A kind of texturing process of solar cell silicon wafer

A technology for solar cells and silicon wafers, applied in the field of solar cells, can solve the problems of unsatisfactory texturing effect, poor texturing stability and high surface reflectivity, improve photoelectric conversion efficiency, shorten texturing time, and repeat good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

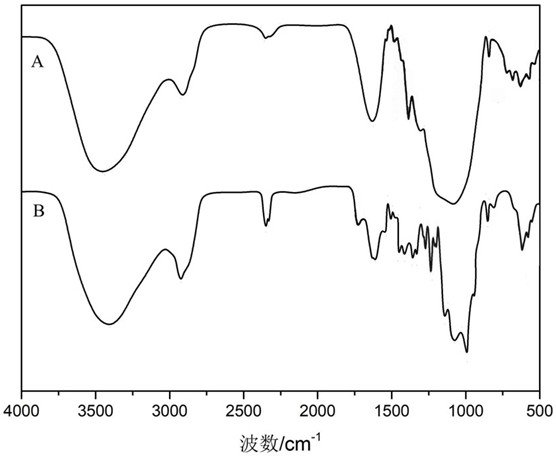

Image

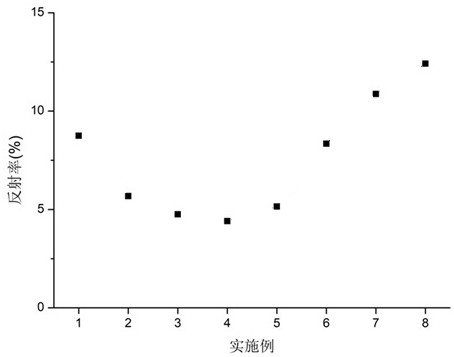

Examples

Embodiment 1

[0043] The present embodiment provides a kind of texturing process of solar cell silicon chip, and described process comprises the following steps:

[0044] S1: Surface pretreatment: immerse the solar cell silicon wafer in the pretreatment solution, and ultrasonically treat it at 80°C for 40min, the ultrasonic frequency is 20kHz, and the power density is 0.4W / cm 2 , the pretreatment solution is added to 53.6 parts by weight of deionized water by 20 parts by weight of lauryl alcohol polyethylene oxide ether, 10 parts by weight of ethylene glycol, 8 parts by weight of hydrogen fluoride, 8 parts by weight of nitric acid, and 0.4 parts by weight of sodium hypochlorite, Ultrasonic treatment for 20 minutes to obtain the pretreatment solution, the ultrasonic frequency is 20kHz, and the power density is 0.3W / cm 2 ;

[0045] S2: Texturing: Add 1.6 parts by weight of xylan esterified derivatives, 0.8 parts by weight of trisodium citrate, and 1 part by weight of ethylene glycol monobuty...

Embodiment 2

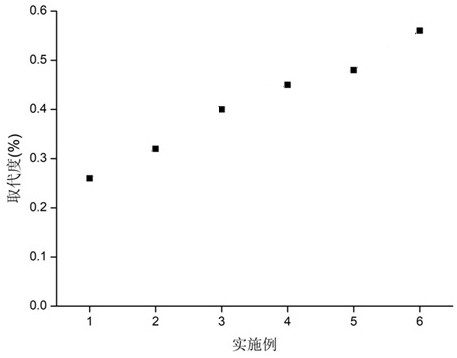

[0050] This embodiment provides another texture process for solar cell silicon wafers. The only difference between its steps and that of Example 1 is that in the preparation process of xylan esterified derivatives, the amount of carboxybenzoylsulfathiazole added 6 parts by weight.

Embodiment 3

[0052] This embodiment provides another texture process for solar cell silicon wafers. The only difference between its steps and that of Example 1 is that in the preparation process of xylan esterified derivatives, the amount of carboxybenzoylsulfathiazole added 7 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com