Additive for chambering acid liquid for texturing polycrystal black silicon and application of additive

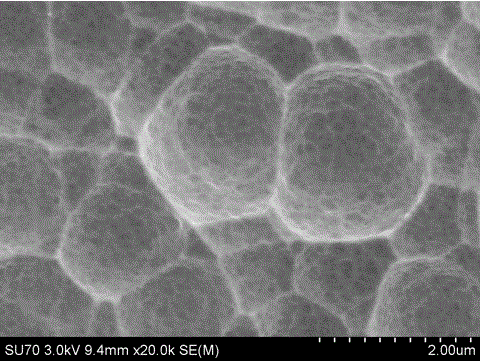

A technology of additives and pore-expanding acid, which is applied in the field of additives for pore-expanding acid liquid for polycrystalline black silicon texturing, and can solve the problem of the decline in acceptance of black silicon texturing, the influence of the uniformity of nano-textured surface, and the rapid response of pore-expanding treatment and other problems, to achieve the effect of improving battery efficiency, uniform appearance, and crystal flower color tending to be consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0031] The technical scheme of concrete implementation of the present invention is:

[0032] The invention provides an additive for polycrystalline black silicon pore-expanding acid solution, the mass percentage of each component is: polyvinyl alcohol 0.5%-2%, triethanolamine 1%-5%, tartaric acid 1% ~3%, silane coupling agent 0.5%~2%, the balance is water.

[0033] Preferably, the silane coupling agent is selected from one or more of KH550, KH560 and KH570.

[0034] Preferably, the water is deionized water.

[0035] The present invention also provides a pore-enlarging acid solution for polycrystalline black silicon texture, which contains an acid solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com