Patents

Literature

39results about How to "Shorten the time of texturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

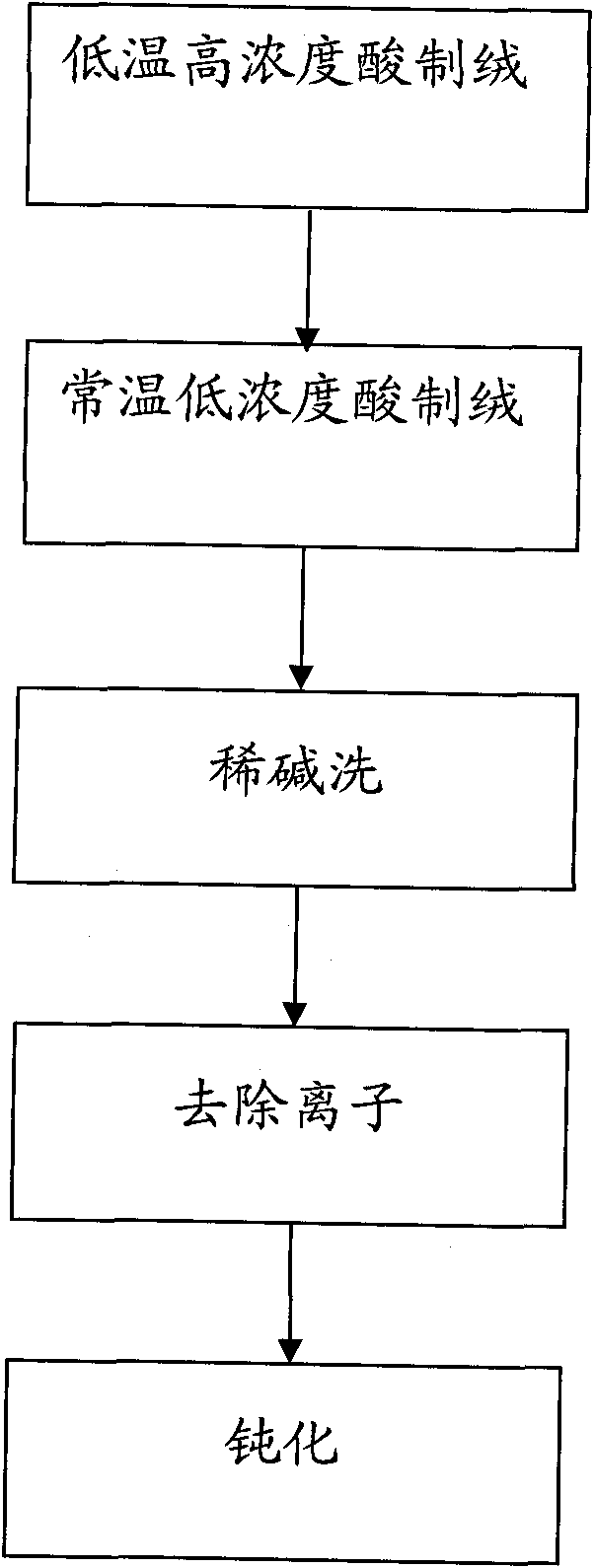

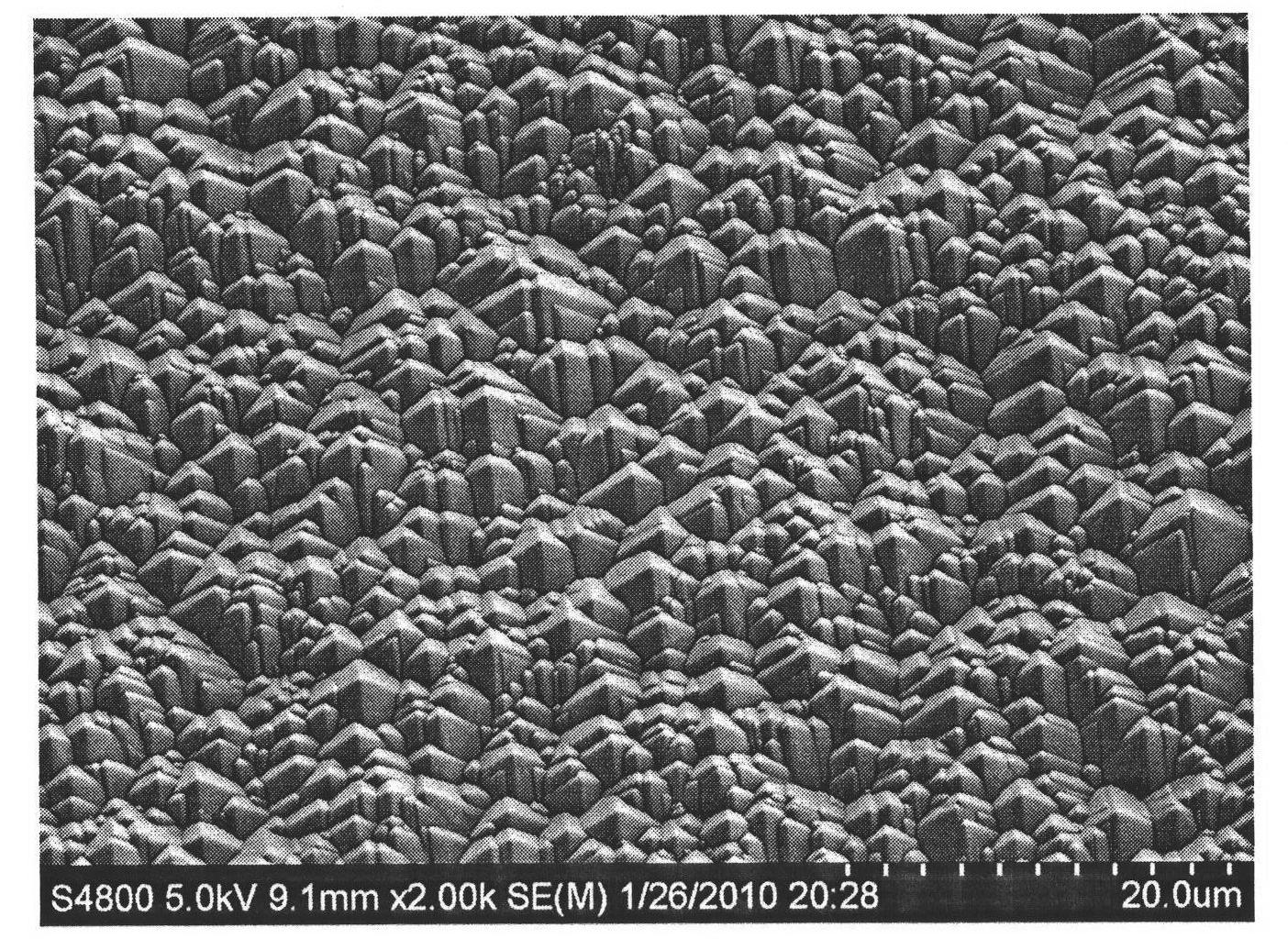

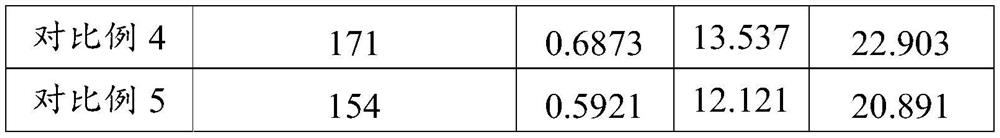

Polycrystalline silicon texturing method

ActiveCN101876088APrecisely control the degree of texturizationPrecise control of thinningAfter-treatment detailsFinal product manufactureElectricityHigh concentration

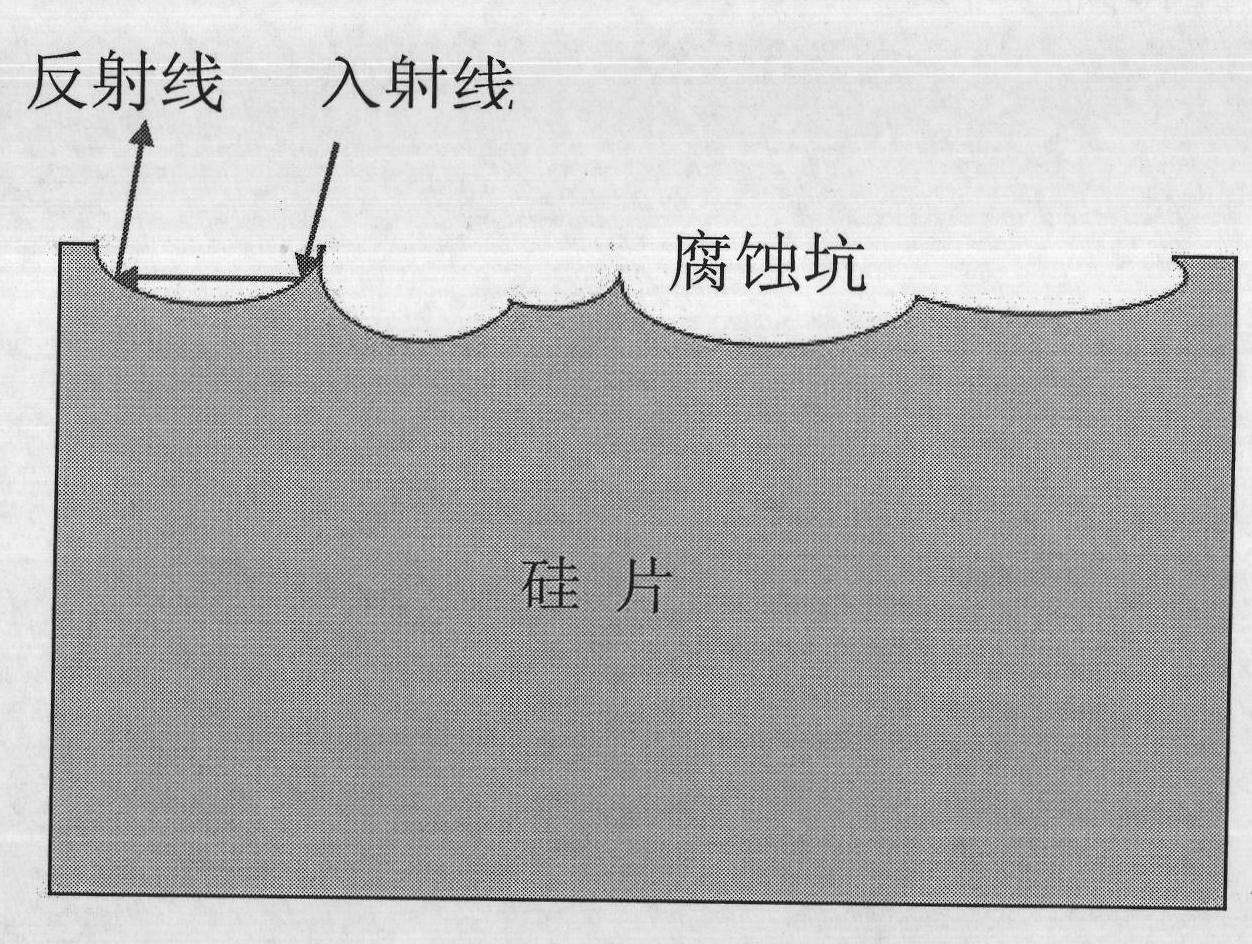

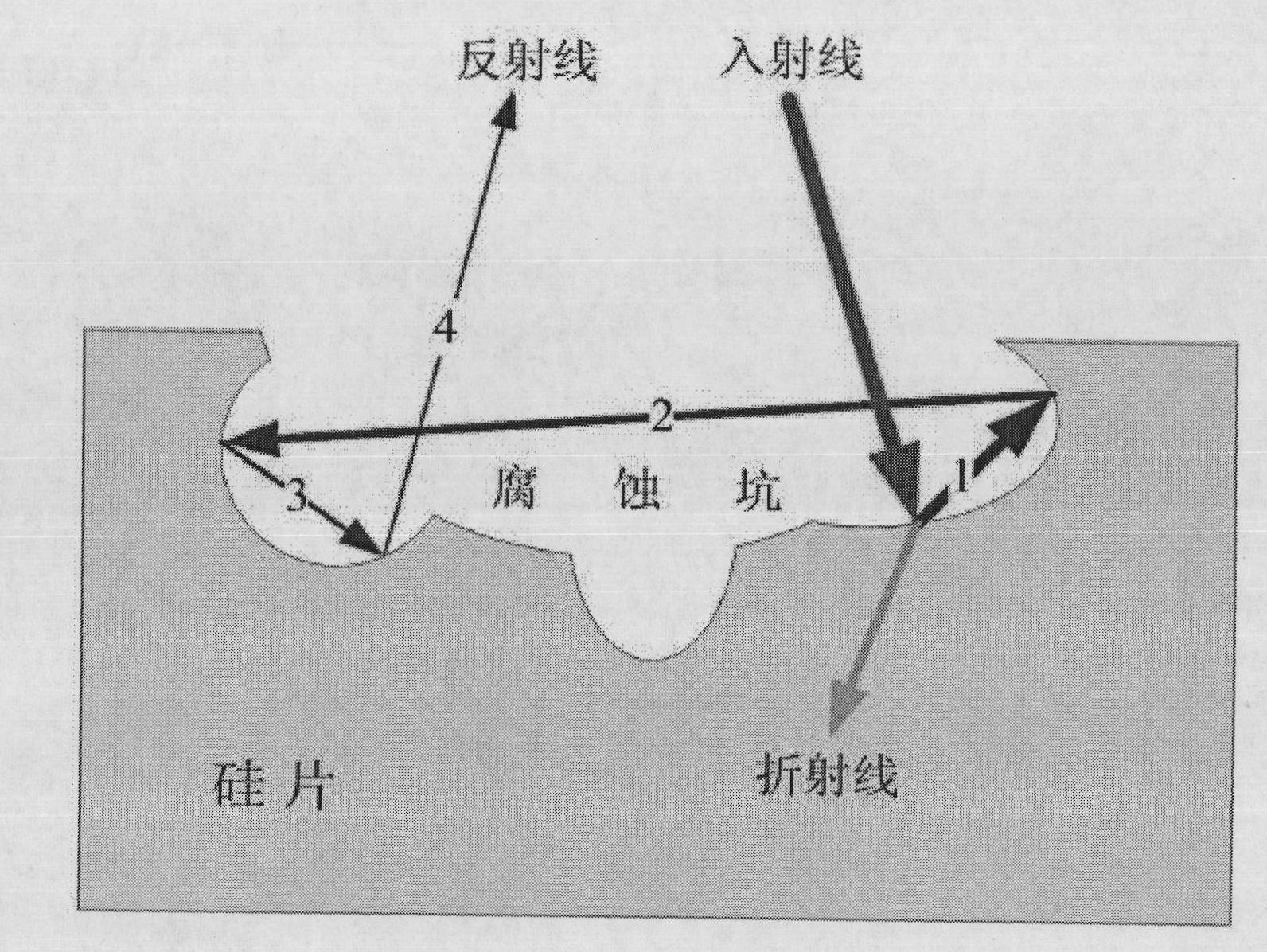

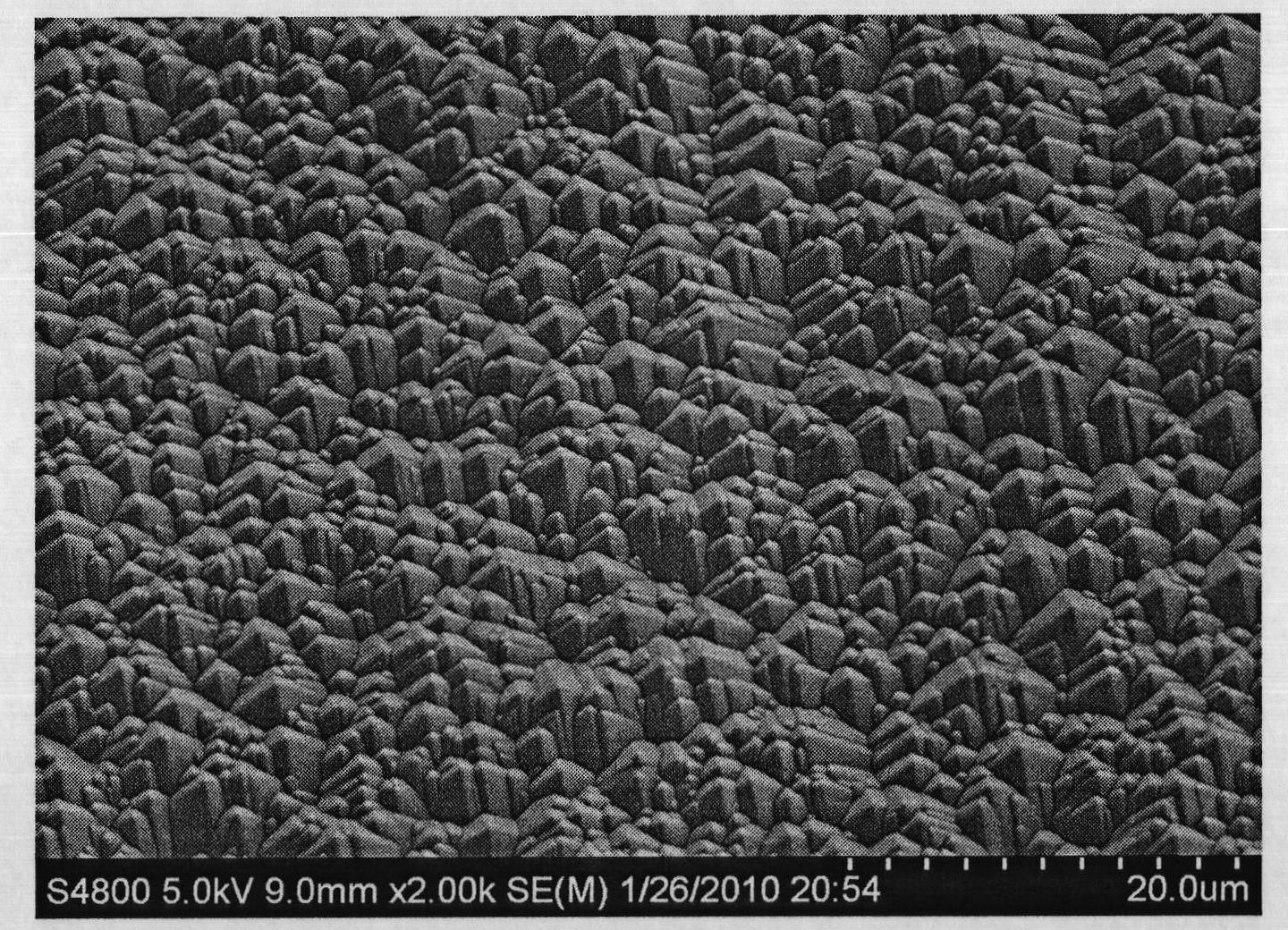

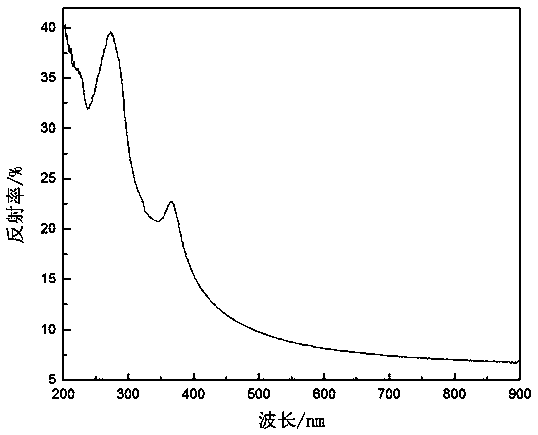

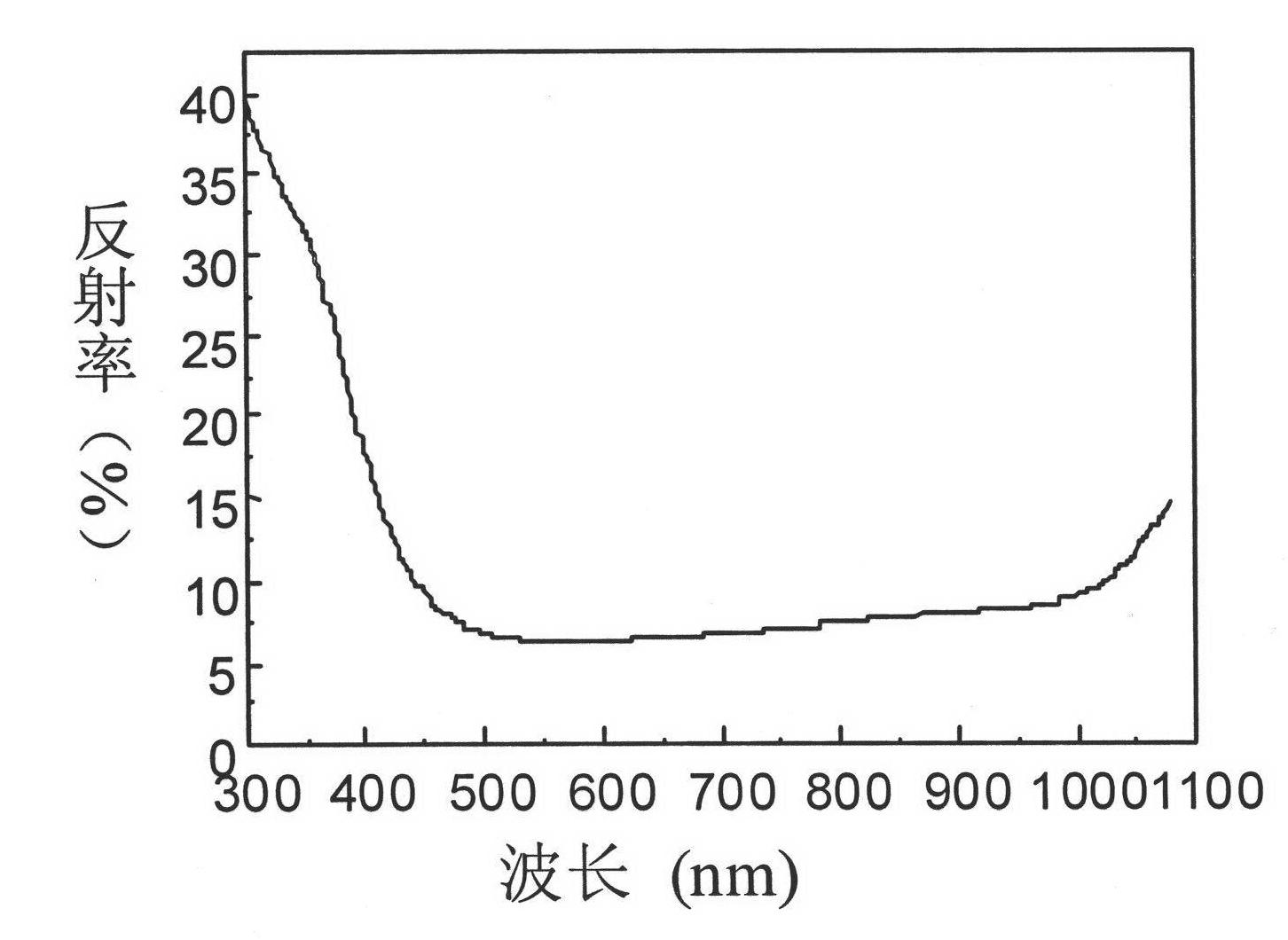

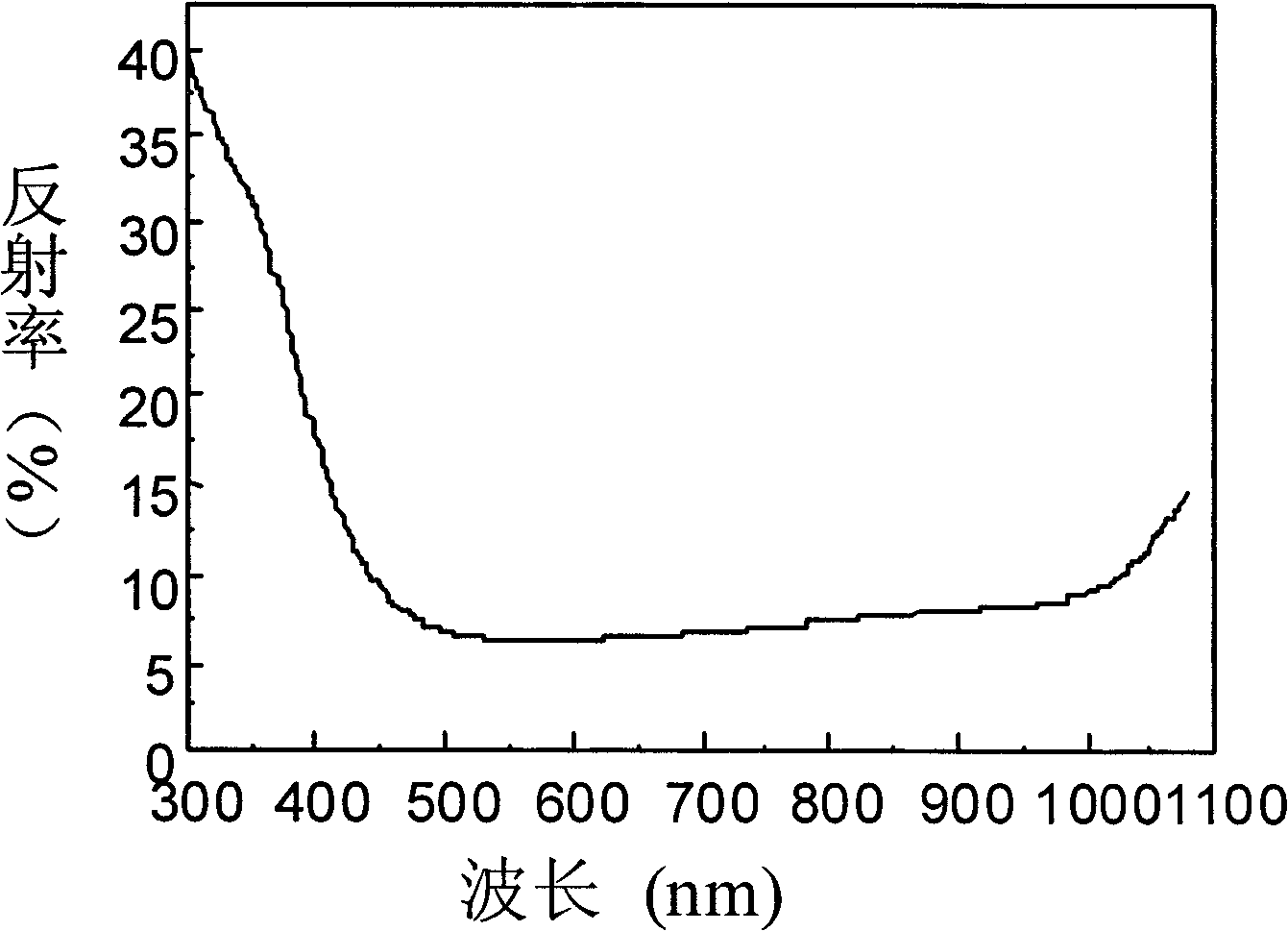

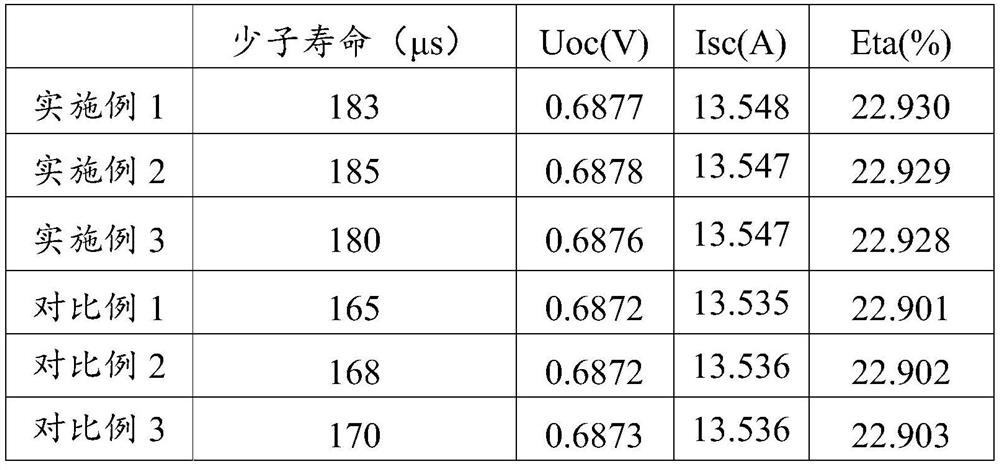

The invention discloses a polycrystalline silicon texturing method which comprises low-temperature high-concentration acidizing fluid texturing, normal-temperature low-concentration acidizing fluid, alkali cleaning, ion removal and passivation. The invention provides more a proper acid treatment fluid and a corrosion texturing process for the polycrystalline silicon texturing to ensure that the removal of a mechanical damage layer on the surface of a silicon slice and the texturing are easier to control, can accurately control the texturing degree of the surface of the silicon slice and the thickness reduction of the silicon slice, shorten the texturing time, improve the texturing yield of a battery, reduce the surface reflectivity, increase the light absorption and the short-circuit current, and improve the photo-electricity conversion efficiency of the battery.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

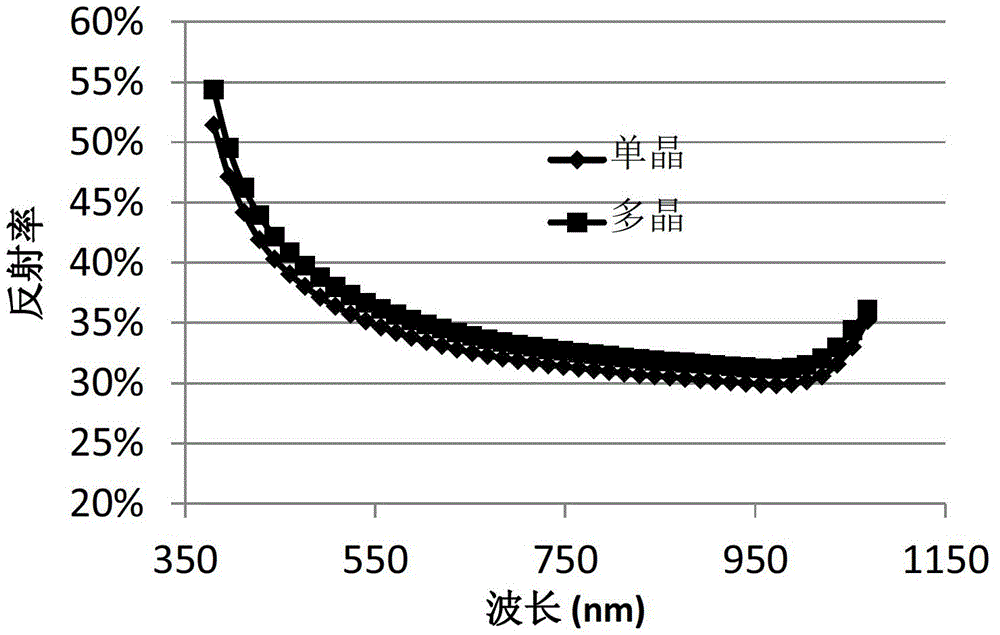

Additive of wool making solution for monocrystalline silicon pieces and using method

ActiveCN101851757AReduce reflectivityImprove yieldFinal product manufactureSemiconductor devicesSolar cellVitamin

The invention relates to an additive of a wool making solution for monocrystalline silicon pieces, containing the components of lactic acid, vitamin and the balance of water. When the monocrystalline silicon pieces for solar cells are subjected to surface wool making, the additive is added in the alkali wool making solution so that an excellent wool making effect is achieved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

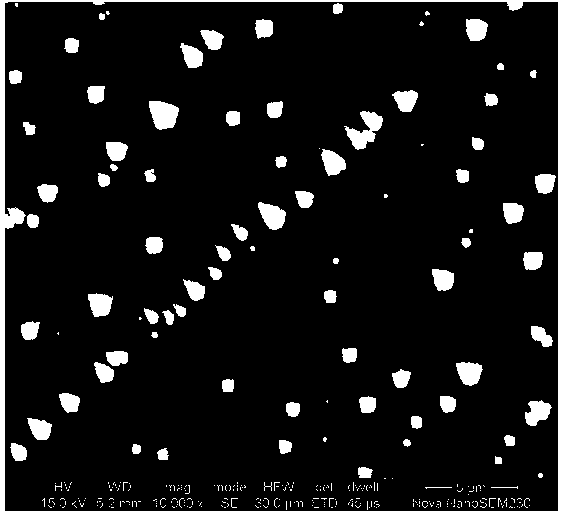

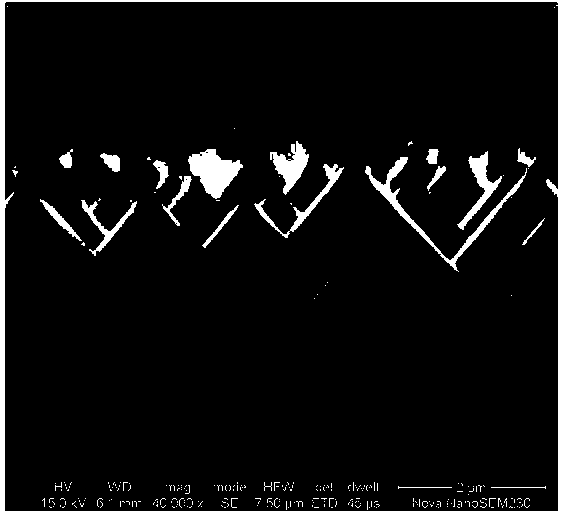

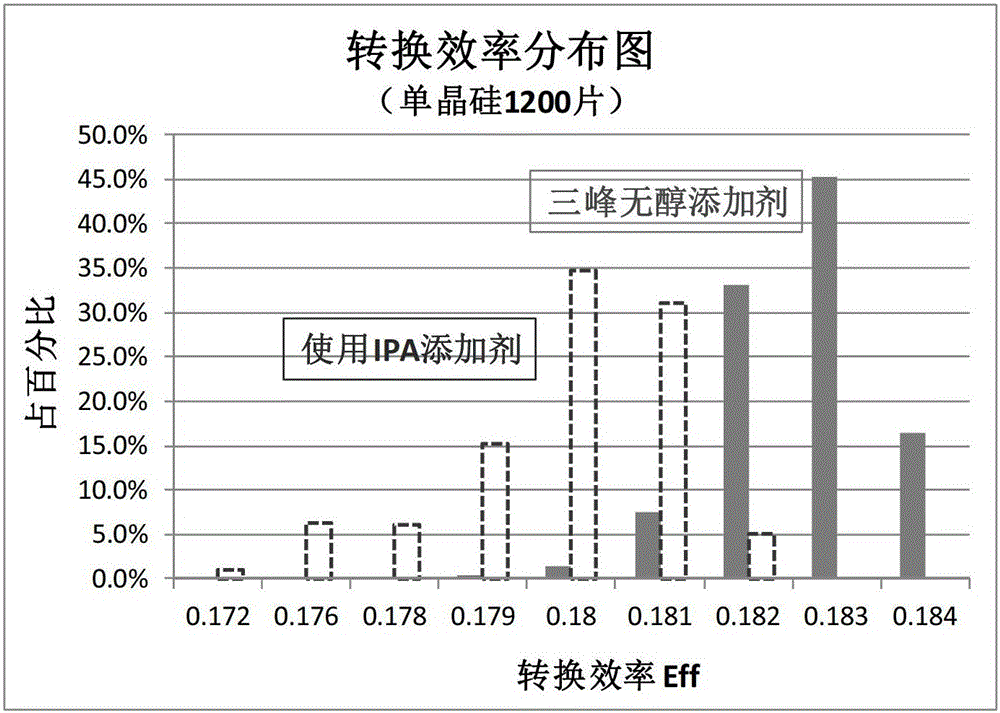

Additive for alkali environment-protecting type no-alcoholic felting liquid of mono-crystal silicone chip and using method thereof

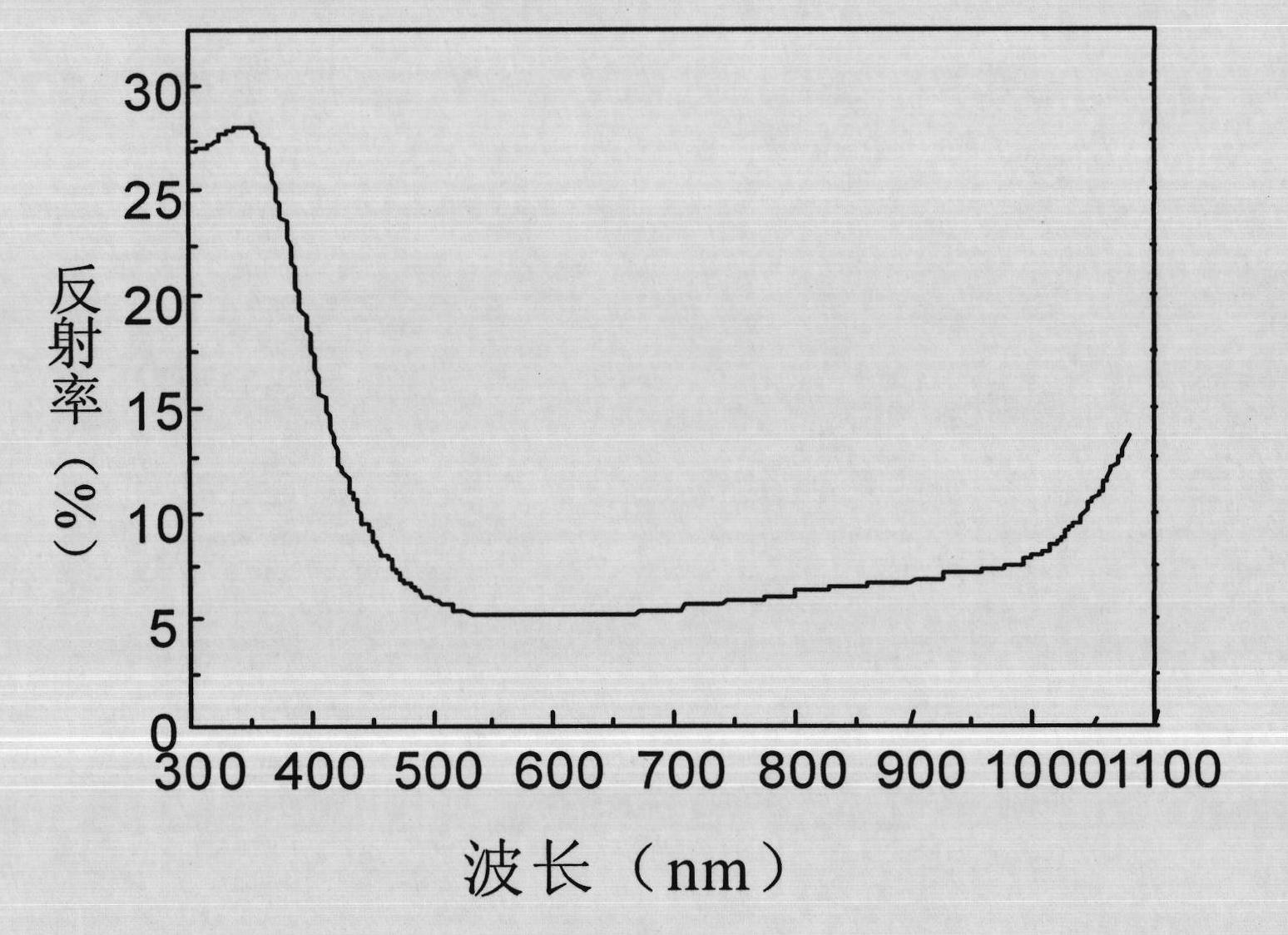

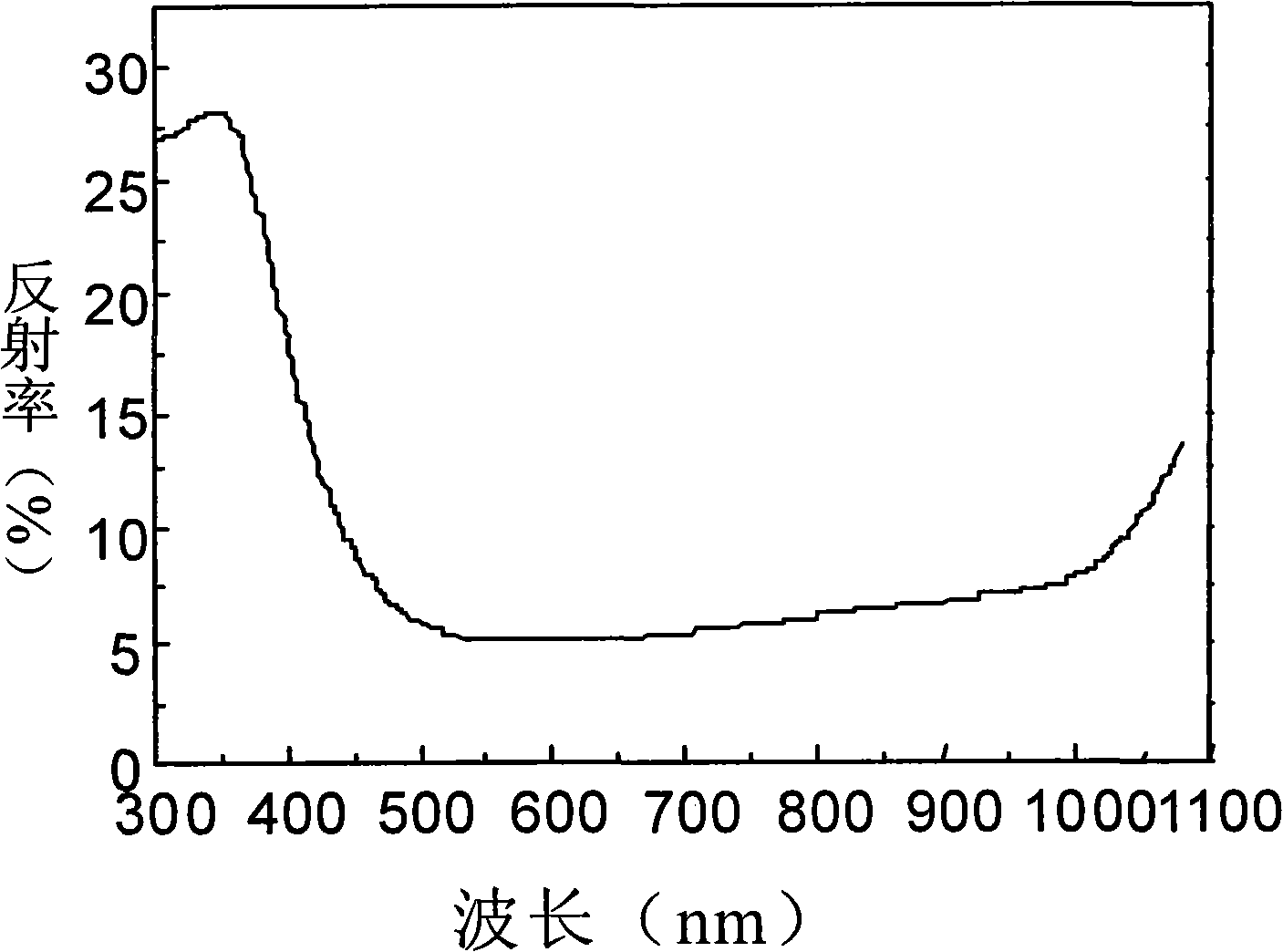

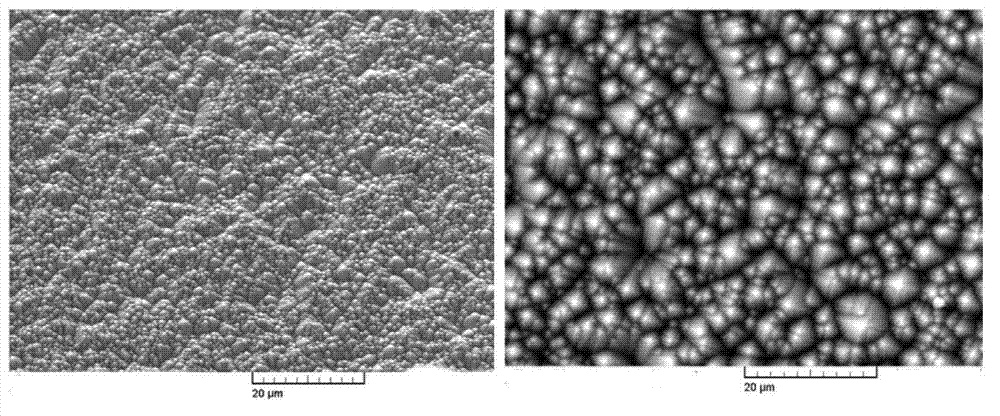

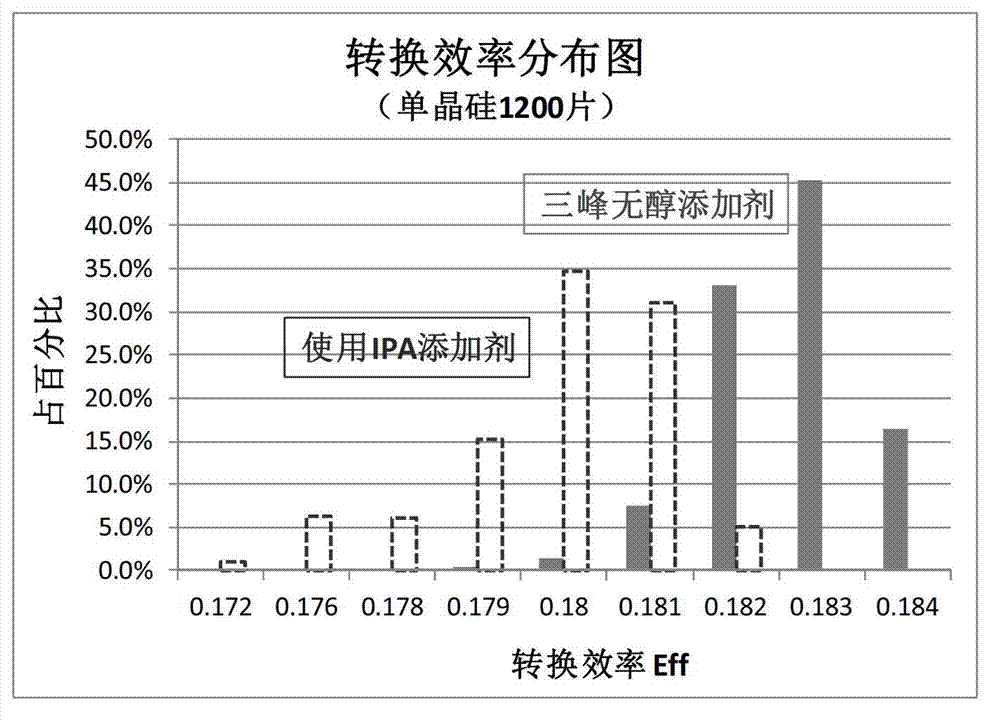

ActiveCN102877135ALower the texturing temperatureShorten the time of texturingAfter-treatment detailsChemistryMonocrystalline silicon

The invention provides an additive for an alkali environment-protecting type no-alcoholic felting liquid of a mono-crystal silicone chip, which comprises the following components in percent by weight: 0.05 to 1 percent of protein, 0.01 to 1 percent of detergent, 0.001 to 0.003 percent of vitamin, donkey-hide gelatin or tea polyphenol or the combination thereof, and the balance of water. After adopting the additive for the alkali environment-protecting type no-alcoholic solution of the mono-crystal silicone chip and the using method thereof, compared with the condition without the additive for an alkali environment-protecting type no-alcoholic felting liquid of a mono-crystal silicone chip, the felt temperature can be decreased, no isopropanol is required to be used, the felting time is shortened, and the felting effect is obviously improved.

Owner:湖州三峰能源科技有限公司

Additive for acidic texturing agent for polycrystalline silicon solar battery sheet

The invention discloses an additive for an acidic texturing agent for a polycrystalline silicon solar battery sheet, which is prepared from the following raw materials in percentage by mass: 5 to 30 percent of phosphoric acid, 5 to 10 percent of sulfuric acid and the balance of pure water. The invention has the advantages that: the additive has the stabilizing effect on the acidic texturing liquid and can reduce texturing temperature and shorten texturing time, and a process condition is easy to control; the size of a formed texture is fine, the distribution is more uniform, the reflectivity of a silicon wafer is reduced, the short-circuit current of the battery sheet is improved, the fill factor of the battery sheet is increased, and the photoelectric conversion efficiency of the solar battery sheet is improved; and preparation and using processes are simple, and the repeatability is high.

Owner:DALIAN SANDAAOKE CHEM

Method for cleaning surface of monocrystalline silicon wafer

ActiveCN103681239AShorten the time of texturingIncrease productionSemiconductor/solid-state device manufacturingSilicon chipChemical used

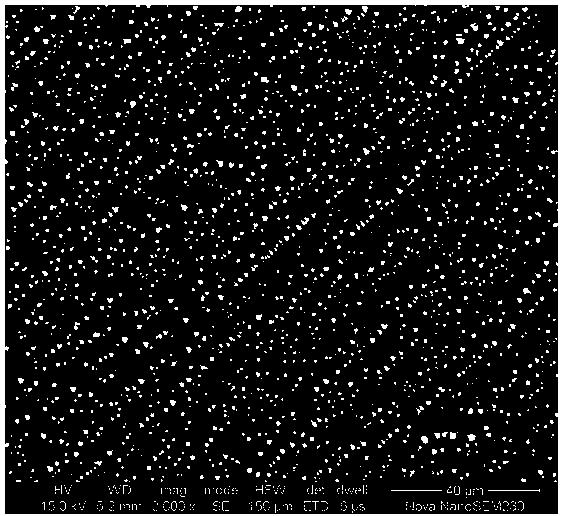

The invention relates to a method for cleaning the surface of a monocrystalline silicon wafer. The method is characterized by comprising the following steps: first of all, adding hydrogen peroxide (H2O2) and sodium hydroxide (NaOH) in a precleaning tank to obtain a mixed solution, in the mixed solution, the concentration of the hydrogen peroxide being 2% to 3%, and the concentration of NaOH being 0.15% to 0.3%; and cleaning the monocrystalline silicon wafer through cooperation with ultrasonic sound, the monocrystalline silicon wafer being immersed into the mixed solution during cleaning. Tests show that by adoption of the method provided by the invention, the texturing time is shortened, the output is increased, the smudginess on the surface of the silicon wafer such as oil stains, white spots, fingerprints and the like is completely cleaned, the quantity of reworking wafers is substantially reduced, silicon wafer discard proportion is reduced, and chemical use amount for reworking after texturing of the silicon wafer is correspondingly reduced.

Owner:NINGXIA YINXING ENERGY

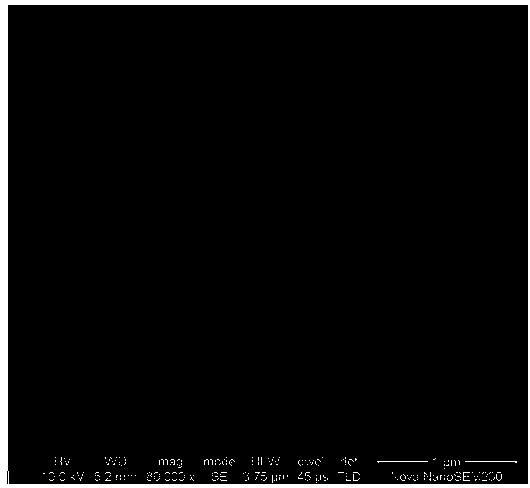

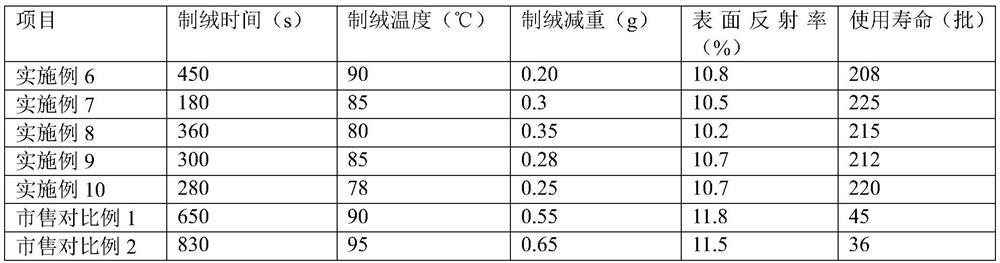

Low-weight-loss monocrystalline silicon texturing additive and application thereof

ActiveCN111321471AShorten the time of texturingImprove single-slot productivityPolycrystalline material growthAfter-treatment detailsSulfonatePhysical chemistry

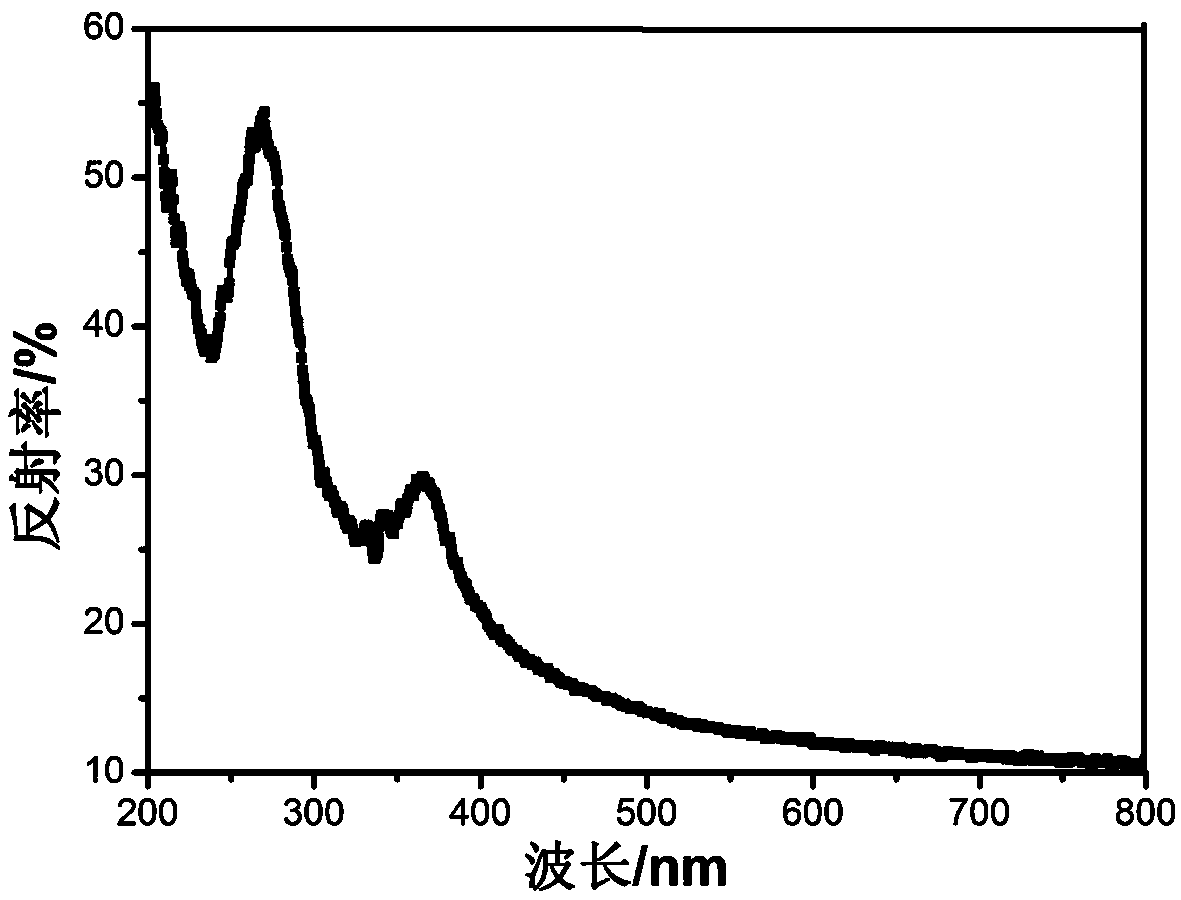

The invention relates to the field of monocrystalline silicon surface treatment, in particular to a low-weight-loss monocrystalline silicon texturing additive and application thereof. The monocrystalline silicon texturing additive comprises the following components in percentage by weight: 0.01%-1% of polysaccharide sulfonate, 0.1%-3% of a defoaming dispersant, 0.01%-1% of a corrosion inhibitor, 0.05%-0.5% of a water-soluble polymer protective agent, 0.05%-2% of an alkali and the balance being water. The texturing additive and an alkali solution are mixed and compound to obtain a low-weight-loss texturing corrosion solution. The defects of low production capacity, large weight loss of texturing silicon slices, high alkali consumption, short service life and the like in the prior art, are overcome. The additive has the advantages that the reflectivity of a silicon wafer is reduced, the battery efficiency is effectively improved, the texturing time is shortened, and the single-tank yieldis improved. Meanwhile, the additive is suitable for surface texturing of a large-size and thin silicon slice, and has positive effects of reducing the alkali consumption, prolonging the service lifeof a single groove, and the like.

Owner:杭州飞鹿新能源科技有限公司

Monocrystalline silicon flocking additive

ActiveCN102912450AReduce consumptionImprove conversion efficiencyAfter-treatment detailsPhosphatePhysical chemistry

The invention discloses a monocrystalline silicon flocking additive which is characterized by comprising the following components in percentage by mass: 5-20% of sodium dodecyl benzene sulfonate, 10-18% of polyphosphates, 0-7% of lactic acid, 2-10% of sulfuric acid and the balance of water. Compared with the prior art, the formula is simple, the flocking time is reduced, the flocking pyramid is uniform, the flocking repeatability is good, and the battery cell conversion efficiency is correspondingly improved; and moreover, the consumption of chemicals is reduced, and the production cost is lowered.

Owner:JIANGSU RONGMA NEW ENERGY

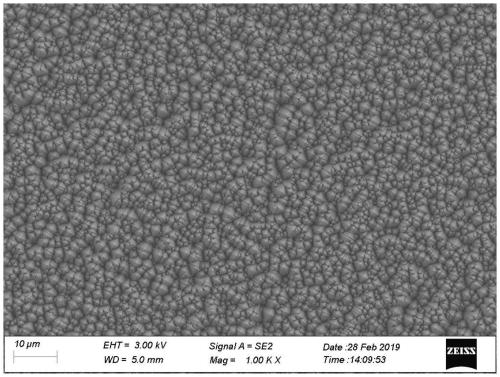

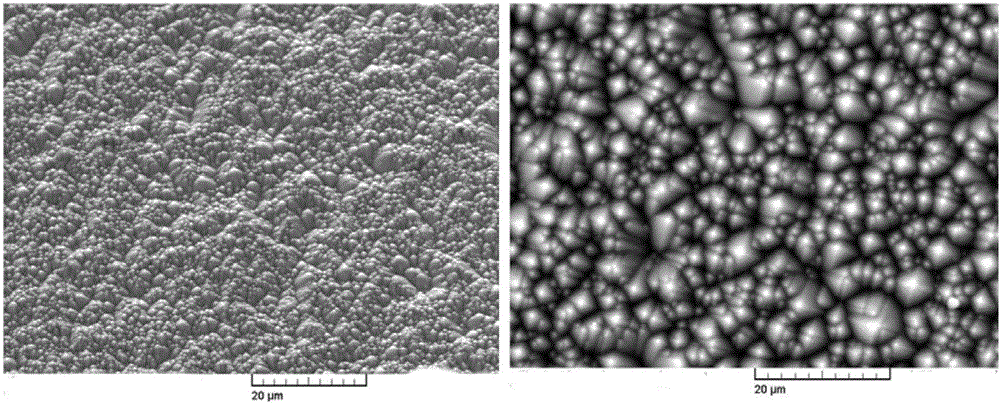

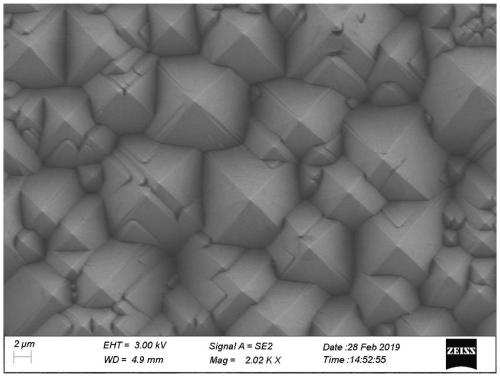

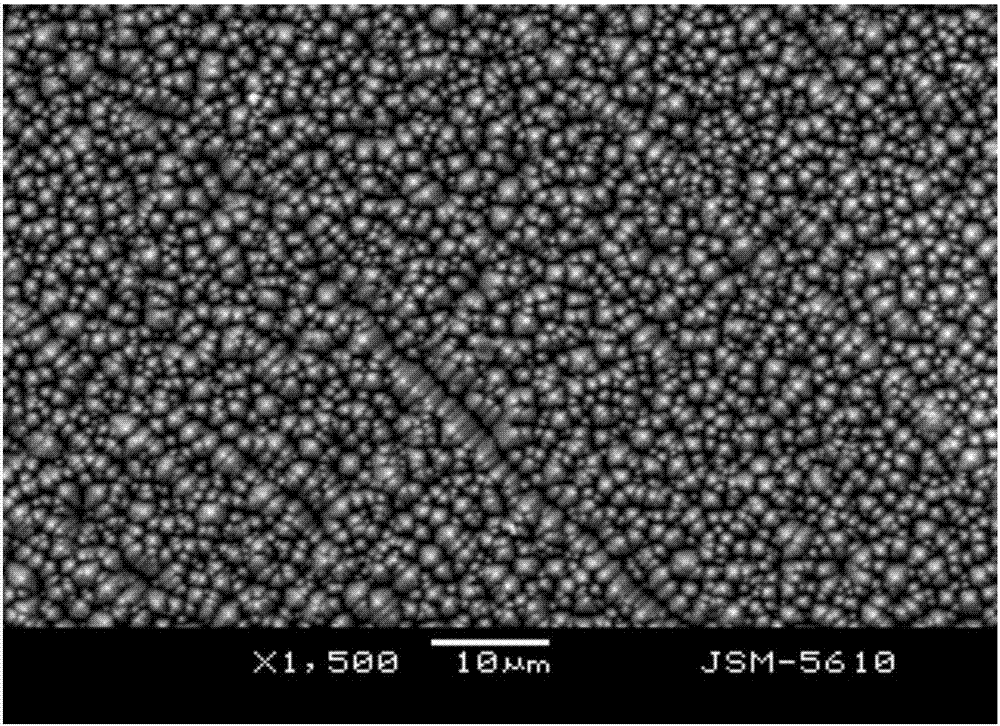

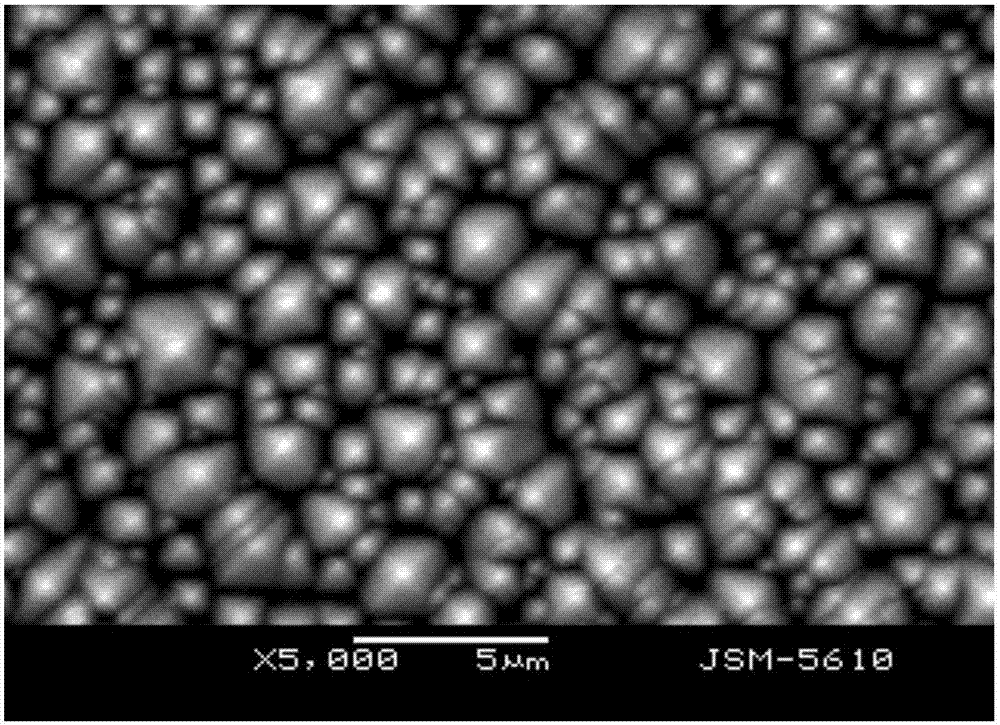

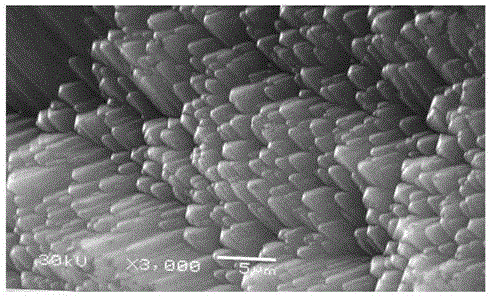

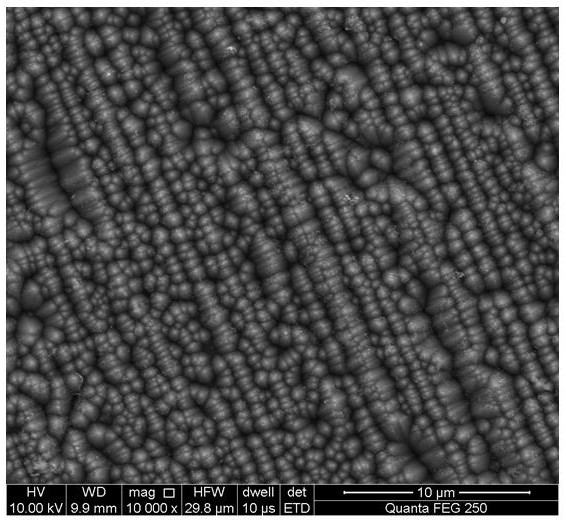

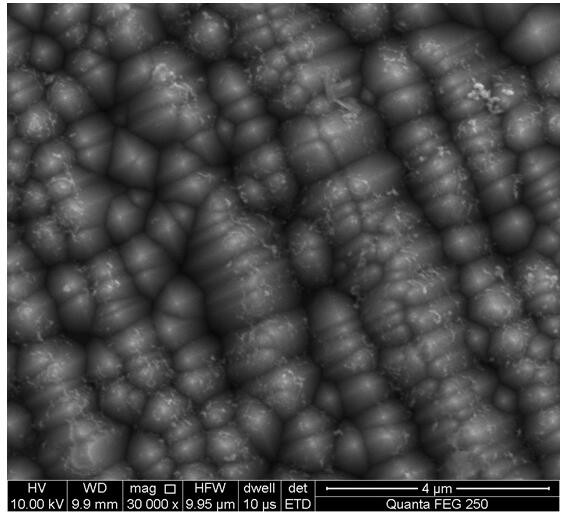

Formula of composite texturing additive for preparing maize-shaped monocrystal silicon textured surface as well as use method of additive

InactiveCN110644053AReduce reflectionImprove photoelectric conversion efficiencyPolycrystalline material growthAfter-treatment detailsPolyethylene glycolPyrrolidinones

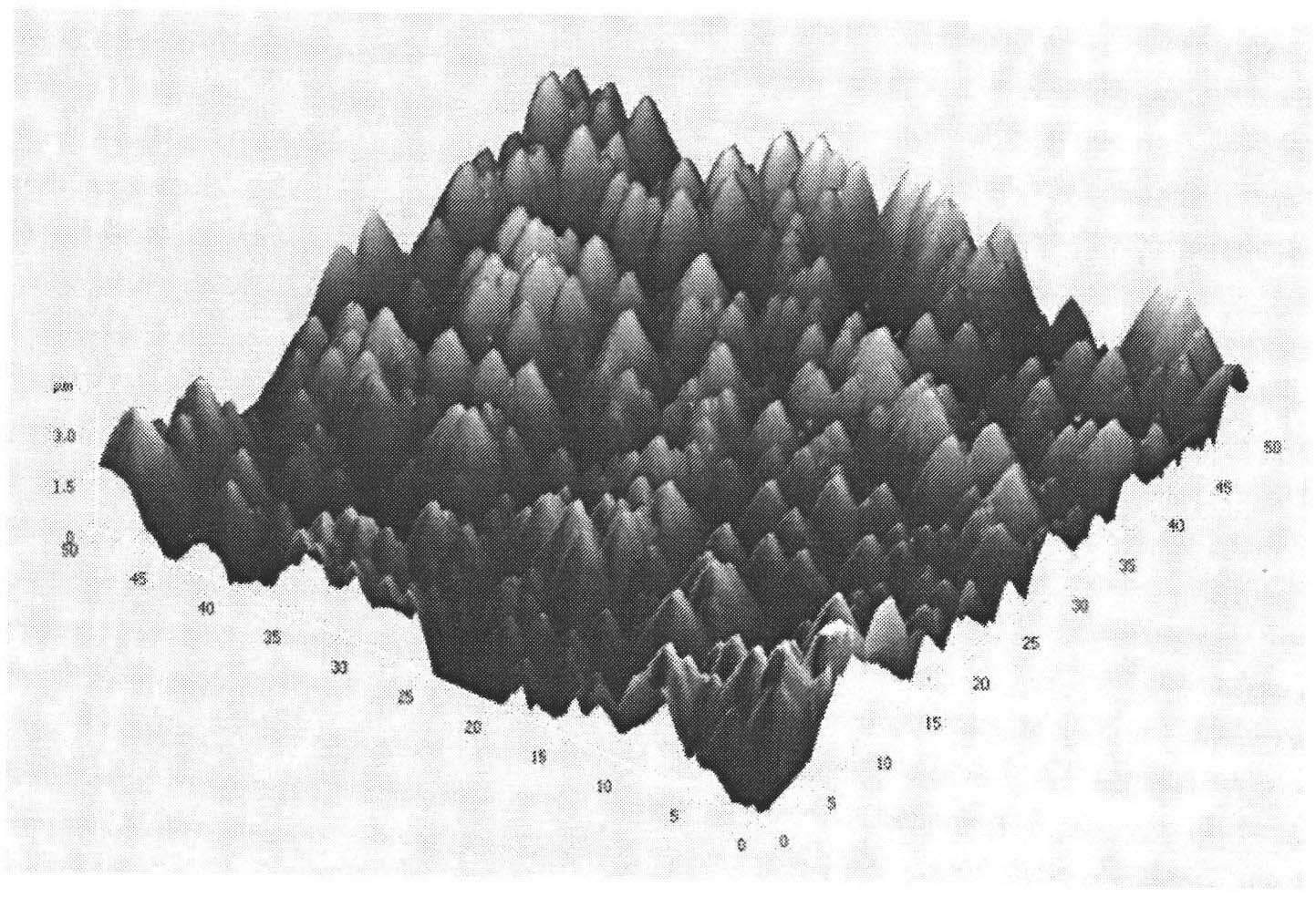

The invention relates to a nonionic surfactant-containing additive of monocrystal silicon wafer texturing liquid. The additive comprises the following components: three nonionic surfactants such as polyethylene glycol (PEG), polyvinylpyrrolidone (PVP) and alkyl polysaccharide glycoside (APG), organic acid, inorganic salt and the balance of water. The invention also discloses a texturing method ofa monocrystal silicon wafer. The texturing method of the monocrystal silicon wafer comprises the following steps: 1) preparing a texturing additive; 2) preparing texturing liquid; 3) putting the monocrystal silicon wafer into the texturing liquid prepared in the step 2) and performing texturing at the texturing liquid temperature of 70 to 90 DEG C for 8 to 16 minutes; and 4) mixing the monocrystalsilicon wafer after texturing liquid with acid, cleaning with deionized water again and drying to obtain a product. The texturing effect is excellent; after texturing the texturing surface pyramids are arranged in a maize shape and the size distribution is 0.2 to 1.5 um; and reflection on light can be effectively reduced and the photoelectric conversion efficiency of a solar battery piece can besignificantly improved.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

A kind of etching solution for preparing monocrystalline silicon solar cell textured surface

ActiveCN102286785AGuaranteed suede sizeGuaranteed uniformityAfter-treatment detailsSilicon solar cellSodium silicate

The invention discloses an etching liquid for preparing a texture surface of a monocrystalline silicon solar cell. The etching liquid comprises the following components by weight: (a) 1-10% of base; (b) 3-15% of sodium silicate; (c) 5-20% of 1,3,5-cyclohexane triol; and the balance of water. By using the etching liquid disclosed by the invention, the size and uniformity of the texture surface areguaranteed; the prepared texture surface has the size and uniformity equivalent to those of an IPA system; and the etching liquid can be applied to a monocrystalline silicon texturing system and has a positive practical significance.

Owner:CSI CELLS CO LTD +1

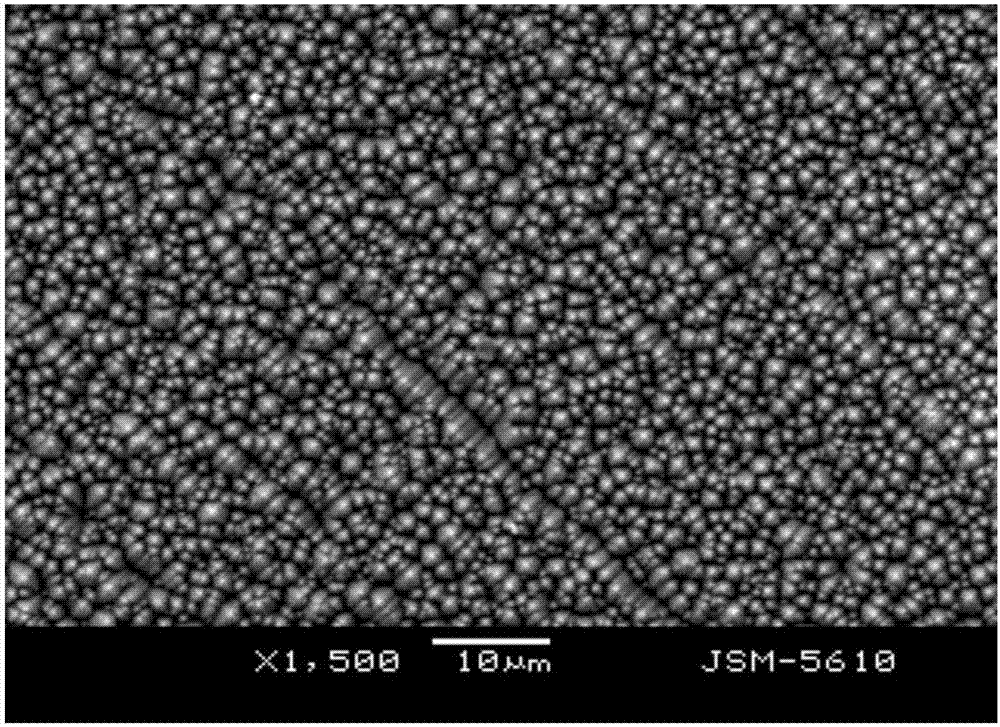

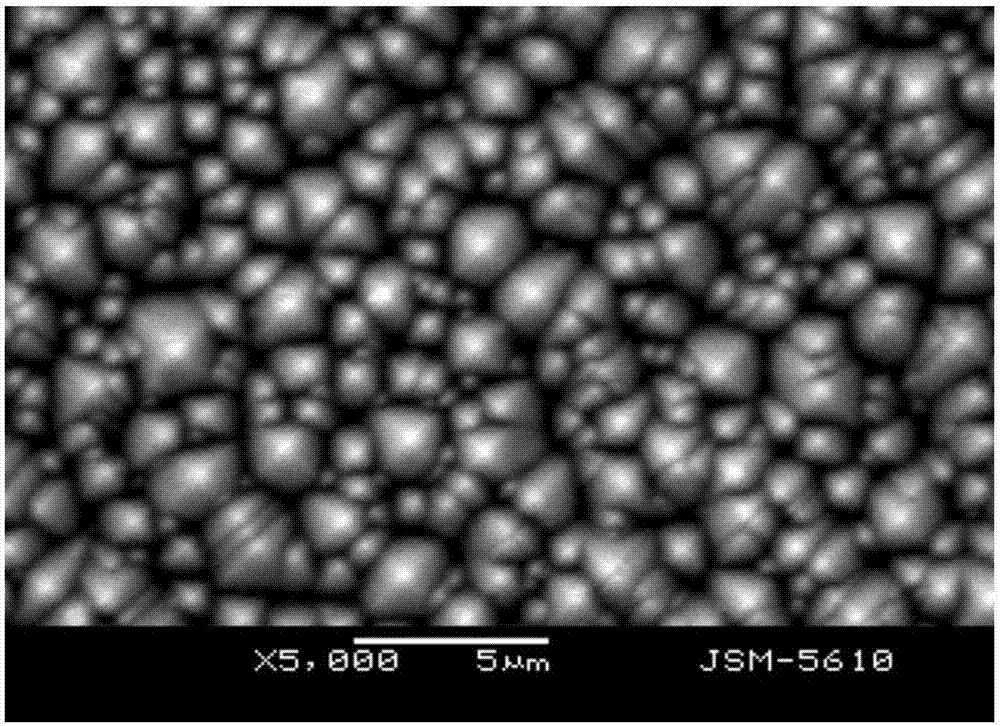

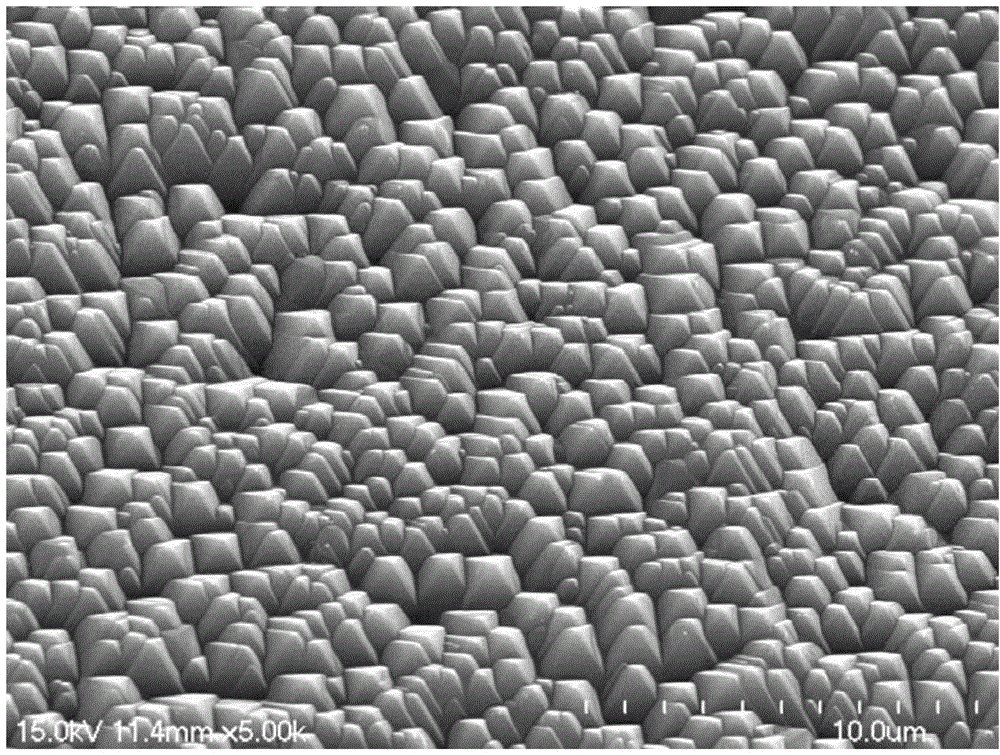

Monocrystalline silicon texturing additive formula containing alkyl glycoside and use method

InactiveCN110644057AUniform colorLower average reflectancePolycrystalline material growthAfter-treatment detailsElectrical batteryMonocrystalline silicon

The invention relates to an additive of a monocrystalline silicon wafer texturing solution containing alkyl glycoside. The additive comprises the following components of alkyl glycoside, disaccharide,organic sodium salt, inorganic salt, sodium silicate and the balance of water. The invention also discloses a texturing method of the monocrystalline silicon wafer, and the method comprises the following steps of 1) preparing a texturing additive; 2) preparing a texturing solution; 3) putting the monocrystalline silicon wafer into the texturing solution prepared in the step 2) for texturing, wherein the temperature of the texturing solution is 75-90 DEG C, and the texturing time is 7-15 min; and 4) and cleaning the monocrystalline silicon wafer subjected to the texturing solution by using mixed acid, cleaning the monocrystalline silicon wafer by using deionized water, and drying the monocrystalline silicon wafer to obtain the product. The texturing effect is excellent, the size of the texture pyramid after the texturing is small, the distribution is narrow, the reflection of the light can be effectively reduced, and the photoelectric conversion efficiency of the solar cell can be improved.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Texture etching solution of monocrystaline silicon solar cell, preparation method, and application thereof

InactiveCN102400225AOvercome timeOvercome uniformity issuesAfter-treatment detailsFinal product manufactureTetramethylammonium hydroxideSilicon solar cell

The invention relates to a texture etching solution of a monocrystaline silicon solar cell, a preparation method, and an application thereof. Raw materials of the texture etching solution comprise the following components, by weight, 1-3% of tetramethylammonium hydroxide, 7-9% of isopropyl alcohol and 88-92% of deionized water. The preparation method comprises: adding the deionized water to a texture etching groove, then adding the tetramethylammonium hydroxide and the isopropyl alcohol, controlling a temperature to 75-85 DEG C, completely and uniformly stirring to obtain the texture etching solution, which is applicable for treatment of silicon wafers. Compared to the prior art, with the present invention, the texture etching solution has a good anisotropic etching characteristic and high etching rate, the etching surface has good homogeneity, the etching solution does not contain free-alkali metal ions, has advantages of no toxicity and easy operation and control, and can provide compatibility with the microelectronic technology.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Formula of single-crystal silicon texturing additive containing polysaccharide and alcohol

InactiveCN110644055ANo toxicityNot corrosivePolycrystalline material growthAfter-treatment detailsSodium acetatePropanoic acid

The invention relates to an additive of a single-crystal silicon texturing liquid. The components of the additive are a polysaccharide, an alcohol, an organic acid sodium salt, sodium silicate and deionized water, wherein the polysaccharide is one or a mixture of more of water-soluble chitin, polyfructose, water-soluble starch, beta-cyclodextrin, and dextrin, and a weight ratio of the polysaccharide to water is 0.1-1.0:100; the alcohol is a lower alcohol, and is one or a mixture of more of n-propanol, 1,2-propanediol, n-butanol, 1,2-butanediol and tert-butanol, and a weight ratio of the alcohol to water is 1.0-3.0:100; the organic acid sodium salt is one or a mixture of more of sodium acetate, sodium formate, sodium propionate, sodium benzoate, and sodium phenylacetate, and a weight ratioof the organic aicd sodium salt to water is 0.1-1.0:100; and a weight ratio of sodium silicate to water is 0.1-1.0:100. A formula of a single-crystal silicon surface texturing agent is as follows: 30.0-50.0 mL of a NaOH solution with a concentration of 30% by weight is added into 1 L of deionized water, and 8.0-18.0 mL of the additive is added.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Additives for monocrystalline silicon wafer alkaline environment-friendly non-alcoholic texturing liquid and its application method

ActiveCN102877135BReduce reflectivityLower average reflectanceAfter-treatment detailsAlcohol freePolyphenol

The invention provides an additive for an alkali environment-protecting type no-alcoholic felting liquid of a mono-crystal silicone chip, which comprises the following components in percent by weight: 0.05 to 1 percent of protein, 0.01 to 1 percent of detergent, 0.001 to 0.003 percent of vitamin, donkey-hide gelatin or tea polyphenol or the combination thereof, and the balance of water. After adopting the additive for the alkali environment-protecting type no-alcoholic solution of the mono-crystal silicone chip and the using method thereof, compared with the condition without the additive for an alkali environment-protecting type no-alcoholic felting liquid of a mono-crystal silicone chip, the felt temperature can be decreased, no isopropanol is required to be used, the felting time is shortened, and the felting effect is obviously improved.

Owner:湖州叁峰能源新材料有限公司

Monocrystalline silicon wafer pre-cleaning method

InactiveCN102719896ATo achieve the purpose of pre-cleaningAvoid driftingAfter-treatment detailsMetallurgySolar battery

The invention relates to a cleaning technology in solar battery production process, concretely to a monocrystalline silicon wafer pre-cleaning method which can completely and effectively clean off smudginess from monocrystalline silicon incoming materials. The pre-cleaning method comprises three technical steps of first-time fluid preparation, cleaning and fluid supplementation. The method overcomes the disadvantages of the prior art and is capable of completely removing smugness, fingerprints, organic matter residues and the like from monocrystalline silicon wafers manufactured with different technologies and by different manufacturers without affecting any indexes of the monocrystalline silicon wafers. By using the method, good pile faces are obtained through pile-face manufacturing, pile-face making time is shortened, drug amount needed for pile-face making is reduced and surface clearness of the monocrystalline silicon wafer cleaned through the abovementioned steps meets class A wafer standard.

Owner:JILIN QINGDA NEW ENERGY ELECTRIC POWER

Making of novel monocrystalline silicon chip suede making additive and simple suede making method

InactiveCN108660510AReduce corrosion rateGuaranteed stabilityPolycrystalline material growthAfter-treatment detailsBarium dichlorideSURFACTANT BLEND

The invention discloses a novel monocrystalline silicon chip suede making additive which comprises the following components: rhamnose, a gemini surfactant, glutathione, catechol, ethylene glycolm barium chloride and residual deionized water. The invention further discloses monocrystalline silicon chip suede making liquid and a simple suede making method; the suede making liquid contains an alkaline solution and the suede making additive; the surface of a monocrystalline silicon chip is subjected to suede making under the suede making method. When suede of the monocrystalline silicon chip is made by adopting the process, the suede making time is shortened; a made suede pyramid is uniform, fine, dense and low in reflectivity; the suede making process is simple, suede making equipment is low,and the environmental pollution is low, therefore, practical values are good.

Owner:天津赤霄科技有限公司

A low-weight monocrystalline silicon texturing additive and its application

ActiveCN111321471BShorten the time of texturingImprove single-slot productivityPolycrystalline material growthAfter-treatment detailsSulfonatePhysical chemistry

The invention relates to the field of monocrystalline silicon surface treatment, in particular to a low-weight monocrystalline silicon texturing additive and its application. The monocrystalline silicon texturing additive includes the following components in terms of weight percentage: 0.01-1% polysaccharide sulfonate, 0.1-3% defoaming dispersant, 0.01-1% corrosion inhibitor, water-soluble polymer protective agent 0.05~0.5%, alkali 0.05~2%, and the balance is water. The described texturing additive is mixed and compounded with an alkali solution to obtain a low-weight texturing corrosion solution. The invention overcomes the defects of low production capacity, weight reduction of textured silicon wafers, high alkali consumption and short service life in the prior art, and has the advantages of reducing the reflectivity of silicon wafers, effectively improving battery efficiency, and shortening the texturing time. The advantage of improving the production capacity of a single tank; at the same time, the invention is suitable for surface texturing of large-size and thin-sheet silicon wafers, and has positive effects on reducing alkali consumption and prolonging the life of a single tank.

Owner:湖州飞鹿新能源科技有限公司

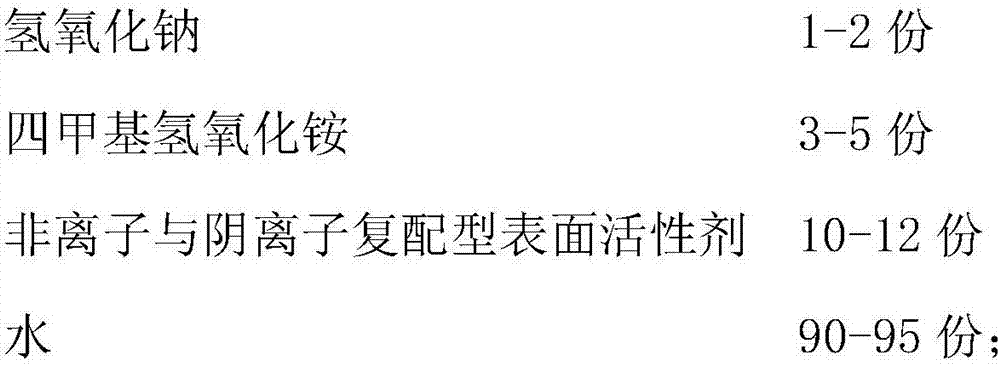

Battery piece wool making corrosive liquid and preparation process thereof

InactiveCN107400926AImprove surface activityReduce reflectivityPolycrystalline material growthAfter-treatment detailsTetramethylammonium hydroxideElectrical battery

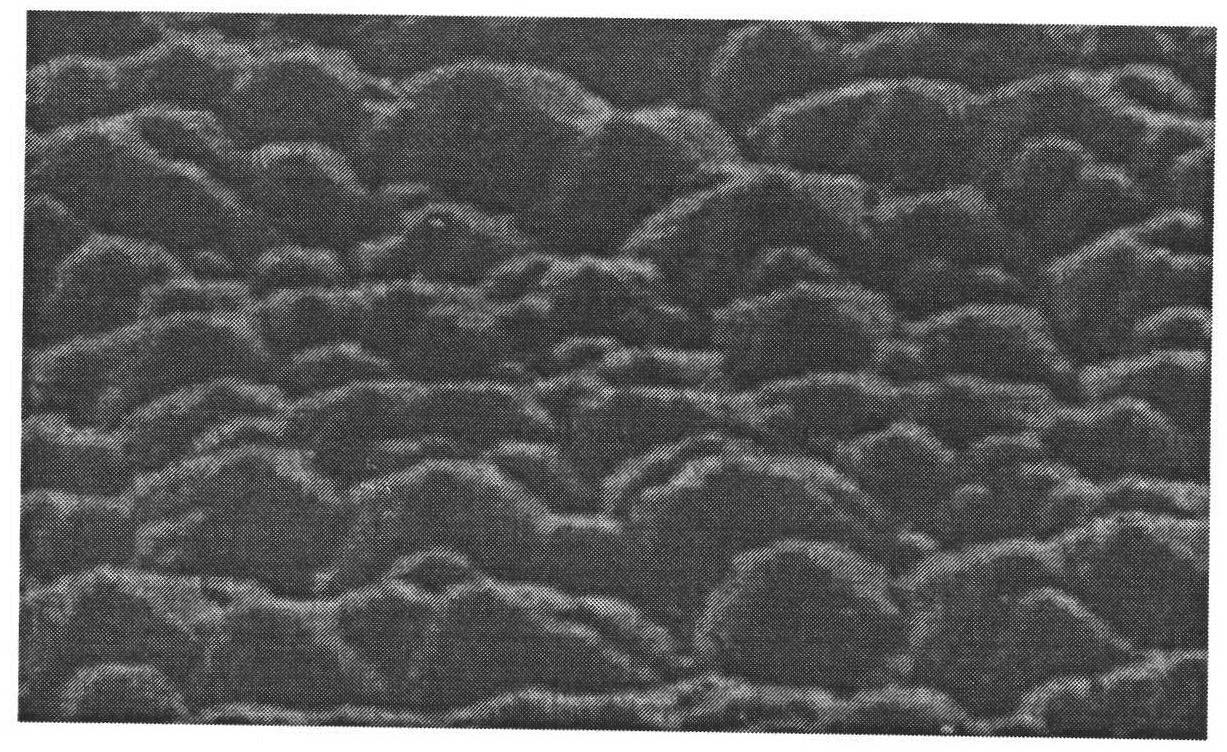

The invention discloses a battery piece wool making corrosive liquid which contains sodium hydroxide, tetramethylammonium hydroxide, nonionic and anion compounded surfactant and water, wherein the nonionic surfactant in the nonionic and anion compounded surfactant is sodium silicate; and the anion surfactant in the nonionic and anion compounded surfactant is one or two of lauryl sodium sulfate fatty alcohol ether sodium sulfate. Due to adoption of the nonionic and anion compounded surfactant in the corrosive liquid, an ideal texture effect is achieved when being compared with that of IPA (Isopropanol), and a silicon piece is low in reflection rate and relatively good in surface cleanliness after wool making; meanwhile tetramethylammonium hydroxide has a corrosion selective ratio approximate to that of NaOH, a pyramid formed on a woof surface on the surface of the silicon piece is small in size and high in corrosion velocity, and then the wool making time is effectively shortened; and in addition, the surfactants in the solution act up together, so that the smoothness and the uniformity of the wool surface are improved, and the surface reflection rate is reduced.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

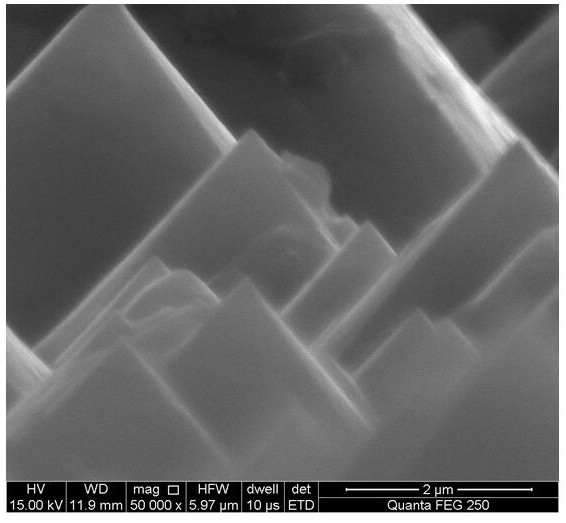

Basket mark prevention texturing solution for HIT battery and texturing method of basket mark prevention texturing solution

ActiveCN111326410APrevent bad anomaliesShorten the time of texturingFinal product manufactureSemiconductor/solid-state device manufacturingMetallurgySilicon chip

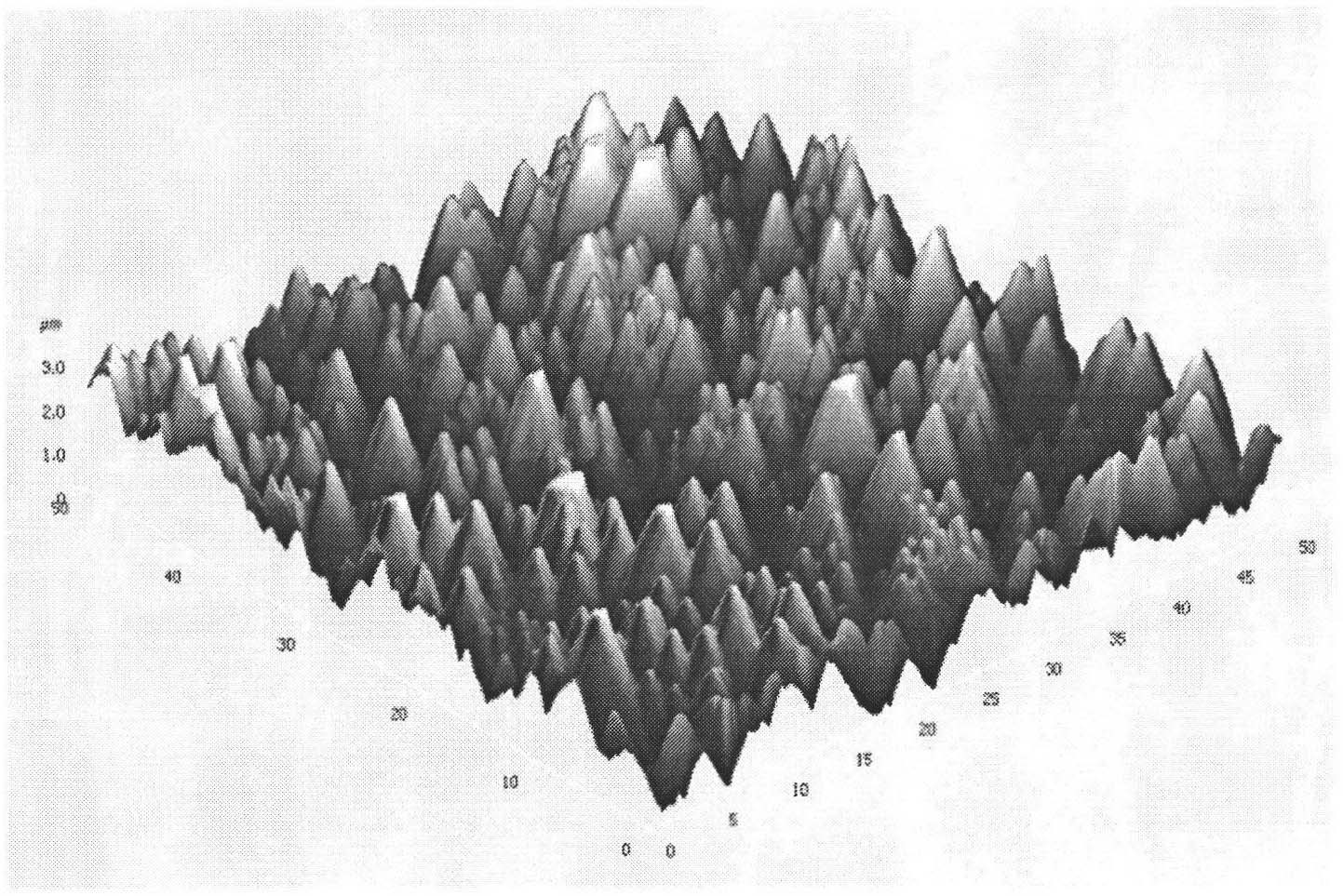

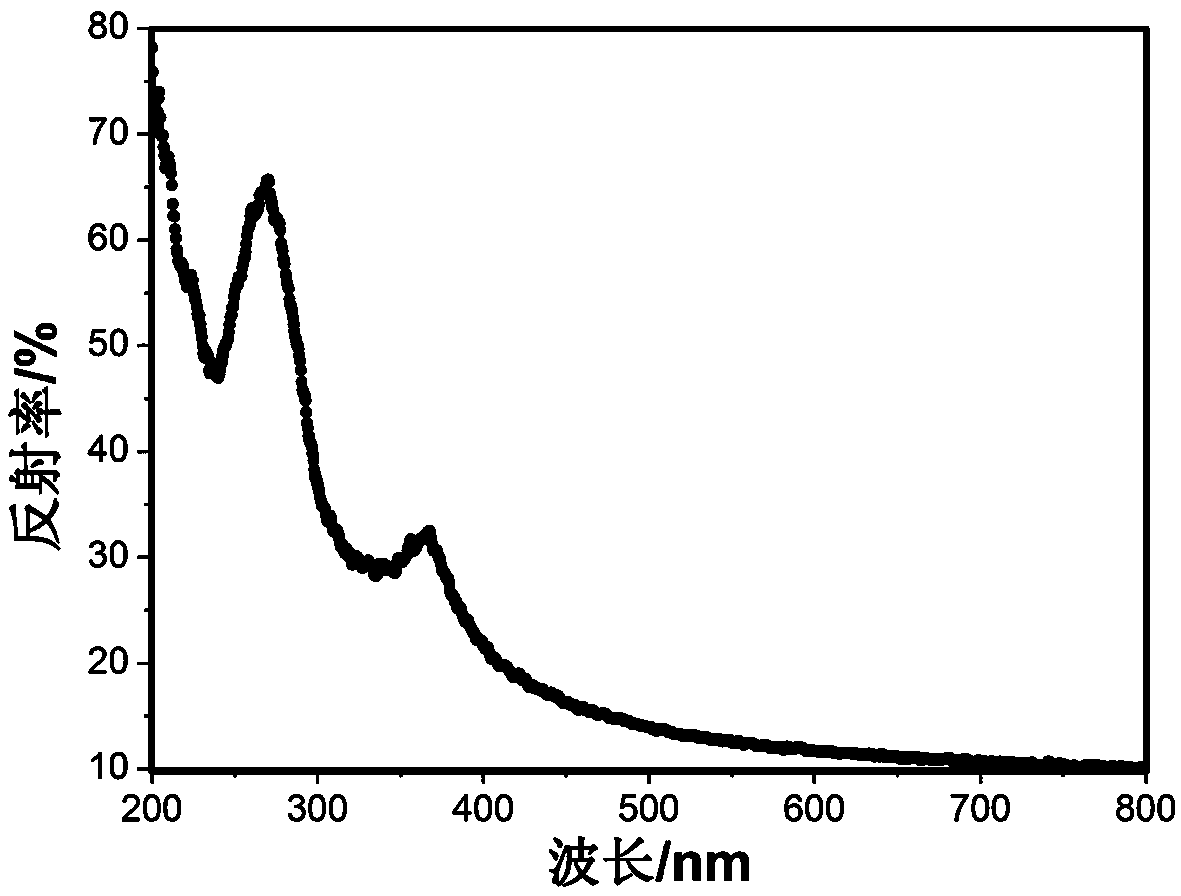

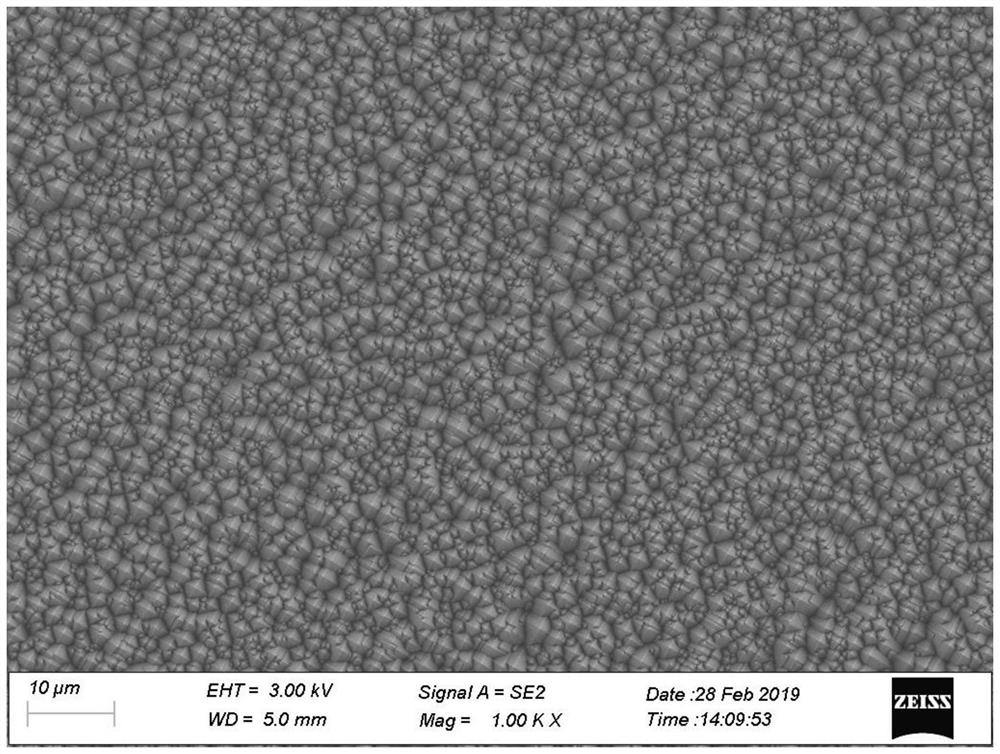

The invention relates to the field of monocrystalline silicon surface treatment, and particularly relates to a basket mark prevention texturing solution for an HIT battery and a texturing method of the basket mark prevention texturing solution. The texturing solution comprises the following components in percentage by weight: 0.1-5% of a basket mark prevention texturing additive, 0-0.5% of an auxiliary texturing agent, 0.1-0.8% of a pH buffer agent and the balance of alkali liquor. The texturing solution is suitable for the texturing process of the HIT battery, the defects that the productioncapacity is low, a large amount of isopropanol needs to be used, the phenomena of poor appearance such as basket marks are easy to occur in the existing HIT texturing technology are overcome, so thatthe texturing solution has the advantage of preventing the adverse phenomena of basket marks, bubble columns and the like during silicon wafer texturing. Meanwhile, the size of the textured pyramid reaches 5-12 microns, on the premise that the large pyramid is maintained, the texturing time of the silicon wafer is effectively shortened, and the production capacity of a single tank is improved. Inaddition, the texturing solution has the advantages that the weight of the silicon wafer is reduced, the alkali consumption is reduced and the service life of the texturing solution is prolonged during texturing.

Owner:湖州飞鹿新能源科技有限公司

Environment-friendly high-efficient silicon chip texturing agent and preparation method thereof

InactiveCN105177719AControl corrosion rateImprove conversion efficiencyAfter-treatment detailsSodium hydroxideHydroxyethylidene Diphosphonic Acid

The invention discloses an environment-friendly high-efficient silicon chip texturing agent, which is characterized by being prepared from the following raw materials in parts by weight: 1.5 to 2.5 parts of sodium hydroxide, 0.5 to 1 part of sodium cocoyl methyl taurate, 0.3 to 0.5 part of castor oil-polyoxyethylene ether, 0.2 to 0.4 part of hydroxyethylidene diphosphonic acid, 1 to 2 parts of sodium polyacrylate, 0.3 to 0.5 part of sodium oleate, 0.3 to 0.5 part of sodium silicate, 5 to 10 parts of texturing conditioning agent, and 100 to 150 parts of water. The provided silicon chip texturing agent can improve the texturing efficiency and stability of texturing technology, effectively improves the conversion efficiency of battery chips, reduces the texturing time, improves the production efficiency, reduces the using amount of chemical products, has a good degradable property, is pollution-free to the environment, reduces the production cost and wastewater treatment cost, and generates good economic benefits and environment benefits.

Owner:安徽飞阳能源科技有限公司

Texturing additive for monocrystalline silicon wafer and application thereof

InactiveCN111139531AReduce reflectivityShorten the time of texturingPolycrystalline material growthAfter-treatment detailsSodium acetateSoluble polymer

The invention discloses a texturing additive for a monocrystalline silicon wafer. The texturing additive comprises the following components in percentage by mass: 0.2%-4% of a water-soluble polymer, 0.15%-0.5% of sodium humate, 1%-2% of potassium sorbate, 1.5%-3.5% of sodium acetate and the balance of water. The additive disclosed by the invention is added into a texturing liquid of the monocrystalline silicon wafer, so that the texturing time can be shortened, and the texturing wafer with low reflectivity can be obtained.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Method for removing fingerprints from single crystal silicon wafers in solar cell production

InactiveCN102842641AEfficient removalShorten the time of texturingFinal product manufactureFlexible article cleaningHydrogen fluorideSolar cell

The invention relates to a process for washing single crystal silicon wafers in solar cell production, in particular to a method capable of cleanly and effectively washing off fingerprints on the single crystal silicon wafers during transfer. The method comprises the steps as follows: (1) adding 150-160 L of de-ionized water into a process tank with the volume of 150-180 L, increasing the temperature of water in the process tank, and keeping the temperature to be 15-25 DEG C; preparing various chemicals, adding 16 L of HF (Hydrogen Fluoride) (electronic grade), and uniformly stirring with a PP (Propene Polymer) long bar to obtain a prepared solution for use; and (2) placing the single crystal silicon wafers with the sizes of 125*125 into bearing boxes, placing the bearing boxes into a big flower basket to serve as a batch of the single crystal silicon wafers, requiring the number of the single crystal silicon wafers in each batch to be 300-400, placing the big flower basket with the single crystal silicon wafers into the process tank with the prepared solution in the step (1), soaking for about 200-300 s, and taking out the single crystal silicon wafers in the big flower basket, so that the washing process is finished.

Owner:JILIN QINGDA NEW ENERGY ELECTRIC POWER

A kind of texturing process of solar cell silicon wafer

ActiveCN113817472BImprove uniformityReduce reflectivityFinal product manufacturePhotovoltaic energy generationXylanSurface cleaning

The invention provides a texturing process for silicon wafers of solar cells, which belongs to the technical field of solar cells, and specifically includes: 1) surface pretreatment: pretreating silicon wafers of solar cells with a pretreatment liquid; The cleaned solar cell silicon wafers are etched and textured, and the texturizing liquid used is the texturing liquid prepared by the aforementioned method; 3) Surface cleaning: the solar cell silicon wafers after texturing are cleaned with an alkaline solution. During the texturing process, adding xylan esterified derivatives to the texturing liquid can not only obtain a finely uniform microstructured textured surface, but also effectively reduce the reflectivity of polycrystalline silicon solar cells to sunlight, improve the photoelectric conversion efficiency, and improve the efficiency of silicon wafers. Less loss.

Owner:绍兴拓邦新能源股份有限公司

Texturing method for monocrystalline silicon pieces for batteries

InactiveCN107955973ANo toxicityNot corrosivePolycrystalline material growthAfter-treatment detailsEdetic AcidSodium-p-toluenesulfinate

The invention provides a texturing method for monocrystalline silicon pieces for batteries. The texturing method comprises the following steps: dissolving a vinyl pyrrolidone-vinyl imidazole copolymer, a polyethylene glycol-polypropylene glycol-polyethylene glycol copolymer, edetic acid, monoethanolamine, sodium benzoate and paratoluenesulfonic acid sodium salt in the balance of water; adding a texturing additive prepared in step (1) in an alkaline solution, and mixing uniformly; and placing monocrystalline silicon pieces in texturing liquid prepared in step (2) and carrying out texturing. When the monocrystalline silicon pieces are subjected to texturing by the method, the texturing additive in the patent is added in the alkaline solution according a certain proportion, and thus, a rapidtexturing effect can be achieved.

Owner:DEQING LIJING ENERGY TECH CO LTD

Texturization method of monocrystalline silicon chip for solar cells

InactiveCN107964684AImprove cashmere efficiencyLow costPolycrystalline material growthAfter-treatment detailsChemistrySingle crystal silicon wafer

The invention provides a texturization method of a monocrystalline silicon chip for solar cells. The texturization method includes the steps of: dissolving a vinyl pyrrolidone-vinyl imidazole copolymer, a polyethylene glycol-polypropylene glycol-polyethylene glycol copolymer, ethylene diamine tetraacetic acid, monoethanolamine, sodium benzoate, and sodium p-toluenesulfonate in the balance water; adding a texturization additive prepared by step 1) into an alkali solution and mixing the substances evenly; and putting a monocrystalline silicon chip into a texturization solution prepared by step 2) and conducting texturization. During texturization of the monocrystalline silicon chip by the method provided by the invention, the texturization additive is added into the alkali solution accordingto certain proportion, thus realizing a rapid texturization effect.

Owner:DEQING LIJING ENERGY TECH CO LTD

Additive of alkali wool making solution for monocrystalline silicon pieces and using method

ActiveCN101851756BReduce reflectivityImprove yieldFinal product manufactureSemiconductor devicesAlcoholSolar cell

The invention relates to an additive of an alkali wool making solution for monocrystalline silicon pieces, containing the components of urea (carbamide), sorbic alcohol and the balance of water. When the monocrystalline silicon pieces for solar cells are subjected to surface wool making, the additive is added in the alkali wool making solution so that an excellent wool making effect is achieved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Etching liquid for preparing texture surface of monocrystalline silicon solar cell

ActiveCN102286785BGuaranteed uniformityHigh boiling pointAfter-treatment detailsSolar cellSodium silicate

Owner:CSI CELLS CO LTD +1

Solar cell and texturing cleaning method thereof

PendingCN114823972ASmall sizeUniform size distributionAfter-treatment detailsSemiconductor devicesElectrical batteryEngineering

The invention discloses a solar cell texturing cleaning method comprising the following steps: removing pollutants on the surface of a solar cell panel to obtain a first solar cell panel; performing first alkali texturing treatment on the first solar cell panel by using a first alkali texturing solution to obtain a second solar cell panel; performing second alkali texturing treatment on the second solar cell panel by adopting second alkali texturing liquid to obtain a third solar cell panel; performing first acid texturing treatment on the third solar cell panel by using a first acid texturing solution to obtain a fourth solar cell panel; performing second acid texturing treatment on the fourth solar cell panel by adopting second acid texturing liquid to obtain a fifth solar cell panel; and the fifth solar cell panel is cleaned and dried, and texturing is completed. The obtained textured surface is low in reflectivity, long in minority carrier lifetime and high in cell conversion efficiency.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +3

A method for surface treatment of crystalline silicon wafers

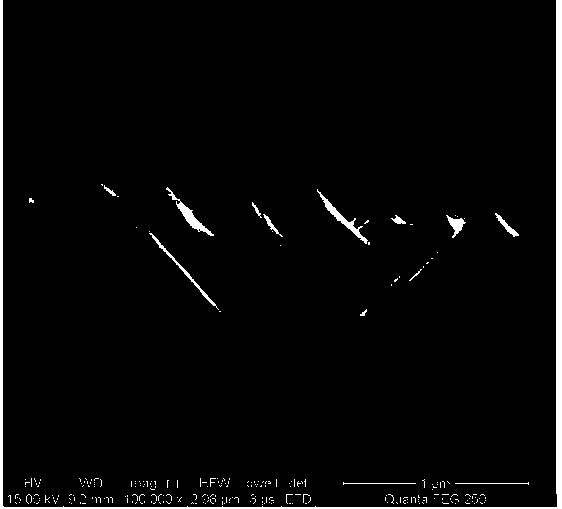

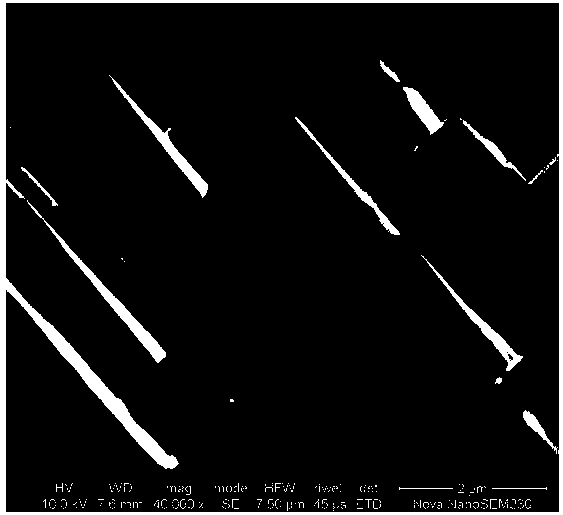

ActiveCN102856189BShorten the time of texturingIncrease concentrationSemiconductor/solid-state device manufacturingChemical solutionPhysical chemistry

The invention discloses a woolen making method of a crystal wafer. The woolen making method comprises the steps of: (1) carrying out isotropic etching polishing of chemical solution on the surface of the crystal wafer, reducing the surface roughness of the crystal wafer, (2) carrying out isotropic etching woolen making treatment of the chemical solution on the surface of the crystal wafer, and reducing the surface reflectance of the crystal wafer. The woolen making method is characterized in that the woolen making method is suitable for all types of crystal wafers, and is small in woolen surface, low in production cost and short in woolen making time.

Owner:SHARESUN CO LTD

Monocrystalline silicon flocking additive

ActiveCN102912450BReduce consumptionImprove conversion efficiencyAfter-treatment detailsPhosphatePhysical chemistry

The invention discloses a monocrystalline silicon flocking additive which is characterized by comprising the following components in percentage by mass: 5-20% of sodium dodecyl benzene sulfonate, 10-18% of polyphosphates, 0-7% of lactic acid, 2-10% of sulfuric acid and the balance of water. Compared with the prior art, the formula is simple, the flocking time is reduced, the flocking pyramid is uniform, the flocking repeatability is good, and the battery cell conversion efficiency is correspondingly improved; and moreover, the consumption of chemicals is reduced, and the production cost is lowered.

Owner:JIANGSU RONGMA NEW ENERGY

A compound texturizing liquid additive formula for preparing fine and dense pyramid monocrystalline silicon texture

ActiveCN110644056BNo toxicityNot corrosivePolycrystalline material growthAfter-treatment detailsTripropylene glycolSodium acetate

The invention relates to an additive for monocrystalline silicon texturing liquid. The components of the additive include polyvinylpyrrolidone (PVP), diol, benzene-containing organic acid salt, sodium silicate and deionized water. Among them, PVP is a mixture of one or more of PVP‑K12, PVP‑K15, PVP‑K17, PVP‑K25, PVP‑K30, and the weight ratio to water is 0.2‑1.0:100; A mixture of one or more of ethylene glycol, triethylene glycol, tetraethylene glycol, dipropylene glycol and tripropylene glycol, with a weight ratio of 1.0‑3.0:100 to water; containing benzene Organic acid salt is a mixture of one or more of sodium benzoate, potassium benzoate, sodium phenylacetate, sodium terephthalate and sodium isophthalate, with a weight ratio of 0.1‑1.0:100 to water; sodium silicate and water The weight ratio is 0.1‑1.0:100. The formula of the monocrystalline silicon surface texturing agent is: add 25.0-45.0 mL of NaOH solution with a concentration of 30% by weight in 1 L of deionized water, and add 10.0-20.0 mL of this additive.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com