A method for surface treatment of crystalline silicon wafers

A technology of crystalline silicon wafer and single crystal silicon wafer, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc. Problems such as falling conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

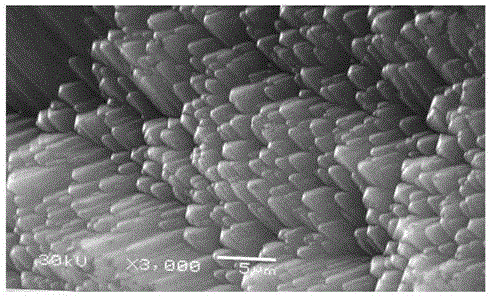

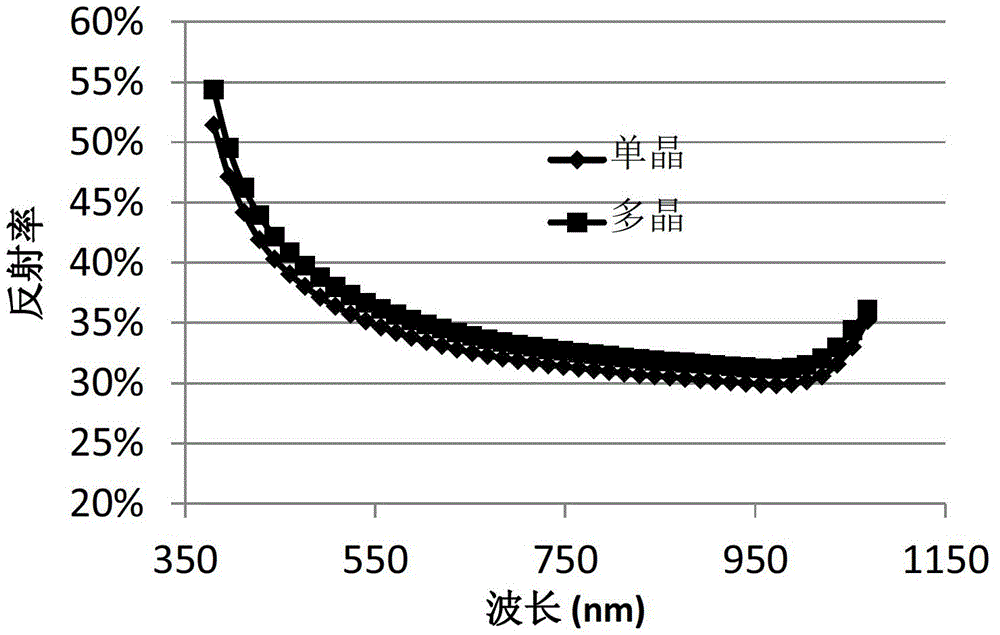

[0071] A 20% by weight tetramethyl ammonium hydroxide solution is used as the etching and polishing solution, and the etching and polishing solution is heated to 90 degrees for use. Configure 1.5% by weight sodium hydroxide solution as the corrosion texturing solution, heat the corrosion texturing to 78 degrees, add appropriate amount of isopropanol and texturing additives for later use. Put the cast monocrystalline silicon wafer containing 30% polycrystalline silicon area into the etching and polishing solution. After 5 minutes, the cast monocrystalline silicon wafer was taken out of the etching and polishing solution, and then put into the etching and texturing solution. After 7 minutes of texturing, take it out and wash with deionized water. The average reflectivity in the monocrystalline silicon region was 9.9%, and the average reflectivity in the polycrystalline silicon region was 18%. The cast monocrystalline silicon wafer was prepared into a solar cell, and the photoel...

Embodiment 2

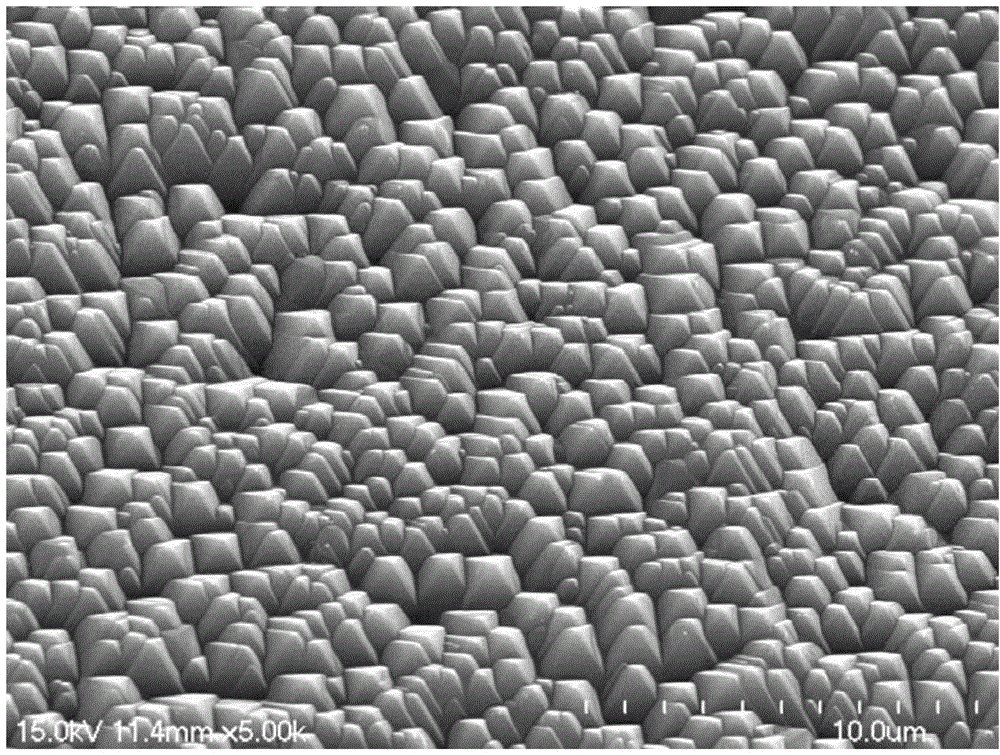

[0073] A mixed solution of 20% by weight of hydrofluoric acid, 45% by weight of nitric acid and 20% by weight of acetic acid was prepared as the corrosion polishing solution, and the temperature of the corrosion polishing solution was kept at 5 degrees for use. Prepare 1.5% by weight potassium hydroxide solution as the corrosive texturing solution, heat the corrosive texturing solution to 75 degrees and add appropriate amount of texturing additives for later use. Put the polysilicon wafer into the etching and polishing solution. The polycrystalline silicon wafer was taken out of the etching and polishing solution after 2 minutes, washed with deionized water, and put into the etching and texturing solution. Take it out after 10 minutes of texturing and wash it with deionized water. The measured average reflectivity is 19%. The polycrystalline silicon wafer was prepared into a solar cell, and the photoelectric conversion efficiency of the solar cell was measured to be 16.8%. Th...

Embodiment 3

[0075] A 5% weight percent sodium hydroxide solution is used as the corrosion polishing solution, and the corrosion polishing solution is heated to 85 degrees for use. Configure 2% tetramethyl ammonium hydroxide solution as the corrosive texturing solution, heat the corrosive texturing to 80 degrees, add appropriate amount of isopropanol and texturing additives for later use. Put the monocrystalline silicon wafer into the etching and polishing solution. The monocrystalline silicon wafer was taken out of the etching and polishing solution after 3 minutes, and directly put into the etching and texturing solution. After 5 minutes of texturing, take it out and wash with deionized water. The average reflectivity of the single crystal silicon wafer was 10.1%. The monocrystalline silicon wafer was prepared into a solar cell, and the photoelectric conversion efficiency of the solar cell was measured to be 18.4%, in which the open circuit voltage, short circuit current and quality fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com