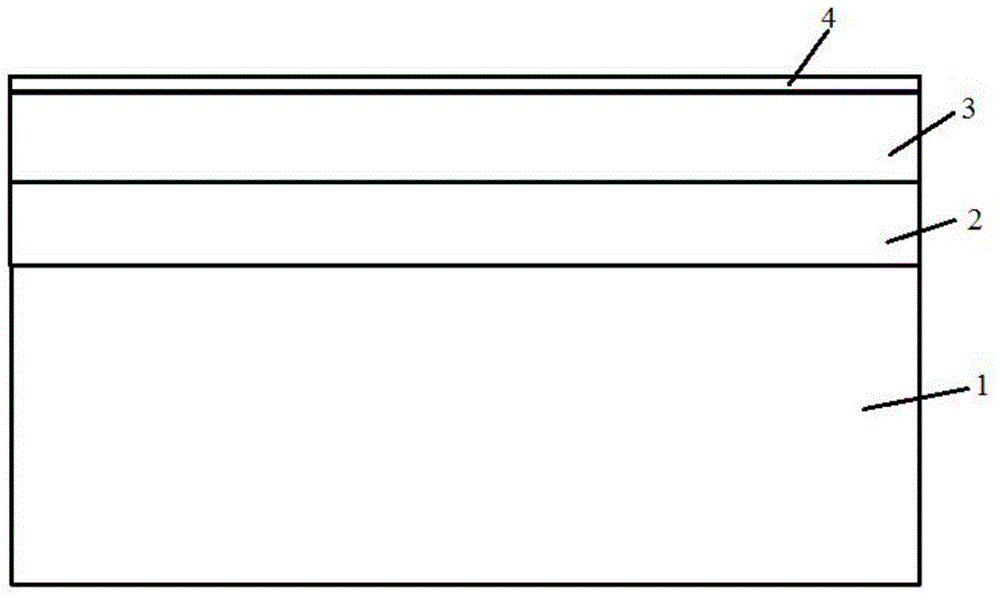

Monolithic catalyst for methane catalytic combustion and preparation method thereof

InactiveCN104084199AHigh conversion rate of catalytic combustionImprove performanceFuel additivesMetal/metal-oxides/metal-hydroxide catalystsHoneycombCordierite

The invention discloses a monolithic catalyst for methane catalytic combustion and a preparation method thereof. The monolithic catalyst comprises a carrier, a coating on the carrier, and precious metal loaded on the coating, wherein the carrier is cordierite honeycomb ceramics, and the coating is a gamma-Al2O3 sol transition coating and a CeO2-Y2O3 sol assistant coating. The preparation method comprises the steps of impregnating the cordierite honeycomb ceramics in gamma-Al2O3 sol, drying and roasting to obtain a carrier coated with the gamma-Al2O3 sol transition coating; impregnating the carrier coated with the gamma-Al2O3 sol transition coating in CeO2-Y2O3 sol to obtain a carrier; and with Pd sol as an active ingredient, and coating the carrier with the Pd sol to obtain the monolithic catalyst, wherein the loading amount of the palladium accounts for 0.05-0.2 percent of the total weight of the monolithic catalyst, and the Pd sol is palladium nitrate sol, palladium acetate sol or palladium chloride sol. The monolithic catalyst has high catalytic combustion conversion rate to methane, and consumes few amount of Pd.

Owner:SOUTHEAST UNIV

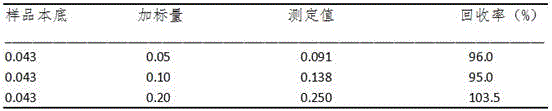

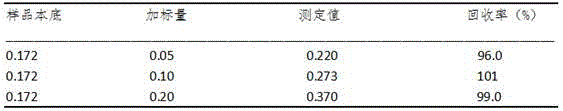

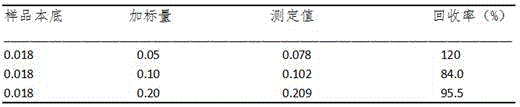

Method for measuring lead content in soybean sauce through microwave digestion-graphite furnace atomic absorption

InactiveCN106501197AImprove stabilityReduce distractionsPreparing sample for investigationColor/spectral properties measurementsLead measurementGraphite

The invention relates to a method for measuring lead content in soybean sauce through microwave digestion-graphite furnace atomic absorption. The method comprises the following steps: weighing a defined amount of sample and putting into a polytetrafluoroethylene digestion tank; adding nitric acid and hydrogen peroxide; performing digestion pretreatment in a microwave digestion instrument; respectively taking the digested sample, palladium nitrate in mass percent of 10% and ammonium dihydrogen phosphate in mass percent of 10% and jointly injecting into a pyrolytic coating graphite tube for measuring. According to the method provided by the invention, the influence of soybean sauce substrate on lead measurement can be effectively reduced, the stability and precision of the method can be increased and the test process is simple, quick, sensitive and accurate. The method is suitable for the measurement for the lead content in soybean sauce and daily food, such as, pickle, salt, vegetable and milk powder.

Owner:SHANDONG INST FOR FOOD & DRUG CONTROL

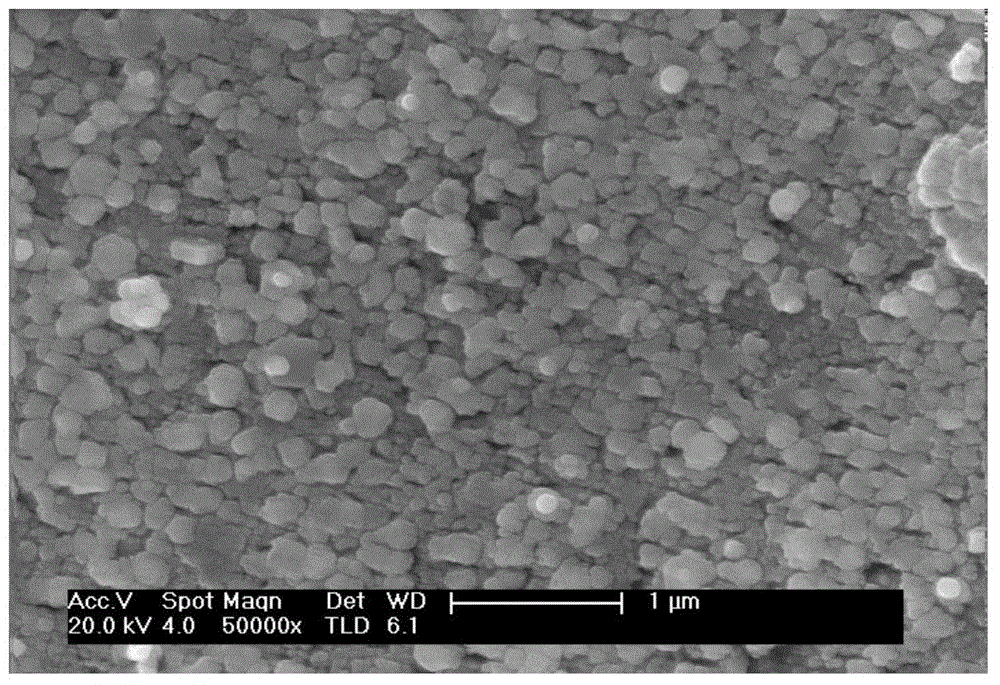

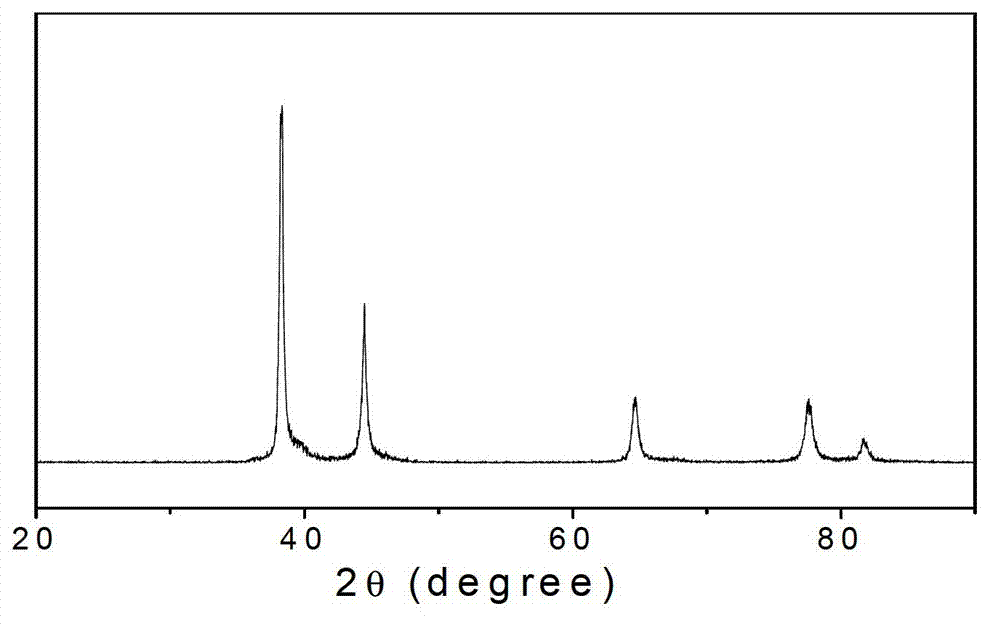

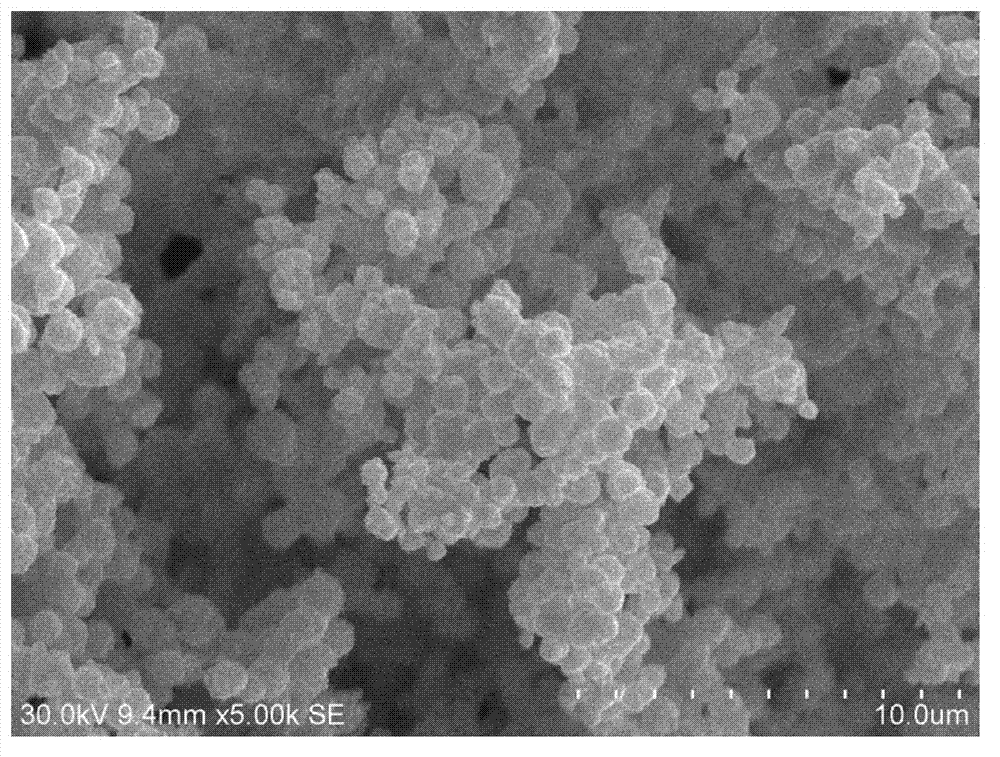

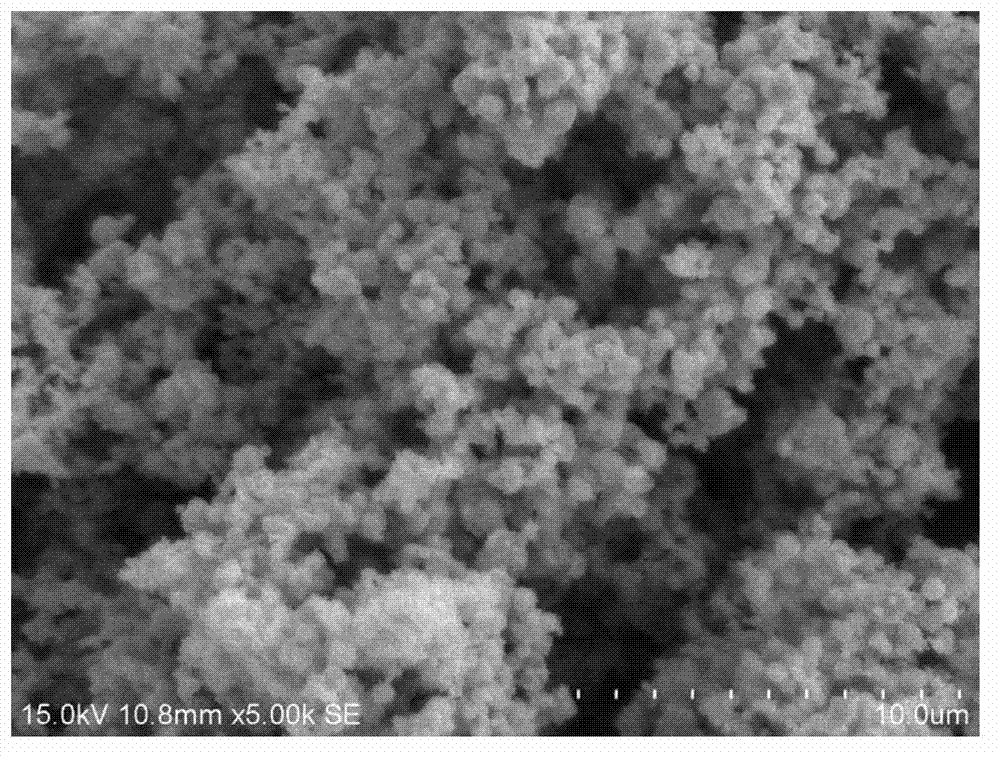

Palladium-based catalyst for thermocatalytic formaldehyde degradation

ActiveCN109529821AReduce loadGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReduction treatmentAnatase

The invention discloses a palladium-based catalyst for thermocatalytic formaldehyde degradation. In the Pd / TiO2 catalyst, mass fraction of Pd is 0.1%-0.4%, on the basis of the weight of catalyst being100%. A preparation method comprises the following steps: 1) performing reduction treatment on a TiO2 carrier; 2) adding a defined amount of TiO2 into a palladium nitrate solution; 3) regulating pH of the solution and reducing; 4) drying the acquired mixture, thereby acquiring the required Pd / TiO2 catalyst for formaldehyde oxidation. The preparation method disclosed by the invention is simple; the prepared Pd / TiO2 catalyst has an anatase (ATiO2) phase structure; the formed Pd / TiO2 shows an excellent catalytic performance for formaldehyde oxidation.

Owner:SUN YAT SEN UNIV

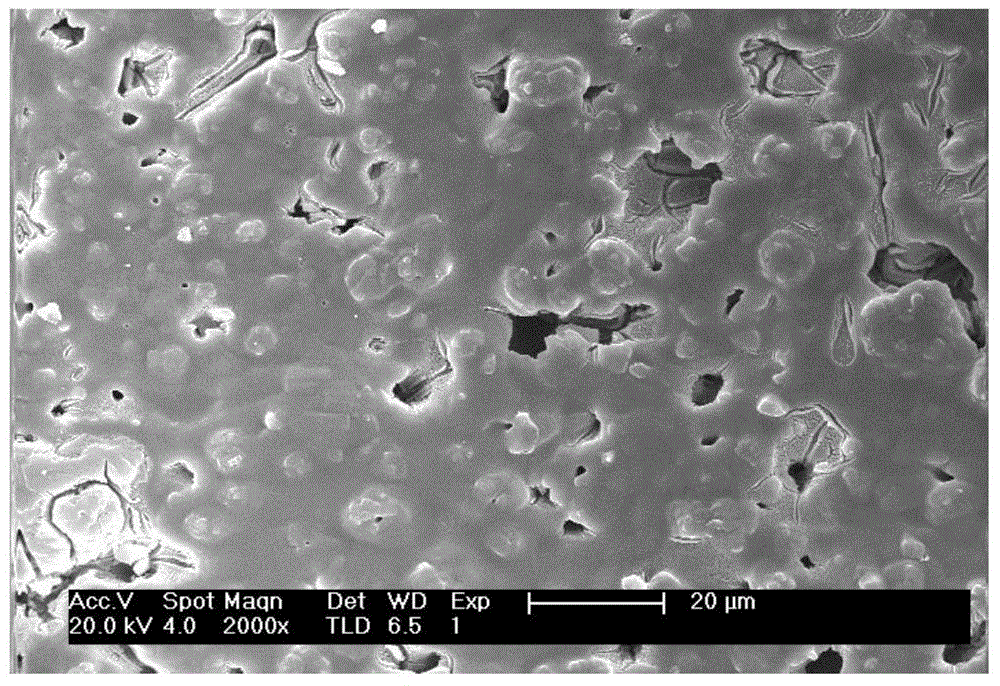

Method for preparing monodisperse silver-palladium composite microsphere

The invention discloses a method for preparing a monodisperse silver-palladium composite microsphere. The method includes the steps: sequentially adding a certain amount of silver nitrate and palladium nitrate, a certain quantity of surfactants and deionized water into a beaker, and adding a certain amount of alkali adjusting solution with alkaline pH (potential of hydrogen) into the beaker in a stirring manner after fully dissolving the silver nitrate, the palladium nitrate, the surfactants and the deionized water to obtain a silver-palladium mixed system serving as feed solution; adding a certain amount of hydrazine hydrate into the deionized water and uniformly stirring the hydrazine hydrate and the deionized water to serve as reducing solution; and dripping the feed solution into the reducing solution and reacting for 5-30min. The monodisperse silver-palladium composite microsphere is synthesized by a common liquid phase reduction method. Compared with other methods, the method has the advantages of simplicity, low cost, high yield, easiness in cleaning and the like. The silver-palladium composite microsphere prepared by the method is uniform, fine in dispersity and controllable in grain diameter.

Owner:SINO PLATINUM METALS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com