Additive of alkali wool making solution for monocrystalline silicon pieces and using method

A technology of texturing liquid and additives, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, and final product manufacturing, and can solve the problems of poor surface uniformity of silicon wafers, poor texture stability, and corrosion of silicon wafers. Large and other problems, to achieve the effect of improving photoelectric conversion efficiency, shortening the time of making texture, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the following process steps: 1) Prepare additives: dissolve 2 grams of urea and 2 grams of sorbitol in deionized water to obtain 100 grams of solution; Dissolve in deionized water to obtain 1000 grams of solution; 3) Add 20 grams of additives in weight percent to 1000 grams of alkaline texturing solution; 4) Immerse monocrystalline silicon wafers for solar cells into the additive-added manufacturing The surface texture is carried out in the texture liquid, the texture temperature is 75°C, and the texture time is 900s.

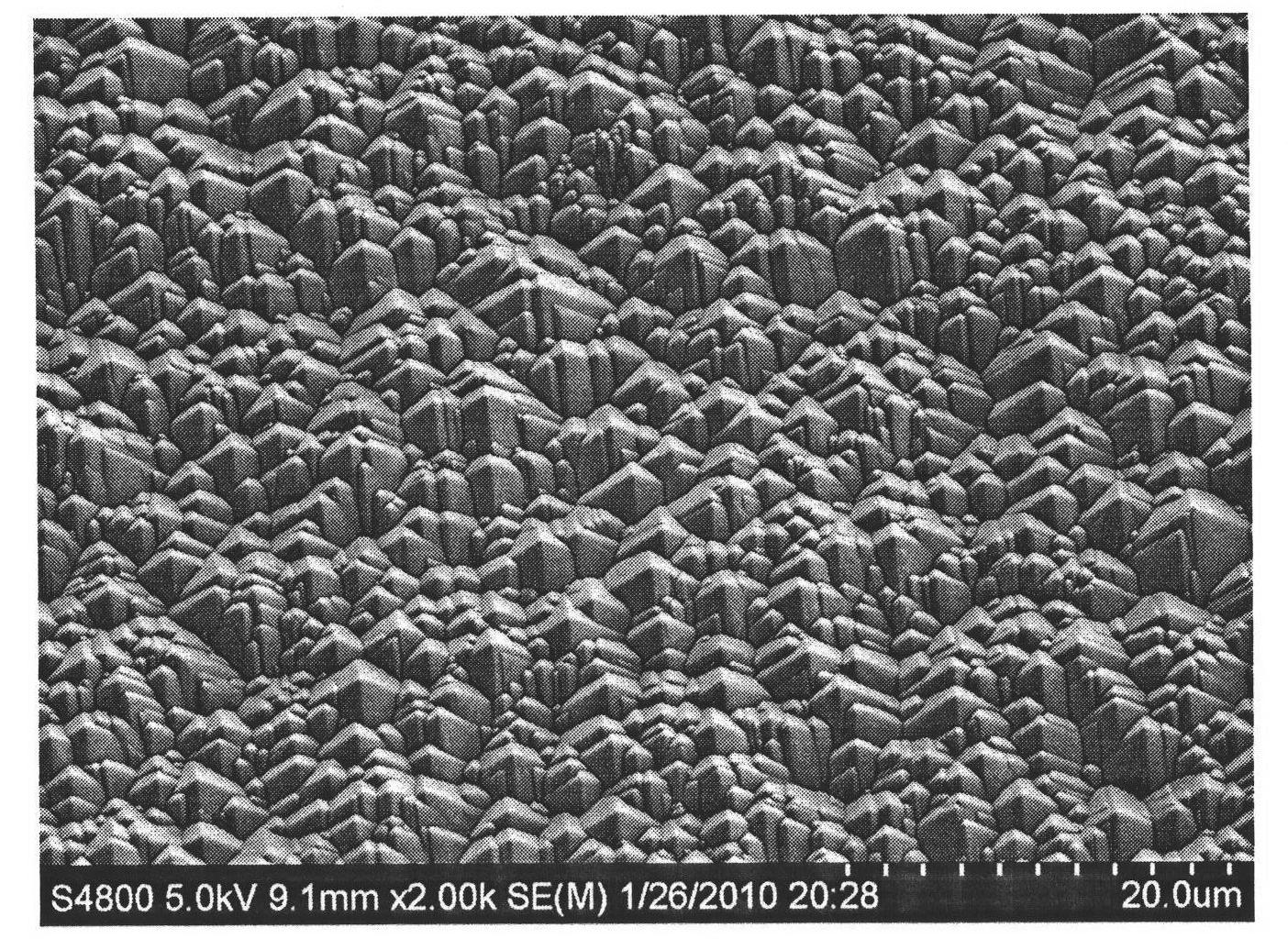

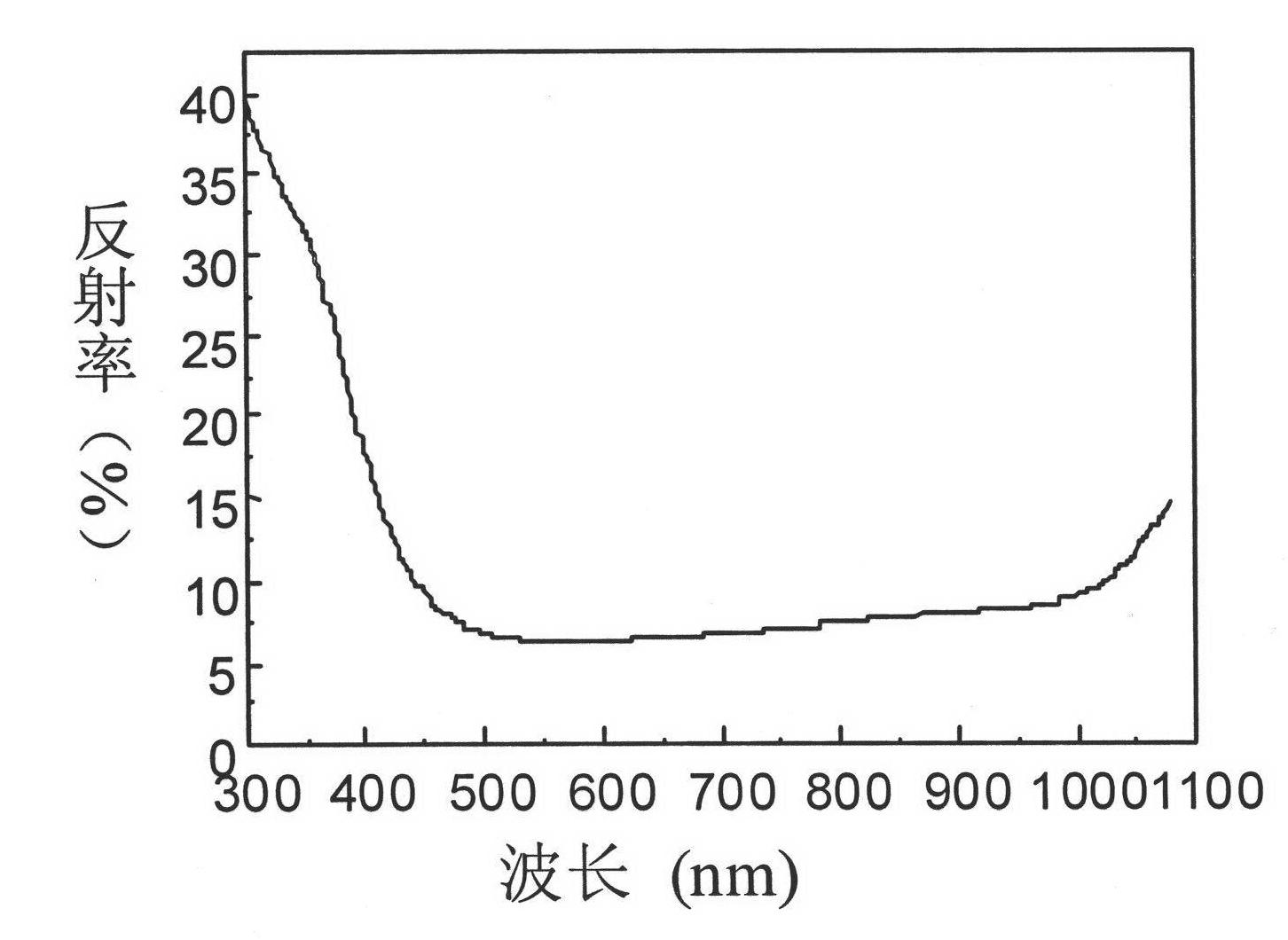

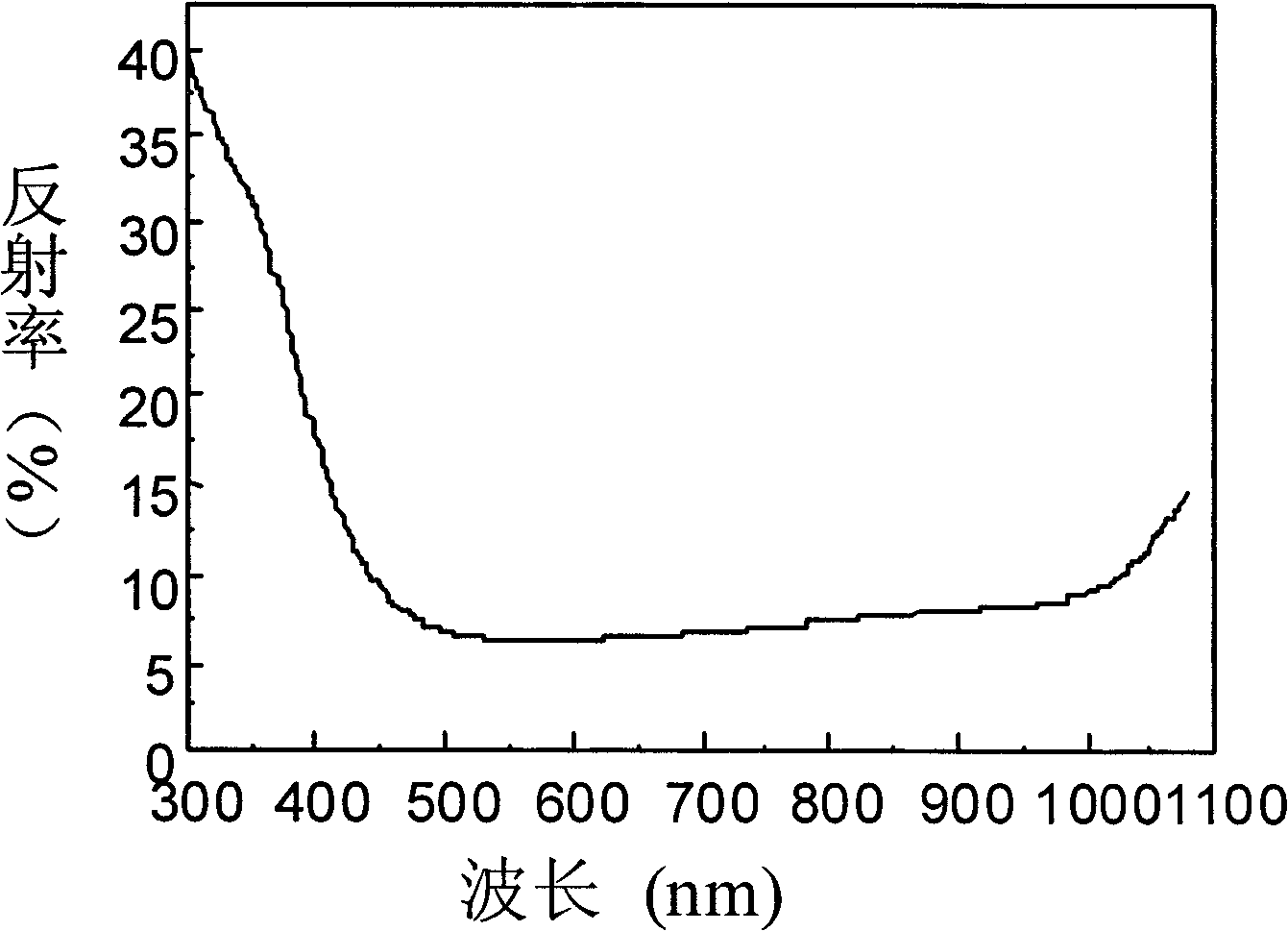

[0028] figure 1 A scanning electron microscope plane photo of the textured surface of the obtained silicon wafer is given. It can be seen from the picture that the size of the formed pyramids is small, about 1-4 μm, and the distribution is relatively uniform. figure 2 The reflectance spectrum of the textured surface of the prepared silicon wafer is given, and it can be seen from the figure that the reflectance of the textured surface of the silico...

Embodiment 2

[0030] The following process steps are taken: 1) preparation of additives: 1 gram of urea and 1.5 grams of sorbitol are dissolved in deionized water to obtain 100 grams of sorbitol; 2) configuration of alkaline texturing solution: 11 grams of NaOH and 60 grams of isopropyl alcohol Dissolve in deionized water to obtain 1000 grams of solution; 3) Add 25 grams of additives in weight percent to 1000 grams of alkaline texturing liquid; 4) Immerse the monocrystalline silicon wafer for solar cells in the texturing liquid For velvet making, the velvet making temperature is 70°C, and the velvet making time is 800s.

Embodiment 3

[0032] Take the following process steps: 1) Prepare additives: dissolve 0.5 gram of urea and 1 gram of sorbitol in deionized water to obtain 100 grams of solution; 2) configure alkaline texturing solution: mix 11 grams of NaOH and 60 grams of isopropanol Dissolved in deionized water to obtain 1000 grams of solution; 3) Adding 30 grams of additives in weight percent to 1000 grams of alkaline texturing liquid; 4) Immersing monocrystalline silicon wafers for solar cells in the texturing liquid for surface For velvet making, the velvet making temperature is 80°C, and the velvet making time is 720s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com