Patents

Literature

42results about How to "Uniform suede" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

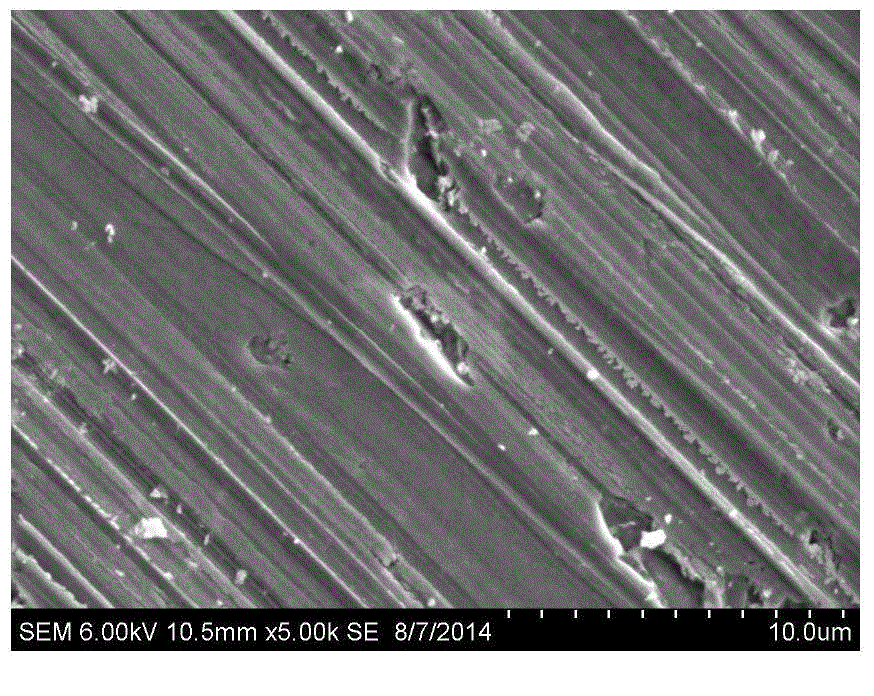

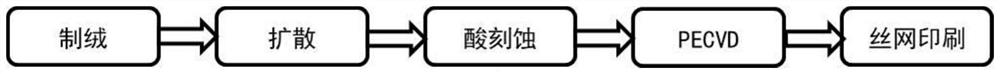

Texturing method of polycrystalline silicon wafer cut by diamond wire

ActiveCN105810761AControl reaction rateImprove conversion efficiencyPolycrystalline material growthAfter-treatment detailsHydrofluoric acidInorganic ions

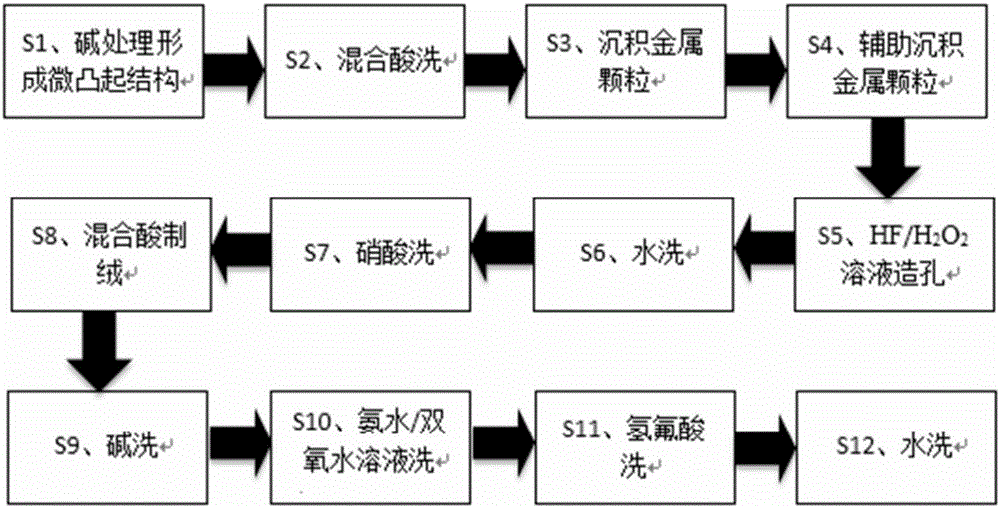

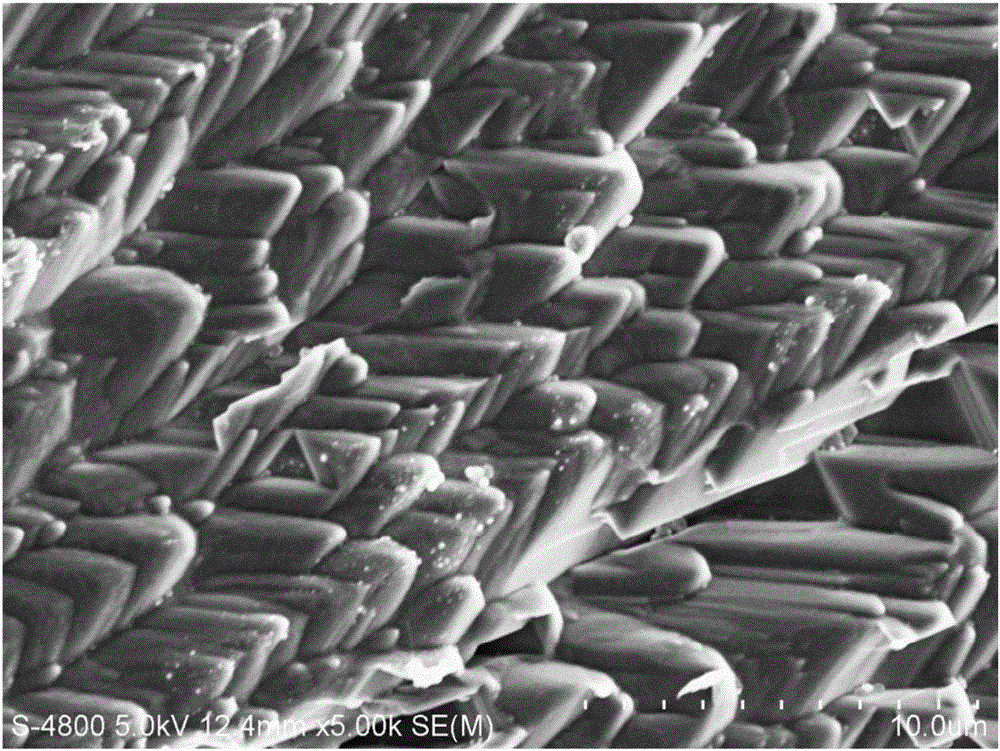

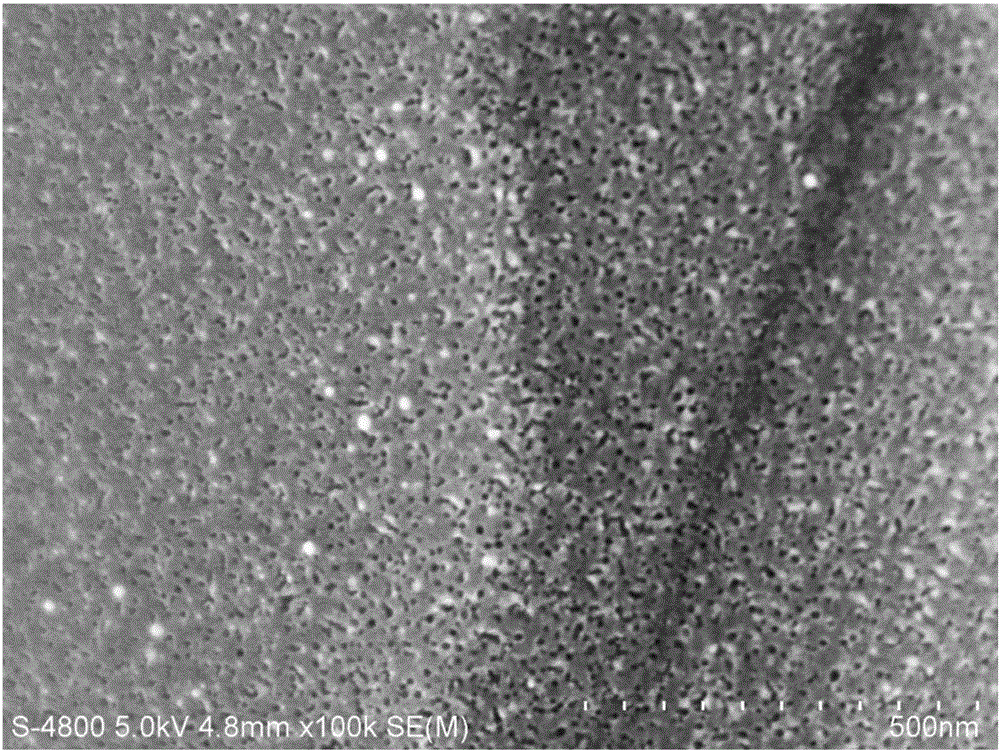

The invention discloses a texturing method of a polycrystalline silicon wafer cut by a diamond wire. The method comprises the following steps: firstly, immersing the polycrystalline silicon wafer cut by the diamond wire into a mixed water solution of an alkaline solution and an alkaline reaction control agent, removing a surface damage layer of the silicon wafer and immersing the polycrystalline silicon wafer into a hydrofluoric acid solution containing inorganic ions and organic molecules for reaction; secondly, carrying out pretreatment on the polycrystalline silicon surface by a mixed solution of a hydrofluoric acid and hydrogen peroxide and simultaneously adding a pore-forming regulator; and finally texturing the silicon wafer surface by a mixed acid solution of the hydrofluoric acid and a nitric acid. The texturing method has the advantages that the prepared polycrystalline textured wafer is uniform in suede, small in color difference and consistent in etching depth, and has low surface reflectivity and relatively high conversion efficiency; the preparation method is simple and feasible; the reagent cost is relatively low; the reaction conditions are easy to implement; and the texturing method is relatively good in compatibility with an existing industrial production procedure and is suitable for popularization and application.

Owner:NANJING TECH UNIV

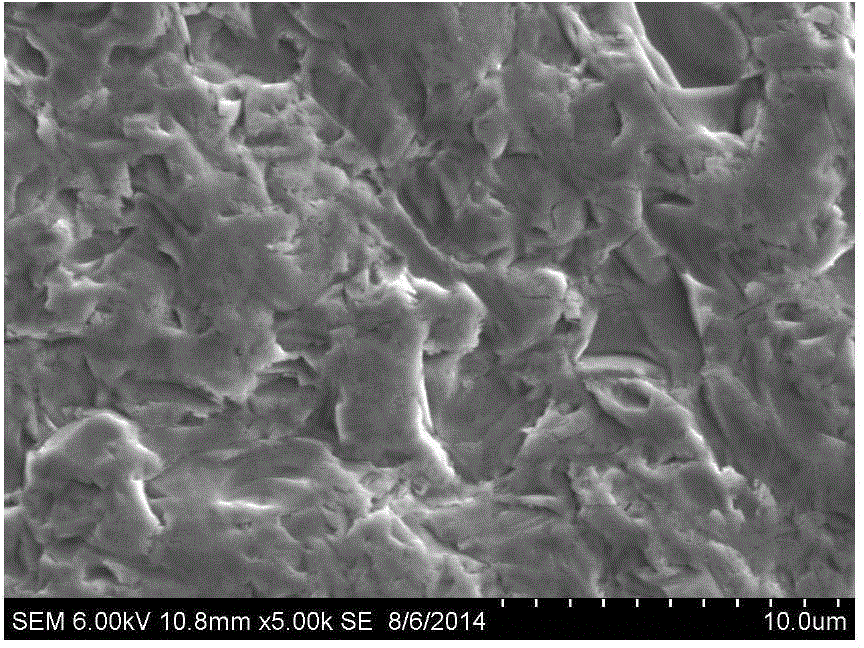

Polycrystalline black silicon texturization treatment fluid, polysilicon chip texturization method applying treatment fluid, and polycrystalline black silicon texturization product

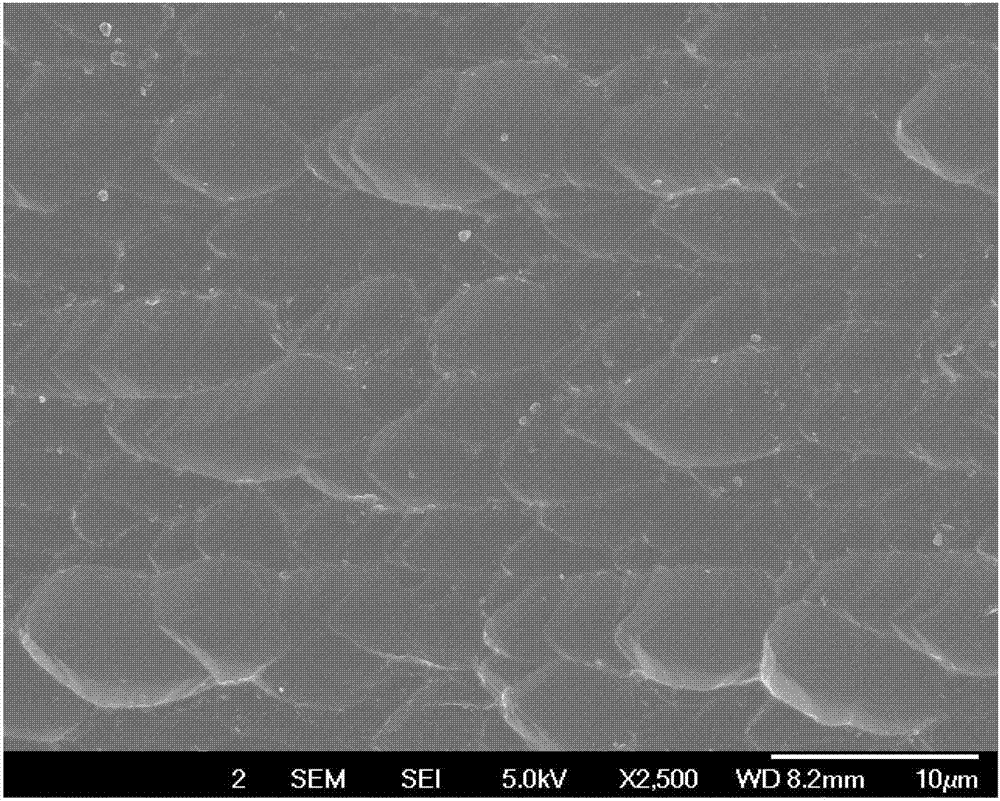

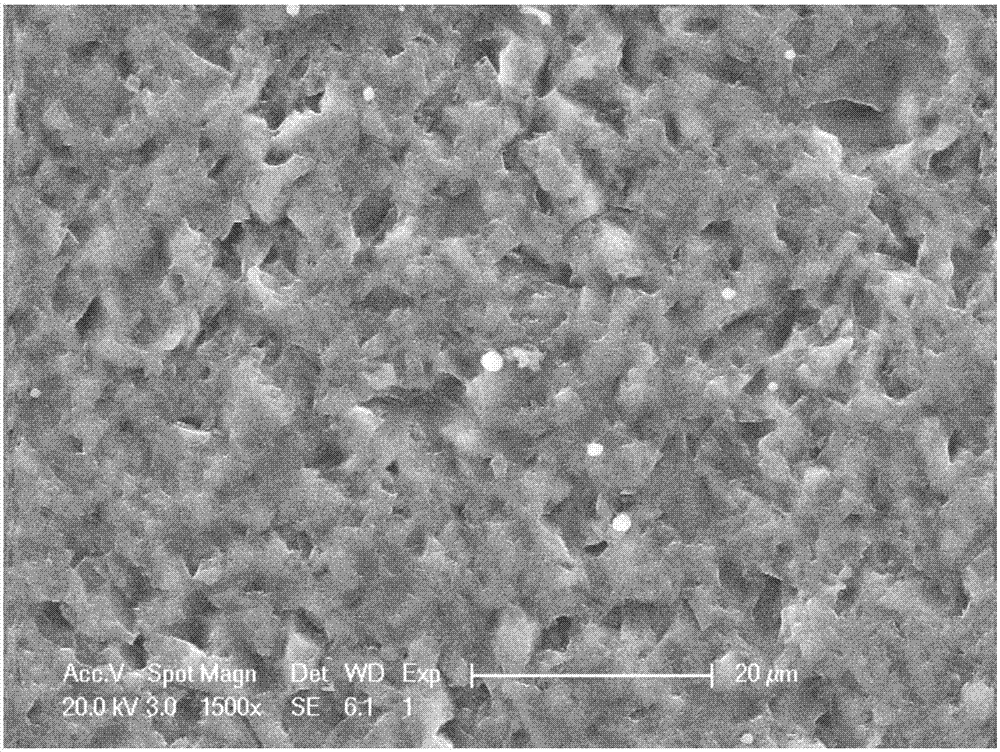

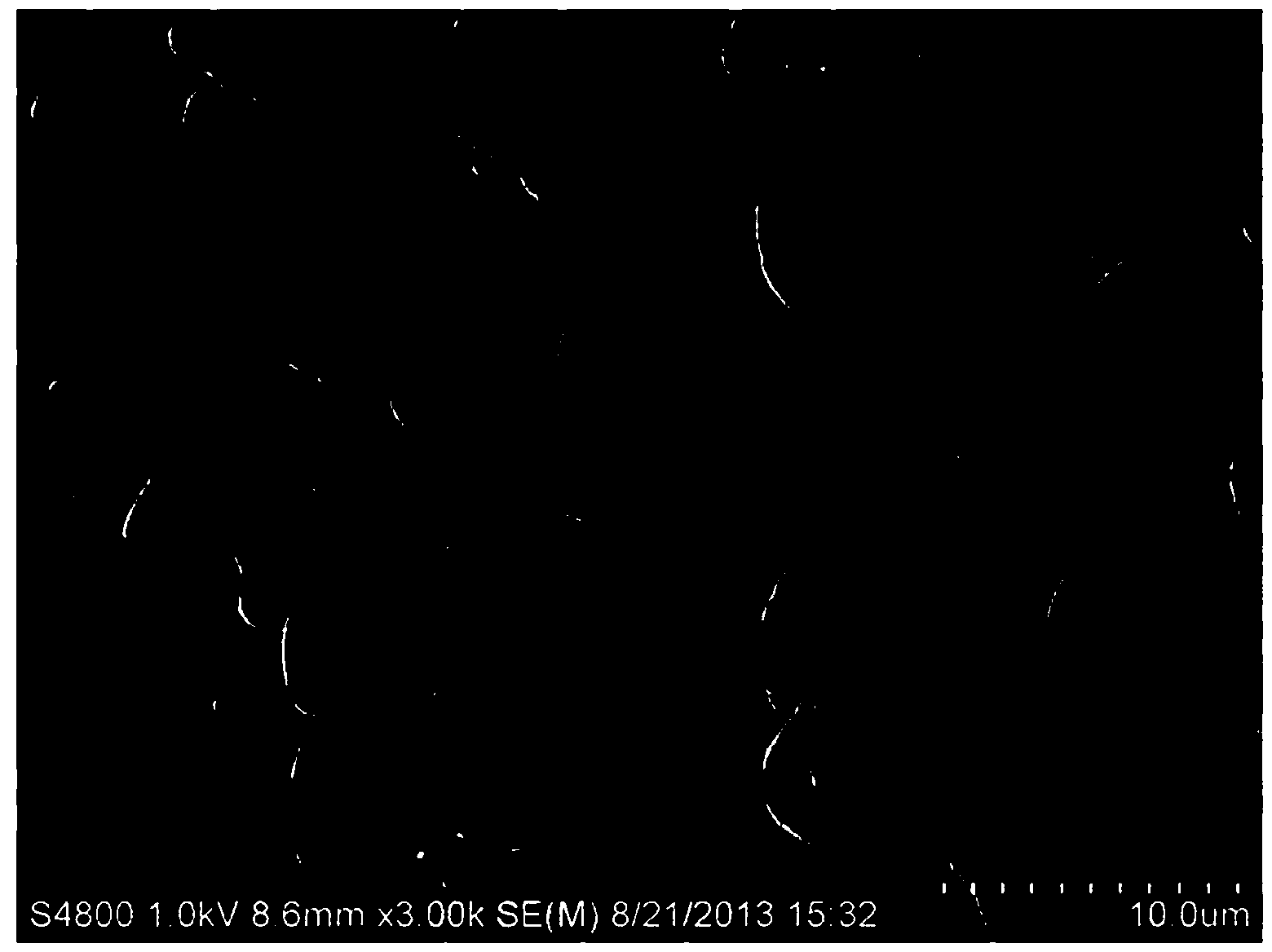

InactiveCN105154982AUniform suedeImprove trapping effectPolycrystalline material growthAfter-treatment detailsPlatanic acidPalladium nitrate

The invention provides a polycrystalline black silicon texturization treatment fluid. The polycrystalline black silicon texturization treatment fluid comprises a hydrofluoric acid solution, a hydrogen peroxide solution and a metal salt, wherein a volume ratio of the hydrofluoric acid solution to the hydrogen peroxide solution is 1-25:5-40, the mass fraction of hydrofluoric acid in the hydrofluoric acid solution is 40-50%, the mass fraction of hydrogen peroxide in the hydrogen peroxide solution is 20-55%, the metal salt is at least one of copper nitrate, silver nitrate, palladium nitrate, copper chloride, auric chloride acid, chloroplatinic acid, potassium chromate and nickel sulfate, and the mole concentration of the metal salt is 1-10<5>[mu]mol / L. The invention also provides a polysilicon chip texturization method applying the polycrystalline black silicon texturization treatment fluid, and a polycrystalline black silicon texturization product.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Texturing pretreatment liquid and texturing pretreatment method for diamond wire cutting polycrystalline silicon sheet, texturing pretreatment silicon sheet and application of texturing pretreatment silicon sheet

ActiveCN104576830ARaise the ratioLow costAfter-treatment detailsFinal product manufactureHydrofluoric acidPretreatment method

The invention provides texturing pretreatment liquid for a diamond wire cutting polycrystalline silicon sheet. The texturing pretreatment liquid comprises first treatment liquid and second treatment liquid A or B, wherein the first treatment liquid is a mixed solution of hydrofluoric acid, hydrogen peroxide, metal salt and water; the treatment liquid A comprises nitric acid and strong alkali; the treatment liquid B is a mixed solution of nitric acid, hydrofluoric acid and water. The invention further provides a texturing pretreatment method for the diamond wire cutting polycrystalline silicon sheet. The surface of the silicon sheet is treated by the pretreatment liquid to form a uniform damaged layer to obtain the texturing pretreatment silicon sheet. The invention further provides a texturing method for the diamond wire cutting polycrystalline silicon sheet. The texturing pretreatment silicon sheet is subjected to conventional texturing treatment, so that a uniform and low-reflexibility textured surface is formed on the surface of the silicon sheet, and a diamond wire cutting polycrystalline silicon sheet product is obtained. The invention further provides the texturing pretreatment silicon sheet and the diamond wire cutting polycrystalline silicon sheet product.

Owner:滁州赛维能源科技有限公司

Method for cleaning diamond wire-electrode cutting silicon wafer

ActiveCN102225406AReduce reflectivityImprove battery efficiencyCleaning using liquidsIncrease phBiological activation

The invention relates to the technical field of cutting silicon wafer post-treatment, and in particular relates to a method for cleaning a diamond wire-electrode cutting silicon wafer. The method comprises the following steps: coarsely cleaning a degummed silicon wafer in an alkaline cleaning agent and lactic acid respectively, wherein the pH of the alkaline cleaning agent is between 9 and 10, the temperature of the alkaline cleaning agent is between 30 and 50 DEG C, and the temperature of the lactic acid is 60 DEG C; and finely cleaning in the alkaline cleaning agent and purified water respectively, wherein the PH of the alkaline cleaning agent is between 9 and 10, and the temperature of the alkaline cleaning agent is between 70 and 90 DEG C. The cleaning method has the advantages that: the silicon wafer surface is cleaner and the surface damaged layer is better removed by increasing pH of the silicon wafer cleaning solution and increasing the temperature, and the cleaning solution plays a surface activation effect in the alkaline etching process of the silicon wafer. When the silicon wafer is etched, the pyramid etching surface has higher coverage rate, and the etching surface is uniform.

Owner:TRINA SOLAR CO LTD

Additive for chambering acid liquid for texturing polycrystal black silicon and application of additive

ActiveCN106119976ACrystal flower improvementReactions become controllablePolycrystalline material growthAfter-treatment detailsPolyvinyl alcoholReaction rate

The invention provides an additive for chambering acid liquid for texturing polycrystal black silicon. The additive comprises the following components in percentage by mass: 0.5%-2% of polyvinyl alcohol, 1%-5% of triethanolamine, 1%-3% of tartaric acid, 0.5%-2% of a silane coupling agent and the balance of water. The invention further provides the chambering acid liquid adopting the additive and a method for texturing polycrystal black silicon. By adding the additive into the chambering acid liquid, the reaction of the chambering treatment can be decelerated, and the reaction rates of the chambering acid liquid on crystal surfaces of the polycrystal black silicon can be furthest kept consistent, so that the anisotropic corrosion is inhibited, crystal patterns of the polycrystal black silicon are obviously improved, and the appearance superiority and the performance superiority of the black silicon are embodied.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Method for fine-hair maring using monocrystalline silicon slice

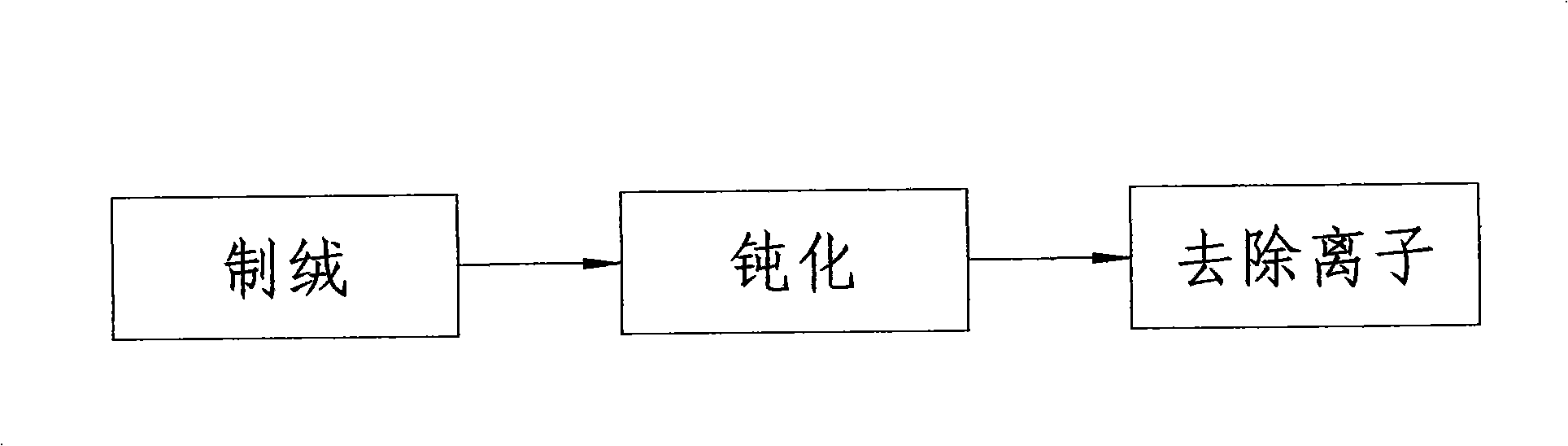

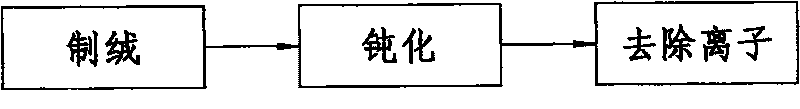

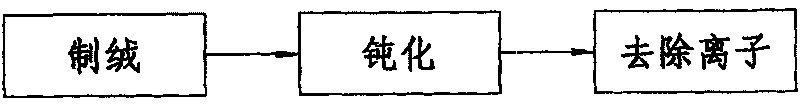

InactiveCN101409312AUnbreakableUniform and fine suedeFinal product manufactureSemiconductor devicesHigh reflectivitySteady state

The invention discloses a method for texturing a monocrystalline silicon wafer. The method comprises the steps of texturing by corrosion, passivation and deionization. By the technical scheme of cancelling rough polishing, and changing a formula, reaction conditions and treatment flow, the method overcomes the problems and the disadvantages of the prior art that the texturing technological process is difficult to be controlled, the thickness reduction of the monocrystalline silicon wafer is greater, the silicon wafer is easily cracked during the treatment process, the textures formed on the silicon wafer is uneven, and bulky dimension of a cone structure leads to high reflectivity of the silicon wafer, lower short circuit current (Isc) and lower photoelectric conversion rate. The method provided for texturing the monocrystalline silicon wafer realizes that corrosive liquid is in a steady state which is easy to be controlled, the thickness reduction of the silicon wafer is reduced, the formed textures are even and the dimension of the cone structure is compact; the method reaches the purposes of reducing the reflectivity of the silicon wafer, increasing the short circuit current (Isc), and improving the photoelectric conversion rate, meanwhile, the method improves the quality and the qualification rate of the product on the whole, reduces the consumption of chemical reagents and lowers the cost.

Owner:SHANGHAI CHAORI (LUOYANG) SOLAR ENERGY CO LTD

Texturing preprocessing solution and method of diamond wire cutting polycrystalline silicon wafer, texturing preprocessing silicon wafer and application of texturing preprocessing silicon wafer

ActiveCN104505437ARaise the ratioLow costAfter-treatment detailsFinal product manufactureHydrofluoric acidPretreatment method

The invention provides a texturing preprocessing solution of a diamond wire cutting polycrystalline silicon wafer. The texturing preprocessing solution is a mixed solution of nitric acid, hydrofluoric acid, acetic acid and water with the volume ratio being 10-15:1-5:2-6:10-30. The invention further provides a texturing preprocessing method of the diamond wire cutting polycrystalline silicon wafer. The method includes: the texturing preprocessing solution is used to process the surface of the diamond wire cutting polycrystalline silicon wafer to form a multi-hole silicon structure, namely a deeper damage layer so as to obtain a texturing preprocessing silicon wafer. The invention further provides a texturing method of the diamond wire cutting polycrystalline silicon wafer, the method performs conventional texturing processing on the texturing preprocessing silicon wafer, an even and low-reflectance textured surface is formed on the surface of the silicon wafer, and the diamond wire cutting polycrystalline silicon wafer textured product is acquired. The invention further provides the texturing preprocessing silicon wafer and the diamond wire cutting polycrystalline silicon wafer textured product.

Owner:LDK SOLAR XINYU HI TECH XINYU CO LTD

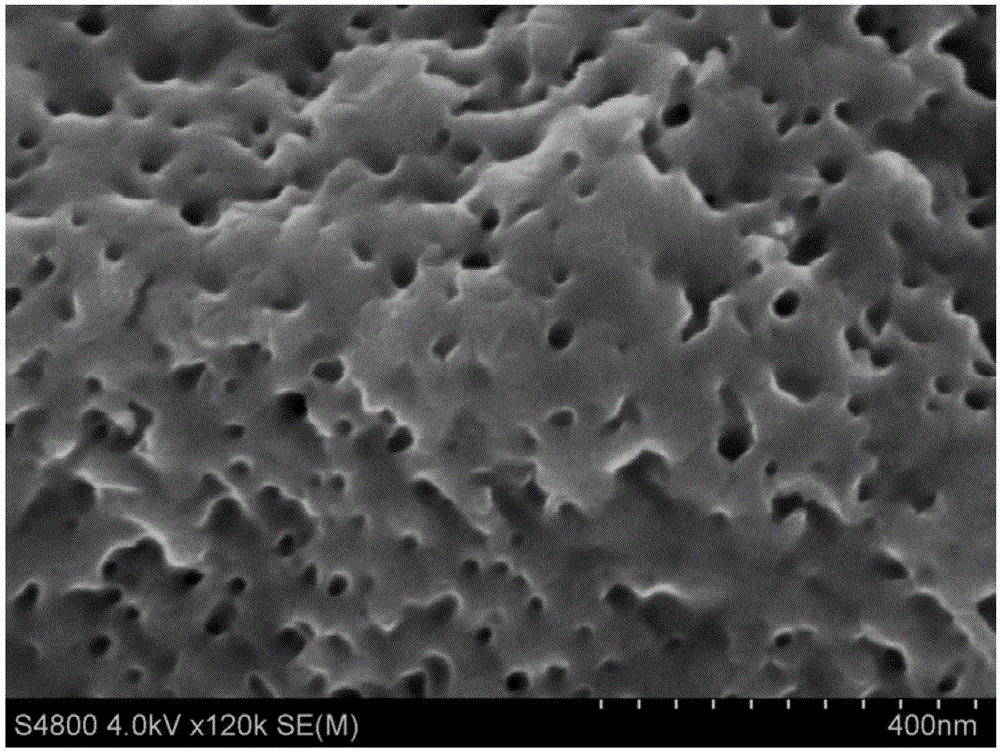

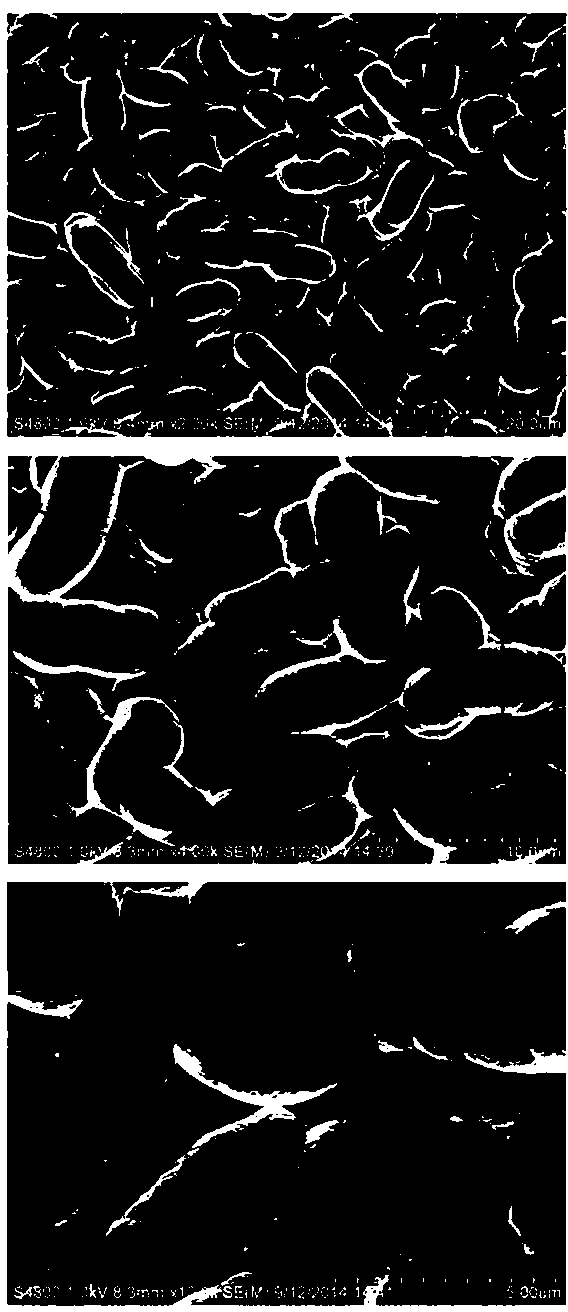

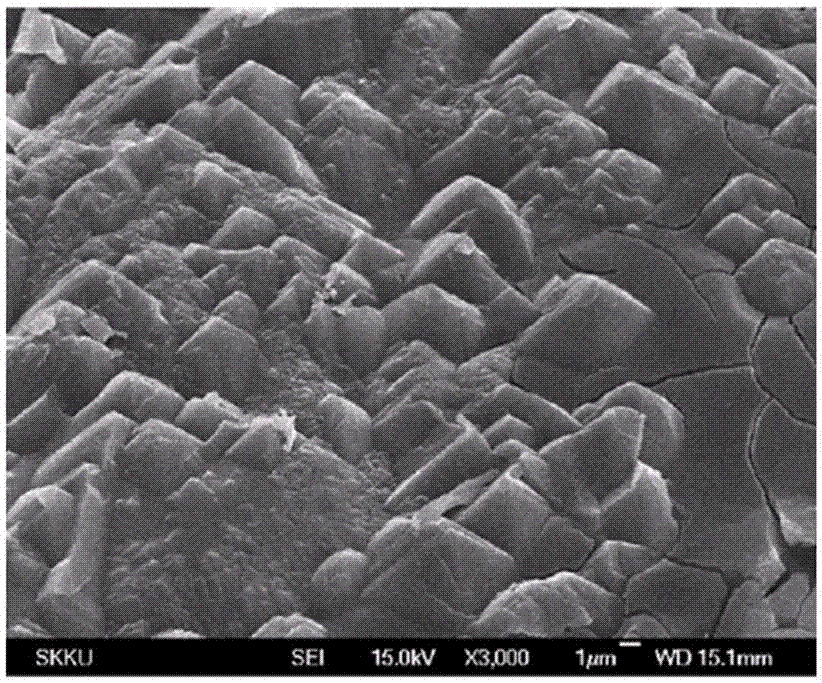

Honeycomb-shaped wet-method black-silicon texturing structure and preparing method thereof and black-silicon cell and preparing method thereof

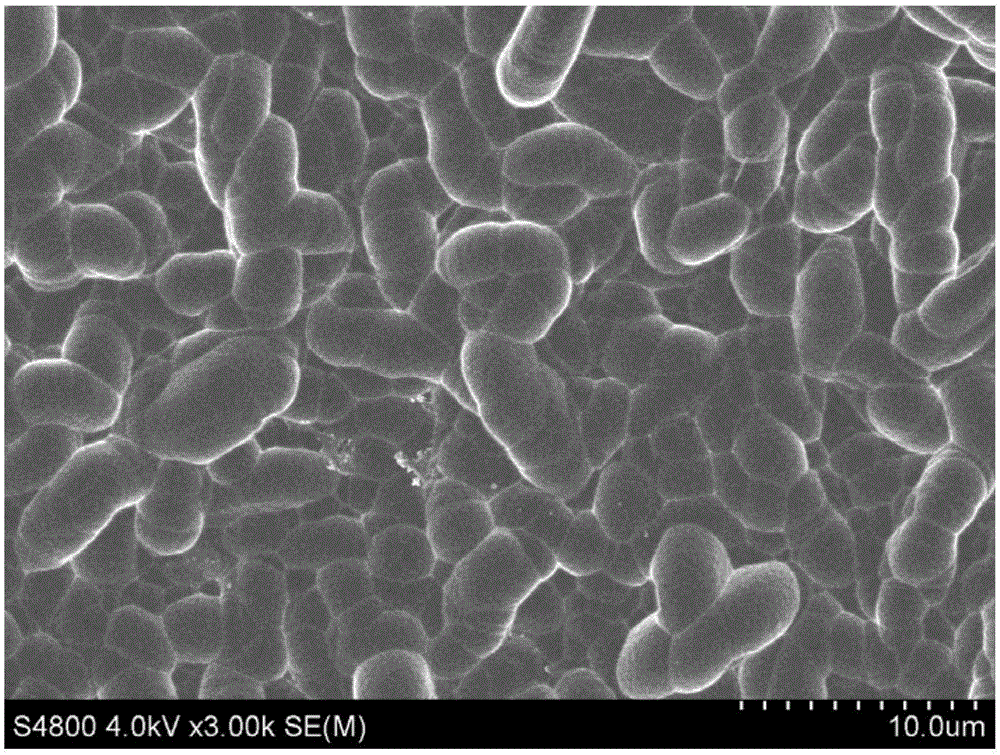

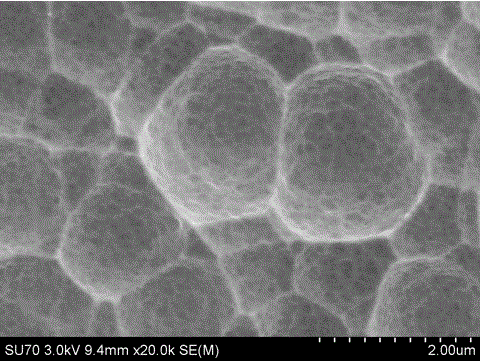

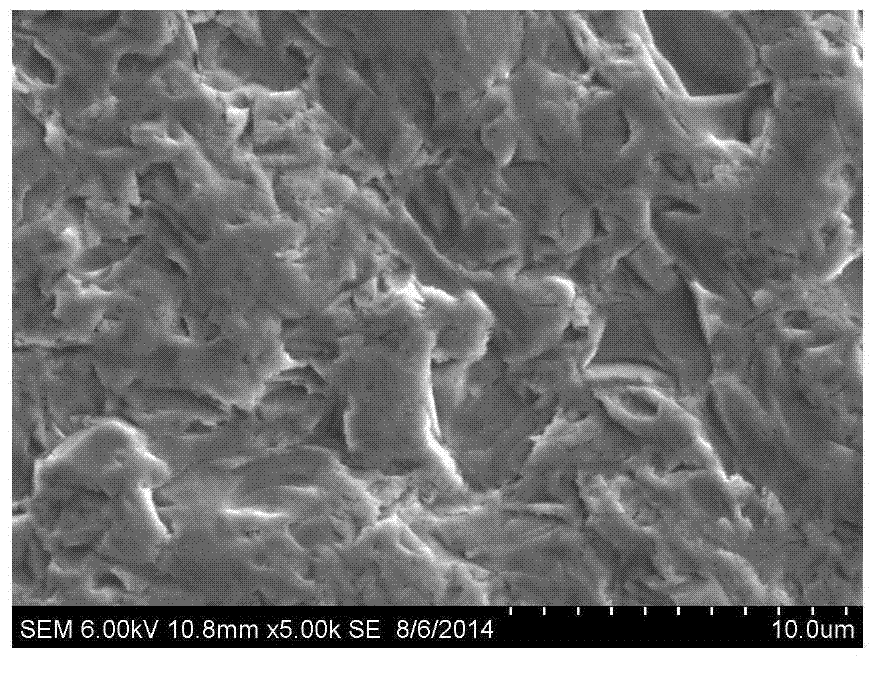

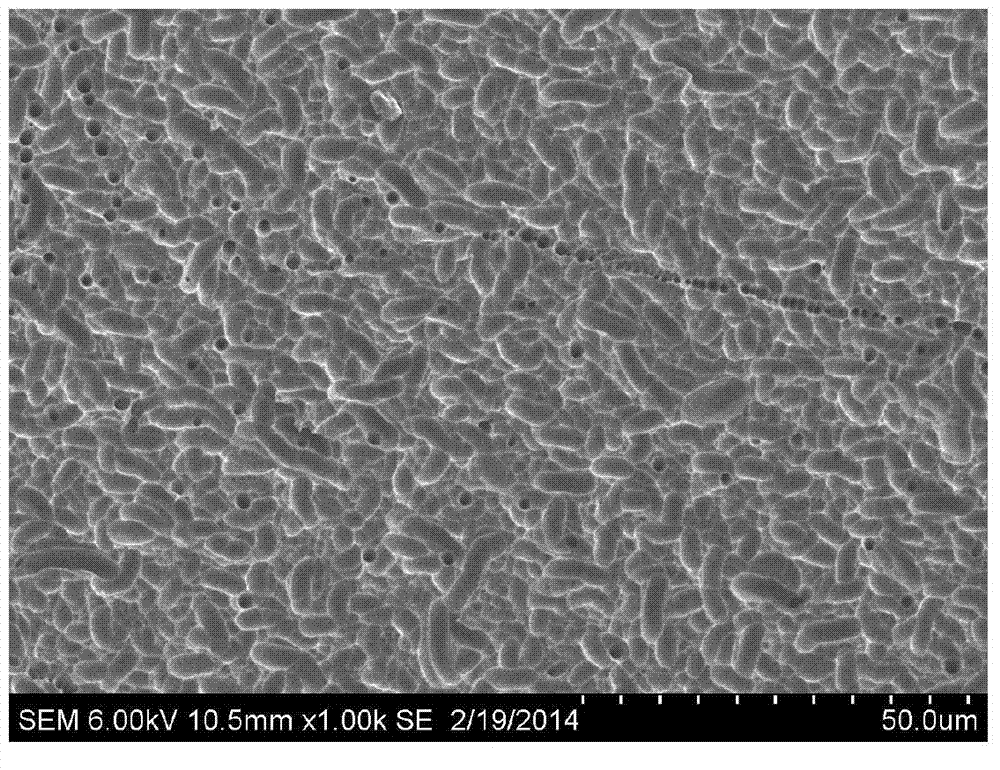

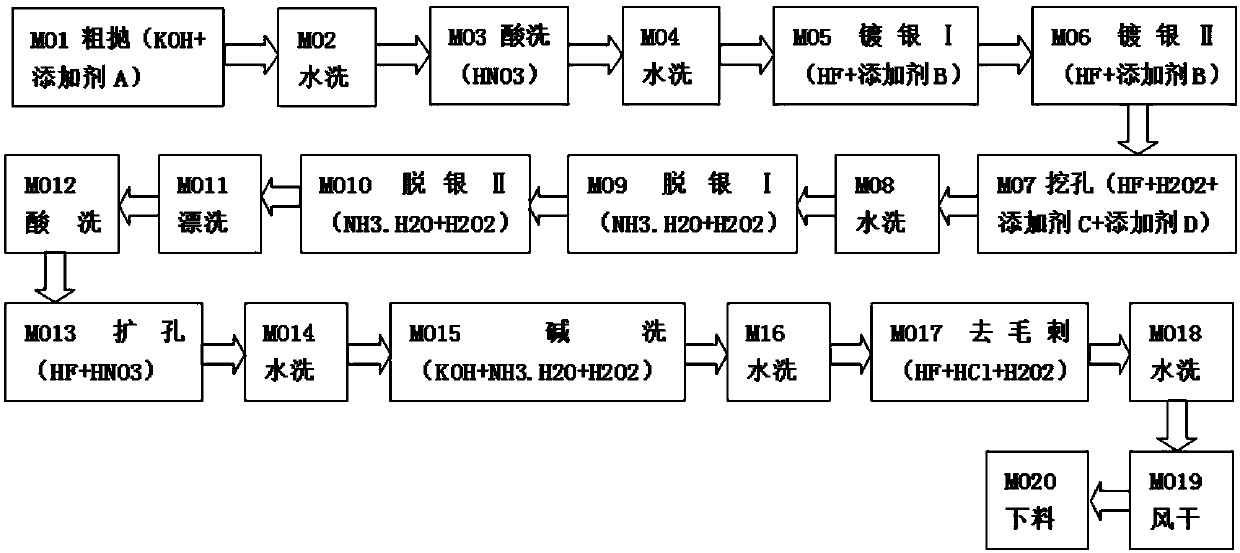

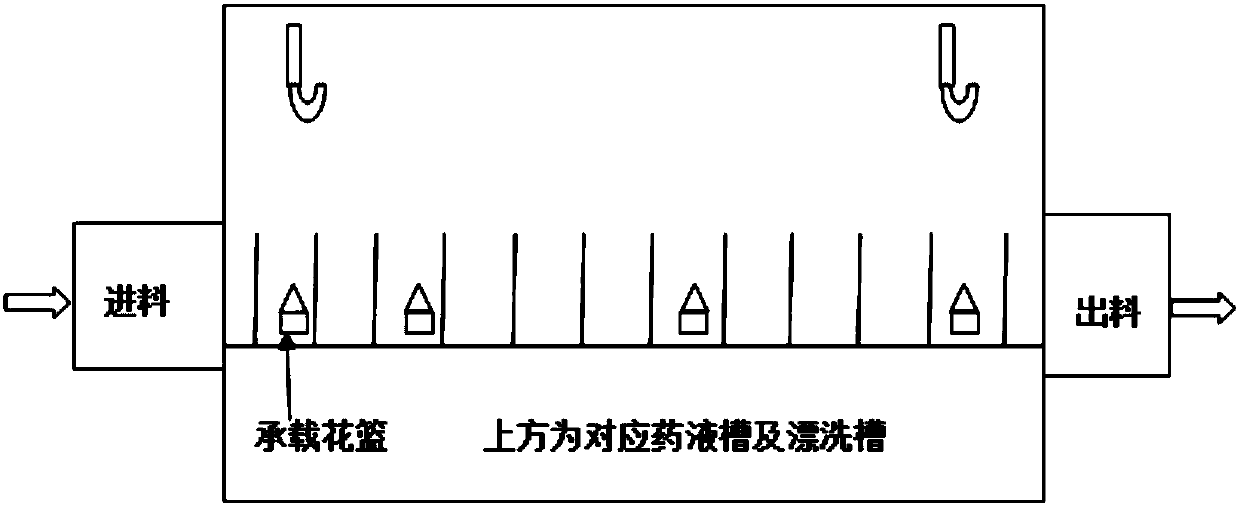

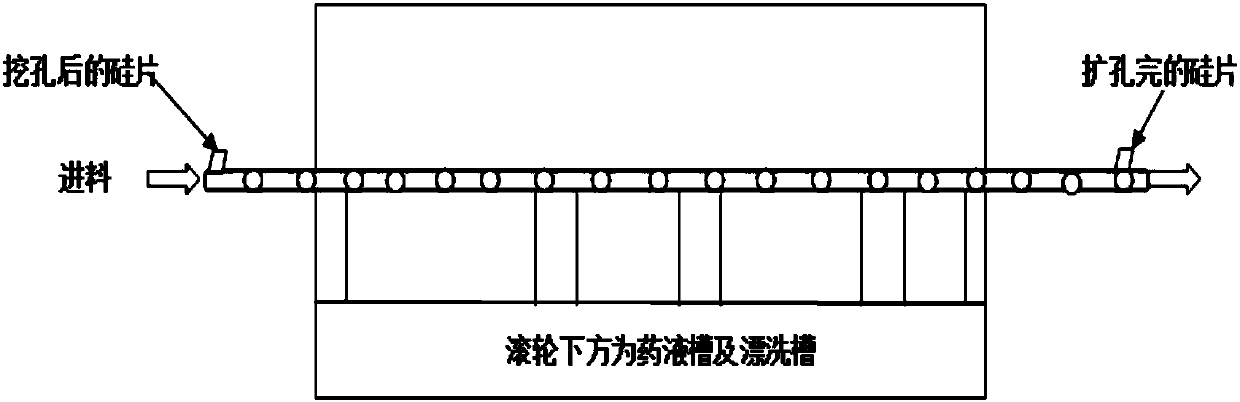

ActiveCN107742662AEfficient reuseSmall footprintFinal product manufactureSemiconductor devicesHoneycombChain type

The invention provides a honeycomb-shaped wet-method black-silicon texturing structure and a preparing method thereof and a black-silicon cell and a preparing method thereof, and relates to the technical field of black-silicon cell preparing. The preparing method of the honeycomb-shaped wet-method black-silicon texturing structure includes the steps that a diamond-wire polycrystalline silicon slice is subjected to hole digging operation through a wet-method black-silicon-tank hole digging device; products after hole digging operation is completed are subjected to hole expanding operation through a RENA chain-type device, NH3.H2O and H2O2 are added into alkaline wash liquid in an alkaline wash tank of the RENA chain-type device, and H2O2 is added into acid wash liquid of an acid wash tank.The ideal honeycomb-shaped wet-method black-silicon texturing structure with the excellent quality can be prepared, existing polycrystal production devices are fully used, and the device procurement / improvement costs are effectively reduced. The black-silicon cell prepared with the method is good in appearance performance and excellent in electric performance and has the large market popularization value.

Owner:江西瑞安新能源有限公司

Texturing preprocessing method of diamond wire cut polycrystalline silicon chip, textured preprocessed silicon chip and application thereof

ActiveCN104480532ATexture pretreatment method is simpleEasy to operateAfter-treatment detailsFinal product manufacturePretreatment methodSurface layer

The invention provides a texturing preprocessing method of a diamond wire cut polycrystalline silicon chip. The method comprises the following step of preprocessing the diamond wire cut polycrystalline silicon chip by phosphorus diffusion under the temperature of 850 to 900 DEG C to form an N type heavily-doped layer with square resistance of 40 to 100 ohm / Sq on the surface layer of the silicon chip so as to obtain a textured preprocessed silicon chip. The invention further provides a texturing method of the diamond wire cut polycrystalline silicon chip. The textured preprocessed silicon chip is textured generally to form a uniform and low-reflectivity textured surface so as to obtain the diamond wire cut polycrystalline silicon chip textured product. The invention also provides the textured preprocessed silicon chip and the diamond wire cut polycrystalline silicon chip textured product.

Owner:滁州赛维能源科技有限公司

Acid texturing additive for polysilicon film and use method thereof

InactiveCN104294369AEasy to cleanReduce in quantityAfter-treatment detailsActive agentCell fabrication

The invention belongs to the field of manufacture of solar batteries, relates to an acid texturing additive for a polysilicon film and a use method thereof, and the additive comprises the components of a perfluorinated nonionic surfactant, polyalcohol, citric acids and the balance of water. A method for acid texturing by using the additive comprises the following steps: (1) preparing the perfluorinated nonionic surfactant, the polyalcohol, the citric acids and the water to obtain the acid texturing additive for the polysilicon; (2) preparing hydrofluoric acids, nitric acids and the water to obtain an acid texturing solution; (3) adding the additive into the acid texturing solution which is obtained in the step (2); and (4) putting a silicon film into the acid texturing solution which is obtained in the step (3) for texturing. Through the use of the additive, a texturing surface is more uniform, an etch pit is finer, and compared with the conventional texturing, the reflectivity can be reduced by 2-3%.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

Texturing process for polycrystalline silicon solar cell slice

InactiveCN104073883AReduce reflectivityUniform suedeAfter-treatment detailsFinal product manufactureReflectivityChemistry

The invention discloses a texturing process for a polycrystalline silicon solar cell slice. The texturing process comprises the following steps of (1) spraying a layer of silicon dioxide particles on the surface of a silicon wafer; (2) carrying out primary texturing in a mixed solution containing nitric acid and hydrofluoric acid; (3) deacidifying in a sodium hydroxide solution; (4) carrying out secondary texturing in a mixed solution containing nitric acid and hydrofluoric acid; (5) deacidifying again in a sodium hydroxide solution. The solar cell slice produced by using the process is low in reflectivity, uniform in fabric surface and increased in photoelectric conversion efficiency.

Owner:邬时伟

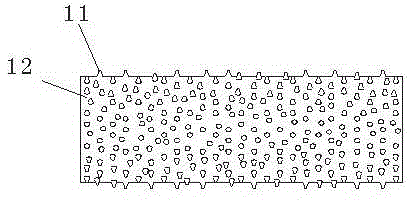

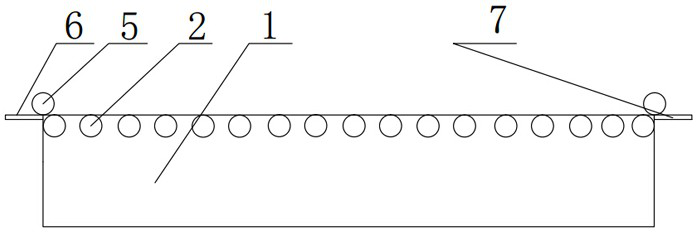

Novel conveying roller used for silicon wafer chained texturing

InactiveCN104538339ASolve the printing problemAlleviate the problem of uneven corrosionFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a novel conveying roller used for silicon wafer chained texturing. A gear or gears is / are arranged at one end or the two ends of the conveying roller and meshed with a transmission chain or a transmission belt of a chained texturing groove, the conveying roller is of a columnar structure or a cylindrical structure, and protrusions are arranged on the surface of the columnar structure or the cylindrical structure and are distributed on the surface of the columnar structure or the cylindrical structure in a prismatic shape, a rectangular shape and a honeycombed shape or distributed on the surface of the columnar structure or the cylindrical structure at will. According to the novel conveying roller, as the protrusions are arranged on the surface of the roller, the time for the same portions of a silicon wafer to be in contact with the protrusions is quite short, all the portions of the silicon wafer can be effectively in contact with corrosive liquid, and the roller printing problem is accordingly solved; in addition, bubbles generated when the silicon wafer is reacted with the corrosion liquid are pressed by the protrusions, and the large bubbles are broken up into the small bubbles; meanwhile, the bubbles are pressed to move among the protrusions distributed at will, parts of the bubbles are discharged out from the bottom of the silicon wafer, the problem of uneven corrosion, caused by bubble accumulating, of the bottom of the silicon wafer is effectively solved, and the textured surface is more even.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

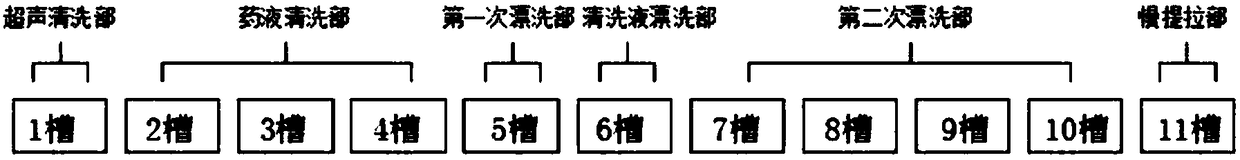

Cleaning liquor, cleaning equipment and cleaning process for silicon chip

InactiveCN108441353AEasy to cleanImprove cleaning efficiencyOrganic/inorganic per-compounds compounding agentsInorganic non-surface-active detergent compositionsEtchingSurface cleaning

The invention provides a cleaning liquor for a silicon chip. The cleaning liquor contains a potassium hydroxide liquor with concentration being 45% and a hydrogen peroxide liquor with concentration being 31%, wherein the volume ratio of the potassium hydroxide liquor to the hydrogen peroxide liquor is 1:1.05-1:7.25. Cleaning equipment for the silicon chip comprises an ultrasonic cleaning part usedfor removing granular silicon powder; a chemical cleaning part used for removing grease, metal ions and organic impurities, a first rinsing part used for removing chemical remaining on the surface ofthe silicon chip, a cleaning liquor cleaning part used for removing organic matter with the cleaning liquor for the silicon chip, a second rinsing part used for removing the cleaning liquor remainingon the surface of the silicon chip as well as a slow pulling part used for removing water on the surface of the silicon chip, so that water stains do not remain on the surface of the silicon chip. The invention further provides a cleaning process for the silicon chip on the basis of the cleaning equipment. The cleaning liquor, the cleaning equipment and the cleaning process for the silicon chip have the beneficial effects that the silicon chip surface cleaning effect is improved, cleaning efficiency and cleaning quality are improved, cleaning cost is saved, inspection proves that dirty chip rate is reduced obviously, and texture surface of the silicon chip is uniform and free of dirt after texture etching.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

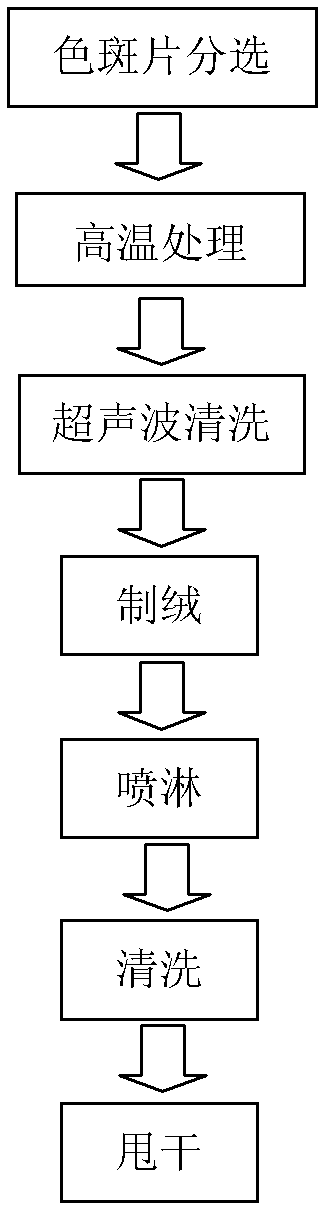

Method for reworking monocrystal colored spot sheet

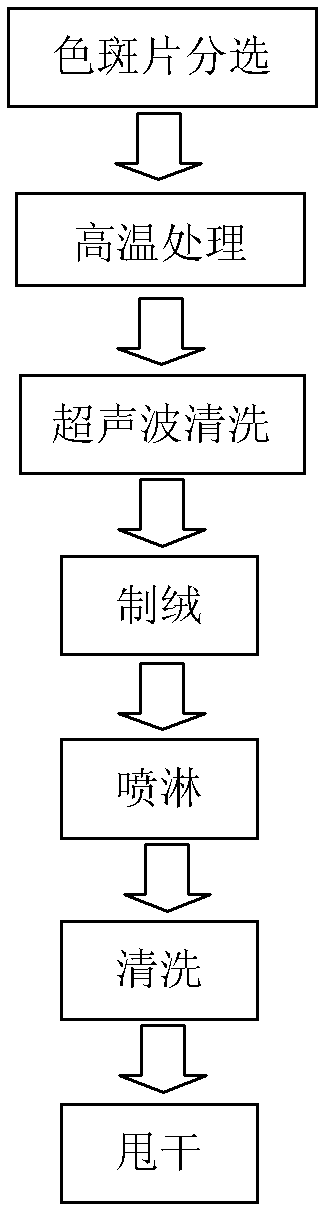

InactiveCN102522458AUniform suedeImprove conversion efficiencyAfter-treatment detailsFinal product manufactureSpinsMegasonic cleaning

The invention discloses a method for reworking a monocrystal colored spot sheet. The method comprises the steps of performing high-temperature treatment in a diffusion furnace, performing ultrasonic cleaning, flocking, pickling, rinsing, spin-drying and the like, and specifically comprises the following steps of: (1) sorting the colored spot sheet, putting the sorted colored spot sheet into the diffusion furnace passive, and treating in a certain temperature range for several minutes; (2) putting the colored spot sheet subjected to high-temperature treatment into deionized water for ultrasonic cleaning; (3) putting the cleaned silicon sheet into an alkali and IPA mixed solution with certain concentration, and performing alkali flocking in a flocking tank within a certain temperature range; and (4) pickling, rinsing and spin-drying the flocked silicon sheet, and finishing flocking. According to the method for treating the colored spot sheet produced by flocking a crystalline silicon solar battery, a colored spot phenomenon can be eliminated effectively; the obtained flocked surface is uniform; the conversion efficiency of a reworked sheet is improved; and the production cost is reduced effectively.

Owner:ZHEJIANG FORTUNE ENERGY

Method for removing fingerprints and heavy oil stain of monocrystalline silicon wafers

InactiveCN103184524AEasy to operateReduce downgrade issuesAfter-treatment detailsNon-surface-active detergent compositionsActive enzymePre treatment

The invention aims at disclosing a method for removing fingerprints and heavy oil stain of monocrystalline silicon wafers. The method comprises the following steps: a, performing pretreatment to a silicon wafer; b, laying the silicon wafer into a flocking groove, into which flocking liquid is injected so as to perform flocking to the silicon wafer; and adding active enzyme in at least one step. Compared with the prior art, the method has the advantages that the effect of obviously removing fingerprints and heavy oil stain on surfaces of silicon wafers can be achieved, suede is more uniform after flocking, the appearance is better, the problems of color spots and degradation of finished products caused by the color spots are effectively reduced, the operation of subsequent processes is convenient, and the purpose of the method is realized.

Owner:上海晶太新能源科技有限公司

Removing device for diamond wire cutting damage layer on surface of multicrystalline wafer

ActiveCN106363542ANo breaksSand blasting process continuousAbrasive machine appurtenancesCleaning using gasesDrive wheelSand blasting

The invention discloses a removing device for a diamond wire cutting damage layer on the surface of a multicrystalline wafer, which is lower in cost and can form a better suede. The removing device comprises a support, a headless belt, a driving wheel and a driven wheel, wherein the headless belt bypasses the driving wheel and the driven wheel and is tightened by the driving wheel and the driven wheel; the headless belt is horizontally arranged, and a supporting platform is arranged between the headless belt positioned on an upper layer and the headless belt positioned on a lower layer; the upper surface of the supporting platform is a smooth plane; the headless belt positioned on the upper layer is in contact with the upper surface of the supporting platform; a sandblasting apparatus is arranged above the supporting platform. By using the sand blasting device, the diamond wire cutting damage layer of the multicrystalline wafer can be effectively removed, and uniform suede, low reflectivity and better suede quality of a finally-obtained silicon wafer are guaranteed; in addition, by using the device, the streamline operation can be realized, the efficiency is higher, and the production cost of the multicrystalline wafer can be greatly reduced. The removing device is suitable for popularization and application in the technical field of processing of silicon wafers.

Owner:LESHAN TOPRAYCELL

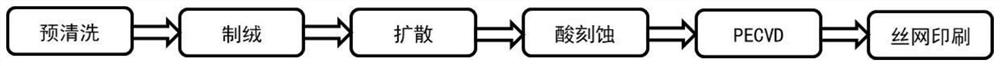

Monocrystalline silicon wafer pre-cleaning method

InactiveCN102719896ATo achieve the purpose of pre-cleaningAvoid driftingAfter-treatment detailsMetallurgySolar battery

The invention relates to a cleaning technology in solar battery production process, concretely to a monocrystalline silicon wafer pre-cleaning method which can completely and effectively clean off smudginess from monocrystalline silicon incoming materials. The pre-cleaning method comprises three technical steps of first-time fluid preparation, cleaning and fluid supplementation. The method overcomes the disadvantages of the prior art and is capable of completely removing smugness, fingerprints, organic matter residues and the like from monocrystalline silicon wafers manufactured with different technologies and by different manufacturers without affecting any indexes of the monocrystalline silicon wafers. By using the method, good pile faces are obtained through pile-face manufacturing, pile-face making time is shortened, drug amount needed for pile-face making is reduced and surface clearness of the monocrystalline silicon wafer cleaned through the abovementioned steps meets class A wafer standard.

Owner:JILIN QINGDA NEW ENERGY ELECTRIC POWER

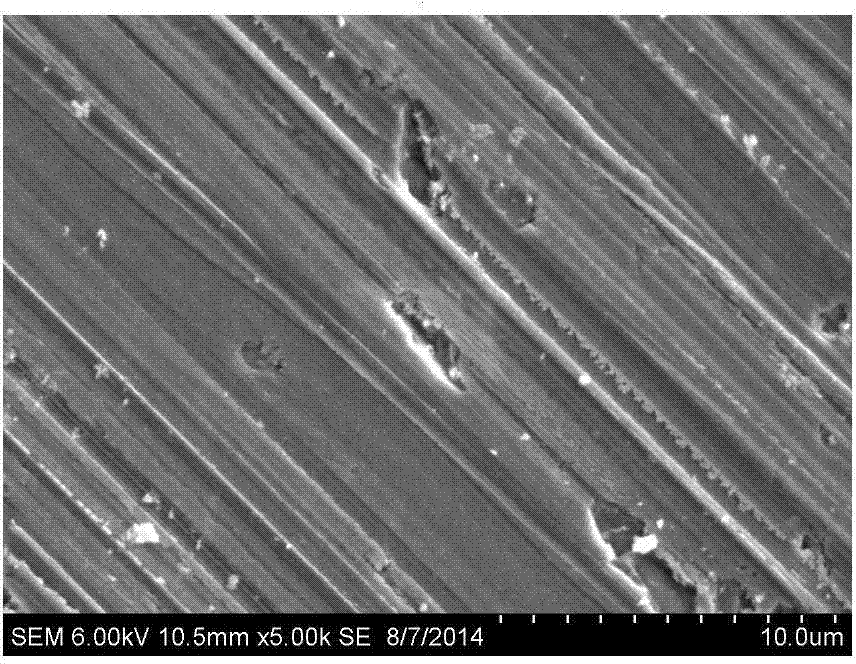

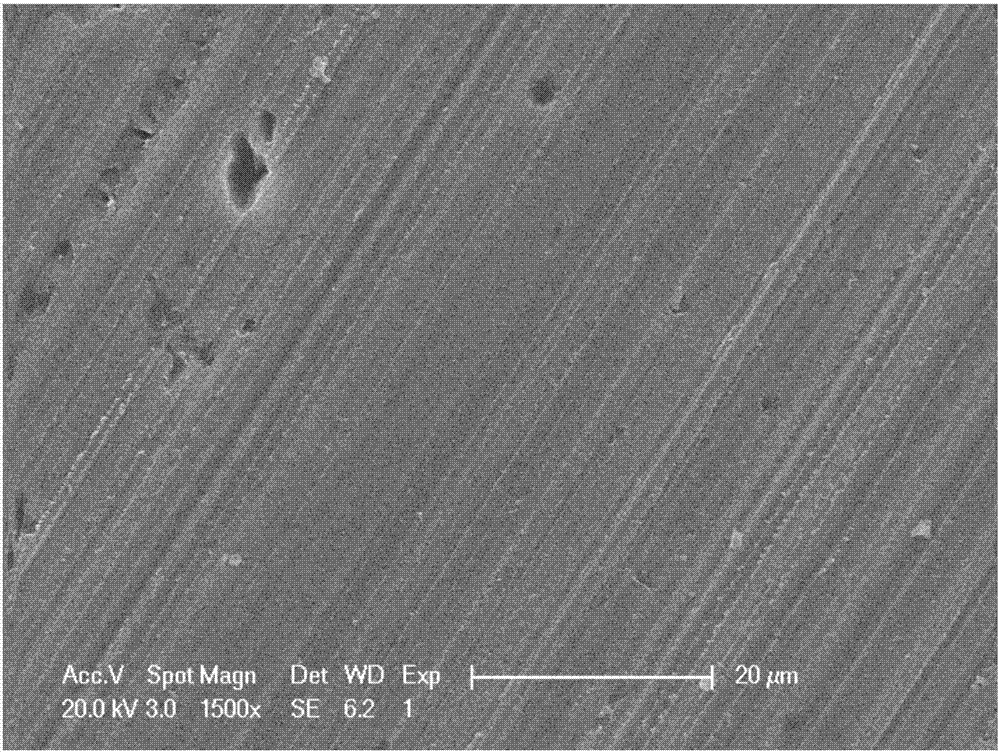

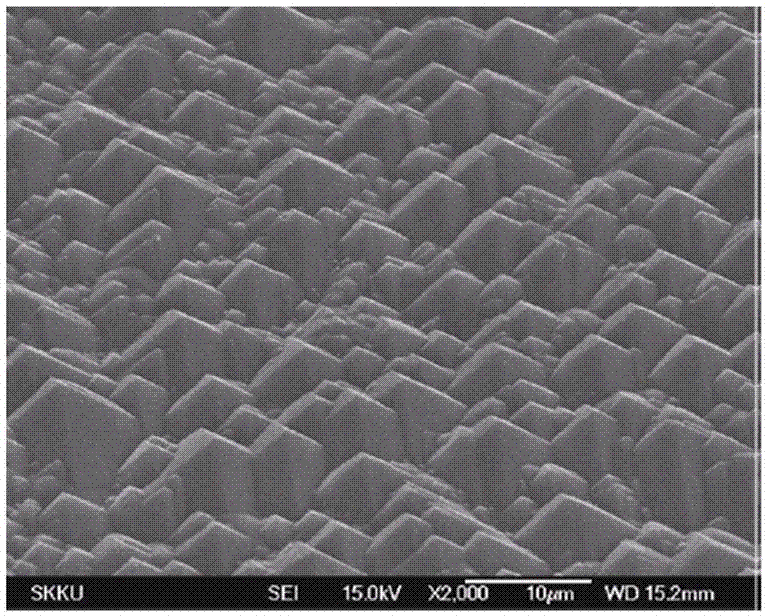

Texturing method for diamond wire-cut polycrystalline silicon wafers

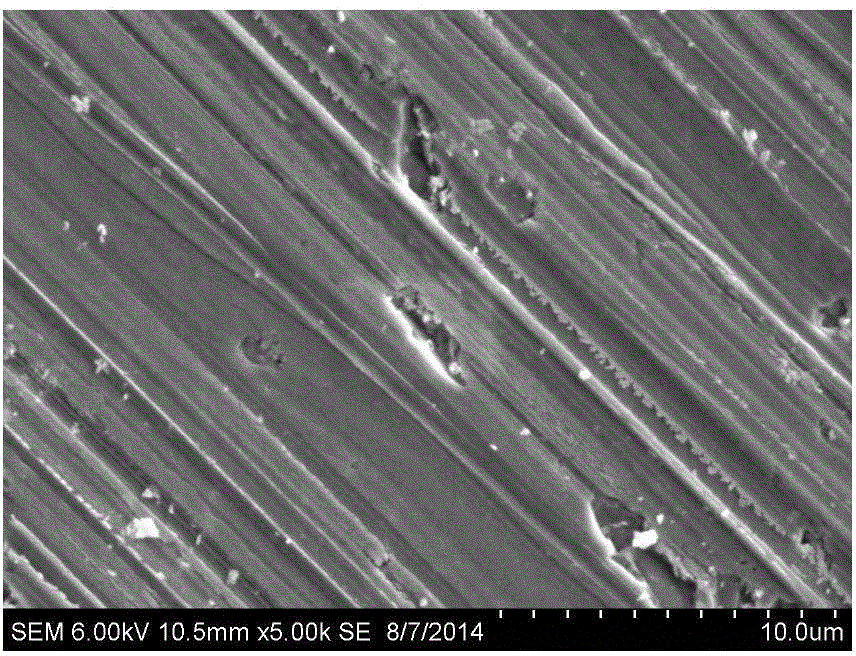

ActiveCN105932078BEliminate cut linesUniform suedeAfter-treatment detailsPhotovoltaic energy generationAbrasive blastingDiamond cutting

The invention relates to a texturing method of a polycrystalline silicon wafer cut by a diamond wire. The method comprises the following steps: getting a polycrystalline silicon wafer obtained after diamond wire cutting; carrying out preprocessing on the surface of the polycrystalline silicon wafer through grinding or abrasive blasting to fully eliminate cutting lines in the surface of the polycrystalline silicon wafer, and meanwhile, to make an appropriate damage layer on the surface of the polycrystalline silicon wafer; carrying out water washing on the polycrystalline silicon wafer obtained after processing, and placing the washed polycrystalline silicon wafer to acidic texturing liquid to form a textured surface; and carrying out water washing, alkaline washing, water washing, acid washing, water washing and drying in sequence on the polycrystalline silicon wafer obtained after texturing to finish texturing. The method can completely eliminate the cutting lines in the surface of the polycrystalline silicon wafer obtained after being cut by the diamond wire; and the shape of the damage layer on the surface of the polycrystalline silicon wafer can be controlled flexibly by controlling grinding or abrasive blasting parameters to enable the textured surface of the polycrystalline silicon wafer obtained after texturing to be more uniform and lower in reflection rate.

Owner:云南合义德新材料有限公司

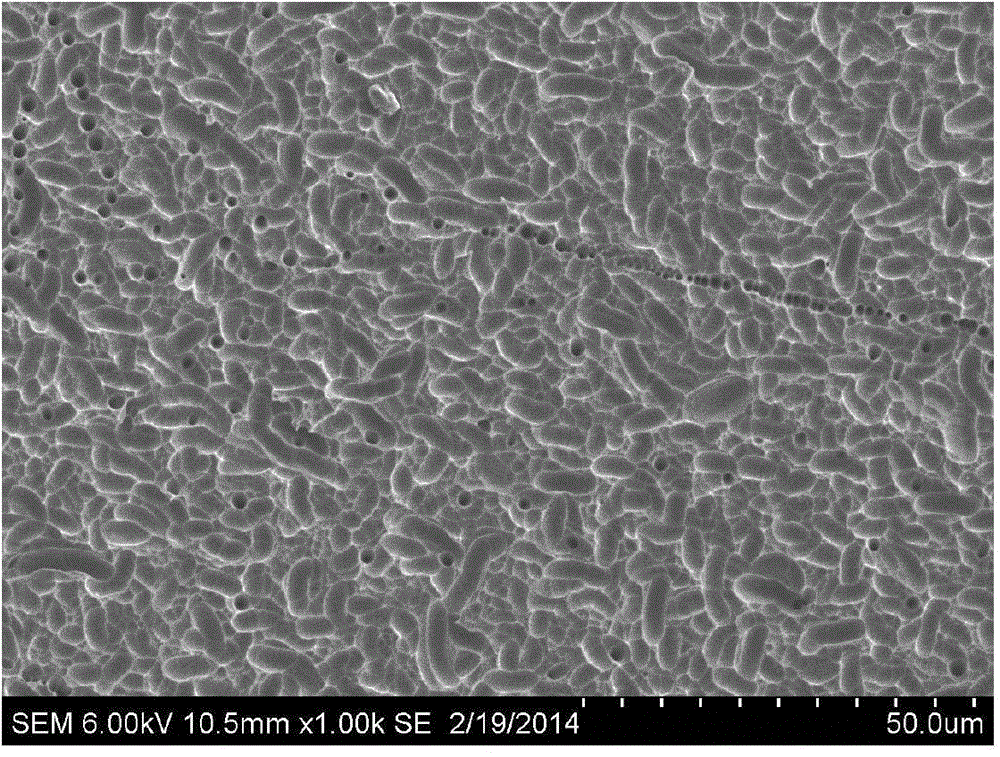

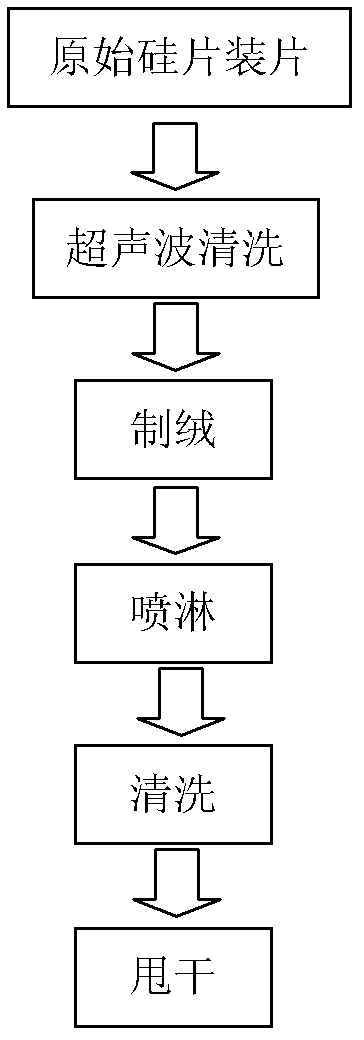

Method for cleaning silicon wafer after diamond wire cutting

ActiveCN107240546AGood removal effectIncrease coverageSemiconductor/solid-state device manufacturingWire cuttingAcid activation

The invention relates to the field of silicon wafer cleaning, particularly to the field of silicon wafers after diamond wire cutting. The method for cleaning a silicon wafer after diamond wire cutting is carried out according to the following steps: 1. a step of cleaning the silicon wafer cut by a diamond wire in a citric acid aqueous solution; 2. a step of cleaning the silicon wafer in an alkaline cleaner; and 3. a step of cleaning the silicon wafer in hydrogen peroxide. A weak acid activation process is added before alkaline cleaning, so that metal ions remaining on the surface of the silicon wafer are less, a hydrogen peroxide cleaning process is added after alkaline cleaning to remove surface residual alkaline liquor, organic matter and metal ions, and at the same time, a surface damaged layer is better removed. The coverage rate of pyramid suede of the silicon wafer is relatively high in a subsequent battery etching process, and the suede is relatively uniform.

Owner:SHANXI LUAN PHOTOVOLTAICS TECH

Polycrystal texturing auxiliary and application method thereof

InactiveCN104328504AEasy to cleanReduce in quantityPolycrystalline material growthAfter-treatment detailsSilicic acidActive agent

The invention belongs to the field of solar battery manufacturing and particularly relates to a polycrystal texturing auxiliary and an application method thereof. The polycrystal texturing auxiliary comprises the following components: a perfluor nonionic surfactant, polyhydric alcohols, citric acid and the balance of water. The method of applying the auxiliary to perform acid texturing comprises the following steps: (1) preparing the auxiliary for polycrystal silicic acid texturing from the perfluor nonionic surfactant, the polyhydric alcohols, the citric acid and the water; (2), preparing an acid texturing solution from hydrofluoric acid, nitric acid and water; (3) adding the auxiliary into the acid texturing solution prepared in the step (2); and (4) putting a silicon wafer into the acid texturing solution prepared in the step (3) for texturing. After the auxiliary is used, the suede is relatively uniform and relatively small in etching pit, and the reflectance can be reduced by 2-3% in comparison with that of conventional texturing.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

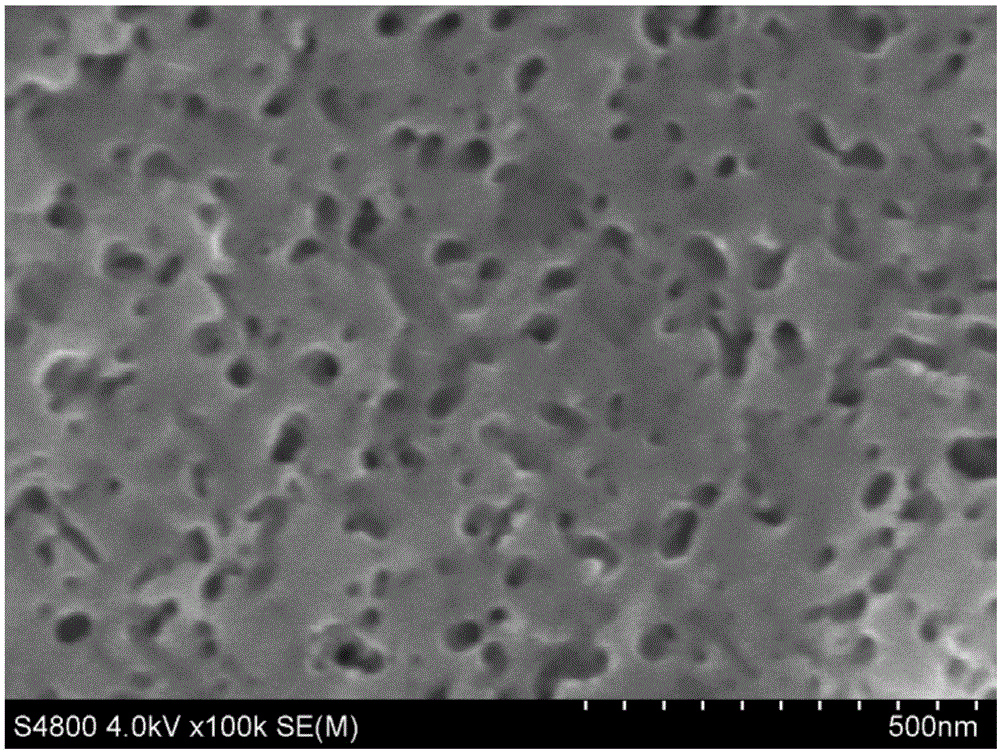

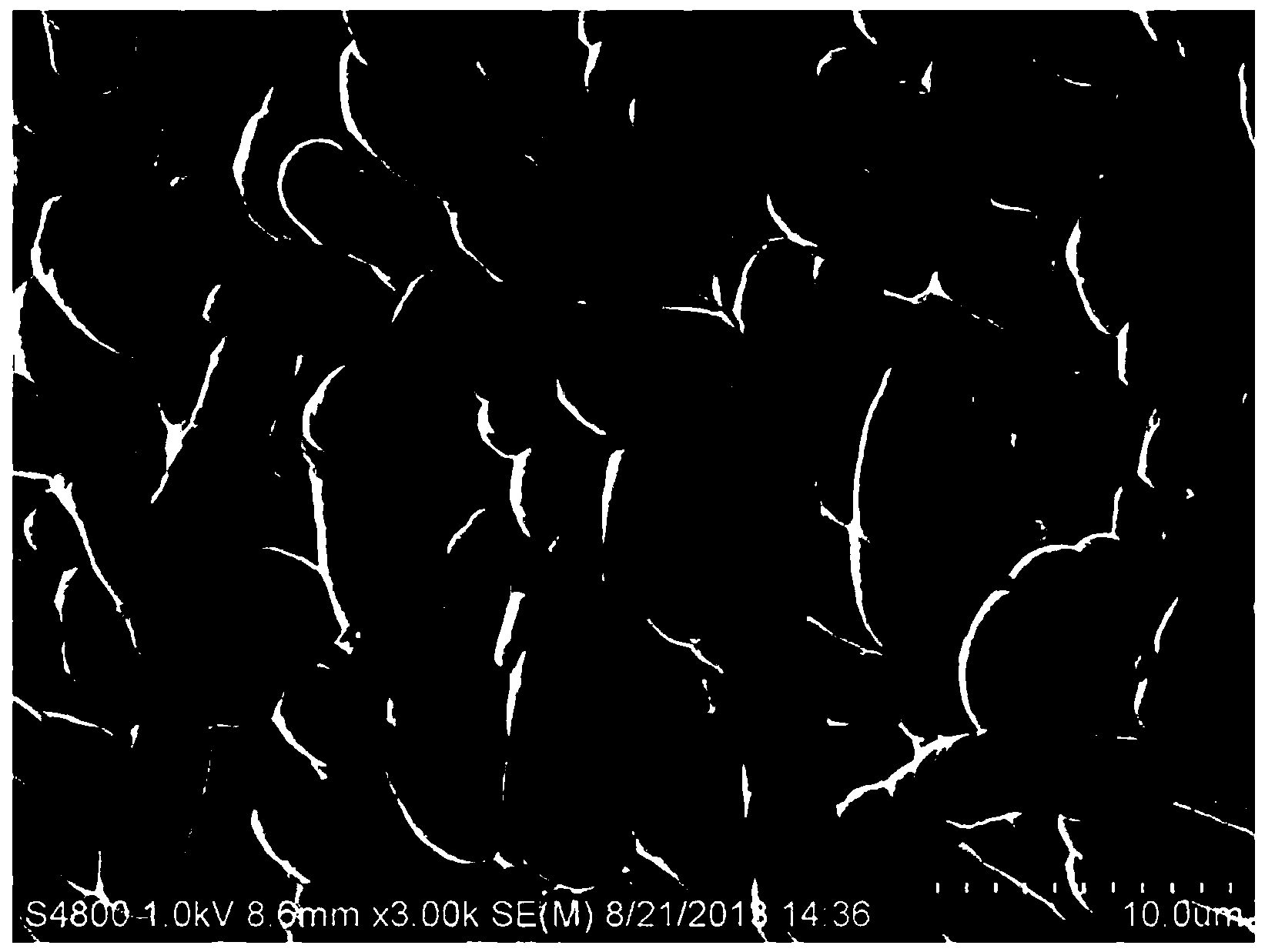

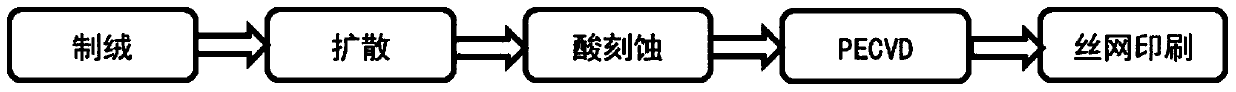

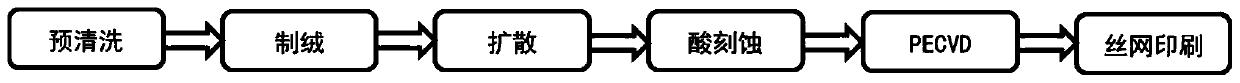

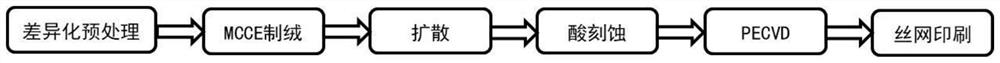

Reworking method for acid etching polycrystalline battery

ActiveCN110518080AReduce Surface State VariationsReduce surface reflectivityPolycrystalline material growthAfter-treatment detailsAcid etchingSilicon

The invention relates to a reworking method for an acid etching polycrystalline battery, which belongs to the technical field of photoelectricity. The method is used for producing an acid etching polycrystalline reworked wafer, bad wafers generated in etching, diffusion, acid etching and PECVD procedures are collected, differentiation pretreatment is carried out on the reworked wafers generated indifferent procedures, and then a metal catalytic chemical etching (MCCE) method is adopted for etching. The differentiation pretreatment scheme is selected for a reworked wafer generated in a different procedure, the surface state difference of the reworked wafer is reduced, and uniform etched surfaces can be obtained after the reworked wafers are etched again. 200-800 nanometer holes are formedin the surface of the reworked wafer through MCCE, the cell is further prepared through a subsequent processing procedure, the surface reflectivity of a silicon wafer can be greatly reduced, the photoelectric conversion efficiency is further improved, meanwhile, a more uniform etched surface can be obtained, and the proportion of a chromatic aberration wafer is reduced.

Owner:WUXI SUNTECH POWER CO LTD

Triggering agent applicable for etching treatment of solar cell

InactiveCN105226116AReasonable formula designImprove processing efficiencyPhotovoltaic energy generationSemiconductor devicesMethyl salicylateEthyl acetate

The invention relates to the technical field of machining, in particular to a triggering agent applicable for etching treatment of a solar cell. The triggering agent is prepared from 5 parts of polydimethylsiloxane, 5 parts of ethyl acetate, 0.5 part of alantolactone, 5 parts of methyl salicylate, 5 parts of sodium chloride and 79.5 parts of water according to the following steps of: firstly, adding 5 parts of polydimethylsiloxane, 5 parts of ethyl acetate and 50 parts of water to a vessel and stirring the mixture for 10 minutes; secondly, slowly adding 0.5 part of alantolactone and 5 parts of methyl salicylate, stirring the mixture with adding, and stirring the mixture for 10 minutes after addition is completed; and finally, adding 5 parts of sodium chloride and 29.5 parts of water at one time, thereby obtaining the triggering agent. In the triggering agent, a few amount of the alantolactone is added, so that the processing efficiency of the triggering agent can be remarkably improved; by using the triggering agent in a matching way, etching surfaces of a battery substrate subjected to surface etching and side-wall protection are uniform and consistent; with a method of addition step by step, the dissolving performance among substances can be improved, and the possibility of particle agglomeration also can be prevented.

Owner:尚成荣

Method for removing fingerprints from single crystal silicon wafers in solar cell production

InactiveCN102842641AEfficient removalShorten the time of texturingFinal product manufactureFlexible article cleaningHydrogen fluorideSolar cell

The invention relates to a process for washing single crystal silicon wafers in solar cell production, in particular to a method capable of cleanly and effectively washing off fingerprints on the single crystal silicon wafers during transfer. The method comprises the steps as follows: (1) adding 150-160 L of de-ionized water into a process tank with the volume of 150-180 L, increasing the temperature of water in the process tank, and keeping the temperature to be 15-25 DEG C; preparing various chemicals, adding 16 L of HF (Hydrogen Fluoride) (electronic grade), and uniformly stirring with a PP (Propene Polymer) long bar to obtain a prepared solution for use; and (2) placing the single crystal silicon wafers with the sizes of 125*125 into bearing boxes, placing the bearing boxes into a big flower basket to serve as a batch of the single crystal silicon wafers, requiring the number of the single crystal silicon wafers in each batch to be 300-400, placing the big flower basket with the single crystal silicon wafers into the process tank with the prepared solution in the step (1), soaking for about 200-300 s, and taking out the single crystal silicon wafers in the big flower basket, so that the washing process is finished.

Owner:JILIN QINGDA NEW ENERGY ELECTRIC POWER

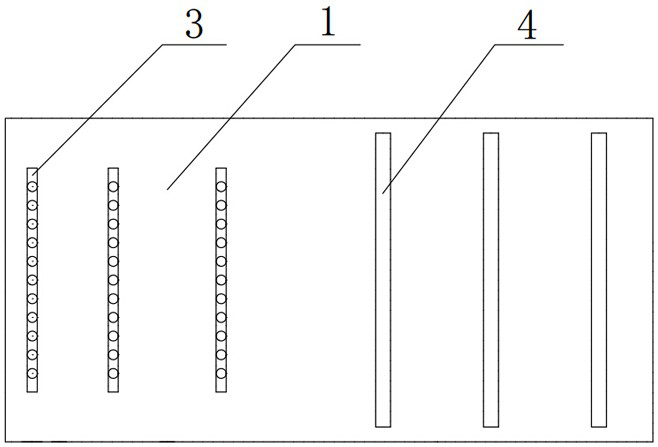

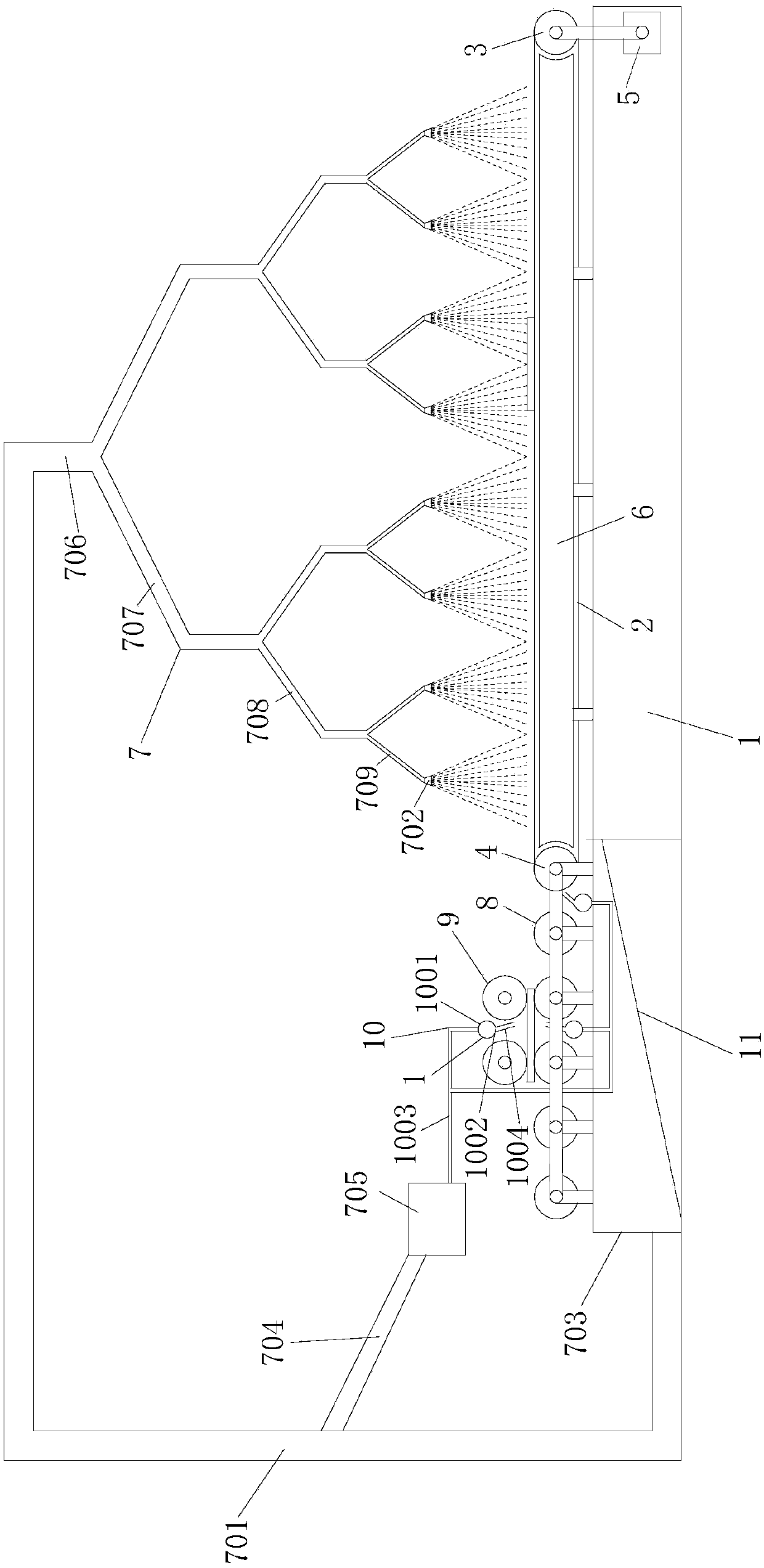

Texturing device and method for polycrystalline silicon wafer

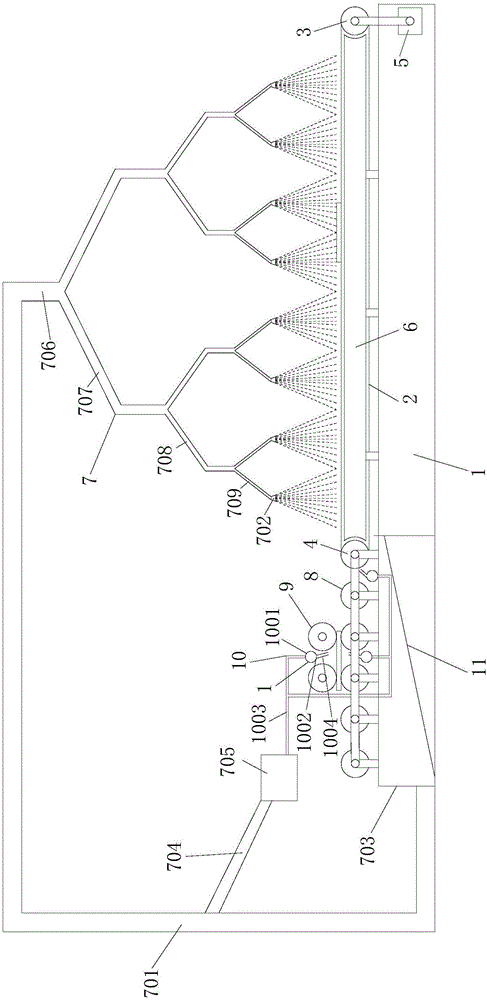

ActiveCN108963033BCycle evenlyReduce concentrationAfter-treatment detailsFinal product manufactureChemical solutionManufacturing technology

The present invention relates to the field of solar cell manufacturing technology, and in particular, to a polycrystalline silicon sheet texturing apparatus and method. The apparatus comprises a texturing groove (1) and a moving roller (2) disposed in the texturing groove for driving the movement of the silicon wafer, the bottom of the texturing groove is provided with a return pipe (3) near the entrance position of the silicon wafer, the bottom of the texturing groove is provided with a liquid inlet pipe (4) near the exit position of the silicon wafer, and liquid retaining wheels (5) for blocking the outflow of a chemical solution are provided at the entrance and exit positions of the silicon wafer of the texturing groove. The polycrystalline silicon sheet texturing apparatus and method have a better texturing effect.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

Fabric production method capable of improving pilling resistance of worsted fabrics

ActiveCN104313826BAvoid fuzzMuch underliningSingeingLiquid/gas/vapor textile treatmentCooking & bakingWorsted

The invention discloses a production method of a fabric capable of improving the anti-pilling property of worsted fabric, and belongs to the field of fabric weaving. The method uses two times of singeing and two times of crabbing, and includes the following steps: a first singeing, a first crabbing, milling, a first drying, a second singeing, scouring, a second crabbing, a second drying, brushing, shearing, baking and decating. Compared with the prior art, the worsted fabric produced by the method of the invention retains the original characteristics, also has good anti-pilling performance and very good application value.

Owner:SHANDONG RUYI WOOLEN GARMENT GRP CO LTD

A device for removing the diamond wire cutting damage layer on the surface of polycrystalline silicon wafer

ActiveCN106363542BNo breaksSand blasting process continuousAbrasive machine appurtenancesCleaning using gasesDiamond cuttingDrive wheel

Owner:LESHAN TOPRAYCELL

Wet-process groove type black silicon texturing method

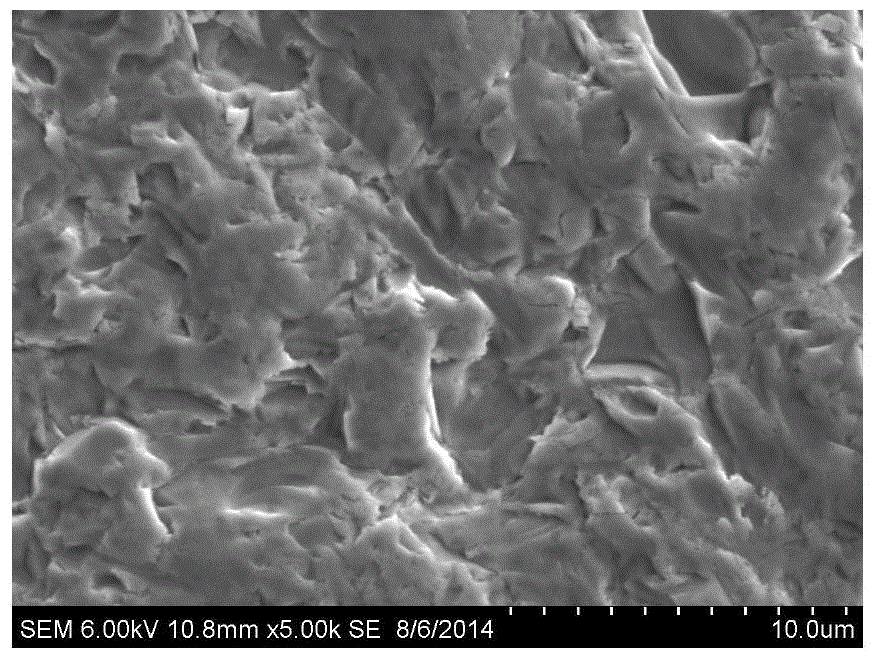

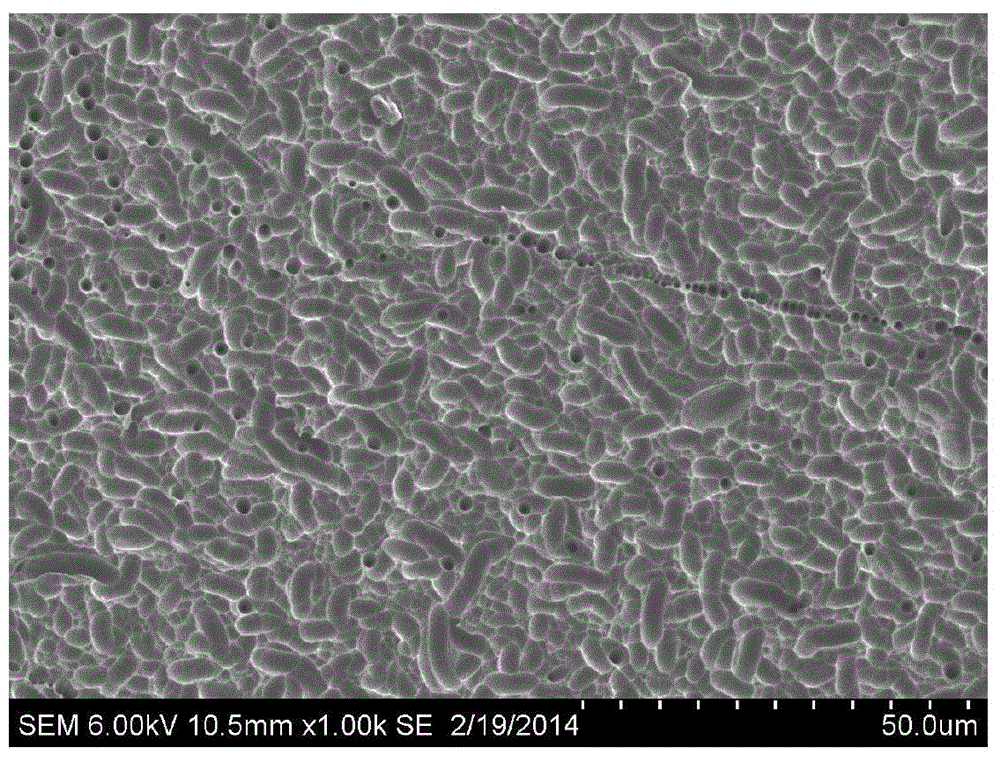

InactiveCN110416353AReduce the impact of digging effectsUniform suedeFinal product manufactureSemiconductor/solid-state device manufacturingStop flowSmall hole

The invention discloses a wet-process groove type black silicon texturing method. The method comprises the following steps: carrying out surface treatment on a silicon wafer, and putting the silicon wafer into a primary treatment groove to remove line marks on the surface of the silicon wafer so as to obtain a primary silicon wafer with the smooth surface; performing hole digging and texturing onthe silicon wafer subjected to surface treatment, and putting the obtained primary silicon wafer into a secondary treatment groove for reaction for 180-220s to obtain a secondary silicon wafer with nanoscale small holes in the surface, wherein before the primary silicon wafer is put into the secondary treatment groove, a mixed solution in the secondary treatment groove stops flowing circularly 10-20s in advance until the hole digging is completed; carrying out hole expanding on the silicon wafer subjected to the hole digging and texturing, and putting the secondary silicon wafer subjected to the hole digging into a tertiary treatment groove for treatment for 85-95s to obtain a tertiary silicon wafer; and putting the obtained tertiary silicon wafer into a cleaning groove to obtain a siliconwafer with no metal ions on the surface, and drying the cleaned silicon wafer to obtain a finished silicon wafer. The obtained textured silicon wafer is same in hole size and good in uniformity.

Owner:阜宁苏民绿色能源科技有限公司

Method for fine-hair maring using monocrystalline silicon slice

InactiveCN101409312BUnbreakableUniform and fine suedeFinal product manufactureSemiconductor devicesStable stateState of art

The invention discloses a method for texturing a monocrystalline silicon wafer. The method comprises the steps of texturing by corrosion, passivation and deionization. By the technical scheme of cancelling rough polishing, and changing a formula, reaction conditions and treatment flow, the method overcomes the problems and the disadvantages of the prior art that the texturing technological processis difficult to be controlled, the thickness reduction of the monocrystalline silicon wafer is greater, the silicon wafer is easily cracked during the treatment process, the textures formed on the silicon wafer is uneven, and bulky dimension of a cone structure leads to high reflectivity of the silicon wafer, lower short circuit current (Isc) and lower photoelectric conversion rate. The method provided for texturing the monocrystalline silicon wafer realizes that corrosive liquid is in a steady state which is easy to be controlled, the thickness reduction of the silicon wafer is reduced, theformed textures are even and the dimension of the cone structure is compact; the method reaches the purposes of reducing the reflectivity of the silicon wafer, increasing the short circuit current (Isc), and improving the photoelectric conversion rate, meanwhile, the method improves the quality and the qualification rate of the product on the whole, reduces the consumption of chemical reagents andlowers the cost.

Owner:SHANGHAI CHAORI (LUOYANG) SOLAR ENERGY CO LTD

A kind of method for making texture of solar cells

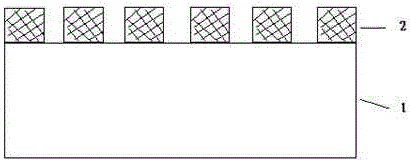

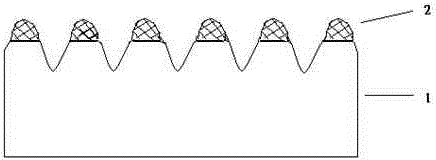

ActiveCN103378212BImprove performanceSimple processAfter-treatment detailsFinal product manufactureSlurrySolar cell

The present invention provides a texturing method for a solar cell. The texturing method comprises a step A. coating a surface of a silicon wafer with a silicon slurry which is a mixture of ganister sand, a binder and water to form a ganister sand dot matrix with a height of 3-30[Mu]m; and a step B. carrying out chemical etching on the surface, where the ganister sand dot matrix is formed, of the silicon wafer, and forming a concave-convex antireflection structure on the surface of the silicon wafer after etching to obtain a textured silicon wafer. According to the texturing method for the solar cell, texturing reflectance of the silicon wafer is below 5% with regular and uniform texturing and few surface defects, and therefore the performance of the solar cell can be effectively improved. In addition, the process is simple and mass production can be achieved.

Owner:HUIZHOU BYD BATTERY

A kind of reworking method of acid textured polycrystalline battery

ActiveCN110518080BReduce Surface State VariationsReduce surface reflectivityPolycrystalline material growthAfter-treatment detailsAcid etchingElectrical battery

The invention relates to a reworking method for an acid etching polycrystalline battery, which belongs to the technical field of photoelectricity. The method is used for producing an acid etching polycrystalline reworked wafer, bad wafers generated in etching, diffusion, acid etching and PECVD procedures are collected, differentiation pretreatment is carried out on the reworked wafers generated indifferent procedures, and then a metal catalytic chemical etching (MCCE) method is adopted for etching. The differentiation pretreatment scheme is selected for a reworked wafer generated in a different procedure, the surface state difference of the reworked wafer is reduced, and uniform etched surfaces can be obtained after the reworked wafers are etched again. 200-800 nanometer holes are formedin the surface of the reworked wafer through MCCE, the cell is further prepared through a subsequent processing procedure, the surface reflectivity of a silicon wafer can be greatly reduced, the photoelectric conversion efficiency is further improved, meanwhile, a more uniform etched surface can be obtained, and the proportion of a chromatic aberration wafer is reduced.

Owner:WUXI SUNTECH POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com