Basket mark prevention texturing solution for HIT battery and texturing method of basket mark prevention texturing solution

A technology of texturing liquid and flower baskets, which is applied in the manufacture of circuits, electrical components, and final products. It can solve problems such as black line marks, burning risks, and environmental pollution, so as to improve service life, shorten texturing time, and improve texturing. The effect of velvet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

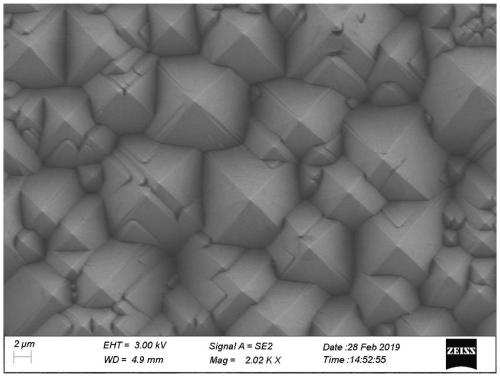

Image

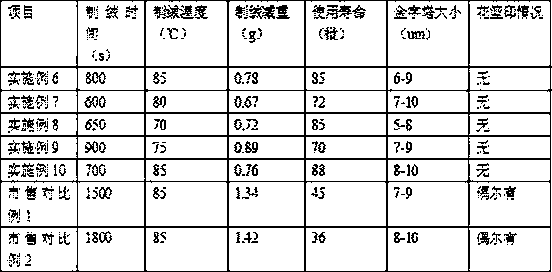

Examples

Embodiment 1

[0047] An anti-scratch printing liquid for HIT batteries, said texturing liquid includes 0.1-5% anti-scratch printing additive and 0.1% sodium acetate, and the balance is 5wt% tetramethyl ammonium hydroxide aqueous solution;

[0048] Wherein: the anti-scratch printing additives include 0.05% sodium carboxymethyl humate, 0.01% polyoxypropylene oxide glyceryl ether, 0.2% carboxymethyl cellulose, The balance of 0.5% of the protective agent is water.

[0049] The preparation method of the sodium carboxymethyl humate in the described anti-staggered printing velvet additive is as follows:

[0050] (1) Purification of humic acid: crush and grind humic acid, soak in dilute hydrochloric acid, stir for 0.5h, filter to get filter residue, wash with deionized water and dry to obtain purified humic acid;

[0051] (2) Carboxymethylation: Mix the purified humic acid with 10 times the mass of 10mol / L sodium hydroxide aqueous solution and place it in a three-necked flask. After reflux for 1 ...

Embodiment 2

[0058] A kind of anti-scratch printing liquid for HIT battery, described texturing liquid comprises anti-scratch printing velvet additive 5%, the mixture 0.5% of potassium tetraborate and borax 1: 1, ammonium acetate 0.8% by weight percentage % surplus is the cesium hydroxide aqueous solution that concentration is 0.2wt%;

[0059] Wherein: the described anti-staggered printing additives include sodium carboxymethyl humate, 0.5% lauryl phenylacetate, 1% poloxamer, 2% sodium carboxymethyl humate accounting for 3% of the overall texture additive mass. The balance of the protective agent is water.

[0060] The preparation method of the sodium carboxymethyl humate in the described anti-staggered printing velvet additive is as follows:

[0061] (1) Purification of humic acid: crush and grind humic acid, soak in dilute hydrochloric acid, stir for 3 hours, filter to get filter residue, wash with deionized water and dry to obtain purified humic acid;

[0062] (2) Carboxymethylation: ...

Embodiment 3

[0069] An anti-staggered texturing liquid for HIT batteries, said texturing liquid includes 0.1-5% anti-stirring additive, 0.25% mixture of potassium tetraborate and borax 1:3, acetic acid Sodium and ammonium acetate 1: 1 mixture 0.5% surplus is the sodium hydroxide aqueous solution that concentration is 1.8wt%;

[0070] Wherein: the described anti-staggered printing additives include 0.2% sodium carboxymethyl humate, 0.25% phenylethyl alcohol oleate, 0.8% PEG-40 hydrogenated castor oil and hydrogenated Castor oil polyoxyethylene ether 1:1 mixture, 1.5% of the protective agent and the balance of water.

[0071] The preparation method of the sodium carboxymethyl humate in the described anti-staggered printing velvet additive is as follows:

[0072] (1) Purification of humic acid: crush and grind humic acid and soak in dilute hydrochloric acid, stir for 2 hours, filter to get filter residue, wash with deionized water and dry to obtain purified humic acid;

[0073] (2) Carboxym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com