Method for reworking monocrystal colored spot sheet

A color spot and single crystal technology, applied in the field of crystalline silicon solar cell production, can solve the problems of affecting production efficiency, reducing conversion efficiency, and scrapping, so as to reduce the number of degraded or scrapped silicon wafers, improve conversion efficiency, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

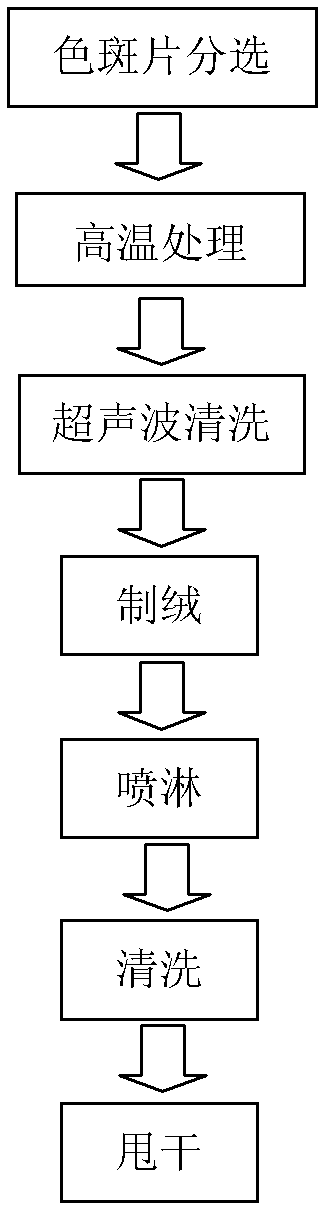

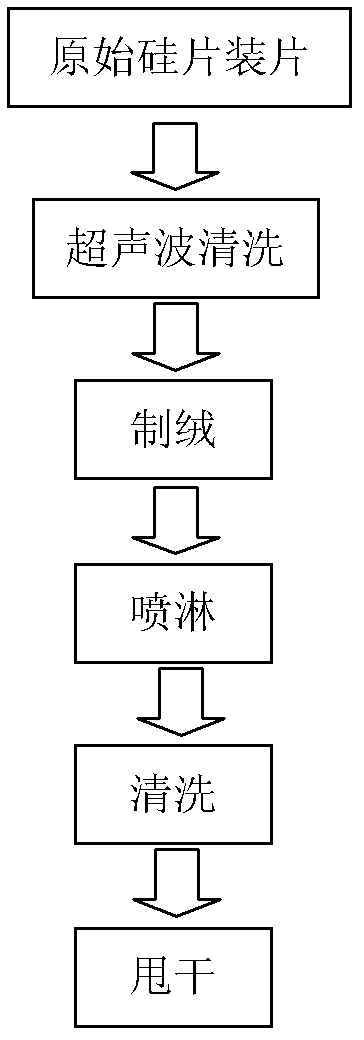

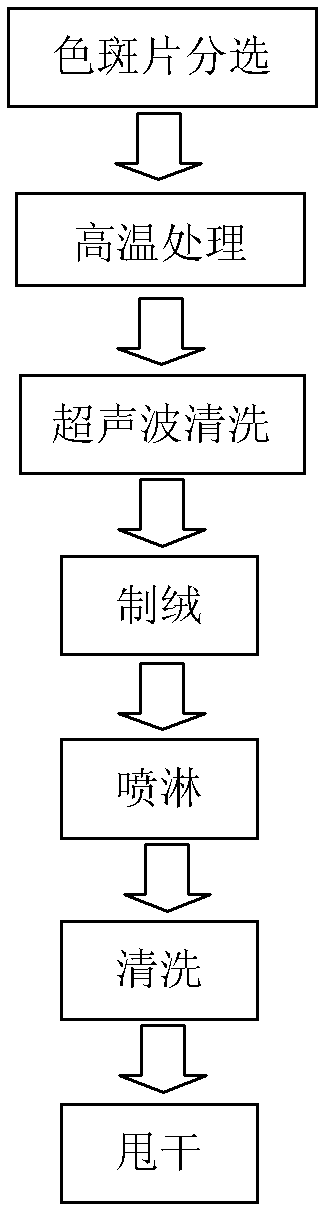

[0014] The invention provides a method for reworking a single crystal color patch comprising the following steps:

[0015] 1. Sorting out the color spots, and placing one or two silicon wafers in each slot of the quartz boat;

[0016] 2. Place the quartz boat with the silicon wafer in a diffusion furnace without a source, and treat it at a temperature of 830±0.5°C for 5-10 minutes at a high temperature, so that the organic matter can be volatilized to achieve the purpose of removing stains;

[0017] 3. Put it in deionized water for ultrasonic cleaning or alkali cleaning at room temperature. The frequency of ultrasonic wave is 80KHZ, the power is 1800W, and the cleaning time is 0-8min. The purpose is to remove the dirt adsorbed on the surface of the silicon wafer;

[0018] 4. Place the cleaned silicon wafer in a mixed solution of alkali and IPA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com